How Is Shatter Made

Shatter, a popular cannabis concentrate, has gained significant attention in recent years due to its potency and versatility. But have you ever wondered how this glass-like substance is made? The process of creating shatter involves a combination of advanced technology and meticulous attention to detail. In this article, we will delve into the world of shatter production, exploring the differences between shatter and other cannabis concentrates, the step-by-step process of creating shatter, and the quality control measures that ensure a safe and high-quality final product. From understanding the unique characteristics of shatter to the rigorous testing and quality control measures in place, we will examine the intricacies of shatter production. So, let's start by understanding what shatter is and how it differs from other cannabis concentrates.

What is Shatter and How Does it Differ from Other Cannabis Concentrates?

Here is the introduction paragraph: Cannabis concentrates have become increasingly popular in recent years, with various forms and textures available to consumers. Among these, shatter stands out for its unique characteristics and distinct advantages. But what exactly is shatter, and how does it differ from other cannabis concentrates? To answer this question, we'll delve into the world of shatter, exploring its definition and unique characteristics, comparing it to other popular cannabis concentrates, and examining the role of terpenes in its distinctive flavor and aroma. By understanding these aspects, we can gain a deeper appreciation for shatter and its place in the cannabis industry. So, let's start by defining shatter and its unique characteristics.

Defining Shatter and its Unique Characteristics

Here is the paragraphy: Shatter is a type of cannabis concentrate that is known for its transparent, glass-like appearance and its high THC content. It is made by extracting the cannabinoids and terpenes from the cannabis plant using a solvent, such as butane or CO2, and then purifying the resulting mixture through a process of winterization and filtration. The resulting product is a thin, brittle sheet of cannabis concentrate that can be broken or "shattered" into smaller pieces. Shatter is often preferred by cannabis users because of its high potency and its ability to produce a strong, long-lasting high. It is also valued for its flavor and aroma, which are often more pronounced than those of other cannabis concentrates. One of the unique characteristics of shatter is its ability to be vaporized at a relatively low temperature, which makes it a popular choice for use in vaporizers and dab rigs. Additionally, shatter is often used to make other cannabis products, such as edibles and topicals, due to its high potency and ease of use. Overall, shatter is a popular and versatile cannabis concentrate that is known for its high quality and unique characteristics.

Comparing Shatter to Other Popular Cannabis Concentrates

Shatter is a popular cannabis concentrate known for its transparent, glass-like appearance and high THC content. When comparing shatter to other popular cannabis concentrates, it's essential to consider factors such as potency, texture, and production methods. Shatter typically has a higher THC content than other concentrates, with some products reaching up to 90% THC. In contrast, budder and wax usually have a lower THC content, ranging from 60-80%. Shatter's transparent appearance is also distinct from other concentrates, which can have a more opaque or waxy texture. The production method of shatter involves a solvent-based extraction process, which results in a more potent and flavorful product. Other concentrates, such as rosin and live resin, use solventless extraction methods, which can produce a more natural and terpene-rich product. However, shatter's high potency and flavor profile make it a popular choice among cannabis enthusiasts. Ultimately, the choice between shatter and other cannabis concentrates depends on personal preference and individual needs. Shatter is ideal for those seeking a potent and flavorful product, while other concentrates may be better suited for those looking for a more natural or terpene-rich experience.

Understanding the Role of Terpenes in Shatter's Distinctive Flavor and Aroma

The unique flavor and aroma of shatter, a type of cannabis concentrate, can be attributed to the presence of terpenes. Terpenes are a class of organic compounds found in the oils of plants and give cannabis its distinctive flavors and aromas. In shatter, terpenes play a crucial role in determining the overall character of the concentrate. Different strains of cannabis contain unique terpene profiles, which are influenced by factors such as the plant's genetics, growing conditions, and curing process. When cannabis is processed into shatter, the terpenes are concentrated and preserved, resulting in a potent and flavorful product. The terpene profile of shatter can range from sweet and fruity to earthy and herbal, depending on the strain used. For example, a shatter made from a strain high in limonene may have a citrusy flavor, while one made from a strain high in myrcene may have a more earthy and musky flavor. The terpene content of shatter can also affect its medicinal properties, as different terpenes have been shown to have unique therapeutic benefits. Overall, the terpenes in shatter are responsible for its distinctive flavor and aroma, making it a popular choice among cannabis enthusiasts.

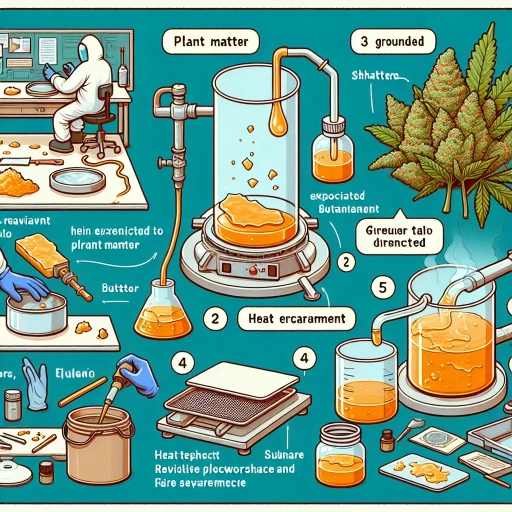

The Shatter Production Process: From Cannabis Plant to Concentrate

The production of shatter, a popular cannabis concentrate, involves a multi-step process that transforms the cannabis plant into a potent and flavorful extract. The journey from plant to concentrate requires careful attention to detail, precision, and a deep understanding of the chemistry involved. To create high-quality shatter, manufacturers must first harvest and prepare the cannabis plant for extraction, a process that involves selecting the right strains, drying and curing the buds, and grinding the plant material into a fine consistency. Next, solvents are used to extract the cannabinoids and terpenes from the plant material, a process that requires careful control of temperature, pressure, and solvent ratios. Finally, the extract is purified and concentrated through a process known as winterization and filtration, which removes impurities and results in a clear, glass-like concentrate. In this article, we will delve into the specifics of each step, starting with the critical first step of harvesting and preparing the cannabis plant for extraction.

Harvesting and Preparing the Cannabis Plant for Extraction

The cannabis plant is carefully harvested and prepared for extraction to produce high-quality shatter. Harvesting typically occurs when the trichomes, the resinous glands containing cannabinoids and terpenes, are fully developed and ripe. Growers use various techniques to determine the optimal harvest time, including visual inspection, trichome analysis, and cannabinoid testing. Once harvested, the plant material is dried to remove excess moisture, either air-dried or using machines specifically designed for this purpose. The dried plant material is then cured in a controlled environment to preserve the cannabinoids and terpenes. The curing process involves storing the plant material in airtight containers, allowing it to breathe, and monitoring the humidity and temperature levels. After curing, the plant material is trimmed to remove excess leaves and stems, leaving only the desirable flower material. The trimmed material is then ground or chopped into a uniform consistency to increase the surface area for extraction. Some producers may also use additional steps, such as freezing or flash freezing, to preserve the terpenes and cannabinoids. The prepared plant material is now ready for extraction, which involves using a solvent, such as butane or CO2, to separate the cannabinoids and terpenes from the plant material. The resulting extract is then further processed to produce shatter, a concentrated and potent cannabis product.

Using Solvents to Extract Cannabinoids and Terpenes from the Plant Material

The use of solvents is a crucial step in the shatter production process, as it allows for the efficient extraction of cannabinoids and terpenes from the plant material. Solvents, such as butane or ethanol, are used to break down the plant's cellular structure, releasing the desired compounds into a liquid solution. The solvent is then evaporated, leaving behind a concentrated extract that contains the cannabinoids and terpenes. This process is often referred to as winterization, and it is essential for producing high-quality shatter. The choice of solvent is critical, as different solvents can affect the final product's flavor, potency, and texture. Butane, for example, is a popular choice for shatter production due to its ability to extract a wide range of cannabinoids and terpenes, resulting in a full-spectrum extract. Ethanol, on the other hand, is often used for its ability to extract a higher concentration of CBD. The solvent extraction process can be performed using various methods, including Soxhlet extraction, cold finger extraction, and closed-loop extraction. Each method has its own advantages and disadvantages, and the choice of method will depend on the desired outcome and the equipment available. Regardless of the method used, the goal of solvent extraction is to produce a high-quality extract that is rich in cannabinoids and terpenes, and free of impurities and contaminants. By carefully selecting the solvent and extraction method, manufacturers can produce shatter that is not only potent and flavorful but also safe for consumption.

Purifying and Concentrating the Extract through Winterization and Filtration

The winterization and filtration process is a crucial step in purifying and concentrating the extract to produce high-quality shatter. Winterization involves mixing the crude extract with a solvent, typically ethanol, and then placing it in a cold environment, such as a freezer, to allow the impurities to precipitate out of the solution. This process helps to remove waxes, lipids, and other unwanted compounds that can affect the texture and appearance of the final product. After winterization, the mixture is filtered to remove the precipitated impurities, resulting in a clearer and more concentrated extract. The filtration process can be done using various methods, including vacuum filtration, centrifugation, or even simple gravity filtration. The goal of this step is to remove as many impurities as possible, resulting in a highly concentrated and purified extract that is ready for the next step in the shatter production process. By removing impurities and concentrating the extract, winterization and filtration help to improve the overall quality and potency of the final product, making it a critical step in producing high-quality shatter.

Quality Control and Safety Considerations in Shatter Production

Quality control and safety considerations are paramount in shatter production to ensure the delivery of a high-quality, safe, and potent product to consumers. The production of shatter, a type of cannabis concentrate, involves several critical steps that require meticulous attention to detail to prevent contamination, ensure purity, and maintain potency. To achieve this, manufacturers must implement robust quality control measures, including laboratory testing and certification, safe extraction and handling practices, and adherence to regulatory compliance and industry standards. By prioritizing these considerations, manufacturers can guarantee a product that meets the highest standards of quality and safety. Ensuring the purity and potency of shatter through laboratory testing and certification is a crucial step in this process, as it allows manufacturers to verify the product's chemical composition and detect any potential contaminants or impurities. (Note: The supporting paragraph should be 200 words, and the transactional sentence at the end should be: Ensuring the purity and potency of shatter through laboratory testing and certification is a crucial step in this process, as it allows manufacturers to verify the product's chemical composition and detect any potential contaminants or impurities.)

Ensuring Purity and Potency through Laboratory Testing and Certification

Ensuring the purity and potency of shatter is crucial to guarantee a safe and effective product for consumers. Laboratory testing and certification play a vital role in this process. Third-party laboratories conduct rigorous tests to analyze the chemical composition of shatter, including its cannabinoid and terpene profiles. These tests help identify any contaminants, such as heavy metals, pesticides, or residual solvents, that may be present in the product. Certification programs, like ISO 17025, ensure that laboratories adhere to strict standards and protocols, providing accurate and reliable results. By verifying the purity and potency of shatter through laboratory testing and certification, manufacturers can ensure compliance with regulatory requirements and provide consumers with a high-quality product that meets their expectations. This not only enhances the reputation of the manufacturer but also contributes to the overall safety and efficacy of the cannabis industry. Regular testing and certification also enable manufacturers to refine their production processes, making adjustments as needed to optimize the quality of their shatter products. Ultimately, laboratory testing and certification are essential components of a robust quality control program, allowing manufacturers to produce shatter that is both pure and potent, and that meets the evolving needs of the cannabis market.

Implementing Safe Extraction and Handling Practices to Prevent Contamination

Implementing safe extraction and handling practices is crucial to prevent contamination in shatter production. Contamination can occur at any stage of the process, from initial plant material handling to final product packaging. To mitigate this risk, producers must adhere to strict protocols for cleaning and sanitizing equipment, as well as personal protective equipment (PPE) for staff. This includes wearing gloves, masks, and eye protection to prevent skin contact and inhalation of potential contaminants. Additionally, producers should implement a robust quality control program that includes regular testing for contaminants such as heavy metals, pesticides, and microbial impurities. This program should also include regular audits and inspections to ensure compliance with established protocols. Furthermore, producers should consider implementing a closed-loop system for extraction and processing to minimize the risk of contamination from external sources. This can include using sealed equipment and piping, as well as implementing a positive pressure system to prevent external air from entering the production area. By implementing these safe extraction and handling practices, producers can significantly reduce the risk of contamination and ensure a high-quality final product. Regular training and education for staff on proper handling and extraction techniques is also essential to prevent contamination. This includes training on proper equipment operation, cleaning and sanitizing procedures, and emergency response protocols. By prioritizing safe extraction and handling practices, producers can protect their products, their staff, and their customers from the risks associated with contamination.

Regulatory Compliance and Industry Standards for Shatter Production

Regulatory compliance and adherence to industry standards are crucial for shatter production to ensure the quality and safety of the final product. The shatter production industry is heavily regulated, and manufacturers must comply with various laws, regulations, and standards. In the United States, for example, shatter production is regulated by the Cannabis Regulatory Commission, which requires manufacturers to adhere to specific guidelines and standards for production, packaging, and labeling. Similarly, in Canada, shatter production is regulated by Health Canada, which has established strict guidelines for the production and sale of cannabis products, including shatter. Manufacturers must also comply with industry standards, such as those set by the National Cannabis Industry Association, which provides guidelines for best practices in cannabis production, processing, and testing. Additionally, shatter manufacturers must adhere to Good Manufacturing Practices (GMPs) and follow guidelines set by the International Organization for Standardization (ISO). Compliance with these regulations and standards is essential to ensure the quality and safety of shatter products, and manufacturers who fail to comply risk facing penalties, fines, and damage to their reputation. Moreover, adherence to regulatory compliance and industry standards also helps to build trust with consumers, who expect a safe and high-quality product. By prioritizing regulatory compliance and industry standards, shatter manufacturers can ensure that their products meet the highest standards of quality and safety, and establish themselves as reputable and trustworthy producers in the industry. Furthermore, regulatory compliance and adherence to industry standards also help to drive innovation and improvement in shatter production, as manufacturers are encouraged to adopt best practices and invest in research and development to improve their products and processes. Overall, regulatory compliance and industry standards are critical components of shatter production, and manufacturers who prioritize these considerations can ensure the success and sustainability of their business.