How Long Does Wood Glue Take To Dry

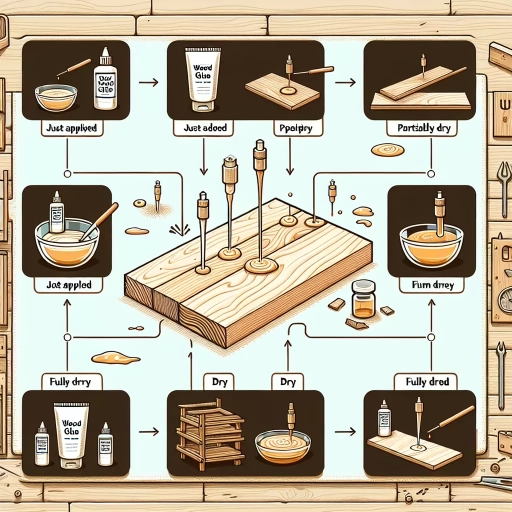

Crafting, carpentry, or any do-it-yourself project involving wood often incorporates the use of wood glue. But, how long does it take for wood glue to fully dry? The answer may surprise and enlighten you, as there's more to wood glue than meets the eye. Navigating through the complexities of wood glue and its drying time can prove both fascinating and essential. This article will not only demystify the drying times linked with different types of wood glue but will also delve deep into the myriad factors that influence these timelines. Moreover, for those in a hurry, we'll explore several strategies to expedite the drying process. So let's break the topic down to its very core, starting with understanding the variety of wood glues available and their respective drying times.

Crafting, carpentry, or any do-it-yourself project involving wood often incorporates the use of wood glue. But, how long does it take for wood glue to fully dry? The answer may surprise and enlighten you, as there's more to wood glue than meets the eye. Navigating through the complexities of wood glue and its drying time can prove both fascinating and essential. This article will not only demystify the drying times linked with different types of wood glue but will also delve deep into the myriad factors that influence these timelines. Moreover, for those in a hurry, we'll explore several strategies to expedite the drying process. So let's break the topic down to its very core, starting with understanding the variety of wood glues available and their respective drying times.Understanding Different Types of Wood Glues and Their Drying Times

Wood glue is an essential tool for both professional craftsmen and DIYers, yet with a wide array of options available in the market, it can be challenging to choose the right one for your specific needs. This article will delve into the diverse types of wood glues available, their drying times, and the factors influencing these times to empower you with the knowledge you need when handling your woodworking projects. Our first exploration will be a detailed probe into the myriad of wood glues available in the market. We acknowledge the potential confusion that a vast array of product choices can lead to and aim to help you classify and comprehend these options. The second section of this article will demystify the factors that influence the drying times of these glues, enhancing your understanding of the adhesive's behavior on different surface types. Lastly, we will walk you through some popular wood glues in the market and their respective drying times. By understanding these elements, you can make more informed decisions for your woodworking needs. Let's first delve into the variety of wood glues available in the market.

The Variety of Wood Glues Available in the Market

When delving into the world of woodworking, it's essential to have a basic understanding of the different types of wood glues available in the market. These adhesive varieties can significantly affect both the quality of workmanship and the drying times. Primary among these is PVA (Polyvinyl Acetate). Known for its excellent bonding capabilities, PVA is a favorite among crafters and furniture makers because of its easy application and quick drying periods that often range between 15 minutes to an hour. It comes in two main types: the regular white PVA and the yellow aliphatic-resin, the latter being more water-resistant and typically drying slightly faster than its counterpart. Epoxy resin is another versatile glue offering a robust bond. This two-part adhesive is renowned for its incredible strength, weather, and heat resistance, making it a go-to solution for outdoor woodworking projects or materials exposed to high-stress levels. However, it often takes longer to dry, ranging from a few minutes to several hours, depending on the formulation. Then there’s hide glue, a traditional and organic adhesive derived from animal collagen. While it has a slower drying time, usually between 12 to 24 hours, its unique reversibility feature makes it ideal for antique restoration and musical instrument construction. Polyurethane glue is a modern adhesive known for its strong, water-resistant bonds, and foaming expansion that seeps into wood pores for a tighter bond. It, however, comes with a considerably long curing time that can stretch up to 24 hours. Lastly, Cyanoacrylate (CA) or super glue, offers instant bonding on a variety of surfaces. While it is not typically used for large woodworking projects, it is perfect for quick fixes with its drying time ranging from a few seconds to a couple of minutes. Understanding these varieties and their respective drying times not only allows you to choose the most suitable adhesive for your woodworking project but also plays a significant part in planning your working pace, clamping time, and overall project timeline. These factors collectively contribute towards achieving a high-quality, lasting bond, and successful woodworking masterpiece.

What Determines the Drying Time of Different Wood Glues

Wood glue drying time is a subject of paramount importance to both professional woodworkers and hobbyists alike as it greatly influences the project timeline. Several factors play significant roles in determining the drying times of various wood glues. First and foremost, the type of adhesive used is a dominating determinant of the drying time. Different formulations imply varying drying periods. For instance, PVA (Polyvinyl Acetate) glues, the common white and yellow wood glues, are favored for their relatively quick setting times, drying in about 15 minutes to an hour, yet they require 24 hours to achieve full strength. On the other hand, Epoxy resins, renowned for their superior bonding strength and durability, exhibit a longer curing period, typically 24-72 hours. Individual product formulation also comes into play. Some manufacturers may incorporate quicker drying components into their products, cutting drying time without necessarily compromising on the strength of the bond. Environmental factors significantly influence wood glue drying times too. Optimum curing temperature and humidity levels differ across the different types of adhesives. For example, Epoxy resin cures faster in warm environments, while PVAs are highly susceptible to humidity. Therefore, woodworkers must consider the local climate and adapt their timelines accordingly. In addition to the aforementioned factors, the wood's nature itself contributes to the drying time. Different wood species have varying densities and moisture content which affect adhesive absorption and thereby influence drying time. Further, the surface preparation and the amount of glue applied on the surfaces to be joined could affect the drying process. In essence, factors such as adhesive type, product formulation, environmental conditions, wood properties, and application methodology collectively determine the drying time of wood glues. Hence, understanding these factors is critical for effectively planning and executing any woodworking project.

A Quick Look at The Drying Times for Popular Wood Glues

When it comes to woodworking and DIY projects, understanding the drying times of popular wood glues is crucial for successful execution. Among the most popular types, we primarily have PVA (polyvinyl acetate), polyurethane, hide glue, and epoxy resin. PVA, such as the common white and yellow woodworking glue, is a popular choice due to its versatility and user-friendly nature. PVA typically takes about 24 hours to dry completely, but it reaches a point of sufficient bond strength in approximately 30 minutes to an hour. This partially dried state is optimal for gentle handling or minor adjustments. However, keep in mind that humidity, temperature, and the type of wood can alter these drying times. Up next is polyurethane wood glue, known for its strong bond and water-resistant properties. Polyurethane glue usually requires a longer drying time, typically around 24 hours, to fully cure and harden. However, it achieves a firm hold in approximately one to four hours. Hide glue, a choice for traditional woodworking projects, has fairly quick drying times. Hot hide glue sets in less than a minute, while liquid hide glue, with additives to prolong drying time, often sets in a few hours to overnight. Lastly, we have epoxy resin, one of the most potent wood glues available. Its drying times can vary widely with different formulas, but most epoxies will be dry to the touch in about 5 hours and fully cured within 24 hours. Understanding the drying times of these popular wood glues helps to plan the pace and process of your woodworking projects. Bear in mind, letting the glue dry fully ensures optimal bond strength and durability, while rushed jobs can compromise the integrity of the final outcome. Therefore, even if your chosen glue feels dry to the touch or holds firm under gentle stress, it's crucial to respect the indicated curing times for the best results. Always refer to the manufacturer's instructions for the most accurate timeline.

Factors Influencing the Drying Time of Wood Glue

Understanding the factors that influence the drying time of wood glue can greatly enhance your woodworking projects. While wood glue seems to be a straightforward adhesive substance, its actual behavior depends on multiple elements that might not be visible at plain sight. Three significant contributors to the drying time of this indispensable material include the ambient room temperature, the surrounding humidity levels, and the type of wood you're working with. Begin by examining the room temperature. A seemingly mundane facet of your everyday environment, it can remarkably shape how wood glue operates. Room temperatures, particularly, exert a substantial effect on the curing or drying process of the adhesive. Colder spaces can delay drying time, while warmer ones can hasten it. Thus, understanding how these temperatures interact with your wood glue can save you ample time and provide a more defined work schedule. Transitioning to our discussion on the role and impact of room temperature, how exactly does it influence the drying time of wood glue? And, can we manipulate these temperatures to benefit our woodworking efforts? Let's delve deeper into the matter to unearth the correlations and mechanisms behind this intriguing phenomenon.

Room Temperature and its Impact on Wood Glue Drying Time

Room temperature, a much-ignored element in everyday life, plays a crucial role in the performance of many substances - including the drying time of wood glue. Scientifically, the temperature of the surroundings directly affects the evaporation rate, which is decisive in the drying process of adhesives such as wood glue. Typically, when the ambient temperature is higher, the molecules within the glue gain more kinetic energy, causing them to move faster. This increased rate of molecular motion facilitates the process of evaporation, where the water content in the glue changes from liquid to gas and leaves the adhesive, subsequently increasing the drying speed. On the other hand, cooler temperatures tend to slow down this molecular activity, thereby extending the drying time of the glue. Besides quickening the drying process, a warmer environment also tends to provide stronger glue joints. This occurs because such conditions are more conducive for the water or solvents present in the glue to dissolve, allowing the adhesive to penetrate deeper into the pores of the wood, and thus yielding a stronger bond. However, there is a caveat, extremely hot conditions could compromise the glue's quality resulting in a brittle joint. Hence, to maximize the efficiency of wood glue, it is recommended to work in an environment with controlled room temperature, ideally between 70 and 80 degrees Fahrenheit. This temperature-dependent drying process is not unique to wood glue but is a manifestation of a common scientific principle that governs the performance of many substances. Therefore, understanding the room temperature's impact on the drying time of wood glue allows craftspersons and DIY enthusiasts to manipulate these conditions to their advantage, further emphasizing the importance of this often overlooked factor. Remember that, while factors such as glue type, wood species, and humidity have their roles, the room temperature remains a pivotal influence to reckon with when assessing the drying time of wood glue.

The Role of Humidity in Wood Glue Drying

Humidity plays a crucial role in the drying time of wood glue and hence forms a part of the essential factors influencing the drying process of adhesives used in woodworking projects. Contrary to popular belief, the process is not simply about the water evaporating, but it's also about the glue undergoing the chemical process of polymerization. Thus, the liberation and absorption of moisture in the surrounding environment directly control the time consumed during this process. The higher the humidity in the air, the longer it takes for the wood glue to dry, as moisture in the air slows down the process by preventing the release of steam. On the other side, in a low humidity environment or a climate-controlled setting, the drying process becomes expedited as the moisture readily evaporates from the glue. The gelling time, i.e., the initial setting time of the glue is also largely dependent on the humidity levels. However, it is important to note that while drier environments hasten drying time, very arid conditions may cause the adhesive to dry out too quickly before strong bonding can be established, which might lead to weak joints and structural instability. The above humidity effects can be attributed to the hygroscopic properties of the glue's substances. That is, the ability of these materials to absorb and retain moisture from the environment. While this property helps in creating a lasting bond, it is a double-edged sword that can prolong the drying time in high humidity environments. In conclusion, understanding the role of humidity in wood glue drying is paramount to ensure optimal adherence and successful execution of woodworking projects. By managing and considering the influence of these conditions, one can accordingly plan for proper drying time, leading to more durable and reliable woodworking results. Always remember that the balancing act between the adhesive's drying time and the surrounding humidity levels isn't about speeding up the process but ensuring a perfect and strong bond every time. The role of humidity is just one of several factors influencing the drying time of wood glue; other elements like temperature, type of wood, and glue brand also play an integral part.

The Effect of Wood Type on the Drying Time of Wood Glue

The Effect of Wood Type on the Drying Time of Wood Glue plays a crucial role in determining not only how long it will take your applied adhesive to dry but also the overall quality and longevity of your woodworking project. Each type of wood, with its unique properties, interacts differently with wood glue and impacts its drying time. Hardwoods like maple, walnut, or oak, known for their compact and less porous structure, provide a less absorbent bonding surface for the glue. The lack of absorbency can lead to a longer drying time, as the glue concentration doesn't disperse as quickly into the fibres of the wood. It's important to note that although the drying process may be prolonged, the end result with hardwoods is typically a stronger, more durable bond. On the other hand, softwoods like pine, cedar or fir, known for their less dense and more porous makeup, soak up the glue at an accelerated rate. This increased absorption reduces the drying time significantly. However, the drawback is that the glue may seep deeper into the wood, creating a less surface-level bond. This can potentially result in a weaker join. Furthermore, certain exotic or oily woods like teak or ipe possess natural resins that may resist the bonding of wood glue, prolonging the drying process and potentially affecting the strength of the bond. It is advisable to lightly sand and clean such surfaces before applying glue. In essence, understanding the type of wood at hand is quite the cornerstone to nailing (or, in this case, gluing) a woodworking project. It equips the DIY enthusiast or professional carpenter with the insights crucial for ensuring optimal glue drying periods. By choosing the right type of wood and preparing it appropriately, the optimal balance between drying time and bond strength can be maintained, resulting in high-quality and enduring woodwork.

Tips and Tricks to Speed Up the Drying Time of Wood Glue

Optimizing the drying time of wood glue is pivotal not only for efficient craftsmanship but also for ensuring a durable and stable result. In this article, we will explore three uncomplicated yet effective techniques to speed up the drying process of your wood glue, providing you with convenient and foolproof methods to enhance your woodworking projects. First, we'll delve into the application of heat and how it boosts the drying speed of the adhesive. Next, we will discuss the significance of applying thin layers of glue and their role in hastening the drying process. Lastly, we're going to uncover the potential benefits of utilizing dehumidifiers for faster wood glue drying. By implementing these tips and tricks, you can save time, enhance productivity, and excel in your woodworking endeavors. With that said, let's kick off by turning up the heat - an efficient and cost-effective technique to increase the drying speed of wood glue.

Using Heat to Increase the Drying Speed of Wood Glue

When working with wood glue, waiting for it to dry can feel like an eternity, especially for woodworkers who are on a tight deadline. However, the application of heat can significantly reduce the drying time. The chemical composition of wood glue allows it to respond positively to heat, accelerating its drying process and creating a secure bond faster. When using heat to expedite the drying time of wood glue, it is important to keep in mind that it's not about applying high heat, but rather a consistent and moderate heat. Too much heat can harm the integrity of the wood or even make the glue brittle. Equally, it's recommended to ensure the glue is exposed evenly to the heat, as uneven heating could result in some parts drying faster than others, thereby compromising the union of the wooden pieces. One effective method to achieve this is to use a heat gun or hairdryer set on a low to medium setting and evenly distribute the heat across the applied glue. Another valuable strategy involves using a heated workspace, especially beneficial in winter months. This includes placing the glued piece in a warm room or using space heaters to maintain the temperature of the workspace. Apart from speed, heat also contributes to the strength of the adhesive bond making it more durable over time. To determine if the heat has successfully accelerated the drying process, look for a clear film to develop over the glue. This is typically a good indicator that the glue has dried. However, it's important not to rush the adhering process, as the aim is to create a long-lasting bond. In sum, while there's no way to make wood glue dry instantly, utilizing heat in a controlled manner can greatly reduce drying time, making the woodworking process more efficient without compromising the integrity of the finished product. Using these heat techniques in tandem with the proper application methods, appropriate clamping, and the right glue for the job can significantly enhance the outcome of your woodworking projects. Remember, the goal is not just to speed up drying time but also to ensure a solid, durable bond that stands the test of time.

How Thin Application Layers Can Boost Wood Glue Drying

Applying glue in thin layers is an effective trick to speed up the drying time of wood glue. It’s commonly believed that more glue equates to a stronger bond. On the contrary, it extends the curing period and may create a weaker bond. Here, less is more. When applied in thin layers, wood glue has less moisture to release, enhancing the drying process significantly. Drying times can reduce from 24 hours to just a matter of few hours, or even less. Thin application layers enable the moisture in the glue to evaporate quicker, hence hardening and curing faster. Moreover, thin layers of glue provide a neat finish, reducing cleanup time and the potential for glue stains. The surface contact between the glue and wood increases, providing a stronger bond. This method is time-efficient, cost-effective, and creates a cleaner, stronger finished product. It’s essential to apply evenly spread thin layers of glue on both surfaces for optimum results. Embracing this concept of thin application layers, however, needs a level of skill. You have to strike a balance to achieve the optimal quantity that will guarantee a robust bond without compromising the drying duration. You may use a glue spreader or an old credit card to achieve a consistent thin layer. Moreover, always double-check the glue's specifications for any specific guidance on the optimal thickness for a particular product. In summary, practicing a thinner application layer is not just about saving time, it's about increasing the quality of your woodworking project. This technique is a simple yet beneficial trick that supports the quick drying of wood glue without sacrificing the enduring strength and quality of your work. The thin application gives a win-win scenario, providing faster curing times, improving the overall quality, and facilitating a mess-free application.

Benefiting from Dehumidifiers for Faster Wood Glue Drying

A dehumidifier is a powerful tool for reducing humidity and moisture levels within your environment, making this device incredibly advantageous in the realm of woodworking—particularly when it comes to the drying of wood glue. With its ability to extract excess water from the air, the dehumidifier creates an ideal environment for the speedier drying of wood glue, minimizing the time required to wait for your woodworking projects to finally come together. When wood glue is set within an overly humid environment, it takes a noticeably longer time for the glue to dry. This is largely due to the moisture in the environment which prevents the complete evaporation of water in the glue composition. The utilization of a dehumidifier effectively combats this issue. Removing excess moisture from the air allows the water within the glue to evaporate at a much faster rate, hastening the process of glue drying drastically. Dehumidifiers come in a variety of sizes and types, with different capacities to lower the humidity level depending on the size of your workspace. Large capacity dehumidifiers can achieve considerable reductions in humidity over a wide area, which can be ideal for workshops or garages. Smaller, portable dehumidifiers can effectively reduce humidity in smaller spaces, like a shed or a compact workspace. Regardless of the size or type, the introduction of a dehumidifier into your woodworking space can significantly improve the drying times of your wood glue, streamlining your process like never before. It's also important to note that investing in a dehumidifier for your woodworking tasks isn't just beneficial for the quick drying of wood glue. Reduction in the ambient humidity can also prevent warping or cracking in the wood, especially when it's stored for an extended period, leading to better-quality end products. When it comes to woodworking, patience is a virtue, but time is also money. Therefore, leveraging the capability of a dehumidifier to expedite the drying process of wood glue brings not only efficiency but also the benefit of better overall craftsmanship. In conclusion, utilizing a dehumidifier in your woodworking space is a lesser-known yet highly effective trick to speed up wood glue drying time. Whether you're an amateur hobbyist or a professional carpenter, this investment will certainly pay off by reducing waiting periods and enhancing the quality of your work.