How To Use Plumbers Tape

Plumbers tape, also known as Teflon tape, is a versatile and essential tool in every homeowner's and DIY enthusiast's toolkit. It is used to create a watertight seal on threaded pipes and fittings, preventing leaks and ensuring a secure connection. However, using plumbers tape effectively requires some knowledge and technique. In this article, we will explore the best practices for using plumbers tape, from preparation to application and maintenance. To get the most out of plumbers tape, it is crucial to understand the importance of preparation, applying the tape correctly, and troubleshooting common issues. By following these guidelines, you can ensure a leak-free and secure connection. Preparation is key to a successful outcome, so let's start by discussing the essential steps to take before applying the tape.

Preparation is Key

When it comes to plumbing, preparation is key to ensuring a successful and leak-free installation. One of the most crucial steps in preparing for a plumbing project is selecting the right materials, including plumber's tape. With so many types of plumber's tape available, it can be overwhelming to choose the right one. To make the right choice, it's essential to consider the type of pipe and fitting being used, as well as the level of pressure and temperature involved. Additionally, measuring the thread size of the pipe is critical to ensure a proper fit. A thread size that is too small or too large can lead to leaks and other issues. Furthermore, cleaning the threads of the pipe is also vital to ensure a secure connection. By taking the time to choose the right type of plumber's tape, measure the thread size, and clean the threads, individuals can ensure a successful plumbing project. By starting with the right type of plumber's tape, individuals can set themselves up for success.

Choose the Right Type of Plumber's Tape

When it comes to choosing the right type of plumber's tape, it's essential to consider the specific application and the type of pipe or fitting you're working with. There are two main types of plumber's tape: Teflon tape and pipe dope. Teflon tape, also known as PTFE tape, is a non-stick, non-reactive tape made from polytetrafluoroethylene. It's suitable for most plumbing applications, including threaded pipes, fittings, and valves. Teflon tape is available in various thicknesses, with thicker tapes providing a more secure seal. Pipe dope, on the other hand, is a type of pipe joint compound that's applied to the threads of pipes and fittings. It's typically used for more heavy-duty applications, such as industrial or commercial plumbing, and is available in different formulas for various types of pipes and fittings. When selecting a plumber's tape, consider the temperature and pressure ratings, as well as the type of fluid or gas being transported. It's also crucial to choose a tape that's compatible with the materials of the pipes and fittings to ensure a secure and leak-free seal. By selecting the right type of plumber's tape for your specific application, you can ensure a reliable and long-lasting seal that meets your plumbing needs.

Measure the Thread Size

To measure the thread size, you will need a thread gauge or a caliper. A thread gauge is a specialized tool that is designed specifically for measuring the size of threads, while a caliper is a more versatile tool that can be used to measure a variety of dimensions, including thread size. To use a thread gauge, simply place the gauge over the thread and read the measurement off the gauge. To use a caliper, place the caliper over the thread and take a reading of the diameter of the thread. It's essential to take multiple measurements to ensure accuracy, as the thread size can vary slightly along the length of the pipe or fitting. Once you have determined the thread size, you can use this information to select the correct size of plumber's tape to use. It's also important to note that there are two types of thread sizes: National Pipe Tapered (NPT) and British Standard Pipe (BSP). NPT threads are tapered, meaning they get smaller as they go deeper into the pipe, while BSP threads are parallel, meaning they remain the same size along the length of the pipe. Knowing the type of thread size you are working with is crucial to selecting the correct plumber's tape and ensuring a secure and leak-free connection.

Clean the Threads

Cleaning the threads is a crucial step in preparing the pipe for taping. It ensures that the tape adheres properly and creates a secure seal. To clean the threads, use a wire brush or a thread cleaning tool to remove any dirt, debris, or old tape residue. This will help to create a smooth surface for the tape to bond to. Additionally, cleaning the threads will also help to prevent any leaks or corrosion from occurring in the future. It's also important to note that cleaning the threads should be done gently, as rough handling can damage the pipe or strip the threads. By taking the time to properly clean the threads, you can ensure a strong and reliable seal that will last for a long time.

Applying the Tape

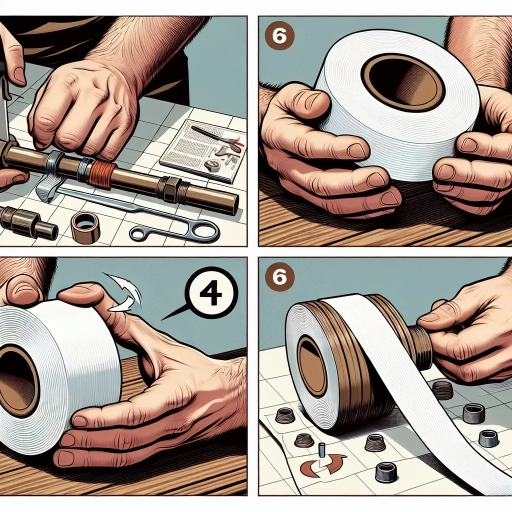

Applying the tape is a crucial step in the process of preparing a pipe for threading. It is essential to apply the tape correctly to ensure a secure and leak-free connection. To achieve this, it is necessary to wrap the tape in the correct direction, apply the right amount of tape, and press the tape firmly onto the threads. By following these steps, you can ensure a reliable and long-lasting connection. In this article, we will explore each of these steps in detail, starting with the importance of wrapping the tape in the correct direction.

Wrap the Tape in the Correct Direction

When applying plumber's tape, it is crucial to wrap the tape in the correct direction to ensure a secure and leak-free connection. The correct direction is clockwise, which means you should wrap the tape around the pipe or fitting in a clockwise direction. This is because the tape is designed to be threaded onto the pipe in a clockwise direction, and wrapping it in the opposite direction can cause the tape to unravel or come loose over time. Wrapping the tape in the correct direction also helps to create a tighter seal, as the tape is able to compress and conform to the shape of the pipe or fitting more effectively. To wrap the tape correctly, start by holding the tape in one hand and the pipe or fitting in the other, with the tape facing away from you. Then, begin wrapping the tape around the pipe or fitting in a clockwise direction, applying gentle to moderate pressure to ensure the tape adheres properly. As you wrap the tape, make sure to maintain a consistent overlap of about half the width of the tape to ensure a secure seal. By wrapping the tape in the correct direction, you can ensure a reliable and long-lasting connection that will withstand the rigors of water pressure and flow.

Apply the Right Amount of Tape

Applying the right amount of tape is crucial to ensure a secure and leak-free connection. Too little tape may not provide enough grip, while too much tape can lead to a messy and uneven application. The ideal amount of tape to apply depends on the size of the threads and the type of connection being made. A general rule of thumb is to apply 2-3 wraps of tape for smaller threads and 4-5 wraps for larger threads. It's also important to apply the tape in the correct direction, typically clockwise, to ensure that the tape is wrapped tightly around the threads. Additionally, it's essential to apply even pressure while wrapping the tape to prevent air pockets and ensure a smooth, consistent application. By applying the right amount of tape, you can ensure a secure and reliable connection that will withstand the test of time and use.

Press the Tape Firmly onto the Threads

Press the tape firmly onto the threads to ensure a secure seal. Apply even pressure to the tape, making sure it is not twisted or bunched up. This will help prevent leaks and ensure a watertight connection. It's also important to press the tape firmly onto the threads in a consistent manner, as uneven pressure can lead to a poor seal. By applying even pressure, you can ensure that the tape is properly seated and will provide a reliable seal. Additionally, pressing the tape firmly onto the threads will help to remove any air pockets that may be present, which can also contribute to leaks. Overall, pressing the tape firmly onto the threads is a crucial step in ensuring a secure and watertight connection.

Troubleshooting and Maintenance

Troubleshooting and maintenance are crucial steps in ensuring the longevity and effectiveness of various products, including adhesives and tapes. When it comes to troubleshooting and maintenance, there are several key considerations to keep in mind. First, it is essential to check for leaks after application to ensure that the product is functioning as intended. Additionally, replacing the tape as needed can help prevent damage and maintain performance. Finally, storing the tape properly can help extend its shelf life and prevent degradation. By following these simple steps, individuals can help ensure that their products continue to function optimally and provide the desired results. In this article, we will explore each of these considerations in more detail, starting with the importance of checking for leaks after application.

Check for Leaks After Application

After applying plumber's tape, it's essential to check for leaks to ensure a secure and watertight seal. To do this, turn on the water supply and inspect the threaded connection for any signs of moisture or water droplets. You can also use a leak detection tool or a mixture of equal parts water and dish soap to help identify any leaks. Apply the soap solution to the threaded connection and look for bubbles, which indicate a leak. If you find a leak, tighten the connection slightly and reapply the plumber's tape. Repeat the process until the leak is resolved. Regularly checking for leaks after application will help prevent water damage, reduce the risk of mold and mildew growth, and ensure the longevity of your plumbing system. Additionally, it's recommended to recheck the connections periodically, especially after extreme temperature changes or water pressure fluctuations, to ensure the seal remains intact. By taking the time to check for leaks, you can have peace of mind knowing that your plumbing system is secure and functioning properly.

Replace the Tape as Needed

When it comes to troubleshooting and maintenance, one of the most important things to keep in mind is to replace the tape as needed. Over time, plumber's tape can wear out and lose its effectiveness, leading to leaks and other issues. If you notice that your tape is no longer creating a tight seal, it's time to replace it. Check the tape regularly for signs of wear and tear, such as fraying, cracking, or discoloration. If you notice any of these signs, it's best to replace the tape immediately to avoid any potential problems. Additionally, if you're using plumber's tape in an area that's exposed to extreme temperatures, chemicals, or other harsh conditions, you may need to replace it more frequently. By replacing the tape as needed, you can ensure that your pipes and fittings remain secure and leak-free, saving you time and money in the long run.

Store the Tape Properly

Store the tape properly to ensure it remains effective and lasts longer. When not in use, keep the tape in a cool, dry place, away from direct sunlight and moisture. Avoid storing it in areas with high humidity, such as basements or attics, as this can cause the adhesive to degrade. It's also essential to keep the tape away from chemicals, cleaning products, and other substances that can damage the adhesive or the tape itself. Store the tape in its original packaging or a protective case to prevent it from getting damaged or tangled. If you need to store the tape for an extended period, consider wrapping it around a cardboard or plastic core to prevent it from becoming misshapen. By storing the tape properly, you can ensure it remains effective and ready to use when you need it.