How To Measure Flange Size

Understanding Flange and Its Importance

Definition of Flange

A flange is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. They provide ease of cleaning, inspection, or modification, making them essential fixtures in most industrial operations. Depending on its type and construction, a flange can handle different pressures and temperatures. Its size links to the pipe size and can significantly impact the flow of materials.

Role of Flange in Industrial Applications

Flanges play a critical role in many industrial applications, from the energy industry to manufacturing, construction, and water treatment plants. They allow for easy assembly and disassembly of piping systems, enabling preventive maintenance and system modifications without significant impacts on operations. The choice of flange size can influence the efficiency and safety of these processes.

Various Types of Flanges

There are several types of flanges, and each serves different applications. The common types include weld neck flanges, slip-on flanges, socket weld flanges, threaded flanges, blind flanges, reducing flanges, and lap joint flanges. Their diverse designs cater to the unique needs of different industries. Understanding these types can help when choosing the right flange and measuring its size.

Methods to Measure Flange Size

Overview of Measuring Flange Size

Measuring the size of a flange is not as straightforward as it may seem. Essentially, flange size does not entirely correspond to the pipe size. While the inner diameter of the flange generally matches the pipe’s inner diameter, the flange’s outer diameter and the bolt circle diameter are other critical dimensions to consider. These measurements influence the flange’s performance and compatibility.

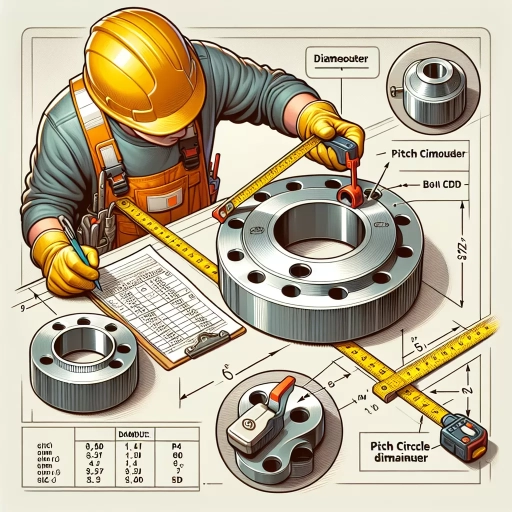

Tools Needed for Measuring Flange

The basic tools for measuring flange size include a ruler or a measuring tape, a Vernier caliper for more precise measurements, and a flange bolt chart for reference. These tools ensure accuracy in flange dimension measurement, contributing to the overall efficiency and safety of the piping system.

Step-by-Step Guide to Measure Flange Size

Measuring a flange size involves several steps. Firstly, measure the flange’s inner diameter, which should match the pipe’s inner diameter. Next, measure the outer diameter and the bolt circle diameter. Lastly, count the number of bolt holes and measure their size. These dimensions are crucial in selecting an appropriate flange for your pipe system.

Common Flange Size Measurement Mistakes and How to Avoid Them

Potential Errors in Flange Measurement

Several factors can lead to errors in flange size measurement, such as inaccurate tools, environmental factors, or lack of understanding of flange dimensions. These mistakes can lead to mismatched components, resulting in system inefficiencies, leakages, and safety hazards. Awareness of these potential pitfalls is essential to achieve proper flange measurement and selection.

Importance of Precision and Accuracy in Flange Measurement

Accuracy and precision in flange size measurement are crucial as inaccuracies can lead to improper fit and potential operational hazards. It is thus vital to ensure that measurement tools are in good condition and used correctly. In addition, a flange bolt chart can be a critical guide in matching flange sizes with corresponding bolt sizes and quantity.

Tips to Avoid Typical Flange Size Measurement Mistakes

Avoiding common flange size measurement mistakes involves several strategies. These include understanding the critical flange dimensions, using accurate tools, and checking environmental conditions during measurement. Furthermore, referring to a flange bolt chart and consulting with experts can prevent potential errors and ensure appropriate flange selection.