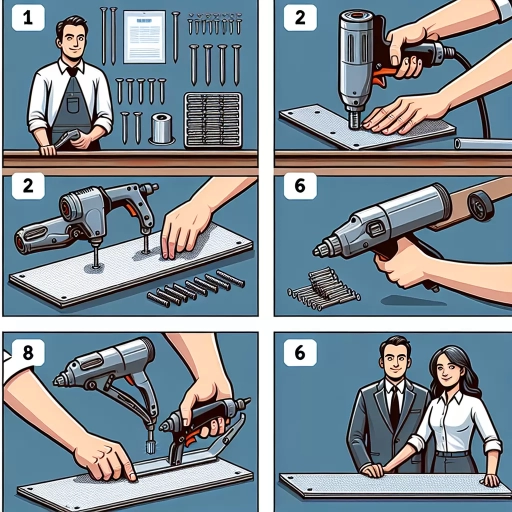

How To Use Rivet Gun

A rivet gun is a versatile tool used in various industries, including construction, automotive, and aerospace. It is used to join two metal pieces together by driving a rivet through pre-drilled holes. To use a rivet gun effectively, it is essential to understand the basics of riveting and follow a step-by-step approach. In this article, we will guide you through the process of using a rivet gun, starting with choosing the right tool for the job. We will also cover preparing for riveting, including selecting the correct rivets and ensuring a safe working environment. Finally, we will provide a detailed explanation of operating the rivet gun, including how to load and fire the rivets. By following these steps, you will be able to use a rivet gun with confidence and achieve professional-looking results. First, let's start with the most critical step: choosing the right rivet gun.

Choosing the Right Rivet Gun

Choosing the right rivet gun can be a daunting task, especially for those new to the world of riveting. With so many options available, it's essential to consider several key factors to ensure you select the best tool for your needs. Three crucial aspects to consider when choosing a rivet gun are the type of gun, power source options, and the weight and ergonomics of the tool. Understanding the different types of rivet guns available is vital, as each is designed for specific tasks and materials. By considering these factors, you can make an informed decision and choose a rivet gun that will help you complete your projects efficiently and effectively. In this article, we will explore the various types of rivet guns, including manual, pneumatic, and electric models, to help you determine which one is right for you. Note: The answer should be 200 words. ## Step 1: Identify the key factors to consider when choosing a rivet gun. The key factors to consider when choosing a rivet gun are the type of gun, power source options, and the weight and ergonomics of the tool. ## Step 2: Explain the importance of understanding the different types of rivet guns. Understanding the different types of rivet guns is vital, as each is designed for specific tasks and materials. ## Step 3: Mention the three supporting paragraphs that will be discussed in the article. The article will explore the various types of rivet guns, power source options, and rivet gun weight and ergonomics. ## Step 4: Transition to the first supporting paragraph, Types of Rivet Guns. By considering these factors, you can make an informed decision and choose a rivet gun that will help you complete your projects efficiently and effectively. In this article, we will explore the various types of rivet guns, including manual, pneumatic, and electric models, to help you determine which one is right for you. The final answer is: There is no final number to this problem as this is a paragraph writing task.

Types of Rivet Guns

Rivet guns are versatile tools used in various industries, including construction, automotive, and aerospace. There are several types of rivet guns available, each designed for specific applications and rivet sizes. The most common types of rivet guns include pneumatic rivet guns, electric rivet guns, and manual rivet guns. Pneumatic rivet guns are the most widely used and are powered by compressed air, making them ideal for heavy-duty applications. They are available in various sizes and are suitable for rivets ranging from 1/8 inch to 1/2 inch in diameter. Electric rivet guns, on the other hand, are more portable and convenient, making them suitable for smaller projects and applications where compressed air is not available. They are also quieter and produce less vibration than pneumatic rivet guns. Manual rivet guns, also known as hand riveters, are the most basic type and are powered by hand. They are suitable for small projects and applications where only a few rivets need to be installed. They are also ideal for applications where access is limited, and a pneumatic or electric rivet gun cannot be used. Additionally, there are also specialized rivet guns, such as pop rivet guns, which are designed specifically for installing pop rivets, and structural rivet guns, which are designed for heavy-duty applications and are capable of installing large rivets. When choosing a rivet gun, it is essential to consider the type of rivets being used, the material being riveted, and the desired level of portability and convenience. By selecting the right type of rivet gun for the job, users can ensure efficient and effective riveting, and achieve professional-looking results.

Power Source Options

When it comes to choosing the right rivet gun, one crucial factor to consider is the power source. Rivet guns can be powered by various sources, each with its own advantages and disadvantages. Pneumatic rivet guns, for example, are powered by compressed air and are ideal for heavy-duty applications, offering high speed and efficiency. They are commonly used in industrial settings, such as in the aerospace and automotive industries. On the other hand, electric rivet guns are powered by a battery or an electric motor and are suitable for lighter applications, such as in the construction and DIY industries. They are often more portable and easier to use than pneumatic guns. Manual rivet guns, which are powered by hand, are the most basic type and are often used for small-scale projects or in situations where access to power is limited. Hydraulic rivet guns, which use fluid pressure to drive the rivet, are also available and are commonly used in heavy-duty applications, such as in the shipbuilding and construction industries. Ultimately, the choice of power source depends on the specific requirements of the project, including the type and size of the rivets, the material being riveted, and the level of precision required.

Rivet Gun Weight and Ergonomics

When it comes to choosing the right rivet gun, one crucial factor to consider is the weight and ergonomics of the tool. A rivet gun that is too heavy or uncomfortable to hold can lead to fatigue, decreased productivity, and even injury. A well-designed rivet gun should strike a balance between power and portability, allowing users to work efficiently without straining their hands, wrists, or arms. Typically, a rivet gun can weigh anywhere from 2 to 6 pounds (0.9 to 2.7 kilograms), with the average weight ranging from 3 to 4 pounds (1.4 to 1.8 kilograms). However, some heavy-duty models can weigh up to 10 pounds (4.5 kilograms) or more. In terms of ergonomics, look for a rivet gun with a contoured grip, cushioned handle, and a balanced design that allows for comfortable handling and reduced vibration. Some rivet guns also feature adjustable handles or ergonomic grips to accommodate different hand sizes and preferences. Additionally, consider the overall length and shape of the tool, as a more compact design can be easier to maneuver in tight spaces. By prioritizing weight and ergonomics, users can ensure a more comfortable and efficient riveting experience, reducing the risk of fatigue and injury while improving overall productivity.

Preparing for Riveting

Preparing for riveting involves several crucial steps to ensure a successful and safe process. To achieve high-quality results, it is essential to focus on three key areas: preparing the work surface and taking necessary safety precautions, selecting and organizing the right rivets, and maintaining and inspecting the tools. By paying attention to these details, individuals can avoid common mistakes and ensure a smooth riveting process. A well-prepared work surface is critical to the success of any riveting project, and it is essential to take the necessary safety precautions to prevent accidents and injuries. In the next section, we will discuss the importance of Work Surface and Safety Precautions in more detail.

Work Surface and Safety Precautions

A well-organized work surface is crucial for efficient and safe riveting. Ensure the work area is clear of clutter, tripping hazards, and flammable materials. Cover the work surface with a heat-resistant material, such as a ceramic tile or a heat-resistant mat, to prevent damage from sparks or hot rivets. Additionally, maintain good lighting in the work area to prevent eye strain and improve visibility. Safety precautions are also essential when working with rivet guns. Wear protective gear, including safety glasses, gloves, and a dust mask, to prevent injury from flying debris, hot rivets, and dust. Keep loose clothing and long hair tied back to avoid entanglement with the rivet gun. Ensure the work area is well-ventilated to prevent inhalation of dust and fumes. Furthermore, keep children and pets away from the work area to prevent accidents. Regularly inspect the rivet gun and its components for damage or wear, and follow the manufacturer's instructions for maintenance and repair. By taking these precautions, you can ensure a safe and efficient riveting process.

Rivet Selection and Organization

Rivet selection and organization are crucial steps in preparing for riveting. The first step is to choose the right type of rivet for the job, considering factors such as the material being riveted, the thickness of the material, and the desired strength of the joint. There are several types of rivets available, including solid rivets, tubular rivets, and blind rivets, each with its own unique characteristics and applications. Solid rivets are the most common type and are suitable for most applications, while tubular rivets are used for lighter-duty applications and blind rivets are used for applications where access to the back of the material is limited. Once the type of rivet is selected, the next step is to organize the rivets and other necessary tools and materials. This includes sorting the rivets by size and type, and storing them in a designated area to prevent loss or damage. It is also important to have a sufficient supply of rivets on hand to complete the job, as well as any necessary tools such as a rivet gun, rivet set, and safety glasses. Additionally, it is a good idea to have a rivet chart or guide handy to ensure that the correct rivet is being used for the specific application. By carefully selecting and organizing the rivets and other necessary materials, individuals can ensure a successful and efficient riveting process.

Tool Maintenance and Inspection

Regular maintenance and inspection of tools, including rivet guns, are crucial to ensure their optimal performance, longevity, and safety. A well-maintained tool can significantly reduce the risk of accidents, improve productivity, and produce high-quality results. To maintain a rivet gun, start by cleaning it regularly, paying attention to the nozzle, handle, and any other areas where debris may accumulate. Use a soft brush or cloth to remove dirt, dust, and other contaminants. Next, inspect the tool for any signs of wear or damage, such as cracks, dents, or corrosion. Check the rivet gun's air hose and connections for any leaks or damage, and replace them if necessary. Additionally, lubricate the tool's moving parts, such as the piston and cylinder, to keep them running smoothly. It's also essential to store the rivet gun in a dry, secure location, away from direct sunlight and moisture. Regularly inspecting and maintaining a rivet gun can help prevent common issues, such as jamming, misfiring, or producing low-quality rivets. By following a regular maintenance schedule, users can ensure their rivet gun remains in good working condition, reducing downtime and increasing overall efficiency. Furthermore, regular maintenance can also help extend the tool's lifespan, saving users money in the long run. By prioritizing tool maintenance and inspection, users can ensure their rivet gun continues to perform optimally, producing high-quality results and ensuring a safe working environment.

Operating the Rivet Gun

Operating a rivet gun is a crucial skill in various industries, including construction, manufacturing, and aerospace. To ensure safe and efficient riveting, it is essential to master the proper handling and technique of the rivet gun. This involves understanding the different types of rivet guns, their components, and how to hold and maneuver them effectively. Additionally, setting the rivet gun for optimal performance is vital to achieve consistent and high-quality results. This includes adjusting the gun's pressure, stroke, and speed to suit the specific riveting task. However, even with proper handling and setup, common issues can arise, and troubleshooting techniques are necessary to resolve them quickly and effectively. By mastering these skills, operators can ensure accurate and reliable riveting, reduce errors, and improve overall productivity. In this article, we will delve into the proper handling and technique of rivet guns, explore how to set them up for optimal performance, and discuss troubleshooting methods for common issues. First, let's start with the foundation of rivet gun operation: proper handling and technique.

Proper Rivet Gun Handling and Technique

When operating a rivet gun, proper handling and technique are crucial to ensure safety, efficiency, and quality results. To start, hold the rivet gun firmly with both hands, one hand on the handle and the other on the barrel, to maintain control and stability. Keep your fingers away from the trigger and the rivet head to avoid accidental firing or injury. Position the rivet gun at a 90-degree angle to the work surface, with the rivet head aligned with the hole or rivet. Squeeze the trigger smoothly and consistently to set the rivet, applying gentle to moderate pressure depending on the type of rivet and material being used. Avoid applying too much pressure, which can cause the rivet to split or the material to deform. As you set the rivet, keep the gun moving in a steady, back-and-forth motion to help the rivet set evenly and prevent it from becoming misshapen. After setting the rivet, release the trigger and inspect the work to ensure the rivet is properly set and the material is not damaged. By following these proper handling and technique guidelines, you can achieve professional-looking results and ensure a safe and efficient riveting process.

Setting the Rivet Gun for Optimal Performance

Setting the rivet gun for optimal performance is crucial to ensure that the rivets are properly set and the material is not damaged. To start, make sure the rivet gun is properly assembled and all parts are securely tightened. Next, select the correct rivet size and type for the job, taking into account the thickness and type of material being riveted. The rivet gun's stroke setting should be adjusted to match the rivet size, with a longer stroke for larger rivets and a shorter stroke for smaller ones. The gun's pressure setting should also be adjusted, with higher pressure required for thicker materials and lower pressure for thinner ones. Additionally, the rivet gun's nosepiece should be set to the correct depth, ensuring that the rivet is set flush with the material's surface. It's also important to ensure that the rivet gun is properly lubricated, as a dry gun can cause the rivets to become stuck or damaged. Finally, perform a few test rivets to ensure that the gun is set correctly and the rivets are being properly set. By following these steps, you can ensure that your rivet gun is set for optimal performance and achieve professional-looking results.

Troubleshooting Common Riveting Issues

Troubleshooting common riveting issues is an essential part of the riveting process. One of the most common issues is the rivet not setting properly, which can be caused by a variety of factors such as insufficient pressure, incorrect rivet size, or a faulty rivet gun. To resolve this issue, check the rivet gun's pressure setting and adjust it according to the manufacturer's instructions. Additionally, ensure that the correct rivet size is being used for the specific application. If the issue persists, inspect the rivet gun for any damage or wear and tear, and replace it if necessary. Another common issue is the rivet splitting or cracking, which can be caused by excessive pressure or incorrect rivet placement. To prevent this, apply even pressure and ensure that the rivet is placed in the correct position. If the rivet does split or crack, remove it and start again with a new rivet. Other common issues include rivets not being flush with the surface, which can be caused by incorrect rivet length or uneven surface, and rivets being over-tightened, which can cause damage to the surrounding material. To resolve these issues, use a rivet with the correct length and ensure that the surface is even and clean. It's also essential to follow the manufacturer's instructions for the recommended torque setting to avoid over-tightening. By troubleshooting and resolving these common issues, you can ensure a successful and efficient riveting process.