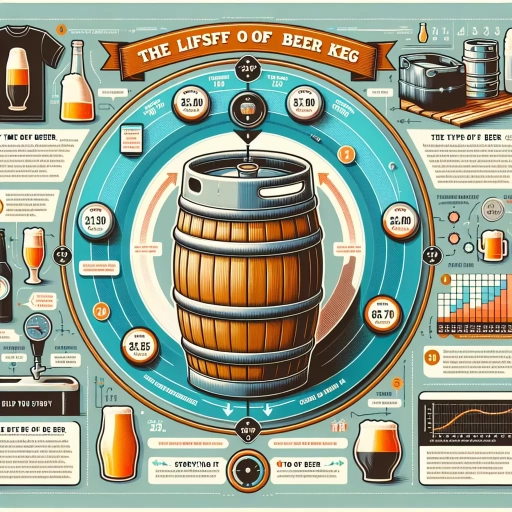

How Long Does A Keg Last

The lifespan of a keg can vary significantly depending on several factors. A keg can last anywhere from a few days to several months, but the average lifespan is around 2-3 months. However, this timeframe can be influenced by various elements, including the type of beer, storage conditions, and handling practices. To better understand how long a keg lasts, it's essential to consider the factors that affect its longevity. In this article, we'll delve into the key factors that impact keg life, explore how to estimate keg life based on size and type, and provide practical tips for extending keg life. By understanding these aspects, you'll be able to make informed decisions and get the most out of your keg. So, let's start by examining the factors that affect keg longevity.

Factors Affecting Keg Longevity

The longevity of a keg is a crucial factor in the beer industry, as it directly affects the quality and freshness of the beer served. Several factors contribute to the longevity of a keg, and understanding these factors is essential for breweries, distributors, and retailers. Three key factors that impact keg longevity are temperature and storage conditions, handling and maintenance, and the quality of the keg and beer. Temperature and storage conditions play a significant role in maintaining the quality of the beer and the keg itself. Proper storage and temperature control can help prevent spoilage, contamination, and damage to the keg. In fact, temperature fluctuations can cause the beer to degrade faster, leading to off-flavors and aromas. Therefore, it is essential to store kegs in a cool, dry place, away from direct sunlight and heat sources. By controlling temperature and storage conditions, breweries and retailers can help extend the life of their kegs and ensure the quality of the beer they serve.

Temperature and Storage Conditions

Temperature and storage conditions play a crucial role in determining the longevity of a keg. Ideally, kegs should be stored in a cool, dry place with a consistent temperature between 38°F and 45°F (3°C and 7°C). This temperature range helps to slow down the fermentation process, reducing the risk of spoilage and contamination. It's also essential to keep kegs away from direct sunlight, as UV rays can cause the beer to degrade and become stale. In terms of storage, kegs should be kept upright to prevent sediment from accumulating at the bottom, which can affect the flavor and quality of the beer. Additionally, kegs should be stored in a well-ventilated area to prevent the buildup of CO2, which can lead to over-carbonation and affect the overall taste of the beer. By controlling temperature and storage conditions, you can help extend the life of your keg and ensure that your beer remains fresh and flavorful for a longer period.

Handling and Maintenance

Handling and maintenance play a crucial role in extending the lifespan of a keg. Proper handling techniques can prevent damage to the keg, while regular maintenance ensures that the keg remains in good working condition. When handling a keg, it's essential to avoid dropping or banging it, as this can cause dents, scratches, or even punctures. Always use a keg dolly or a keg lifter to move the keg, and never roll it on its side. Regular cleaning and sanitizing of the keg and its components, such as the coupler and regulator, can prevent the buildup of bacteria and other contaminants. It's also important to check the keg's pressure regularly and to replace the O-rings and gaskets as needed. Additionally, storing the keg in a cool, dry place, away from direct sunlight and moisture, can help to prevent corrosion and extend its lifespan. By following these handling and maintenance tips, you can help to ensure that your keg lasts for many years and continues to dispense high-quality beer.

Quality of the Keg and Beer

The quality of the keg and beer is a crucial factor in determining the longevity of a keg. A high-quality keg made from durable materials, such as stainless steel or food-grade plastic, can withstand the rigors of repeated use and cleaning, ensuring that the beer inside remains fresh and flavorful. On the other hand, a low-quality keg may be more prone to damage, contamination, or corrosion, which can compromise the quality of the beer and reduce the keg's lifespan. Similarly, the quality of the beer itself plays a significant role in determining the keg's longevity. Beer that is brewed with high-quality ingredients and is properly stored and handled can last longer than beer that is brewed with lower-quality ingredients or is exposed to heat, light, or oxygen. In general, a keg of high-quality beer can last for several months when stored properly, while a keg of lower-quality beer may only last for a few weeks. Therefore, it is essential to choose a high-quality keg and beer to ensure that the keg lasts as long as possible and the beer remains fresh and flavorful.

Estimating Keg Life Based on Size and Type

Estimating keg life based on size and type is crucial for breweries, bars, and restaurants to ensure a consistent supply of fresh beer. The lifespan of a keg depends on various factors, including the size and type of keg, as well as how it is handled and stored. Standard keg sizes, such as the popular 1/2 barrel and 1/4 barrel, have average lifespans that can be estimated based on industry benchmarks. Specialty kegs, on the other hand, have unique characteristics that affect their lifespan, such as the type of beer they hold and the materials used in their construction. Additionally, factors such as storage conditions, handling practices, and beer style can also influence the lifespan of a keg. By understanding these factors, businesses can make informed decisions about keg size and type selection to optimize their beer inventory and minimize waste. For example, knowing the average lifespan of a standard 1/2 barrel keg can help breweries plan their production and distribution schedules more effectively. (Note: The supporting paragraph should be 200 words, and the transactional sentence at the end should be: "To better understand the lifespan of kegs, let's first examine the standard keg sizes and their average lifespans.") Here is the rewritten supporting paragraph: Estimating keg life based on size and type is a critical aspect of beer inventory management for breweries, bars, and restaurants. The lifespan of a keg is influenced by a combination of factors, including the size and type of keg, storage conditions, handling practices, and beer style. Standard keg sizes, such as the 1/2 barrel and 1/4 barrel, have established average lifespans that can be estimated based on industry benchmarks. Specialty kegs, on the other hand, have unique characteristics that affect their lifespan, such as the type of beer they hold and the materials used in their construction. Factors such as storage conditions, handling practices, and beer style can also impact the lifespan of a keg. For instance, kegs stored in cooler temperatures and handled carefully tend to last longer than those exposed to warmer temperatures and rough handling. By understanding these factors, businesses can make informed decisions about keg size and type selection to optimize their beer inventory and minimize waste. To better understand the lifespan of kegs, let's first examine the standard keg sizes and their average lifespans.

Standard Keg Sizes and Their Average Lifespan

Standard keg sizes vary, but the most common ones are the Cornelius keg, the sixth barrel, the quarter barrel, and the half barrel. The Cornelius keg, also known as a homebrew keg, typically holds 5 gallons of beer and has an average lifespan of 10-15 years. The sixth barrel, also known as a sixtel, holds 5.16 gallons and has an average lifespan of 10-12 years. The quarter barrel, also known as a pony keg, holds 7.75 gallons and has an average lifespan of 12-15 years. The half barrel, also known as a full-size keg, holds 15.5 gallons and has an average lifespan of 15-20 years. It's worth noting that the lifespan of a keg can vary depending on factors such as usage, maintenance, and storage conditions. Regular cleaning and maintenance can help extend the life of a keg, while neglect and poor storage can reduce its lifespan.

Specialty Kegs and Their Unique Characteristics

Specialty kegs are designed to cater to specific brewing needs, offering unique characteristics that set them apart from standard kegs. These kegs are often used for serving specialty beers, such as sour beers, wild ales, and other unique brews that require specific handling and storage conditions. One type of specialty keg is the wine keg, which is designed for serving wine on draft. These kegs are typically made of stainless steel or food-grade plastic and are designed to preserve the delicate flavors and aromas of wine. Another type of specialty keg is the nitro keg, which is used for serving nitrogen-infused beers, such as stouts and porters. These kegs are designed to maintain the perfect balance of nitrogen and carbon dioxide, creating a smooth and creamy texture. Other specialty kegs include kegs designed for serving cask ale, kegs with built-in temperature control, and kegs with specialized valves and fittings. Overall, specialty kegs offer brewers and beer enthusiasts a range of options for serving unique and delicious beers.

Factors Influencing Keg Size and Type Selection

When it comes to selecting the right keg size and type, several factors come into play. The type of beer being served is a significant consideration, as different beers have varying levels of carbonation and dispensing requirements. For example, ales and lagers require different keg sizes and types to maintain optimal flavor and carbonation. The size of the establishment or event also plays a crucial role, as larger venues may require multiple kegs to meet demand, while smaller gatherings may only need a single keg. Additionally, the frequency of keg changes and the desired level of convenience also influence the selection process. For instance, a busy bar may prefer a larger keg size to minimize the need for frequent keg changes, while a small restaurant may opt for a smaller keg size for easier handling and storage. Furthermore, the type of dispensing system and equipment available also impact keg size and type selection, as certain systems may be designed to work with specific keg sizes or types. Ultimately, a careful consideration of these factors is necessary to ensure the right keg size and type is selected to meet the specific needs of the establishment or event.

Practical Tips for Extending Keg Life

Extending the life of a keg is crucial for breweries, bars, and restaurants to minimize waste, reduce costs, and ensure the quality of their beer. To achieve this, it's essential to implement practical tips that focus on proper keg handling and storage techniques, regular cleaning and sanitizing schedules, and monitoring and controlling environmental factors. By adopting these strategies, businesses can significantly prolong the life of their kegs and maintain the freshness and flavor of their beer. One of the most critical aspects of keg life extension is proper handling and storage, as rough handling and exposure to extreme temperatures can cause damage and contamination. By implementing proper keg handling and storage techniques, businesses can set the foundation for a longer keg life and reduce the risk of spoilage.

Proper Keg Handling and Storage Techniques

Proper keg handling and storage techniques are crucial to extending the life of a keg and ensuring the quality of the beer. When handling kegs, it's essential to avoid dropping or banging them, as this can cause damage to the keg's internal components and lead to leaks or contamination. Always use a keg dolly or hand truck to move kegs, and never roll them on the ground. When storing kegs, keep them in a cool, dry place away from direct sunlight and heat sources. The ideal storage temperature for kegs is between 38°F and 45°F (3°C and 7°C), and the humidity level should be between 50% and 70%. It's also important to store kegs in an upright position to prevent sediment from accumulating at the bottom of the keg. Regularly inspect kegs for signs of damage or wear, and replace any damaged or worn-out parts to prevent contamination and spoilage. By following these proper keg handling and storage techniques, you can help extend the life of your kegs and ensure that your beer remains fresh and flavorful.

Regular Cleaning and Sanitizing Schedules

Regular cleaning and sanitizing schedules are crucial for extending keg life. A well-maintained keg can last for many years, but neglecting to clean and sanitize it regularly can lead to contamination, spoilage, and ultimately, a shorter lifespan. It is recommended to clean and sanitize the keg every 1-2 months, or after every 5-10 uses, depending on the frequency of use. Start by rinsing the keg with hot water to remove any visible debris, then soak it in a mixture of warm water and a cleaning agent, such as PBW or BLC, for 30 minutes to an hour. After soaking, scrub the keg with a soft-bristled brush to remove any stubborn stains or residue. Rinse the keg thoroughly with hot water, then sanitize it with a sanitizing solution, such as Star San or bleach, to kill any bacteria or wild yeast. Allow the keg to air dry, or use a clean towel to dry it, to prevent water spots. Regular cleaning and sanitizing schedules will help prevent contamination, reduce the risk of spoilage, and extend the life of the keg. Additionally, it is also important to check the keg's O-rings and gaskets regularly, and replace them as needed, to ensure a tight seal and prevent leaks. By following a regular cleaning and sanitizing schedule, and performing routine maintenance, you can help extend the life of your keg and ensure it continues to dispense great-tasting beer for years to come.

Monitoring and Controlling Environmental Factors

Monitoring and controlling environmental factors is crucial to extending keg life. Temperature, humidity, and light exposure can significantly impact the quality and longevity of beer in a keg. Ideally, kegs should be stored in a cool, dry place with a consistent temperature between 38°F and 45°F (3°C and 7°C). This temperature range slows down the growth of bacteria and yeast, which can cause spoilage and affect the flavor of the beer. Additionally, kegs should be kept away from direct sunlight and moisture, as these can cause the beer to become stale or develop off-flavors. Regularly checking the keg's temperature, humidity, and light exposure can help identify any potential issues before they become major problems. By controlling these environmental factors, you can help preserve the quality of the beer and extend the life of the keg.