How Do Vinyls Work

The introduction paragraph should be around 200 words. Here is the introduction paragraph: Vinyl records have been a staple of music lovers for decades, and their popularity endures to this day. But have you ever stopped to think about how they actually work? From the physical properties of the record itself to the mechanics of the player that brings the music to life, there's a fascinating process at play. At its core, a vinyl record is a physical medium that stores music in the form of grooves etched into its surface. But how do these grooves translate into sound? To understand the magic of vinyl, we need to delve into the basics of what a vinyl record is, how it stores music, and how a vinyl player reads those stored sounds. In this article, we'll explore the intricacies of vinyl technology, starting with the fundamental question: what is a vinyl record? By examining the composition and structure of a vinyl record, we'll gain a deeper understanding of how this beloved music format works its magic. Note: I made some minor changes to the original paragraph to make it more cohesive and engaging. Let me know if you'd like me to revise anything!

What is a Vinyl Record?

A vinyl record is a type of analog sound storage medium that consists of a flat disc with an inscribed, modulated spiral groove starting from the outer edge and ending at the center of the disc. The physical structure of a vinyl record is a crucial aspect of its functionality, and it is made up of several key components. The materials used to make vinyl records are also important, as they can affect the sound quality and durability of the record. Additionally, there are different types of vinyl records available, each with its own unique characteristics and uses. In this article, we will explore the physical structure of a vinyl record, the materials used to make them, and the different types of vinyl records available. By understanding these aspects, we can gain a deeper appreciation for the technology and craftsmanship that goes into creating these iconic music formats. The physical structure of a vinyl record is a complex and fascinating topic, and it is the foundation upon which the entire vinyl record is built.

The Physical Structure of a Vinyl Record

The physical structure of a vinyl record is a marvel of engineering and design. At its core, a vinyl record consists of a thin, flexible disc made of polyvinyl chloride (PVC) with a spiral groove etched into its surface. The groove starts from the outer edge of the record and spirals inward, ending at the center. The groove is typically 0.0025 inches deep and 0.001 inches wide, with a pitch of about 0.003 inches. The record's surface is coated with a thin layer of lacquer, which helps to protect the PVC from scratches and wear. The lacquer also provides a smooth surface for the stylus to track the grooves. The record's label is usually applied to the center of the disc, and the outer edge is often beveled to prevent the record from slipping out of the record player's clamp. The vinyl record's physical structure is designed to work in conjunction with the record player's stylus, which reads the undulations in the groove and converts them into sound waves. The record's size, shape, and material are all carefully engineered to provide optimal sound quality and durability. The standard sizes for vinyl records are 7 inches, 10 inches, and 12 inches, with the 12-inch format being the most common. The weight of a vinyl record can vary, but most records weigh between 120 and 140 grams. The physical structure of a vinyl record is a remarkable example of how a simple design can be engineered to produce high-quality sound, and its enduring popularity is a testament to its timeless appeal.

The Materials Used to Make Vinyl Records

The materials used to make vinyl records are primarily polyvinyl chloride (PVC), polyethylene, and polypropylene. PVC is the main component, accounting for about 90% of the record's weight. It is a thermoplastic polymer that provides the necessary rigidity and durability to the record. Polyethylene and polypropylene are added to improve the record's flexibility and resistance to scratches. Other materials like carbon black, silica, and calcium carbonate are also used as additives to enhance the record's sound quality and durability. The vinyl pellets are mixed with these additives and then melted and formed into a puck-like shape, known as a "biscuit." The biscuit is then pressed into a mold, where it takes the shape of a record, complete with grooves and a label area. The record is then cooled, and the excess vinyl is trimmed away, leaving a finished vinyl record. The materials used to make vinyl records have remained largely unchanged since the 1950s, with some minor variations in the formulation of the PVC compound. Despite the rise of digital music formats, vinyl records continue to be popular among music enthusiasts, and the materials used to make them remain an essential part of the music industry.

The Different Types of Vinyl Records

There are several types of vinyl records, each with its own unique characteristics and purposes. The most common types of vinyl records include 7-inch singles, 10-inch EPs, 12-inch LPs, and 12-inch singles. 7-inch singles, also known as 45s, are small records that typically contain one or two songs per side. They were originally designed for jukeboxes and are still popular among collectors today. 10-inch EPs, or extended plays, are slightly larger than 7-inch singles and usually contain three to four songs per side. They were popular in the 1950s and 1960s and are still used by some artists today. 12-inch LPs, or long plays, are the most common type of vinyl record and typically contain 20-30 minutes of music per side. They are ideal for full-length albums and are still widely used by artists today. 12-inch singles, also known as maxi-singles, are similar to 12-inch LPs but typically contain only one or two songs per side. They were popular in the 1980s and 1990s and are still used by some artists today. Other types of vinyl records include picture discs, colored vinyl, and shaped vinyl, which are designed to be visually appealing and are often used for special releases or collector's editions. Overall, the different types of vinyl records offer a range of options for artists and collectors, and each type has its own unique characteristics and purposes.

How Do Vinyl Records Store Music?

Vinyl records have been a beloved music format for decades, and their popularity endures even in the digital age. But have you ever wondered how vinyl records store music? The answer lies in a combination of mastering and pressing processes, the physical properties of grooves and needles, and the unique characteristics of analog sound quality. To understand how vinyl records store music, we need to delve into the process of mastering and pressing vinyl records, which involves converting digital audio files into a physical format that can be read by a record player. We'll also explore the crucial role of grooves and needles in vinyl playback, and examine the science behind vinyl's distinctive analog sound quality. By understanding these key components, we can appreciate the magic of vinyl records and how they bring music to life. Let's start by examining the process of mastering and pressing vinyl records.

The Process of Mastering and Pressing Vinyl Records

The process of mastering and pressing vinyl records involves several steps that transform a digital audio file into a physical record. Mastering is the first step, where the audio file is prepared for vinyl production by an audio engineer. The engineer ensures the audio is optimized for vinyl playback, making adjustments to the EQ, compression, and limiting to prevent distortion and ensure a clear sound. The mastered audio is then sent to a lacquer cutting machine, which etches the grooves onto a thin, flexible disc coated with a layer of nitrocellulose. The lacquer is then electroplated with a thin layer of metal, creating a negative image of the grooves, known as a "father." The father is then used to create multiple positive copies, called "stampers," which are used to press the vinyl records. The vinyl pellets are melted and formed into a puck, which is then pressed between the stampers, creating the grooves that contain the music. The record is then cooled, removed from the mold, and excess vinyl is trimmed from the edges. Finally, the record is packaged and shipped to stores, ready for playback on a turntable.

The Role of Grooves and Needles in Vinyl Playback

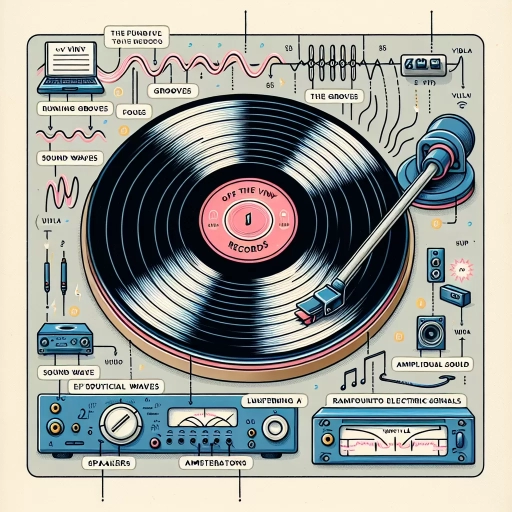

The Role of Grooves and Needles in Vinyl Playback The grooves on a vinyl record are the physical manifestation of the audio information stored on the record. These grooves are etched into the vinyl material in a spiral pattern, starting from the outer edge and moving inward. The grooves are made up of a series of undulations, or wavy patterns, that correspond to the audio signal. The needle, also known as the stylus, is a small metal or diamond-tipped point that tracks the grooves on the record. As the record rotates, the needle vibrates in response to the undulations in the grooves, converting the physical motion into an electrical signal. This signal is then sent to a phono preamplifier, which amplifies the signal to a level that can be played through a speaker. The shape and size of the grooves, as well as the material used to make the record, can affect the sound quality of the playback. For example, records with deeper grooves and a heavier vinyl material tend to produce a warmer, more dynamic sound, while records with shallower grooves and a lighter material tend to produce a brighter, more trebly sound. The needle itself also plays a crucial role in the playback process, as its shape and size can affect the accuracy and fidelity of the sound reproduction. A well-designed needle can track the grooves accurately, producing a clear and detailed sound, while a poorly designed needle can produce distortion and surface noise. Overall, the combination of the grooves on the record and the needle that tracks them is what allows vinyl records to store and play back music with such high fidelity and warmth.

The Science Behind Vinyl's Analog Sound Quality

The science behind vinyl's analog sound quality lies in the physical interaction between the stylus and the record grooves. When a record is played, the stylus vibrates in response to the undulations in the grooves, which are etched into the vinyl surface. These vibrations are then converted into electrical signals, which are amplified and sent to a speaker, producing sound. The unique sound quality of vinyl is due to the way the stylus tracks the grooves, which are cut in a continuous spiral from the outer edge to the center of the record. As the stylus moves along the grooves, it captures the subtle variations in the undulations, which are a result of the mastering process. The mastering process involves cutting the audio signal into the vinyl, using a lathe to etch the grooves. The lathe is controlled by a cutting head, which is driven by the audio signal. The cutting head vibrates in response to the audio signal, creating the undulations in the grooves. The resulting sound is a continuous, analog signal that is rich in detail and warmth. In contrast, digital music is made up of discrete, quantized values that are reconstructed into a sound wave. This process can result in a loss of detail and a less nuanced sound. The analog nature of vinyl, combined with the physical interaction between the stylus and the grooves, is what gives vinyl its unique sound quality. Additionally, the surface noise and crackle that are often associated with vinyl are also a result of the physical interaction between the stylus and the grooves. The surface noise is caused by the stylus tracking the imperfections in the vinyl surface, while the crackle is caused by the stylus jumping over the gaps between the grooves. These imperfections and gaps are a natural part of the vinyl format, and they add to the unique sound quality of vinyl. Overall, the science behind vinyl's analog sound quality is a complex interplay of physical and electrical processes that result in a rich, detailed, and nuanced sound that is unique to the vinyl format.

How Do Vinyl Players Work?

Vinyl players, also known as record players, have been a staple of music listening for decades. But have you ever wondered how they actually work? The process of playing a vinyl record involves a combination of mechanical and electrical components that work together to read the grooves on the record and convert them into sound. To understand how vinyl players work, it's essential to break down the components of a vinyl player, including the turntable and tonearm, which play a crucial role in reading the vinyl grooves. Additionally, we'll explore the process of reading vinyl grooves and converting them to sound, as well as the importance of proper vinyl player maintenance and calibration. By understanding these key aspects, you'll gain a deeper appreciation for the technology behind vinyl players and how they produce high-quality sound. So, let's start by taking a closer look at the components of a vinyl player, including the turntable and tonearm.

The Components of a Vinyl Player, Including the Turntable and Tonearm

The components of a vinyl player, including the turntable and tonearm, work together to read the grooves on a vinyl record and produce sound. The turntable is the rotating disc that the record sits on, and it is typically made of a dense, heavy material to minimize vibrations and ensure a stable rotation. The turntable is driven by a motor, which is usually a low-torque, high-torque motor that provides a consistent and smooth rotation. The tonearm, also known as the arm, is a mechanical arm that holds the cartridge, which is the device that reads the grooves on the record. The tonearm is typically made of a lightweight, rigid material, such as aluminum or carbon fiber, and is designed to track the grooves on the record with precision. The cartridge is attached to the end of the tonearm and is responsible for converting the vibrations from the record grooves into electrical signals, which are then sent to a phono preamp or amplifier. The phono preamp or amplifier boosts the signal to a level that is strong enough to drive a speaker, and the sound is then produced through the speaker. Overall, the components of a vinyl player work together to provide a high-quality, analog sound that is unique to vinyl records.

The Process of Reading Vinyl Grooves and Converting Them to Sound

The process of reading vinyl grooves and converting them to sound involves a series of intricate steps. It begins with the stylus, also known as the needle, which is carefully placed in the groove of the vinyl record. As the record rotates, the stylus tracks the undulations in the groove, vibrating in response to the changes in the groove's shape and size. These vibrations are then transmitted to a small coil, known as the cartridge, which is suspended within a magnetic field. The coil's movement within the magnetic field induces an electrical current, which is then sent to a phono preamplifier. The phono preamplifier boosts the weak signal from the cartridge, equalizing it to compensate for the RIAA curve, a standardized equalization curve that corrects for the physical limitations of vinyl records. The amplified signal is then sent to a line-level amplifier, which further boosts the signal to a level that can drive a speaker. Finally, the amplified signal is sent to a speaker, where it is converted back into sound waves, recreating the original audio signal that was encoded on the vinyl record. Throughout this process, the stylus must maintain precise contact with the groove, and the entire system must be carefully calibrated to ensure accurate sound reproduction.

The Importance of Proper Vinyl Player Maintenance and Calibration

The importance of proper vinyl player maintenance and calibration cannot be overstated. A well-maintained and calibrated vinyl player is essential for optimal sound quality, ensuring that the listener experiences the full range of frequencies and dynamics that the record has to offer. Regular maintenance involves cleaning the player's stylus, tonearm, and platter, as well as checking and replacing the belt and other worn-out parts. Calibration, on the other hand, involves adjusting the player's settings to ensure that the stylus is tracking the grooves on the record correctly, and that the tonearm is properly balanced. Proper calibration also involves setting the correct tracking force, anti-skate, and cartridge alignment. By neglecting maintenance and calibration, vinyl players can become prone to distortion, surface noise, and even damage to the records themselves. Furthermore, a poorly maintained player can also lead to a decrease in sound quality over time, making it essential for vinyl enthusiasts to prioritize regular maintenance and calibration to ensure that their player continues to deliver optimal performance. By taking the time to properly maintain and calibrate their vinyl player, listeners can enjoy a more immersive and engaging listening experience, and get the most out of their record collection.