How To Measure Viscosity

Viscosity is a fundamental property of fluids that plays a crucial role in various industrial, scientific, and everyday applications. Measuring viscosity accurately is essential to ensure the quality, safety, and efficiency of products and processes. However, viscosity measurement can be a complex task, requiring a deep understanding of the underlying principles and the selection of appropriate measurement methods. In this article, we will delve into the world of viscosity measurement, exploring the importance of understanding viscosity, the various methods available for measuring it, and the best practices for achieving accurate results. By grasping the concept of viscosity and its significance, we can better appreciate the need for precise measurement methods, which will be discussed in the following sections, starting with Understanding Viscosity and Its Importance.

Understanding Viscosity and Its Importance

Viscosity is a fundamental property of fluids that plays a crucial role in various aspects of our daily lives, from the flow of oil in pipelines to the consistency of food products. Understanding viscosity is essential for industries such as manufacturing, engineering, and food processing, as it directly affects the performance, efficiency, and quality of their products. In this article, we will delve into the concept of viscosity, its units of measurement, and its significance in different industries. We will also explore the consequences of incorrect viscosity measurement and how it can impact various sectors. By grasping the concept of viscosity, we can better appreciate its importance and make informed decisions in our personal and professional lives. To begin, let's define viscosity and its units of measurement, which will provide a solid foundation for understanding its role in various industries.

Defining Viscosity and Its Units of Measurement

Viscosity is a measure of a fluid's resistance to flow, with higher viscosity indicating a thicker, more resistant fluid. The unit of measurement for viscosity is typically measured in centipoise (cP) or poise (P), with 1 P equal to 100 cP. In the International System of Units (SI), viscosity is measured in pascal-seconds (Pa·s), where 1 Pa·s is equal to 10 P or 1,000 cP. Viscosity can also be expressed in other units, such as millipascal-seconds (mPa·s) or centistokes (cSt), which are commonly used in specific industries or applications. Understanding the units of measurement for viscosity is crucial in various fields, including engineering, chemistry, and materials science, as it allows for accurate calculations and comparisons of fluid properties.

The Role of Viscosity in Various Industries

Viscosity plays a crucial role in various industries, impacting the performance, efficiency, and quality of products and processes. In the food industry, viscosity affects the texture and consistency of food products, such as ketchup, honey, and sauces. Thicker, more viscous liquids are often preferred for their rich and indulgent feel, while thinner liquids are better suited for applications like cooking and baking. In the pharmaceutical industry, viscosity is critical in the development of medications, as it influences the rate of drug release and absorption. Viscous liquids are often used as excipients to control the release of active ingredients, ensuring that medications are delivered effectively and safely. In the automotive industry, viscosity is essential for engine performance and fuel efficiency. Engine oils with optimal viscosity help to reduce friction, prevent wear and tear, and maintain engine temperature, ultimately leading to improved fuel economy and reduced emissions. In the construction industry, viscosity is important for the development of building materials, such as concrete and asphalt. The right viscosity ensures that these materials can be easily mixed, applied, and finished, resulting in strong and durable structures. In the aerospace industry, viscosity is critical for the development of advanced materials and coatings, such as those used in aircraft and spacecraft. Viscous liquids are used to create thin, uniform coatings that provide protection against extreme temperatures, corrosion, and wear. In the cosmetics industry, viscosity is important for the development of personal care products, such as skincare creams and lotions. Thicker, more viscous products are often preferred for their rich and luxurious feel, while thinner products are better suited for applications like facial moisturizing and makeup removal. Overall, viscosity plays a vital role in various industries, influencing the performance, efficiency, and quality of products and processes. By understanding and controlling viscosity, manufacturers can create high-quality products that meet specific requirements and customer expectations.

Consequences of Incorrect Viscosity Measurement

Incorrect viscosity measurement can have severe consequences in various industries, including manufacturing, pharmaceuticals, and food processing. Inaccurate viscosity readings can lead to inconsistent product quality, reduced efficiency, and increased costs. For instance, in the production of paints and coatings, incorrect viscosity measurement can result in uneven application, affecting the final product's appearance and performance. Similarly, in the pharmaceutical industry, incorrect viscosity measurement can impact the efficacy and stability of medications, potentially leading to adverse health effects. In food processing, incorrect viscosity measurement can affect the texture and consistency of products, leading to customer dissatisfaction and potential recalls. Furthermore, incorrect viscosity measurement can also lead to equipment damage, as incorrect viscosity levels can cause excessive wear and tear on machinery, resulting in costly repairs and downtime. In extreme cases, incorrect viscosity measurement can even lead to safety hazards, such as explosions or fires, in industries that handle flammable or hazardous materials. Therefore, it is crucial to ensure accurate viscosity measurement to avoid these consequences and maintain product quality, efficiency, and safety.

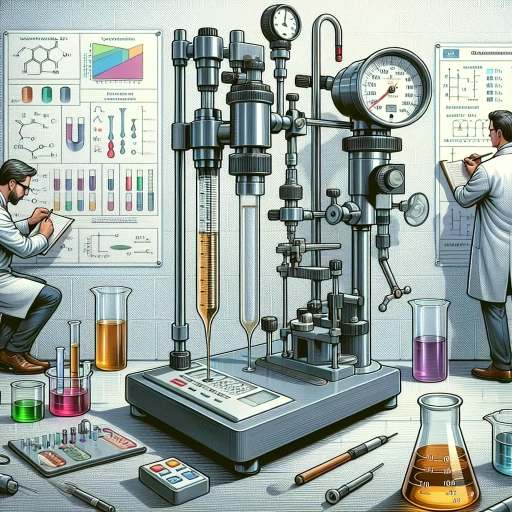

Methods for Measuring Viscosity

Viscosity is a fundamental property of fluids that plays a crucial role in various industrial and scientific applications. Measuring viscosity accurately is essential to ensure the quality and performance of products, as well as to understand the behavior of complex systems. There are several methods for measuring viscosity, each with its own strengths and limitations. In this article, we will explore three widely used methods: Capillary Viscometry, Rotational Viscometry, and Falling Ball Viscometry. These methods offer distinct advantages and are suited for different types of fluids and applications. By understanding the principles and applications of these methods, researchers and engineers can select the most appropriate technique for their specific needs. Capillary Viscometry, a traditional approach, is a widely used method that measures the flow time of a fluid through a narrow capillary tube, providing a direct measurement of viscosity.

Capillary Viscometry: A Traditional Approach

Capillary viscometry is a traditional approach to measuring viscosity, which involves the flow of a fluid through a narrow capillary tube. This method is based on the Hagen-Poiseuille equation, which relates the flow rate of a fluid to its viscosity, the radius of the capillary tube, and the pressure difference between the two ends of the tube. In a capillary viscometer, a fluid is placed in a reservoir and flows through a narrow capillary tube under the influence of gravity or pressure. The flow rate is measured by timing the flow of a known volume of fluid through the tube. By comparing the flow rate of the fluid to that of a reference fluid with known viscosity, the viscosity of the test fluid can be calculated. Capillary viscometry is a widely used method for measuring viscosity, particularly for Newtonian fluids, and is commonly used in various industries, including petroleum, chemical, and pharmaceutical. The advantages of capillary viscometry include its simplicity, accuracy, and low cost, making it a popular choice for viscosity measurement. However, it may not be suitable for non-Newtonian fluids or fluids with high viscosity, as the flow rate may be too slow or the pressure drop too high. Overall, capillary viscometry remains a traditional and reliable approach to measuring viscosity, and its principles continue to be used in modern viscometers.

Rotational Viscometry: A Modern and Versatile Method

Rotational viscometry is a modern and versatile method for measuring viscosity, offering a wide range of applications and benefits. This technique involves measuring the torque required to rotate a spindle or cylinder immersed in a fluid at a constant speed. The resulting data is then used to calculate the fluid's viscosity. Rotational viscometry is particularly useful for measuring the viscosity of non-Newtonian fluids, which exhibit complex flow behavior. The method is also highly sensitive, allowing for accurate measurements of small changes in viscosity. Additionally, rotational viscometry can be used to measure viscosity over a wide range of temperatures and shear rates, making it an ideal choice for characterizing the rheological properties of various materials. Furthermore, rotational viscometers are often equipped with advanced features such as temperature control, automated data acquisition, and software analysis, making them a valuable tool for researchers and quality control professionals alike. Overall, rotational viscometry is a powerful and flexible method for measuring viscosity, offering a high degree of accuracy and versatility in a wide range of applications.

Falling Ball Viscometry: A Simple yet Effective Technique

Falling Ball Viscometry is a simple yet effective technique for measuring the viscosity of liquids. This method involves dropping a ball into a liquid and measuring the time it takes for the ball to fall a certain distance. The viscosity of the liquid is then calculated based on the time it takes for the ball to fall, with higher viscosities resulting in longer fall times. Falling Ball Viscometry is a widely used technique in various industries, including petroleum, chemical, and food processing, due to its ease of use, low cost, and high accuracy. The technique is particularly useful for measuring the viscosity of Newtonian fluids, which exhibit a linear relationship between shear stress and shear rate. In addition, Falling Ball Viscometry can be used to measure the viscosity of non-Newtonian fluids, although the calculations may be more complex. Overall, Falling Ball Viscometry is a reliable and efficient method for measuring viscosity, making it a valuable tool in a wide range of applications.

Best Practices for Accurate Viscosity Measurement

Accurate viscosity measurement is crucial in various industries, including pharmaceuticals, food processing, and petroleum. The viscosity of a fluid can significantly impact its performance, stability, and overall quality. To ensure reliable and precise measurements, it is essential to follow best practices in viscosity measurement. This includes proper calibration and maintenance of viscometers, careful sample preparation and handling techniques, and strategies to minimize errors and ensure data reliability. By adhering to these guidelines, professionals can guarantee accurate viscosity measurements, which is critical for product development, quality control, and regulatory compliance. Regular calibration and maintenance of viscometers, in particular, is vital to prevent instrument drift and ensure consistent results. By prioritizing calibration and maintenance, professionals can ensure the accuracy and reliability of their viscosity measurements, setting the stage for successful product development and quality control.

Calibration and Maintenance of Viscometers

Calibration and maintenance of viscometers are crucial for ensuring accurate viscosity measurements. Calibration involves verifying the accuracy of the viscometer by comparing its readings to a known standard, while maintenance involves regular cleaning and checking of the instrument to prevent contamination and wear. Proper calibration and maintenance can help prevent errors, ensure consistency, and extend the lifespan of the viscometer. It is recommended to calibrate viscometers at least once a year, or more frequently if the instrument is used extensively. Calibration can be performed using certified reference materials, such as silicone oils or glycerin, which have known viscosities. Additionally, regular maintenance tasks, such as cleaning the viscometer's measuring cell and checking for blockages, can help prevent contamination and ensure accurate measurements. Furthermore, it is essential to follow the manufacturer's guidelines for calibration and maintenance to ensure that the viscometer is used correctly and accurately. By following these best practices, users can ensure that their viscometer is functioning correctly and providing accurate viscosity measurements.

Sample Preparation and Handling Techniques

Sample preparation and handling techniques play a crucial role in ensuring accurate viscosity measurements. Proper sample preparation involves selecting a representative sample, cleaning and drying the sample container, and minimizing contamination. It is essential to handle the sample gently to prevent introducing air bubbles or altering the sample's composition. When preparing a sample, it is recommended to use a consistent method, such as stirring or shaking, to ensure uniformity. Additionally, the sample should be allowed to reach thermal equilibrium before measurement to prevent temperature-related errors. Handling techniques, such as using a pipette or syringe to transfer the sample, can also impact measurement accuracy. It is crucial to minimize sample disturbance and prevent spills or drips, which can affect the sample's viscosity. Furthermore, the sample container should be compatible with the sample and the measurement instrument to prevent contamination or reaction. By following proper sample preparation and handling techniques, users can ensure reliable and accurate viscosity measurements.

Minimizing Errors and Ensuring Data Reliability

When it comes to viscosity measurement, minimizing errors and ensuring data reliability are crucial to obtain accurate and reliable results. To achieve this, it is essential to follow best practices and guidelines that can help reduce errors and ensure the accuracy of the data. One of the most critical factors in minimizing errors is to ensure that the viscometer is properly calibrated and maintained. Regular calibration and maintenance can help prevent errors caused by worn-out or damaged parts, and ensure that the instrument is functioning correctly. Additionally, it is essential to use high-quality samples that are free from contaminants and impurities, as these can affect the accuracy of the measurement. Furthermore, it is crucial to follow proper measurement protocols and procedures, such as using the correct measurement technique, temperature control, and data analysis methods. By following these best practices, users can minimize errors and ensure that their viscosity measurement data is reliable and accurate. Moreover, using advanced viscometers with built-in error detection and correction features can also help to minimize errors and ensure data reliability. These features can detect and correct errors in real-time, providing users with accurate and reliable data. Overall, by following best practices and using advanced viscometers, users can ensure that their viscosity measurement data is accurate, reliable, and free from errors.