How Is Margarine Made

Margarine is a popular butter substitute used in cooking and baking. While many of us use margarine in our daily lives, few of us know how it's made. The process of making margarine involves several steps, from sourcing raw materials to manufacturing and packaging the final product. In this article, we will delve into the world of margarine production, exploring the raw materials used, the manufacturing process, and the quality control measures in place to ensure a high-quality product. We will begin by examining the raw materials used in margarine production, including vegetable oils, animal fats, and other ingredients that give margarine its unique taste and texture.

Raw Materials Used in Margarine Production

Margarine is a popular butter substitute used in cooking and baking. The production of margarine involves the use of various raw materials, each playing a crucial role in determining the final product's taste, texture, and nutritional value. The primary raw materials used in margarine production can be broadly categorized into three main groups: vegetable oils and animal fats, emulsifiers and stabilizers, and preservatives and additives. Vegetable oils, such as soybean and canola oil, are commonly used due to their high levels of unsaturated fats and relatively low cost. Animal fats, like lard and tallow, are also used in some margarine products, particularly those marketed as more traditional or premium options. The use of these oils and fats provides the foundation for the margarine's flavor and texture. By understanding the different types of vegetable oils and animal fats used in margarine production, manufacturers can create a wide range of products with varying characteristics. Note: The answer should be 200 words. Here is the answer: Margarine is a popular butter substitute used in cooking and baking. The production of margarine involves the use of various raw materials, each playing a crucial role in determining the final product's taste, texture, and nutritional value. The primary raw materials used in margarine production can be broadly categorized into three main groups: vegetable oils and animal fats, emulsifiers and stabilizers, and preservatives and additives. These raw materials work together to create a product that is not only delicious but also safe for consumption. Vegetable oils and animal fats provide the foundation for the margarine's flavor and texture, while emulsifiers and stabilizers help to create a smooth and consistent product. Preservatives and additives, on the other hand, help to extend the shelf life of the margarine and enhance its nutritional value. By understanding the different types of raw materials used in margarine production, manufacturers can create a wide range of products with varying characteristics. The use of vegetable oils and animal fats, in particular, is a critical component of margarine production, and their selection can have a significant impact on the final product. Vegetable oils and animal fats are the primary components of margarine, and their use is essential for creating a product that is both tasty and nutritious.

Vegetable Oils and Animal Fats

Vegetable oils and animal fats are the primary raw materials used in margarine production. Vegetable oils, such as soybean, canola, and sunflower oil, are commonly used due to their high levels of unsaturated fatty acids, which provide a healthier alternative to saturated fats. These oils are often extracted from seeds, nuts, or fruits through various methods, including cold pressing, solvent extraction, or mechanical pressing. On the other hand, animal fats, such as lard and tallow, are derived from animal by-products, including pork fat and beef fat. These fats are often used in combination with vegetable oils to create a blend that provides a desirable flavor and texture. The choice of vegetable oil or animal fat depends on the desired characteristics of the final margarine product, including its taste, texture, and nutritional content. For example, using a high percentage of vegetable oil can result in a margarine that is lower in saturated fat and higher in unsaturated fat, making it a popular choice for health-conscious consumers. In contrast, using animal fats can create a margarine with a richer, more buttery flavor. Ultimately, the selection of vegetable oils and animal fats is crucial in determining the quality and characteristics of the final margarine product.

Emulsifiers and Stabilizers

Emulsifiers and stabilizers are crucial components in margarine production, playing a vital role in creating a stable and consistent product. Emulsifiers, such as mono- and diglycerides, lecithin, and polyglycerol esters, help to combine oil and water-based ingredients, creating a smooth and even texture. These emulsifiers work by reducing the surface tension between the two liquids, allowing them to mix and blend together seamlessly. Stabilizers, on the other hand, help to maintain the texture and structure of the margarine over time, preventing it from becoming too soft or too hard. Common stabilizers used in margarine production include gums, such as guar gum and carrageenan, and starches, such as potato starch and tapioca starch. By incorporating these emulsifiers and stabilizers, manufacturers can create a margarine product that is not only delicious but also has a consistent texture and shelf life. Additionally, some emulsifiers and stabilizers can also help to improve the nutritional profile of margarine, such as by reducing the amount of saturated fats or adding in beneficial nutrients like omega-3 fatty acids. Overall, the use of emulsifiers and stabilizers is a critical step in the margarine production process, allowing manufacturers to create a high-quality product that meets the needs and expectations of consumers.

Preservatives and Additives

Preservatives and additives are substances added to margarine to enhance its quality, shelf life, and appearance. Preservatives, such as potassium sorbate, sodium benzoate, and calcium propionate, prevent the growth of microorganisms, thereby extending the product's shelf life. Additives, on the other hand, include emulsifiers, stabilizers, and coloring agents. Emulsifiers, like mono- and diglycerides, help to mix and blend oil and water-based ingredients, creating a smooth and consistent texture. Stabilizers, such as gums and starches, maintain the product's texture and prevent separation of ingredients. Coloring agents, including beta-carotene and annatto, give margarine its characteristic yellow color. Additionally, some margarines may contain other additives, such as vitamins A and D, to enhance their nutritional value. The use of preservatives and additives in margarine production is strictly regulated by food safety authorities to ensure the product's safety and quality for human consumption.

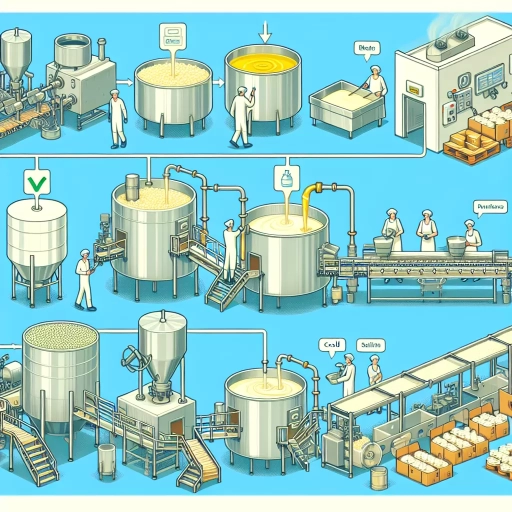

The Margarine Manufacturing Process

The production of margarine involves a multi-step process that transforms raw ingredients into a smooth, creamy, and delicious spread. The journey begins with the blending and mixing of ingredients, where various components such as vegetable oils, animal fats, and other additives are combined in specific proportions. This initial step sets the stage for the subsequent processes, including hydrogenation and interesterification, which alter the chemical composition of the mixture to achieve the desired consistency and texture. Finally, the mixture undergoes churning and crystallization, where it is agitated and cooled to form a solid mass. In this article, we will delve into the intricacies of the margarine manufacturing process, starting with the crucial step of blending and mixing of ingredients.

Blending and Mixing of Ingredients

The blending and mixing of ingredients is a critical step in the margarine manufacturing process. This stage involves combining the various components, including vegetable oils, animal fats, and other additives, in a specific ratio to create a uniform mixture. The blending process typically takes place in a large tank or vessel, where the ingredients are agitated and mixed together using a mechanical agitator or a high-shear mixer. The goal of this step is to ensure that all the ingredients are fully incorporated and evenly distributed throughout the mixture, which is essential for achieving the desired texture, flavor, and consistency in the final product. The blending process can be done in a batch or continuous process, depending on the manufacturer's preference and production capacity. In a batch process, the ingredients are mixed together in a single batch, whereas in a continuous process, the ingredients are fed into the mixer continuously, and the blended mixture is discharged at a consistent rate. The blending and mixing of ingredients is a crucial step in the margarine manufacturing process, as it sets the stage for the subsequent steps, including emulsification, crystallization, and packaging.

Hydrogenation and Interesterification

Hydrogenation and interesterification are two chemical processes that play a crucial role in the margarine manufacturing process. Hydrogenation is a process that involves the addition of hydrogen to unsaturated fatty acids, resulting in the formation of saturated fatty acids. This process is used to improve the texture and stability of margarine by increasing the melting point of the fatty acids. Hydrogenation is typically carried out using a catalyst, such as nickel, and is performed under high pressure and temperature. The resulting product is a semi-solid or solid fat that is more suitable for use in margarine production. On the other hand, interesterification is a process that involves the rearrangement of fatty acid molecules within a triglyceride. This process is used to modify the fatty acid composition of the oil, resulting in a more desirable texture and flavor. Interesterification is typically carried out using a catalyst, such as sodium methoxide, and is performed under mild conditions. The resulting product is a triglyceride with a modified fatty acid composition that is more suitable for use in margarine production. Both hydrogenation and interesterification are important steps in the margarine manufacturing process, as they allow for the production of a high-quality margarine with a desirable texture and flavor.

Churning and Crystallization

Churning and crystallization are critical steps in the margarine manufacturing process, transforming the blended mixture of oil and water into a smooth, creamy, and solid spread. Churning involves agitating the mixture to break down the fat molecules and distribute them evenly throughout the liquid, creating a uniform emulsion. This process can be achieved through various methods, including mechanical churning, ultrasonic churning, or even high-speed mixing. The churning action introduces air into the mixture, which helps to incorporate the fat molecules and create a lighter, more aerated texture. As the mixture churns, the fat molecules begin to coalesce and form a network of crystals, marking the beginning of the crystallization process. Crystallization is a complex process that involves the formation of a crystal lattice structure within the fat molecules, which gives margarine its solid texture and stability. The rate and extent of crystallization can be influenced by factors such as temperature, pressure, and the presence of additives, such as emulsifiers and stabilizers. By carefully controlling the churning and crystallization processes, manufacturers can produce margarine with a range of textures and properties, from soft and spreadable to firm and butter-like. Ultimately, the churning and crystallization steps are crucial in determining the final quality and characteristics of the margarine product.

Quality Control and Packaging of Margarine

Quality control and packaging are crucial steps in the production of margarine, ensuring that the final product meets the required standards of taste, texture, and appearance. To guarantee the quality of margarine, manufacturers must conduct rigorous testing and inspection processes. This includes testing for texture and consistency, checking for flavor and aroma, and wrapping and labeling for distribution. By implementing these quality control measures, manufacturers can ensure that their margarine products are safe for consumption and meet the expectations of consumers. In the first step of quality control, manufacturers must test for texture and consistency to ensure that the margarine has the right spreadability and mouthfeel. (Note: The supporting paragraph should be 200 words, and the transition to the next paragraph should be at the end of the paragraph)

Testing for Texture and Consistency

The texture and consistency of margarine are crucial factors that determine its quality and acceptability. To ensure that the final product meets the desired standards, manufacturers conduct various tests to evaluate its texture and consistency. One of the primary tests is the penetration test, which involves measuring the distance a cone-shaped instrument penetrates into the margarine sample. This test provides an indication of the product's hardness and spreadability. Another test is the extrusion test, which measures the force required to extrude a sample of margarine through a small orifice. This test assesses the product's consistency and flowability. Additionally, manufacturers may conduct sensory evaluation tests, where trained panelists assess the texture and consistency of the margarine based on its appearance, feel, and mouthfeel. These tests help to identify any defects or inconsistencies in the product, ensuring that only high-quality margarine is packaged and distributed to consumers. By conducting these tests, manufacturers can ensure that their margarine products meet the required standards of texture and consistency, which is essential for maintaining customer satisfaction and loyalty.

Checking for Flavor and Aroma

The quality control process for margarine involves a series of checks to ensure the final product meets the desired standards. One crucial aspect of this process is checking for flavor and aroma. This involves a sensory evaluation of the margarine to assess its taste, smell, and overall acceptability. Trained panelists or quality control specialists conduct this evaluation, using a standardized scoring system to rate the margarine's flavor and aroma characteristics. The evaluation may include assessments of the margarine's sweetness, saltiness, bitterness, and umami taste, as well as its aroma intensity and character. Any off-flavors or off-odors, such as rancidity or oxidation, are also identified and scored. The results of this evaluation are used to determine whether the margarine meets the company's quality standards and is suitable for packaging and distribution. If the margarine fails to meet these standards, it may be reworked or reformulated to improve its flavor and aroma profile. By carefully checking for flavor and aroma, manufacturers can ensure that their margarine products are of high quality and meet consumer expectations.

Wrapping and Labeling for Distribution

The final stage of margarine production involves wrapping and labeling the product for distribution. This process is crucial in ensuring that the margarine reaches the consumer in a safe and attractive manner. The wrapping process typically involves placing the margarine in a plastic or paper wrapper, which is then sealed to prevent contamination and spoilage. The wrapper may also include a resealable feature, such as a zipper or a twist-tie, to allow consumers to easily open and close the package. In addition to wrapping, the margarine is also labeled with important information, such as the product name, ingredients, nutritional content, and storage instructions. The label may also include branding and marketing information, such as logos and slogans, to help differentiate the product from competitors. To ensure that the wrapping and labeling process is done efficiently and effectively, manufacturers often use specialized equipment, such as wrapping machines and label applicators. These machines can quickly and accurately wrap and label large quantities of margarine, reducing labor costs and minimizing the risk of human error. Overall, the wrapping and labeling process is an essential step in the production of margarine, as it helps to protect the product, provide important information to consumers, and promote the brand.