How To Make A Blast Furnace

Welcome to the world of artisan skill and technological prowess, where we are about to delve into the process of making a blast furnace. This industrious topic is as hot as the furnaces themselves, and we will navigate this steamy journey through three key stages. Firstly, we will look to unravel the complexities and the intricate fundamentals of a blast furnace, helping you to establish a solid understanding of this potent concoction of chemistry and engineering. From there, we will move to the practical corner by providing you with a detailed step-by-step guide on building a blast furnace of your own, acting as your personal mentor in your quest for industrial craftsmanship. Lastly, but certainly not least, we will ensure you are up to speed on all the operational guidelines and safety measures crucial for a secure and successful operation of a blast furnace. But before we immerse ourselves in the world of molten metals and sky-high temperatures, let's ensure we understand the foundations. So, let's start with uncovering the intricacies of the fundamentals of a blast furnace.

Welcome to the world of artisan skill and technological prowess, where we are about to delve into the process of making a blast furnace. This industrious topic is as hot as the furnaces themselves, and we will navigate this steamy journey through three key stages. Firstly, we will look to unravel the complexities and the intricate fundamentals of a blast furnace, helping you to establish a solid understanding of this potent concoction of chemistry and engineering. From there, we will move to the practical corner by providing you with a detailed step-by-step guide on building a blast furnace of your own, acting as your personal mentor in your quest for industrial craftsmanship. Lastly, but certainly not least, we will ensure you are up to speed on all the operational guidelines and safety measures crucial for a secure and successful operation of a blast furnace. But before we immerse ourselves in the world of molten metals and sky-high temperatures, let's ensure we understand the foundations. So, let's start with uncovering the intricacies of the fundamentals of a blast furnace.Understanding the Fundamentals of a Blast Furnace

Understanding the fundamentals of a blast furnace calls for dissecting this piece into three integral analyses. Firstly, we need to comprehend "The Concept and Design of a Blast Furnace", throwing light on the strategic architectural blueprint put into creating these industrial mammoths. Secondly, the focus shifts to "The Materials and Components Required for Building a Blast Furnace", exploring the gamut of raw materials indispensable to its formation and how each part plays a pivotal role in ensuring its efficient operation. Lastly, we delve into "The Prevalence and Significance of Blast Furnaces in the Industrial Sector", illuminating their widespread use and their consequence on our modern world's industrial landscape. This rich narrative blends the technicalities of design with the essence of its existence, infusing complex technical information into a palatable structure. So, let's embark on this elucidating journey, starting with unpacking the concept and design of a Blast Furnace. These industrial behemoths are marvels of engineering, the comprehending of which will unravel the depths of human ingenuity.

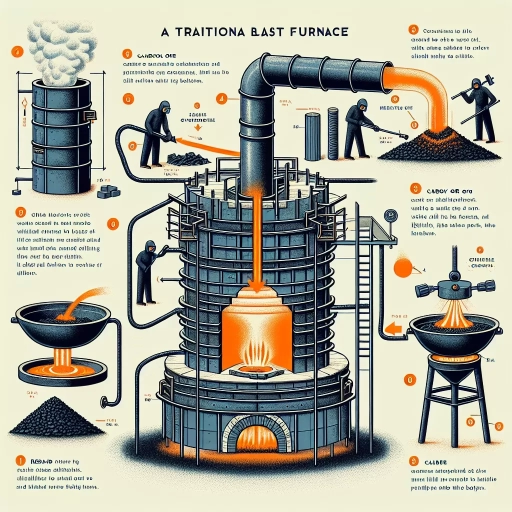

The Concept and Design of a Blast Furnace

The Concept and Design of a Blast Furnace operate on principles that hark back centuries, yet remain fundamentally important in today's industrial world. A blast furnace is an architectural marvel, essential in smelting iron from its ore, liberating it from the shackles of earthly impurities. The design of this colossal structure incorporates elements of thermal engineering, physics, and a finely-honed understanding of materials science, curated to offer utmost efficiency. The blast furnace, a towering structure reaching upto 30 meters, is cylindrical, constructed from steel plates and fortified with refractory bricks resistant to staggering heat. Its tapering upper portion, the stack, is where the magic begins. Iron ore, coke, and limestone, the raw materials for iron making, are fed into the top of the stack, embarking on a fiery descent. The belly of the beast, the central furnace area, holds the high temperature ranging between 1500 to 2000°C, required for the complex chemical reactions. The blast of hot air, or gases, hence the name 'Blast Furnace', is blown into the furnace from the bottom via tuyeres. The high heat reduces the iron ore into molten iron, which sinks to the bottom due to its density, and impurities form the slag, floating above the iron. The components, molten iron and slag are then separately tapped off from the lower part of the furnace. A particularly ingenious aspect of the blast furnace's design is its reliance on counter-current exchange. The raw materials move downwards, while the gases ascend upwards, enabling the gas to cool and the raw material to preheat. Gases exiting the furnace, now laden with carbon monoxide and heat, are not wasted. In fact, they are rerouted to heat the blast air, contributing to the energy efficiency of the process. Moreover, the design of a blast furnace isn’t static but evolves. Modern blast furnaces are computer-controlled, harnessing technology to maximize efficiency and yield. Sensors and software contribute to a precise understanding of temperature dynamics, material flow, and chemical processes occurring within, making it a veritable high-tech operation. In conclusion, the concept and design of a blast furnace are a testament to human ingenuity in harnessing raw elements of the earth, manipulating immensely powerful forces, and creating one of the fundamental building blocks of modern civilization – steel. The design epitomizes a balance between the brute strength of a bygone era and the finesse of future-forward tech solutions.

The Materials and Components Required for Building a Blast Furnace

A blast furnace is an essential component of metal-smelting industries and requires an assortment of materials for construction and operations. One of the main materials is refractory bricks that structurally build the inner lining of the furnace. This lining is particularly designed to withstand high temperatures and physical damage, therefore, materials like alumina, magnesite, and silicon carbide are commonly used to provide the required durability and heat resistance. Besides, these materials are also effective in resisting chemical reactions by slag or metal, ensuring the longevity of the furnace. Steel plates are required to construct the outer shell or casing of the furnace because of their strength, and ability to maintain structural stability even under the extraordinary pressure of the operating conditions. The outer casing is usually made of weather-resistant, galvanised steel to withstand harsh environmental elements. For fuel and heating, blast furnaces primarily use coke, a high-carbon residue, derived from distilling coal at a high temperature. However, in modern times, pulverised coal, natural gas, and oil are being used as auxiliary sources to coke. Considering the fluxing agents, limestone and dolomite are common and crucial, as they help refine the impurities. Meanwhile, iron ores are the central raw material which is smelted in the furnace. Ventilation pipes, blast pipes, and a cooling system are necessary to regulate temperature and maintain required pressure within the furnace. Water cooling systems surround the furnace shell and aid in cooling down the brick lining to prevent possible damages and maintain the operational efficiency. The furnace, further, has a conveyor system for charging the raw materials from the top and a tapping system at the bottom to draw off molten metal and slag. Both systems are made from high-tolerance, impact-resisting materials. The electronic and automation system is the brain of the furnace that monitors temperature, pressure, and controls the raw material feed-rate, ensuring precise and efficient operations. It is significant to note that the materials and components required to build a blast furnace aren’t solely about enduring high temperatures and pressures, but also about facilitating the optimum environment for the chemical reactions that occur inside the furnace. These materials and systems work in perfect synergy to constitute an efficient blast furnace - a prime mover of metal-smelting industries. Without this blend of engineering, knowledge of materials, and understanding of chemical processes, constructing a reliable and effective blast furnace would be challenging, if not impossible.

The Prevalence and Significance of Blast Furnaces in the Industrial Sector

The prevalence and significance of blast furnaces in the industrial sector is worth highlighting as it underscores the foundation of many manufacturing operations worldwide. These industrial giants have been the cornerstone of industries, primarily in steel and iron production, for centuries due to their ability to handle large quantities of raw material at high temperatures. Heat-resistant and designed for continuous operation, blast furnaces are capable of smelting thousands of tons of iron ore each day, thus playing a critical role in the development and maintenance of our modern infrastructure. Technological advancements have not replaced these workhorses, bringing only improvements to their design and functionality to deepen their imprint within the industrial realm. More efficient and environmentally friendly blast furnaces have sprung up across the globe, reducing wastage, and enhancing productivity. The industry's dependence on these furnaces is reflective of their robustness and resilience in handling complex metallurgical processes. The blast furnace's symbolic status in the industrial sector can be equated to its backbone, indicating its relevance in existing and emerging production scenarios. However, beyond the raw material processing role, blast furnaces are significant for their economic, social, and environmental impacts too. Industrial sectors, local economies, and communities heavily depend on steel production, with blast furnaces appearing as the sine qua non of this element. Moreover, the spotlight on reducing carbon footprints has cast blast furnaces into the limelight, as modern designs now focus on harnessing waste gases for energy production, driving sustainability. The evolution of blast furnaces testifies to their indispensability in the industrial segment—from initial designs adapted from ancient Chinese furnaces to the current colossal structures spearheading the steel and iron industries. An understanding of the fundamentals of a blast furnace will reveal its workings and its multi-faceted significance in the industrial sector, further amplifying the appreciation for this pillar of the industrial world.

The Step-by-Step Guide to Building a Blast Furnace

Building an efficient, durable blast furnace is no easy task. It requires detailed attention to each facet of construction, from material preparation to the intricate construction of the primary structure and final touch-ups that tailor the project to perfection. This comprehensive guide elucidates a step-by-step process to help you embark on this industrious journey. Starting off with the critical task of accumulating requisite materials and tools. Next, we'll delve into constructing the core structure of a blast furnace, adhering to specific dimensions and structural norms for safety and efficiency. Lastly, we ingeminate attention to detail as we move on to the application of final touches, ensuring the blast furnace operates optimally under high-temperature conditions. As we embark on this detailed exploration of furnace building, a paramount first step awaits – preparing the materials and tools needed. Keep reading to ace this meticulous project from start to finish.

Preparing the Materials and Tools Needed

Preparing the materials and tools needed for building a blast furnace is a crucial step and involves a detailed understanding of their functionalities. Right off the bat, the essence of a blast furnace lies in its capability to produce iron from iron ore. This process requires some basic yet significant set of materials. The crucial items needed primarily include iron ore, coke, and limestone. These are raw materials that play key roles in the iron-producing sequence. The iron ore acts as the basic element to be transformed while the coke serves to reduce the iron ore into its elemental form. The limestone, in the mix, assists in removing impurities. Next, we need high-end equipment to make certain the procedure is carried out effectively and safely. Blast furnaces are usually massive, towering structures, so you will require sturdy shovels, high-heat resistant buckets, tongs, and protective gear - considering the magnitude of the task. A refractory-lined furnace pot is also essential without which the operation cannot progress. This pot should facilitate the mass-weight of ore, coke, and limestone - setting it as the core of your blast furnace. High-grade industrial blowers are also central to this process, providing the draft necessary for operation. Moreover, quality control tools like a stroboscope - for tracking the rate of the blower, and a handheld thermo-gun - for temperature measurements, among others, are critical to the process. These help ensure the furnace operates at the optimum conditions necessary for transforming iron ore into iron. Finally, it’s necessary to bring together some additional equipment for cleaning and maintenance purposes. A dust extractor, for instance, can help to keep the workspace clean and safe, thereby facilitating a smoother operation. While this list might seem extensive, remember - each component plays a significant role in the process. Precision and commitment to acquiring the right tools and materials set the groundwork for the successful construction and operation of a blast furnace. So, before starting on the actual building, make sure you have all these essentials prepped and ready. The right tools and materials at your disposal guarantee a smoother, safer and more efficient building experience.

Constructing the Primary Structure of the Blast Furnace

Constructing the primary structure of the blast furnace plays a pivotal role in its overall functionality and efficiency. The commencement of this stage blends both artistry and engineering genius, with builders meticulously assembling meticulously designed components in a seemingly symphony of construction. Your furnace must feature an array of elements – from the tuyeres that feed-in hot air to the hearts that contains iron ore. Just imagine this: the blast furnace is not merely a massive structure shimmering in the industry’s glow, but rather, a complex web of interconnected elements, working in harmony to extract valuable iron from its unassuming ore. High-grade refractory bricks, the unsung heroes of blast furnace operation, line the inside of the furnace and endure the extreme conditions occurring inside. This material, capable of withstanding temperatures fluctuating about 2000 degrees Celsius, ensures the furnace’s stability and longevity, making it an essential component in the construction phase. The primary structure is made more complex with the addition of a water cooling system designed to manage extreme temperatures. This conservation mechanism segues into the vertical shaft, a towering aspect of the furnace that guides the descent of the burden – the mix of iron ore, coke, and limestone – down towards the hearth. The slow descent of the burden is a carefully calculated march as each ingredient in the mix meets the rising temperature at just the right point for effective reduction and cohesion. A highlighted component is the 'throat' – the highest point of the furnace where raw materials make their grand entry. Here, bell and hopper systems ensure a measured feed into the furnace while also maintaining a gas-tight seal to avoid energy loss. Moving downward, the stack follows - a broad, cylindrical compartment comprising the largest section of the furnace. It's here that most of the preliminary reduction of iron ore occurs. Progressing further down, the bosh forms an inverted cone, providing a passage for the reduced burden into the crucible-shaped hearth waiting below. Finally, acting as the heart of the operation, the hearth pulses with molten iron and slag, which are eventually tapped out on reaching optimum levels. The construction of the primary structure of the blast furnace requires astute attention to detail, careful coordination, and rigorous commitment. It is the backbone of iron production, built and run with precision, converting barren ores into precious iron – truly a marvel of industrialization. Without correctly constructing this primary structure, it would be impossible to achieve the quality and efficiency required in this entire process. With such steps, the humble ore moves one step closer to fuelling the world's iron needs.

Applying the Final Touches to the Blast Furnace

Applying the final touches to the blast furnace is an essential step in its construction, and utmost attention needs to be exercised to ensure the success and functionality of it. Much like an artist adding the finishing strokes to a masterpiece, these touches can make the difference between a good furnace and an excellent one. First of all, a blast furnace isn't just a piece of architecture. It's technology, years of evolution delicately balanced between science and art. Not only are you assembling materials and resources like hardened bricks, but also engineering a sculpture destined to morph raw ore into refined metal. These final touches aren't merely about aesthetics; they're about efficiency, performance, durability, and safety. Primarily, the checks and balances involve inspecting the furnace's structural integrity. It is essential to make sure the furnace walls and lining are firm and properly insulated to preserve heat and withstand the intense temperatures of the smelting process. This check is specially important for the furnace's throat, where the raw materials are inserted. Any weakness could lead to a substantial loss of heat and an inefficient operation, or worse, pose the risk of a hazardous event. Secondly, a review of the air inlets, vents, and valves is necessary. These elements play critical roles in the control of heat and the regulation of the flow of blasted air in the furnace. Any blockages, leaks, or malfunctioning valves could hamper the air supply, jeopardizing the furnace operation. It's imperative to ensure these can open and close smoothly, and regulate precisely. The final adjustments are also about optimizing the feeder system and the tapping area. An inefficient loading process of raw materials or an improper furnace tapping procedure may lead to a decrease of productivity and an increase of waste and operational costs. Assess the functionality of these areas: the feed table should move seamlessly and the drainage spout should be well-positioned and sealed. In the end, applying the final touches to the blast furnace construction reflect the precision, care, craftsmanship, and technical mastery that goes into this potent symbol of industrial prowess. It is a step that requires expertise, a discerning eye, and a masterly touch. Therefore, irrespective of whether you are building a miniature blast furnace in your backyard or erecting a towering industrial smelter, the process shares the same level of importance. And when applied correctly, these final touches assure the blast furnace's smooth operation, extend its lifespan, and ensure the safety of any personnel involved. Remember, a blast furnace might be a testament to human ingenuity and persistence, but it is the small details and finesse that truly make it shine. Develop the discerning eye and the artistry required, and the building of your blast furnace will move from merely being a technical task to becoming a mastercraft of functional art and science.

Operational Guidelines and Safety Measures for a Blast Furnace

Blast furnaces stand as titanic symbols of industrial progress, yet they require intricate safety measures and operational guidelines to function optimally. The framework within which a blast furnace operates hinges on a careful alignment of preparation, safety measures, and troubleshooting. Understanding these aspects is key to safeguarding facilities and personnel, and to ensure productivity in operations. This article unfurls with the exploration of the methodical procedure and protocols that underpin the running of a blast furnace, a reservoir of molten material governed by scientific principles. It then ventures into the crucible of safety measures necessary to maintain a stable environment while operating. Lastly, we delve into the common challenges that one may encounter in managing a blast furnace and the techniques used to circumvent them. As we begin this immersive journey, it's important to fully comprehend the varying shades of procedure and protocol attached to running a blast furnace, a process notable for both its complexity and its contribution to modern industry.

Running a Blast Furnace: Procedure and Protocol

Running a blast furnace efficiently and correctly requires adherence to a stringent procedure and protocol for the proper extraction of iron from its ore. The blast furnace process is akin to a large-scale cooking recipe, a careful and sequential orchestration of carefully measured ingredients, heat, and time. To begin the process, the blast furnace needs to be charged with raw materials such as iron ore, coke, and limestone, which is typically done from the top. Once the materials are added, a hot blast of air is directed into the furnace, igniting the coke and creating the necessary heat to melt the raw materials. Note that a range of 1500 to 2000 degrees Celsius is needed to facilitate the iron extraction process. Throughout the operation, continuous monitoring and regulation of temperature, pressure, and the composition of flue gases are critical to ensure optimal performance. The extraction of iron ore is an intricate process, particularly because the iron must be separated from the slag – a worthless by-product. The procedure necessitates an embedded precision, as accurate control of the burden distribution impacts the overall quality of the pig iron produced and the smooth running of the furnace. Safety protocols are equally important in conducting the blast furnace procedure. It is necessary to maintain a regular check on the gas cleaning system to prevent leakage of poisonous gases. Each individual involved in the procedure must be provided with appropriate safety gear and regular training to reduce the risk of accidents. Moreover, understanding and complying with the standard operating procedure, furnace operational guidelines, and emergency response plans can significantly improve safety and productivity. The essential aspect of running a blast furnace goes beyond merely following the procedure and protocol. Marshall McLuhan once said, "the medium is the message", which is fitting in the context of blast furnace operation as well. In other words, the condition of the furnace, heating equipment, safety gear, monitoring systems, and more significantly contributes to the end product, the pig iron, as much as the procedure does. In conclusion, the procedure and protocols involved in running a blast furnace are pivotal. Adhering to the established protocols ensures the blast furnace operates efficiently, producing high-quality iron while ensuring the safety of all operatives involved. This structured and methodical precept of running a blast furnace is integral to the central theme of operational guidelines and safety measures in blast furnace operations.

The Crucial Safety Measures to Adhere to When Operating a Blast Furnace

The Crucial Safety Measures When Operating a Blast Furnace As you embark on the operation of a blast furnace, it's essential to understand that this powerful piece of industrial machinery comes with substantial safety considerations. Ensuring proper safety measures can make the difference between a successful operation and a potentially disastrous event. Foremost, ensuring workers’ personal protective equipment (PPE) is imperative. This kit typically includes fire-resistant clothing, helmets, protective eyewear, gloves, safety boots, and occasionally oxygen monitors, designed to safeguard against extreme temperatures and potentially harmful gases. Temperature management is a core duty when handling blast furnaces. It's critical that the furnace's internal temperature is meticulously supervised to prevent overheating. An excessively high temperature may result in a furnace break-out—spilling out molten iron and slag—which is intensely dangerous for the operating crew and surrounding facilities. The handling of raw materials like iron ore, coke, and limestone also requires a high level of care. These substances need to be stored, moved, and loaded into the blast furnace correctly to prevent accidents. Moreover, the quality of the raw materials must be conserved until they're clinched into the furnace. Any contamination of the materials might not only cause a drop in production quality but could also contribute to unexpected, unsafe incidents. In addition, routine maintenance and inspection of the blast furnace and its auxiliary equipment are vital to anticipate and prevent potential problems. Identifying and rectifying wear and tear on furnace parts before they cause a breach can significantly reduce the risk of accidents. Inspections, regular checks, and maintenance offer an opportunity to detect any safety issues before they morph into colossal disasters. Lastly, it’s worth noting that properly trained operators and staff play a fundamental role in furnace safety. Knowledgeable workers can recognize warning signs and respond swiftly in the occurrence of unforeseen events. Furthermore, continuous training and reinforcement of proper procedures and safety protocols are instrumental in guaranteeing the highest safety standards. In conclusion, the safety measures when operating a blast furnace are many and crucial to the smooth functioning of the furnace operation. By following these guidelines and maintaining a vigilant commitment to safety, operators can minimize risks while maximizing operational performance and ensuring the creation of high-quality metal products.

Common Problems and Troubleshooting Techniques for a Blast Furnace

A Blast Furnace's operational integrity is not exempted from challenges. Unforeseen problems could put a brake on the smooth functioning of the furnace, and if not promptly and adequately addressed, could escalate into bigger issues that compromise your safety and overall production. The most common problem faced by Blast Furnace operators is the blockage in the main runner. This typically occurs when hot metal and slag can't be separated. The resulting massive buildup then obstructs the runner, detracting the smooth flow of operations. With comprehensive knowledge and quick action, the removal of this obstruction can be done using a drilling mechanism or through the application of clay gunning. Another common problem is irregular burden descent, which affects the furnace's productivity. To check and eliminate this problem, a burden profile capture and an obstruction removal cycle, which includes a probing operation, are the recommended troubleshooting guidelines. Variations in the efficiency of heating zones or irruptions of back-draft and re-entry of waste gases can also be troublesome. For this, you need to ensure that the Blast Furnace's top gas pressure and temperature are adequately maintained and controlled. The furnace's lining condition also poses occasional challenges. A well-maintained lining safeguards the furnace's interior from high temperature and corrosive waste products while ensuring its longevity. Regular thermal scanning and gunning operations can avert extreme wall erosion or the formation of an accretion ring inside the furnace. Last but not least, one cannot ignore the adequate handling of dust and waste gas emissions - an aspect that ensures not only operational safety but also environmental compliance. An efficacious waste gas cleaning system, optimal slag granulation practices, and a highly functional dust handling system are pivotal in achieving this. When it comes to safety measures, it is imperative for all operators to be properly trained and equipped with essential safety gear. Regular audits and assessments of operational protocols, emergency drills, and constant risk assessment are necessary – they are not just standardized procedures, but our commitment to a safe, efficient, and environment-friendly workspace. Having these troubleshooting techniques in your arsenal doesn't just ensure seamless Blast Furnace operations; they practically equip you with the wherewithal to navigate common problems, thus maintaining a high yield and safety standard. A well-monitored, well-maintained Blast Furnace holds the key to peak operational success.