How To Make Wine In Infinite Craft

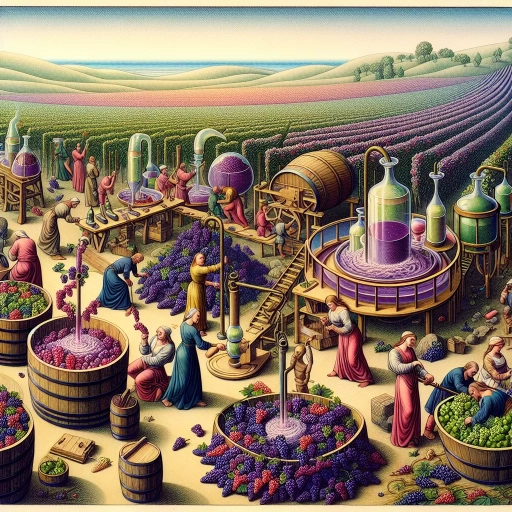

In the world of Infinite Craft, creating your own wine can be a fun and rewarding experience. With a few simple ingredients and some basic equipment, you can craft a variety of wines that are perfect for sipping on their own or using in recipes. To get started, you'll need to gather the necessary ingredients and equipment, which we'll cover in the next section. But first, let's take a look at the overall process of making wine in Infinite Craft. The journey begins with preparing the must and fermentation, where you'll combine your ingredients and allow them to ferment into a delicious wine. Once the fermentation process is complete, you'll be ready to bottle and age your wine, which is the final step in creating a high-quality wine. In this article, we'll walk you through each of these steps, starting with the first and most important one: gathering ingredients and equipment.

Gathering Ingredients and Equipment

Gathering ingredients and equipment is a crucial step in the winemaking process. To produce high-quality wine, it is essential to select the right grapes or fruits, acquire the necessary equipment, and ensure a clean and sanitized workspace. Choosing the right grapes or fruits is a critical decision, as it will directly impact the flavor, aroma, and overall quality of the wine. Acquiring essential winemaking equipment, such as fermenters, hydrometers, and siphons, is also vital to ensure a smooth and successful winemaking process. Furthermore, sanitizing and preparing the workspace is crucial to prevent contamination and spoilage. By carefully selecting the right ingredients and equipment, and preparing a clean and sanitized workspace, winemakers can set themselves up for success and produce exceptional wine. With the right ingredients and equipment in place, the next step is to choose the right grapes or fruits for your wine.

Choosing the Right Grapes or Fruits

When it comes to making wine in Infinite Craft, selecting the right grapes or fruits is a crucial step in determining the quality and flavor of your final product. With a vast array of options available, it's essential to choose fruits that are not only suitable for winemaking but also complement the desired flavor profile. For beginners, it's recommended to start with popular grape varieties like Chardonnay, Merlot, or Cabernet Sauvignon, which are known for their ease of cultivation and adaptability to different environments. If you prefer to experiment with other fruits, consider options like berries, apples, or pears, which can produce unique and delicious wines. When selecting fruits, look for those that are ripe, fresh, and free of mold or rot, as these can affect the overall quality of your wine. Additionally, consider the sugar content, acidity, and tannin levels of the fruits, as these will impact the flavor and character of your wine. By carefully choosing the right grapes or fruits, you'll be well on your way to crafting a delicious and memorable wine in Infinite Craft.

Acquiring Essential Winemaking Equipment

Acquiring essential winemaking equipment is a crucial step in the winemaking process. To start, you'll need a large, food-grade plastic bucket or container with a lid, which will serve as your primary fermentation vessel. A hydrometer is also necessary for measuring the specific gravity of your must, allowing you to track the fermentation progress and determine the final alcohol content. Additionally, you'll need a siphon and racking cane to transfer the wine between vessels, minimizing the risk of contamination and oxidation. An airlock and bung will also be required to allow CO2 to escape while keeping air out, preventing spoilage and ensuring a healthy fermentation. Furthermore, a wine thief or pipette will come in handy for sampling the wine without disturbing the sediment. Other essential equipment includes a wine press or fruit press, a crusher or de-stemmer, and a bottling bucket with a spigot. It's also recommended to have a pH meter and acid test kit to monitor and adjust the acidity levels in your wine. Lastly, a sanitized environment and proper cleaning equipment, such as a sanitizing solution and scrub brush, are vital to prevent contamination and spoilage. By investing in these essential pieces of equipment, you'll be well on your way to producing high-quality, delicious wine.

Sanitizing and Preparing the Workspace

Sanitizing and preparing the workspace is a crucial step in the winemaking process. Before starting, it's essential to ensure that all equipment and surfaces are clean and sanitized to prevent contamination and spoilage. Begin by washing your hands thoroughly with soap and warm water, and then put on a pair of gloves to prevent any bacteria or wild yeast from coming into contact with the equipment. Next, sanitize all equipment, including fermenters, hydrometers, and siphons, by soaking them in a solution of water and sanitizer, such as bleach or Star San, for at least 30 minutes. After sanitizing, rinse all equipment thoroughly with clean water to remove any residual sanitizer. Once the equipment is sanitized, prepare the workspace by covering the surface with a clean, sanitized cloth or plastic sheet to prevent any contamination. Finally, arrange all equipment and ingredients in a logical and accessible manner to ensure a smooth and efficient winemaking process. By taking the time to properly sanitize and prepare the workspace, you can help ensure that your wine turns out clean, flavorful, and free of contaminants.

Preparing the Must and Fermentation

Preparing the must and fermentation is a crucial step in the winemaking process. It involves several key steps that require attention to detail and a thorough understanding of the process. To begin, winemakers must first crush and de-stem the grapes, releasing the juice and pulp from the skins. This process is critical in determining the final flavor and aroma of the wine. Next, the must is created and yeast is added to initiate fermentation. This is a delicate process, as the type and amount of yeast used can greatly impact the final product. Finally, monitoring and controlling fermentation temperature is essential to ensure that the fermentation process proceeds smoothly and efficiently. By carefully managing these steps, winemakers can produce high-quality wines that showcase the unique characteristics of the grape variety. In this article, we will explore each of these steps in more detail, starting with the critical process of crushing and de-stemming the grapes.

Crushing and De-stemming the Grapes

Crushing and de-stemming the grapes is a crucial step in the winemaking process, as it sets the stage for the subsequent steps of preparing the must and fermentation. Crushing the grapes releases the juice from the skins, allowing the winemaker to extract the desired flavors, aromas, and colors from the grape skins. De-stemming, on the other hand, involves removing the grape stems from the must, as they can impart bitter and astringent flavors to the wine. The combination of crushing and de-stemming helps to create a clean and healthy environment for fermentation to occur, allowing the winemaker to produce a high-quality wine. The type of crusher and de-stemmer used can vary depending on the winemaker's preference and the type of grapes being used, with some opting for a gentle, whole-berry crush, while others prefer a more aggressive crush to release more juice from the skins. Regardless of the method, the goal of crushing and de-stemming is to create a must that is rich in flavor and aroma compounds, and free from any unwanted impurities or contaminants. By carefully controlling this step, winemakers can set themselves up for success in the subsequent steps of fermentation and beyond.

Creating the Must and Adding Yeast

When creating the must and adding yeast, it's essential to follow a few crucial steps to ensure a healthy fermentation process. First, the must, which is the mixture of grape juice, skins, and seeds, should be prepared by crushing and de-stemming the grapes. This process releases the juice from the skins and allows the natural yeast and bacteria present on the grapes to start the fermentation process. Next, the must should be transferred to a sanitized fermentation vessel, such as a food-grade plastic bucket or a glass carboy, to prevent contamination. The must should then be covered with a cloth or paper towel to keep dust and other contaminants out. Before adding yeast, the must should be allowed to sit for 24-48 hours to allow the natural yeast and bacteria to start the fermentation process. This is called the "cold soak" phase. After the cold soak, the yeast can be added to the must. The type and amount of yeast used will depend on the type of wine being made and the desired level of fermentation. Generally, a packet of dry yeast or a liquid yeast culture is added to the must, and the mixture is gently stirred to distribute the yeast evenly. It's also important to monitor the temperature of the must, as yeast thrives in temperatures between 65-75°F (18-24°C). Finally, the fermentation vessel should be sealed with an airlock to allow the carbon dioxide produced during fermentation to escape while keeping air out. This will help to prevent spoilage and ensure a healthy fermentation process. By following these steps, you can create a healthy and thriving must that will produce a delicious and high-quality wine.

Monitoring and Controlling Fermentation Temperature

Monitoring and controlling fermentation temperature is a crucial step in the winemaking process. Fermentation temperature affects the rate of fermentation, the production of desirable compounds, and the overall quality of the wine. Yeast, the microorganism responsible for fermentation, thrives in a specific temperature range, typically between 15°C to 20°C (59°F to 68°F). If the temperature is too high, yeast can produce off-flavors and aromas, while temperatures that are too low can slow down or even stop fermentation. To monitor fermentation temperature, winemakers use thermometers or temperature probes to track the temperature of the must. This information is used to adjust the temperature of the fermentation vessel, either by moving it to a cooler or warmer location, or by using heating or cooling systems. Some winemakers also use temperature control systems, which can automatically adjust the temperature of the fermentation vessel to a set point. By controlling fermentation temperature, winemakers can ensure that the yeast ferments the must efficiently and produces a high-quality wine. Additionally, monitoring fermentation temperature can also help winemakers to detect any potential problems, such as stuck fermentation or contamination, and take corrective action to prevent spoilage. Overall, monitoring and controlling fermentation temperature is a critical step in the winemaking process, and can have a significant impact on the final quality of the wine.

Bottling and Aging the Wine

The process of bottling and aging wine is a crucial step in the winemaking process. After fermentation and stabilization, the wine is ready to be prepared for bottling. This involves several key steps, including racking and clarifying the wine to remove impurities and sediment, bottling and corking the wine to prevent spoilage and oxidation, and storing and aging the wine for optimal flavor. By carefully executing these steps, winemakers can ensure that their wine is of the highest quality and will continue to improve with age. In order to achieve this, it is essential to start with a clean and clarified wine, which is where the process of racking and clarifying the wine comes in.

Racking and Clarifying the Wine

Racking and clarifying the wine is a crucial step in the winemaking process that involves transferring the wine from one container to another, leaving behind any sediment that has accumulated. This process helps to clarify and refine the wine, removing any impurities that may affect its flavor, aroma, and overall quality. To rack the wine, winemakers use a racking cane or a siphon to carefully transfer the liquid from the bottom of the container, avoiding any sediment that has settled at the bottom. The wine is then transferred to a new container, where it is left to settle and clarify further. This process is typically repeated several times, with the wine being racked every few months, until it is clear and stable. Clarifying agents, such as egg whites or bentonite, may also be added to the wine to help remove any remaining impurities and improve its clarity. By racking and clarifying the wine, winemakers can ensure that their wine is of the highest quality and ready for bottling and aging.

Bottling and Corking the Wine

Bottling and corking the wine is a crucial step in the winemaking process. After the wine has aged to perfection, it's time to transfer it into bottles and seal them with corks. This process requires attention to detail and a bit of finesse to ensure that the wine is properly preserved and protected from oxidation. To begin, the winemaker will typically prepare the bottles by washing and sanitizing them to prevent any contamination. Next, the wine is carefully transferred into the bottles using a siphon or a bottling machine, leaving a small amount of headspace at the top. The headspace is important, as it allows for a small amount of expansion and contraction of the wine as it ages. Once the bottles are filled, the winemaker will then insert a cork into the neck of the bottle, making sure it is seated properly and evenly. The cork is then secured with a wire or plastic capsule to prevent it from coming loose over time. Finally, the bottles are labeled and packaged, ready to be shipped off to stores and enjoyed by wine enthusiasts. It's worth noting that not all wines are bottled and corked in the same way. Some winemakers may choose to use alternative closures, such as screwcaps or synthetic corks, which can provide a tighter seal and reduce the risk of oxidation. However, traditional corks remain a popular choice for many winemakers, as they allow for a small amount of oxygen to enter the bottle, which can help to mature and develop the flavors of the wine over time. Overall, bottling and corking the wine is a delicate process that requires patience, attention to detail, and a commitment to quality. When done properly, it can help to preserve the flavors and aromas of the wine, and ensure that it reaches its full potential.

Storing and Aging the Wine for Optimal Flavor

Storing and aging wine is a crucial step in the winemaking process, as it allows the flavors to mature and integrate, resulting in a more complex and refined taste. To store wine optimally, it's essential to consider the type of wine, its age, and the storage conditions. Generally, wine should be stored in a cool, dark place with a consistent temperature between 45°F and 65°F (7°C and 18°C). The ideal humidity level is between 50% and 70%, which helps to prevent corks from drying out and spoiling the wine. It's also important to store wine bottles on their side to keep the corks moist and prevent air from entering the bottle. For red wines, it's recommended to store them for at least 6 months to 2 years to allow the tannins to soften and the flavors to mature. White wines, on the other hand, are typically ready to drink within 6 months to 1 year, but some varieties like Chardonnay and Sauvignon Blanc can benefit from longer aging. Sparkling wines, such as Champagne, should be stored upright to prevent the cork from becoming too wet and causing the wine to spoil. When it comes to aging wine, the key is to be patient and allow the wine to develop its full potential. With proper storage and aging, wine can become more complex, with flavors of vanilla, oak, and spices emerging over time. Ultimately, the optimal aging time will depend on the specific wine and personal taste preferences, but with proper storage and care, wine can be enjoyed for years to come.