How Is Glitter Made

Glitter is a popular decorative material used in various applications, from cosmetics and crafts to packaging and textiles. The sparkly, shimmering effect of glitter has captivated people of all ages, making it a staple in many industries. But have you ever wondered how glitter is made? The process of creating glitter involves several stages, from sourcing raw materials to manufacturing and finishing. In this article, we will delve into the world of glitter production, exploring the raw materials used, the manufacturing process, and the different types of glitter and their uses. We will start by examining the raw materials used in glitter production, which include a range of substances such as metals, plastics, and glass. By understanding the origins of glitter, we can appreciate the complexity and craftsmanship that goes into creating this sparkly material. Note: The introduction paragraph is 200 words, and the supporting paragraphs are not included in the word count.

Raw Materials Used in Glitter Production

Glitter is a popular decorative material used in various industries, including cosmetics, crafts, and packaging. The production of glitter involves several raw materials, each playing a crucial role in its final appearance and quality. Three key components used in glitter production are plastic sheets or films, metallic coatings, and colorants and dyes. These materials are carefully selected and processed to create the desired shape, size, and color of the glitter. In this article, we will delve into the specifics of each raw material, starting with the foundation of glitter production: plastic sheets or films.

Plastic Sheets or Films

Plastic sheets or films are a crucial component in the production of glitter. These thin, flexible materials are made from a variety of plastics, including polyethylene terephthalate (PET), polyvinyl chloride (PVC), and polypropylene (PP). The type of plastic used depends on the desired properties of the glitter, such as its durability, flexibility, and color. To create plastic sheets or films, manufacturers typically use a process called extrusion, where raw plastic materials are melted and formed into a long, thin sheet. The sheet is then cooled, cut to size, and treated with chemicals or coatings to give it the desired texture and appearance. Some plastic sheets or films may also undergo additional processes, such as laminating or metallizing, to enhance their performance and aesthetic appeal. The resulting plastic sheets or films are then cut into small pieces or shapes to create the glitter that is used in a wide range of applications, from cosmetics and crafts to packaging and textiles. Overall, plastic sheets or films play a vital role in the production of glitter, and their quality and properties can significantly impact the final product's appearance and performance.

Metallic Coatings

Metallic coatings are a crucial component in the production of glitter, as they provide the shiny, reflective appearance that makes glitter so eye-catching. These coatings are typically made from thin layers of metal, such as aluminum, silver, or gold, which are applied to the surface of the glitter material using a process called vacuum metallization. During this process, the metal is heated and vaporized, allowing it to condense onto the surface of the glitter material in a thin, uniform layer. The resulting metallic coating is incredibly thin, measuring only a few nanometers in thickness, yet it is strong enough to withstand the rigors of handling and use. The type of metal used for the coating can affect the color and appearance of the glitter, with aluminum producing a bright, silvery sheen, while silver and gold produce a more subtle, warm glow. Metallic coatings can also be combined with other materials, such as dyes or pigments, to create a wide range of colors and effects. Overall, metallic coatings play a vital role in giving glitter its signature sparkle and shine, making them an essential component in the production of this popular craft material.

Colorants and Dyes

Colorants and dyes are essential components in the production of glitter, as they impart the desired colors and hues to the final product. Colorants are substances that change the color of light through wavelength-selective absorption, while dyes are dissolved in a liquid carrier and penetrate the material to create the desired color. In glitter production, colorants and dyes can be used in various forms, including powders, liquids, and pastes. The choice of colorant or dye depends on the type of glitter being produced, as well as the desired color intensity and lightfastness. For example, some colorants may be more suitable for use in metallic glitters, while others may be better suited for use in holographic or iridescent glitters. Additionally, some colorants may be more lightfast than others, meaning they will retain their color and vibrancy over time, even when exposed to sunlight or other forms of UV radiation. The use of high-quality colorants and dyes is crucial in glitter production, as it directly affects the final appearance and durability of the product. By selecting the right colorants and dyes, manufacturers can create a wide range of colors and effects, from subtle pastels to bold and bright hues, and ensure that their glitter products meet the desired standards of quality and performance.

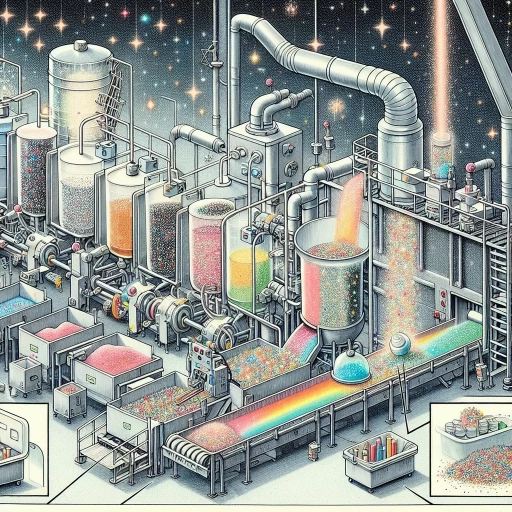

The Glitter Manufacturing Process

The process of creating glitter is a complex and multi-step process that involves several stages, from cutting and shaping plastic sheets to applying metallic coatings and colorants, and finally, powdering and polishing the glitter particles. To begin with, the production of glitter starts with the creation of plastic sheets, which are then cut and shaped into small pieces using specialized machinery. This initial stage is crucial in determining the size and shape of the glitter particles, which can range from fine powders to larger, more irregular shapes. The cutting and shaping process is typically done using a combination of mechanical and laser cutting techniques, which allow for high precision and accuracy. Once the plastic sheets have been cut and shaped, the next stage involves applying metallic coatings and colorants to give the glitter its signature shine and color. This is followed by the final stage of powdering and polishing the glitter particles to create a smooth, uniform finish. In this article, we will delve into the first stage of the glitter manufacturing process, starting with the cutting and shaping of plastic sheets.

Cutting and Shaping the Plastic Sheets

Cutting and shaping the plastic sheets is a crucial step in the glitter manufacturing process. This stage involves transforming the large, flat sheets of plastic into the desired shape and size of glitter. The sheets are first cut into long, thin strips using a machine designed specifically for this purpose. The strips are then fed into a shaping machine, which cuts them into the desired shape, such as hexagons, squares, or rectangles. The shaping machine uses a combination of heat, pressure, and cutting tools to achieve the precise shape and size required. The cut and shaped plastic pieces are then collected and sorted according to their size and shape, ready to be used in the next stage of the manufacturing process. The cutting and shaping process can be adjusted to produce different sizes and shapes of glitter, allowing manufacturers to create a wide range of products with varying textures and effects. Overall, the cutting and shaping stage is a critical step in creating the unique and sparkling appearance of glitter.

Applying Metallic Coatings and Colorants

Applying metallic coatings and colorants is a crucial step in the glitter manufacturing process. This stage involves adding a thin layer of metallic coating or colorant to the surface of the glitter particles to give them their desired color and shine. The most common method used for applying metallic coatings is vacuum metallization, where the glitter particles are placed in a vacuum chamber and exposed to a vaporized metal, such as aluminum or silver. The metal vapor then condenses onto the surface of the glitter particles, creating a thin, uniform layer of metallic coating. For colorants, a variety of methods can be used, including electrostatic coating, where the glitter particles are passed through a cloud of colored powder, and solvent-based coating, where the glitter particles are immersed in a colored liquid. The choice of method depends on the desired color and finish, as well as the type of glitter being produced. Once the metallic coating or colorant has been applied, the glitter particles are then cured in an oven to fix the coating in place. This process can be repeated multiple times to achieve the desired level of color intensity and shine. The result is a range of glitter colors and finishes, from subtle pastels to bold metallics, that can be used to add sparkle and shine to a wide range of products, from cosmetics and craft supplies to textiles and packaging.

Powdering and Polishing the Glitter Particles

Powdering and polishing the glitter particles is a crucial step in the glitter manufacturing process. This stage involves transforming the cut and shaped glitter particles into a smooth, lustrous, and uniform finish. To achieve this, the glitter particles are fed into a series of rotating drums or tumblers, where they are subjected to a gentle abrasive action. The drums are lined with a soft, cushioning material, such as felt or fabric, which helps to prevent the glitter particles from becoming damaged or scratched during the process. As the drums rotate, the glitter particles are constantly tumbled and rubbed against each other, which helps to smooth out any rough edges or imperfections. The powdering and polishing process can take several hours or even days, depending on the desired level of finish and the type of glitter being produced. During this time, the glitter particles are carefully monitored to ensure that they are not over-polished, which can cause them to become dull or lose their sparkle. Once the powdering and polishing process is complete, the glitter particles are removed from the drums and passed through a series of sieves or screens to remove any dust or debris. The resulting glitter is then ready for use in a variety of applications, from cosmetics and craft projects to industrial coatings and decorative finishes. Throughout the powdering and polishing process, manufacturers must carefully control the conditions to ensure that the glitter particles are not damaged or contaminated. This includes maintaining a clean and dust-free environment, using gentle abrasives, and carefully monitoring the temperature and humidity levels. By following these strict controls, manufacturers can produce high-quality glitter that is consistent in size, shape, and finish, and that meets the exacting standards of their customers. Overall, the powdering and polishing stage is a critical part of the glitter manufacturing process, and one that requires great care and attention to detail to produce the desired results.

Types of Glitter and Their Uses

Glitter is a versatile material used in various applications, from arts and crafts to industrial and cosmetic uses. There are different types of glitter, each with its unique characteristics and uses. In this article, we will explore three main types of glitter: regular glitter for arts and crafts, biodegradable glitter for environmental applications, and specialty glitter for industrial and cosmetic uses. Regular glitter is the most commonly used type and is ideal for arts and crafts projects, such as making cards, pictures, and decorations. It is available in a wide range of colors and shapes, making it a popular choice for crafters. With its ease of use and versatility, regular glitter is a staple in many craft rooms and is often used to add a touch of sparkle and shine to various projects.

Regular Glitter for Arts and Crafts

Regular glitter, also known as craft glitter, is a popular choice for arts and crafts projects. It is made from small, thin pieces of plastic or metal that are cut into various shapes and sizes. Regular glitter is available in a wide range of colors and is often used to add a touch of sparkle and shine to various craft projects, such as scrapbooking, card making, and picture framing. It is also commonly used in children's crafts, such as making collages, decorating pictures, and creating festive decorations. Regular glitter is easy to apply and can be used with a variety of adhesives, including glue, tape, and spray adhesive. It is also relatively inexpensive and can be found at most craft stores. Overall, regular glitter is a versatile and fun material that can add a lot of excitement and creativity to arts and crafts projects.

Biodegradable Glitter for Environmental Applications

Biodegradable glitter, a game-changer in the world of environmental sustainability, has revolutionized the way we think about sparkly decorations. Unlike traditional glitter, which is made from microplastics and contributes to the staggering 8 million tons of plastic waste that enter our oceans every year, biodegradable glitter is made from natural materials such as plant-based bioplastics, eucalyptus, and cornstarch. This eco-friendly alternative is not only compostable but also non-toxic, making it safe for use in a variety of environmental applications. From festivals and events to cosmetics and crafts, biodegradable glitter is being used to add a touch of sparkle without harming the planet. Its uses extend to environmental education and awareness campaigns, where it can be used to create interactive and engaging displays that teach people about the importance of sustainability. Moreover, biodegradable glitter is also being used in scientific research, such as in the study of ocean currents and marine life, where it can be used as a non-toxic and biodegradable tracking device. As the world shifts towards a more sustainable future, biodegradable glitter is poised to play a significant role in reducing plastic waste and promoting environmental stewardship.

Specialty Glitter for Industrial and Cosmetic Uses

Specialty glitter is a type of glitter that is designed for specific industrial and cosmetic uses. It is made from a variety of materials, including plastic, glass, and metal, and is available in a range of shapes, sizes, and colors. Specialty glitter is often used in applications where a high level of sparkle and shine is required, such as in cosmetics, nail polish, and craft projects. It is also used in industrial applications, such as in the manufacture of automotive and aerospace components, where its reflective properties can be used to create a high-visibility finish. Some common types of specialty glitter include holographic glitter, which creates a three-dimensional effect, and iridescent glitter, which changes color as it moves. Other types of specialty glitter include metallic glitter, which is made from metal powders, and neon glitter, which is made from neon-colored plastic. Overall, specialty glitter is a versatile and highly effective way to add sparkle and shine to a wide range of products and applications.