How Long Does Dry Ice Last

Dry ice, the solid form of carbon dioxide, is a unique and versatile substance with a wide range of applications, from cooling and freezing to special effects and scientific research. However, one of the most common questions people ask about dry ice is how long it lasts. The answer to this question is not straightforward, as the shelf life of dry ice depends on several factors. In this article, we will explore the factors that affect dry ice shelf life, provide guidance on estimating its duration, and offer tips on how to extend its shelf life. By understanding these key aspects, you can make the most of dry ice and ensure it lasts as long as you need it to. So, let's start by examining the factors that affect dry ice shelf life, including temperature, storage, and handling, which play a crucial role in determining its longevity.

Factors Affecting Dry Ice Shelf Life

The shelf life of dry ice is a critical factor in various industries, including food, pharmaceutical, and entertainment. Several factors contribute to the longevity of dry ice, and understanding these factors is essential to maximize its usage and minimize waste. Three key factors that significantly impact the shelf life of dry ice are storage conditions, handling and transportation, and the initial quality of the dry ice. Proper storage conditions can slow down the sublimation process, while poor handling and transportation can lead to rapid degradation. Moreover, the initial quality of the dry ice can also affect its shelf life, as high-quality dry ice tends to last longer than low-quality dry ice. In this article, we will delve into these factors, starting with the importance of storage conditions in maintaining the shelf life of dry ice.

Storage Conditions

Storage conditions play a crucial role in determining the shelf life of dry ice. To maximize its lifespan, it's essential to store dry ice in a well-insulated container that is specifically designed for dry ice storage. The container should be made of a material that can withstand extremely low temperatures, such as foam or fiberboard, and have a secure lid to prevent moisture and air from entering. It's also crucial to store dry ice in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources. The ideal storage temperature for dry ice is between -109°F and -101°F (-78.5°C and -75°C), and the relative humidity should be below 60%. Additionally, it's recommended to store dry ice in small quantities to minimize sublimation, which is the process of dry ice turning directly into carbon dioxide gas. By following these storage conditions, you can help extend the shelf life of dry ice and ensure it remains effective for its intended use.

Handling and Transportation

Handling and transportation of dry ice require careful attention to ensure safety and maintain its shelf life. When handling dry ice, it is essential to wear protective gloves or use a towel to prevent skin contact, as it can cause severe burns. Dry ice should be stored in a well-ventilated area, away from children and pets, to prevent accidental ingestion or inhalation of carbon dioxide. When transporting dry ice, it is crucial to use a secure, insulated container with adequate ventilation to prevent the buildup of carbon dioxide. The container should be kept away from direct sunlight and heat sources to slow down sublimation. It is also recommended to transport dry ice in a vehicle with good ventilation to prevent the accumulation of carbon dioxide. Additionally, it is essential to follow local regulations and guidelines for handling and transporting dry ice, as they may vary. By taking these precautions, you can ensure safe handling and transportation of dry ice and maintain its shelf life.

Initial Quality of Dry Ice

Dry ice is a frozen form of carbon dioxide, and its initial quality plays a significant role in determining its shelf life. The quality of dry ice is affected by several factors, including the purity of the carbon dioxide used to produce it, the temperature and pressure conditions during production, and the handling and storage procedures. High-quality dry ice is typically produced using high-purity carbon dioxide and is manufactured under controlled conditions to minimize the introduction of impurities. This results in a product with a higher density and a more uniform crystal structure, which in turn affects its sublimation rate and overall shelf life. Dry ice with a higher initial quality will generally have a longer shelf life than lower-quality dry ice, as it is less prone to sublimation and degradation. Additionally, high-quality dry ice is often packaged in a way that minimizes exposure to air and moisture, which can further extend its shelf life. Overall, the initial quality of dry ice is a critical factor in determining its shelf life, and it is essential to source high-quality dry ice from a reputable supplier to ensure optimal performance and longevity.

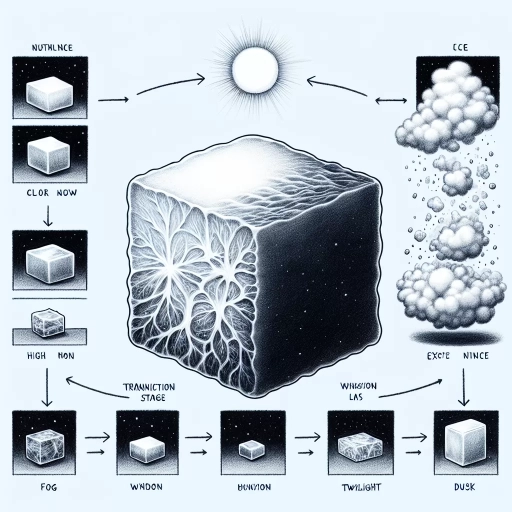

Estimating Dry Ice Duration

Estimating dry ice duration is crucial for various applications, including shipping, storage, and events. To accurately determine how long dry ice will last, it's essential to consider several factors. This article will provide an overview of the general guidelines for dry ice sublimation rate, calculating dry ice usage for specific applications, and the factors that influence dry ice sublimation rate. By understanding these concepts, individuals can make informed decisions about dry ice usage and ensure that their needs are met. In the next section, we will explore the general guidelines for dry ice sublimation rate, which will provide a foundation for understanding the complex process of dry ice duration estimation.

General Guidelines for Dry Ice Sublimation Rate

The sublimation rate of dry ice is influenced by several factors, including the size and shape of the dry ice, the temperature and humidity of the surrounding environment, and the type of container or insulation used to store it. Generally, dry ice sublimates at a rate of 5-10 pounds per 24 hours when stored in a well-insulated container. However, this rate can vary significantly depending on the specific conditions. For example, dry ice stored in a non-insulated container or in a warm and humid environment can sublimate at a rate of 20-30 pounds per 24 hours or more. It's also worth noting that dry ice sublimates more quickly when it's in smaller pieces, as there is more surface area exposed to the air. To minimize sublimation and extend the life of dry ice, it's recommended to store it in a well-insulated container, keep it away from direct sunlight and heat sources, and handle it as little as possible. Additionally, using a dry ice container with a lid or covering it with a towel or cloth can help to reduce sublimation by minimizing air circulation around the dry ice. By following these guidelines, you can help to slow down the sublimation rate of dry ice and keep it frozen for a longer period.

Calculating Dry Ice Usage for Specific Applications

Calculating dry ice usage for specific applications requires careful consideration of several factors, including the desired cooling temperature, the volume of the space or object to be cooled, the duration of cooling, and the ambient temperature. For example, when using dry ice to cool a small insulated container, a general rule of thumb is to use 1-2 pounds of dry ice per hour to maintain a temperature of around 0°F (-18°C). However, this can vary depending on the specific application, such as cooling a large volume of liquid or maintaining a specific temperature for a longer period. In these cases, it's essential to calculate the dry ice usage based on the specific requirements of the application. A common method is to use a dry ice calculator or consult with a dry ice supplier to determine the correct amount of dry ice needed. Additionally, it's crucial to consider the sublimation rate of dry ice, which can vary depending on the ambient temperature and humidity. By taking these factors into account, you can accurately calculate the dry ice usage for your specific application and ensure effective cooling.

Factors Influencing Dry Ice Sublimation Rate

The rate at which dry ice sublimates, or turns directly into carbon dioxide gas, is influenced by several factors. Temperature is a significant factor, as higher temperatures increase the sublimation rate. For example, dry ice stored at room temperature (around 70°F to 75°F) will sublimate faster than dry ice stored in a cooler environment (around 50°F to 60°F). Humidity also plays a role, as dry air can slow down the sublimation process. In contrast, high humidity can accelerate sublimation, as the dry ice absorbs moisture from the air, causing it to sublimate more quickly. Air movement is another factor, as gentle air currents can help to dissipate the carbon dioxide gas, reducing the sublimation rate. However, strong air currents can have the opposite effect, increasing the sublimation rate by stripping away the layer of cold air surrounding the dry ice. The size and shape of the dry ice also impact the sublimation rate, with smaller pieces sublimating faster than larger ones. Additionally, the type of container used to store the dry ice can affect the sublimation rate, as some materials, such as Styrofoam or foam coolers, can provide better insulation than others. Finally, the initial quality of the dry ice can also influence the sublimation rate, as high-quality dry ice with a lower moisture content will generally sublimate more slowly than lower-quality dry ice.

Extending Dry Ice Shelf Life

Extending the shelf life of dry ice requires careful consideration of several key factors. To keep dry ice from sublimating too quickly, it's essential to employ proper storage and handling techniques, use insulated containers and cooling systems, and minimize exposure to air and moisture. By implementing these strategies, you can significantly prolong the life of your dry ice and ensure it remains effective for its intended use. One of the most critical aspects of extending dry ice shelf life is proper storage and handling techniques. By storing dry ice in a well-ventilated area, away from direct sunlight and heat sources, and handling it with gloves or a towel to prevent skin contact, you can slow down the sublimation process and keep your dry ice fresh for longer.

Proper Storage and Handling Techniques

Proper storage and handling techniques are crucial to extending the shelf life of dry ice. To start, it's essential to store dry ice in a well-ventilated area, away from living spaces, to prevent the buildup of carbon dioxide. A dry ice storage container or a Styrofoam cooler with a lid is ideal, as it allows for airflow while keeping the dry ice contained. When handling dry ice, it's vital to wear protective gloves or use a towel to prevent skin contact, as the extreme cold can cause burns. It's also important to handle dry ice in small quantities, as larger blocks can be difficult to manage and may break apart, leading to waste. When storing dry ice for an extended period, it's recommended to keep it in a shaded area, away from direct sunlight, which can cause the dry ice to sublimate more quickly. Additionally, it's essential to keep the storage container or cooler away from heat sources, such as radiators, heaters, or warm appliances, as these can also accelerate sublimation. By following these proper storage and handling techniques, you can help extend the shelf life of your dry ice and ensure it remains effective for your intended use.

Using Insulated Containers and Cooling Systems

Using insulated containers and cooling systems is a highly effective way to extend the shelf life of dry ice. Insulated containers are designed to reduce heat transfer, keeping the dry ice at a lower temperature for a longer period. These containers are typically made of materials with low thermal conductivity, such as foam or fiberglass, and are often equipped with reflective insulation to further minimize heat gain. By storing dry ice in an insulated container, you can slow down the sublimation process, which is the transition of dry ice from a solid to a gas. This can help to extend the shelf life of dry ice by several hours or even days, depending on the quality of the container and the ambient temperature. Additionally, using cooling systems, such as refrigerated containers or cold rooms, can also help to extend the shelf life of dry ice. These systems can maintain a consistent low temperature, which can slow down the sublimation process even further. By combining insulated containers with cooling systems, you can create an optimal storage environment for dry ice, allowing you to keep it for an extended period.

Minimizing Exposure to Air and Moisture

Minimizing exposure to air and moisture is crucial in extending the shelf life of dry ice. When dry ice comes into contact with air, it undergoes a process called sublimation, where it directly transforms from a solid to a gas. This process accelerates the degradation of dry ice, causing it to dissipate rapidly. Similarly, moisture in the air can also contribute to the breakdown of dry ice, as it reacts with the carbon dioxide to form carbonic acid, which further accelerates the sublimation process. To minimize exposure to air and moisture, it is essential to store dry ice in a well-insulated container with a tight-fitting lid, such as a Styrofoam box or a dry ice chest. The container should be kept away from direct sunlight, heat sources, and humid environments. Additionally, it is recommended to handle dry ice with gloves or a towel to prevent skin contact, as the moisture from skin can also contribute to the degradation of dry ice. By taking these precautions, you can significantly reduce the exposure of dry ice to air and moisture, thereby extending its shelf life.