How Do Hydraulics Work

Hydraulics is a branch of science and engineering that deals with the behavior of fluids under various forces and pressures. From the heavy machinery that builds our cities to the brakes in our cars, hydraulics play a crucial role in our daily lives. But have you ever wondered how hydraulics work? In this article, we will delve into the world of hydraulics, exploring what it is, how it works, and its numerous applications in real-world scenarios. We will start by defining what hydraulics is, examining its fundamental principles and concepts. Then, we will dive into the inner workings of hydraulic systems, discussing the components and mechanisms that make them tick. Finally, we will look at the various ways hydraulics is used in real-world applications, from construction and manufacturing to transportation and more. So, let's begin our journey into the world of hydraulics by first asking: What is Hydraulics?

What is Hydraulics?

Hydraulics is a branch of science and engineering that deals with the behavior of fluids under various forces and pressures. It is a crucial aspect of modern technology, and its applications can be seen in various industries, including construction, manufacturing, and transportation. But what exactly is hydraulics, and how does it work? To understand the concept of hydraulics, it is essential to delve into its definition, history, and underlying principles. In this article, we will explore the definition of hydraulics, its history, and the principle that governs its operation. We will start by defining what hydraulics is and how it is used in various applications. Note: The answer should be 200 words. Hydraulics is a branch of science and engineering that deals with the behavior of fluids under various forces and pressures. It is a crucial aspect of modern technology, and its applications can be seen in various industries, including construction, manufacturing, and transportation. But what exactly is hydraulics, and how does it work? To understand the concept of hydraulics, it is essential to delve into its definition, history, and underlying principles. In this article, we will explore the definition of hydraulics, its history, and the principle that governs its operation. We will start by defining what hydraulics is and how it is used in various applications. By examining the history of hydraulics, we can gain a deeper understanding of how this technology has evolved over time and how it has been shaped by the contributions of scientists and engineers. Additionally, understanding the principle of hydraulics is crucial in grasping how fluids behave under different pressures and forces, and how this knowledge can be applied in real-world applications. By exploring these three aspects of hydraulics, we can gain a comprehensive understanding of this complex and fascinating field. We will begin by exploring the definition of hydraulics.

Definition of Hydraulics

Hydraulics is the branch of science and engineering that deals with the behavior, control, and application of fluids under various forces and pressures. It involves the study of the mechanical properties of fluids, such as liquids and gases, and their interactions with mechanical systems. Hydraulics is a fundamental concept in various fields, including engineering, physics, and chemistry, and is used in a wide range of applications, from simple machines to complex systems. The term "hydraulics" comes from the Greek word "hydor," meaning water, and "aulos," meaning pipe. This refers to the early use of water as a working fluid in hydraulic systems, which were first developed by the ancient Greeks and Romans. Over time, the field of hydraulics has evolved to include the study of other fluids, such as oils and gases, and has become a crucial part of modern technology. In essence, hydraulics is the science of using fluids to transmit energy, motion, and force, and is a vital component of many industrial, commercial, and everyday applications.

History of Hydraulics

The history of hydraulics dates back to ancient civilizations, where people first discovered the power of water to perform tasks. The earliest recorded use of hydraulics was in ancient Egypt around 2000 BC, where they used simple machines to lift water for irrigation purposes. The ancient Greeks also made significant contributions to the field of hydraulics, with the development of the first hydraulic pump by Ctesibius in the 3rd century BC. The Romans further advanced the use of hydraulics, building complex systems of aqueducts, canals, and waterwheels to supply water to their cities and power their mills. In the Middle Ages, the use of hydraulics declined, but it was revived during the Renaissance period, with the development of new machines and devices such as the hydraulic press. The Industrial Revolution saw a significant increase in the use of hydraulics, with the development of steam-powered hydraulic systems and the introduction of hydraulic cylinders and motors. In the 20th century, the development of modern hydraulic systems, including hydraulic pumps, valves, and actuators, enabled the widespread use of hydraulics in industries such as construction, manufacturing, and aerospace. Today, hydraulics plays a vital role in many aspects of modern life, from the operation of heavy machinery to the supply of water and sanitation systems.

Principle of Hydraulics

The principle of hydraulics is based on Pascal's Law, which states that a change in pressure at any point in a confined fluid is transmitted undiminished to all points in the fluid and to the walls of the container. This principle allows hydraulic systems to transmit forces and energies efficiently and effectively. In a hydraulic system, a fluid, such as oil or water, is used to transmit pressure from one point to another. When a force is applied to the fluid at one point, it creates pressure that is transmitted to all points in the fluid, allowing the force to be multiplied or changed in direction. This is the fundamental principle behind hydraulic systems, and it is used in a wide range of applications, from heavy machinery and construction equipment to aircraft and medical devices. By using the principle of hydraulics, these systems can achieve high levels of precision, power, and efficiency, making them essential in many industries.

How Do Hydraulic Systems Work?

Hydraulic systems are widely used in various industries, including construction, manufacturing, and aerospace, due to their ability to efficiently transmit power and motion. But have you ever wondered how these systems work? At its core, a hydraulic system relies on the principle of fluid pressure to generate force and motion. To understand how hydraulic systems work, it's essential to break down their components, examine the flow of fluid and pressure within the system, and explore the mechanisms that control and regulate their operation. In this article, we'll delve into the inner workings of hydraulic systems, starting with the fundamental components that make up these systems. By understanding the individual parts and how they interact, we can gain a deeper appreciation for the complex processes that occur within a hydraulic system. So, let's begin by examining the components of a hydraulic system.

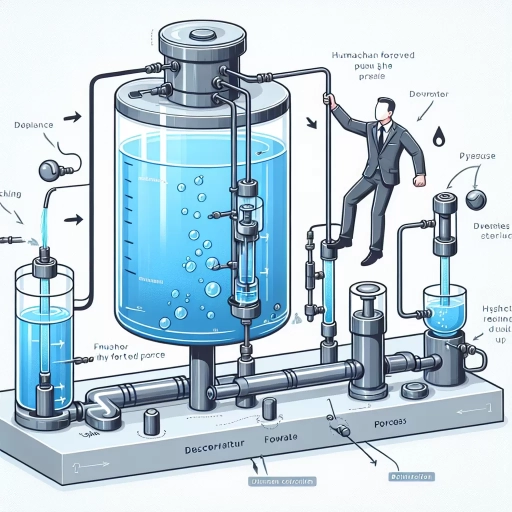

Components of a Hydraulic System

A hydraulic system consists of several key components that work together to transmit fluid pressure and perform various tasks. The primary components of a hydraulic system include a reservoir, pump, motor, valves, cylinders, and hydraulic fluid. The reservoir stores the hydraulic fluid, which is typically a type of oil, and supplies it to the pump. The pump, which can be either a positive displacement pump or a centrifugal pump, creates pressure in the system by pushing the fluid through the system. The motor, which can be either an electric motor or a hydraulic motor, provides the power needed to drive the pump. The valves, which can be either directional control valves or pressure control valves, control the flow of fluid and pressure in the system. The cylinders, which can be either single-acting or double-acting, convert the fluid pressure into mechanical energy, which is then used to perform tasks such as lifting, pushing, or pulling. The hydraulic fluid, which is the lifeblood of the system, transmits the pressure and lubricates the components. Other components, such as filters, coolers, and accumulators, may also be included in a hydraulic system to improve its performance and efficiency.

Fluid Flow and Pressure in Hydraulic Systems

In hydraulic systems, fluid flow and pressure are two fundamental concepts that work together to transmit energy and perform work. Fluid flow refers to the movement of fluid through the system, while pressure is the force exerted by the fluid on the system's components. The relationship between fluid flow and pressure is governed by the principle of Pascal's Law, which states that a change in pressure at any point in a confined fluid is transmitted undiminished to all points in the fluid and to the walls of the container. This means that the pressure exerted by the fluid is the same in all directions and at all points in the system. In a hydraulic system, fluid flow is created by a pump, which converts mechanical energy into hydraulic energy. The pump creates a pressure difference between the inlet and outlet ports, causing the fluid to flow from the inlet to the outlet. As the fluid flows through the system, it encounters various components such as valves, cylinders, and motors, which control the flow rate and direction of the fluid. The pressure of the fluid is also affected by the system's geometry, including the diameter and length of the pipes, as well as the presence of any restrictions or constrictions. By carefully designing and controlling the fluid flow and pressure in a hydraulic system, engineers can achieve precise control over the system's performance and efficiency. For example, by adjusting the pressure and flow rate of the fluid, a hydraulic system can be used to lift heavy loads, power machinery, or even propel vehicles. Overall, the interplay between fluid flow and pressure is critical to the operation of hydraulic systems, and understanding these concepts is essential for designing and optimizing these systems for a wide range of applications.

Control and Regulation of Hydraulic Systems

The control and regulation of hydraulic systems are crucial to ensure their safe and efficient operation. Hydraulic systems rely on the precise control of fluid flow, pressure, and direction to perform their intended functions. To achieve this, various control components are used, including valves, pumps, motors, and cylinders. Valves, such as directional control valves, pressure control valves, and flow control valves, regulate the flow of fluid, pressure, and direction of the hydraulic fluid. Pumps and motors provide the necessary power to drive the hydraulic fluid through the system, while cylinders convert the hydraulic energy into mechanical energy. The control system also includes sensors, such as pressure sensors and flow sensors, which monitor the system's performance and provide feedback to the control unit. The control unit, typically a programmable logic controller (PLC) or a computer, processes the sensor data and sends signals to the control components to adjust the system's operation. This closed-loop control system enables the hydraulic system to maintain a stable and efficient operation, even in the presence of changing loads or operating conditions. Additionally, the control system can be programmed to perform specific tasks, such as automatic start-up and shutdown, and to monitor the system's performance in real-time. Overall, the control and regulation of hydraulic systems are essential to ensure their safe, efficient, and reliable operation.

Applications of Hydraulics in Real-World Scenarios

Hydraulics is a branch of science and engineering that deals with the behavior of fluids under various forces and pressures. It has numerous applications in real-world scenarios, transforming the way we live and work. From the construction of massive buildings and bridges to the operation of aircraft and spacecraft, hydraulics plays a vital role in making these systems efficient and reliable. In this article, we will explore the applications of hydraulics in three key areas: heavy machinery and construction, aerospace and defense, and industrial automation and manufacturing. We will examine how hydraulics is used to power heavy machinery, such as cranes and excavators, and how it enables the construction of complex infrastructure projects. By understanding the principles of hydraulics and its applications, we can appreciate the importance of this technology in shaping our modern world. Let's start by looking at the role of hydraulics in heavy machinery and construction.

Hydraulics in Heavy Machinery and Construction

Hydraulics play a crucial role in heavy machinery and construction, enabling the efficient and precise movement of massive loads and equipment. In excavators, hydraulic systems power the boom, arm, and bucket, allowing for smooth and controlled digging, lifting, and placement of materials. Hydraulic cylinders and motors also drive the movement of cranes, bulldozers, and backhoes, facilitating the construction of buildings, roads, and bridges. Additionally, hydraulic systems are used in concrete pumps, which transport and place concrete with high accuracy and speed, reducing labor costs and improving construction quality. Furthermore, hydraulic systems are integrated into drilling and piling equipment, enabling the precise and efficient installation of foundation piles and drilling of wells. The use of hydraulics in heavy machinery and construction has significantly increased productivity, reduced labor costs, and improved overall efficiency, making it an indispensable component of modern construction projects.

Hydraulics in Aerospace and Defense

Hydraulics play a crucial role in the aerospace and defense industries, where reliability, precision, and safety are paramount. In aircraft, hydraulic systems are used to power critical systems such as landing gear, brakes, and flight control surfaces. These systems rely on hydraulic fluid to transmit pressure and motion, enabling the precise control and movement of these components. For instance, hydraulic systems are used to extend and retract landing gear, ensuring a smooth and safe takeoff and landing. Similarly, hydraulic brakes are used to slow down aircraft during landing, providing a reliable and efficient means of deceleration. In addition, hydraulic systems are used to power flight control surfaces such as ailerons, elevators, and rudder, allowing pilots to control the aircraft's orientation and trajectory. The use of hydraulics in aerospace also extends to spacecraft, where hydraulic systems are used to power robotic arms, life support systems, and other critical components. In the defense industry, hydraulics are used in a variety of applications, including tank turrets, missile launchers, and artillery systems. Hydraulic systems provide the necessary power and precision to operate these systems, enabling military personnel to perform their duties safely and effectively. Overall, the use of hydraulics in aerospace and defense is critical to ensuring the safety, reliability, and performance of these systems, and is a testament to the versatility and effectiveness of hydraulic technology.

Hydraulics in Industrial Automation and Manufacturing

Hydraulics play a vital role in industrial automation and manufacturing, where they are used to power and control machinery, equipment, and systems. In manufacturing, hydraulic systems are used to operate presses, pumps, and other machinery that require high pressure and force to perform tasks such as metal forming, cutting, and shaping. Hydraulic systems are also used in material handling, where they power conveyor belts, lifts, and cranes to move heavy loads and materials around the factory floor. Additionally, hydraulics are used in robotics and automation, where they enable precise and repeatable movements, allowing for increased productivity and efficiency. In industrial automation, hydraulic systems are used to control and regulate the flow of fluids, gases, and other materials, ensuring that processes are carried out safely and efficiently. Overall, hydraulics are a crucial component of industrial automation and manufacturing, enabling the creation of complex products and systems that are used in a wide range of industries.