How To Cut Foam

Cutting foam can be a daunting task, especially for those who are new to working with this versatile material. However, with the right techniques and tools, cutting foam can be a straightforward process that yields professional-looking results. To achieve success, it's essential to understand the different approaches required for various types of foam, as well as the importance of proper preparation and finishing techniques. In this article, we'll explore the key considerations for cutting foam, including the preparation necessary to ensure a smooth cut, the various cutting techniques suited to different foam types, and the methods for finishing and smoothing the cut foam. By mastering these skills, you'll be able to tackle a wide range of foam-cutting projects with confidence. So, let's start by laying the groundwork for a successful foam-cutting experience – preparation is key.

Preparation is Key

When it comes to achieving success in any endeavor, preparation is key. This is especially true when it comes to tasks that require attention to detail and a high level of precision, such as spray foam insulation installation. In order to ensure a successful outcome, it is essential to prepare properly, and this involves several key steps. First, choosing the right tools for the job is crucial, as the wrong equipment can lead to subpar results and even safety hazards. Additionally, selecting the correct foam type is vital, as different types of foam are suited for different applications and environments. Finally, ensuring a safe working environment is also critical, as spray foam insulation installation can involve hazardous materials and situations. By taking the time to prepare properly and address these key areas, individuals can set themselves up for success and achieve high-quality results. With the right tools, the process can begin, and that is where we will start.

Choosing the Right Tools

Choosing the right tools is crucial when it comes to cutting foam. The type of tool you use will depend on the type of foam you are working with, as well as the desired outcome. For example, if you are working with a dense, high-density foam, you may need to use a more heavy-duty tool such as a hot wire cutter or a foam saw. On the other hand, if you are working with a softer, more pliable foam, a utility knife or a craft knife may be sufficient. It's also important to consider the size and shape of the foam you are working with, as well as the level of precision you need to achieve. For instance, if you need to make intricate cuts or shapes, a hot wire cutter or a laser cutter may be the best option. Additionally, it's essential to choose tools that are specifically designed for cutting foam, as they will be able to handle the unique properties of the material. Using the wrong tools can result in uneven cuts, tears, or even damage to the foam. By selecting the right tools for the job, you can ensure a smooth and successful cutting process.

Selecting the Correct Foam Type

When it comes to cutting foam, selecting the correct foam type is crucial for achieving the desired results. There are several types of foam, each with its unique characteristics, advantages, and challenges. The most common types of foam include open-cell foam, closed-cell foam, and rigid foam. Open-cell foam is soft, flexible, and porous, making it ideal for applications such as upholstery, insulation, and soundproofing. Closed-cell foam, on the other hand, is denser and more rigid, making it suitable for applications such as flotation devices, packaging, and construction. Rigid foam is the most dense and hard type of foam, often used in applications such as architectural models, prototypes, and signage. Understanding the properties and uses of each foam type is essential for selecting the correct one for your project. Additionally, considering factors such as the foam's density, thickness, and texture can also impact the cutting process. For instance, thicker foams may require more powerful cutting tools, while denser foams may require specialized blades. By selecting the correct foam type and understanding its characteristics, you can ensure a successful cutting process and achieve the desired outcome for your project.

Ensuring a Safe Working Environment

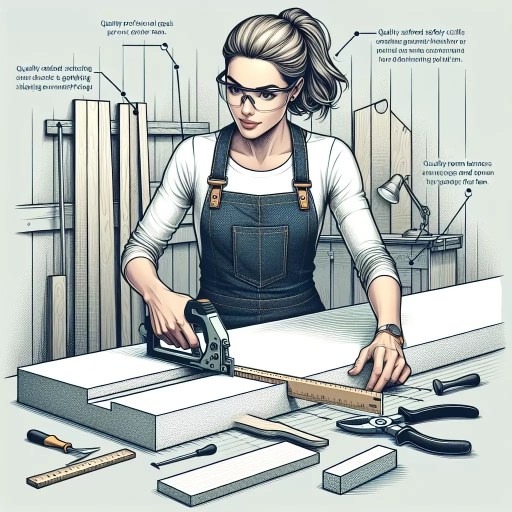

Ensuring a safe working environment is crucial when cutting foam, as it can be a hazardous process if not done properly. To minimize risks, it's essential to prepare a well-ventilated workspace, away from open flames, sparks, or hot surfaces. Wear protective gear, including safety glasses, a dust mask, and gloves, to prevent injuries from flying debris and exposure to foam particles. Additionally, keep loose clothing and long hair tied back to avoid entanglement with cutting tools. A clean and organized workspace is also vital, as clutter can lead to accidents and make it difficult to maneuver. By taking these precautions, you can significantly reduce the risk of injury and ensure a safe working environment for cutting foam.

Cutting Techniques for Different Foam Types

Cutting foam can be a daunting task, especially when working with different types of foam. The key to achieving clean cuts and minimizing waste lies in selecting the right cutting technique for the specific foam type. High-density foam, for instance, requires a hot wire cutter to produce smooth edges and prevent crumbling. On the other hand, low-density foam can be easily cut using a utility knife, which provides a high level of precision and control. Medium-density foam, however, falls somewhere in between and is best cut using a foam saw, which offers a balance between precision and speed. By understanding the unique characteristics of each foam type and choosing the appropriate cutting technique, individuals can achieve professional-looking results and optimize their foam-cutting process. For high-density foam, a hot wire cutter is the tool of choice, and in the next section, we will explore the benefits and best practices of using this technique.

Using a Hot Wire Cutter for High-Density Foam

Using a hot wire cutter is an effective method for cutting high-density foam, which is often used in applications such as upholstery, insulation, and crafting. This technique involves using a heated wire to slice through the foam, creating a smooth and precise cut. To use a hot wire cutter, start by preparing the foam by ensuring it is dry and free of debris. Next, set up the hot wire cutter according to the manufacturer's instructions, taking care to adjust the temperature and wire tension as needed. Place the foam on a stable surface and carefully position the hot wire cutter, making sure it is aligned with the desired cutting path. Slowly and steadily move the cutter through the foam, applying gentle pressure and maintaining a consistent speed. The heat from the wire will melt the foam, creating a clean and precise cut. It's essential to work in a well-ventilated area and use protective gear, such as gloves and safety glasses, to avoid injury. Additionally, it's crucial to follow the manufacturer's guidelines for temperature and wire tension to prevent damage to the cutter or the foam. With practice and patience, using a hot wire cutter can become a reliable and efficient method for cutting high-density foam, allowing for precise and professional-looking results.

Applying a Utility Knife for Low-Density Foam

When working with low-density foam, a utility knife is a suitable tool for making precise cuts. To apply a utility knife effectively, start by selecting a sharp blade, as a dull one can tear the foam instead of cutting it cleanly. Hold the knife at a 45-degree angle, with the blade facing the direction you want the cut to go. Gently press the knife into the foam, using a smooth, sawing motion to make the cut. Apply gentle to moderate pressure, depending on the density of the foam, and avoid applying too much pressure, which can cause the foam to tear or the knife to slip. For straight cuts, use a ruler or straightedge as a guide to ensure accuracy. For curved cuts, use a gentle, sweeping motion, following the desired curve. To make intricate cuts or cut out small shapes, use a craft knife or a hobby knife with a smaller blade. When cutting low-density foam, it's essential to work slowly and carefully to avoid mistakes and achieve a clean, precise cut. By following these steps and using the right technique, you can effectively use a utility knife to cut low-density foam for various applications, such as crafting, DIY projects, or packaging.

Utilizing a Foam Saw for Medium-Density Foam

When working with medium-density foam, a foam saw is an essential tool to achieve clean and precise cuts. A foam saw is designed specifically for cutting through foam materials, and its unique features make it an ideal choice for medium-density foam. The saw's blade is typically made of a high-carbon steel or a specialized foam-cutting material, which allows for smooth and effortless cutting. The blade's teeth are also designed to be extremely sharp, reducing the risk of tearing or ripping the foam. To utilize a foam saw for medium-density foam, start by ensuring the saw is properly aligned with the cutting line. Apply gentle to moderate pressure, depending on the density of the foam, and slowly begin to saw through the material. It's essential to maintain a steady and consistent motion, as applying too much pressure can cause the saw to bind or the foam to tear. As you cut, use a gentle rocking motion to help the saw glide through the foam, reducing friction and preventing the saw from getting stuck. By using a foam saw and following these techniques, you can achieve clean, precise cuts in medium-density foam, making it ideal for a variety of applications, from crafting and DIY projects to industrial and commercial uses.

Finishing and Smoothing the Cut Foam

Finishing and smoothing the cut foam is a crucial step in achieving a professional-looking result. To ensure a smooth and even surface, it's essential to employ various techniques that cater to the specific needs of the foam. Three key methods can be used to achieve a high-quality finish: sanding the cut edges for a smooth finish, applying a sealant to prevent fraying, and using a heat gun to shape and mold the foam. By incorporating these techniques into your workflow, you can significantly enhance the overall appearance and durability of the cut foam. In the next section, we'll delve into the first method, sanding the cut edges for a smooth finish, and explore the best practices for achieving a seamless finish.

Sanding the Cut Edges for a Smooth Finish

Sanding the cut edges of foam is a crucial step in achieving a smooth finish. After cutting the foam, the edges can be rough and uneven, which can be noticeable, especially if the foam is being used for a visible application. To sand the cut edges, start by using a coarse-grit sandpaper, such as 80-100 grit, to remove any excess foam and smooth out the edge. Work your way up to finer grits, such as 120-150 grit, to further refine the edge and remove any remaining imperfections. It's essential to sand in a consistent, back-and-forth motion, applying moderate pressure, to avoid creating scratches or swirl marks. For more intricate cuts or curved edges, consider using a sanding block or a foam sanding tool, which can help to maintain even pressure and prevent uneven sanding. Additionally, when sanding foam, it's crucial to work in a well-ventilated area, as the foam particles can create dust and potentially cause respiratory issues. By taking the time to properly sand the cut edges, you can achieve a smooth, professional-looking finish that enhances the overall appearance of your foam project.

Applying a Sealant to Prevent Fraying

Applying a sealant to prevent fraying is a crucial step in the foam cutting process. Fraying occurs when the cut edges of the foam begin to unravel, leading to a rough and uneven surface. To prevent this, a sealant can be applied to the cut edges of the foam. There are several types of sealants available, including liquid sealants, spray sealants, and tape sealants. Liquid sealants are applied directly to the cut edge of the foam using a brush or cloth, while spray sealants are applied using a spray can. Tape sealants, on the other hand, are applied by wrapping a tape around the cut edge of the foam. Regardless of the type of sealant used, it is essential to apply it evenly and smoothly to ensure that the cut edge of the foam is fully sealed. This will help to prevent fraying and give the foam a clean and finished appearance. Additionally, applying a sealant can also help to protect the foam from moisture and other environmental factors that can cause it to deteriorate over time. By applying a sealant to the cut edges of the foam, you can help to extend its lifespan and keep it looking its best.

Using a Heat Gun to Shape and Mold the Foam

Using a heat gun to shape and mold the foam is a great way to achieve a smooth and even finish. To do this, start by setting the heat gun to a medium to high temperature, depending on the type of foam you are working with. Hold the heat gun about 6-8 inches away from the foam and slowly move it back and forth, applying even heat to the area you want to shape. As the foam begins to soften, use a tool such as a modeling tool or a credit card to gently shape and mold it into the desired shape. Be careful not to apply too much heat, as this can cause the foam to melt or become misshapen. It's also important to work slowly and carefully, as the foam can be fragile and prone to tearing. By using a heat gun to shape and mold the foam, you can create smooth, rounded edges and a professional-looking finish. This technique is especially useful for creating complex shapes or curves, and can be used in conjunction with other techniques, such as cutting and sanding, to achieve a high-quality finish.