How To Cut Rebar

Cutting rebar, a crucial step in various construction and DIY projects, requires attention to detail and the right techniques to ensure a safe and efficient process. Whether you're a seasoned professional or a novice, understanding how to cut rebar effectively is essential to achieving your desired outcome. In this article, we will delve into the world of rebar cutting, exploring the essential steps and methods to help you master this skill. To begin, it's vital to emphasize the importance of preparation, as it sets the stage for a successful cutting experience. We will discuss the necessary tools and safety measures to have in place before starting the cutting process. Additionally, we will examine the various cutting methods available, including their advantages and limitations. Finally, we will touch on the critical aspect of post-cutting safety and cleanup, highlighting the measures to take to prevent injuries and maintain a clean work environment. With these key considerations in mind, let's start by preparing for the task at hand, as we explore the first crucial step: Preparation is Key.

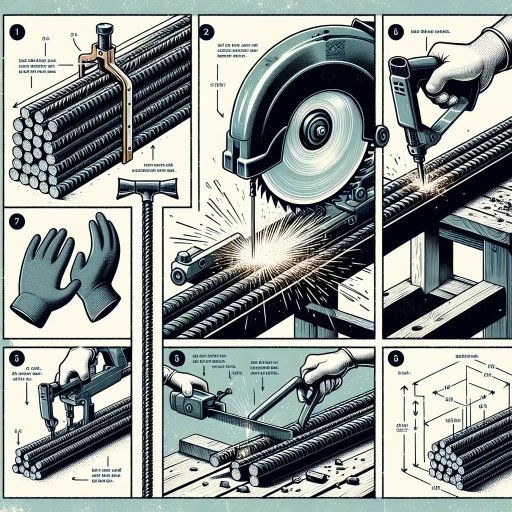

Preparation is Key

When it comes to cutting rebar, preparation is key to ensuring a safe and successful process. To achieve this, it's essential to take a few crucial steps before making the first cut. Firstly, selecting the right cutting tool is vital, as different tools are designed for specific types of rebar and cutting tasks. Additionally, wearing protective gear is a must to prevent injuries from flying debris and sparks. Lastly, measuring and marking the rebar accurately is necessary to avoid errors and ensure precise cuts. By taking the time to prepare properly, you can avoid common mistakes and ensure a smooth cutting process. With the right mindset and preparation, you can tackle even the most challenging rebar cutting tasks with confidence. So, let's start by exploring the importance of choosing the right cutting tool for your rebar cutting needs.

Choose the Right Cutting Tool

Here is the information that you should include in the paragraphy: Cutting rebar can be a challenging task, especially if you don't have the right tools. The type of cutting tool you choose will greatly impact the efficiency and effectiveness of the process. There are several types of cutting tools available, including hacksaws, bolt cutters, and power saws. Hacksaws are a popular choice for cutting rebar, but they can be time-consuming and require a lot of elbow grease. Bolt cutters, on the other hand, are designed specifically for cutting rebar and can make quick work of it. However, they can be expensive and may not be suitable for cutting larger diameter rebar. Power saws, such as circular saws or reciprocating saws, are also effective for cutting rebar, but they can be noisy and produce a lot of dust. Ultimately, the best cutting tool for you will depend on the size and type of rebar you need to cut, as well as your personal preference and budget. Here is the rewritten paragraph in 500 words: When it comes to cutting rebar, having the right cutting tool is crucial for a successful and efficient process. With various options available, selecting the most suitable tool can be overwhelming, especially for those new to rebar cutting. The type of cutting tool you choose will significantly impact the outcome, and it's essential to consider the size and type of rebar you need to cut, as well as your personal preference and budget. One of the most common cutting tools for rebar is the hacksaw. While it's a popular choice, it can be a time-consuming and labor-intensive process, requiring a lot of elbow grease. Hacksaws are best suited for cutting smaller diameter rebar, and they can be effective for making precise cuts. However, for larger diameter rebar, hacksaws may not be the most efficient option. Bolt cutters, on the other hand, are specifically designed for cutting rebar and can make quick work of it. These cutters are available in various sizes and can handle rebar of different diameters. However, they can be expensive, and the cost may not be justified for occasional use. Additionally, bolt cutters may not be suitable for cutting larger diameter rebar, and they can be heavy and cumbersome to use. Power saws, such as circular saws or reciprocating saws, are also effective for cutting rebar. These saws are designed for heavy-duty use and can make quick work

Wear Protective Gear

Wearing protective gear is a crucial step in preparing to cut rebar safely and effectively. This gear serves as a barrier between you and the potential hazards associated with the cutting process, including flying debris, sharp edges, and sparks. A pair of safety glasses or goggles is essential to protect your eyes from flying particles and debris. Safety glasses with a wraparound frame provide additional protection from the sides. A face shield can offer extra protection for your face and neck. A dust mask or respirator is also necessary to prevent inhalation of dust and particles generated during the cutting process. Additionally, wearing gloves can protect your hands from cuts, abrasions, and vibrations. Steel-toed boots or shoes with slip-resistant soles can prevent foot injuries from heavy objects or slippery surfaces. A hard hat or safety helmet can protect your head from falling objects or debris. Wearing protective gear is not only a safety precaution but also a legal requirement in many workplaces. By wearing the appropriate protective gear, you can minimize the risk of injury and ensure a safe working environment.

Measure and Mark the Rebar

Here is the paragraphy: To ensure accurate cutting of rebar, it's essential to measure and mark the rebar correctly. Start by measuring the length of rebar required for your project using a tape measure or a ruler. Take note of any bends or curves in the rebar, as these can affect the overall length. Once you have the measurement, use a marker or a soapstone to mark the cutting point on the rebar. Make sure the mark is clear and visible, and consider using a marker with a fine tip to avoid any mistakes. If you're working with a large quantity of rebar, consider using a template or a jig to help you measure and mark the rebar quickly and accurately. Additionally, double-check your measurements to ensure accuracy, as incorrect measurements can lead to costly mistakes and wasted materials. By taking the time to measure and mark the rebar correctly, you'll be able to cut it accurately and efficiently, saving you time and effort in the long run.

Cutting Methods for Rebar

Cutting rebar is a crucial step in various construction and DIY projects. When it comes to cutting rebar, there are several methods to choose from, each with its own advantages and disadvantages. Three of the most common methods are using a reciprocating saw, a circular saw, and bolt cutters. These methods offer different levels of precision, speed, and safety, making it essential to choose the right one for the job. For instance, a reciprocating saw is ideal for cutting rebar in tight spaces, while a circular saw is better suited for cutting large quantities of rebar quickly. Bolt cutters, on the other hand, are perfect for cutting smaller rebar pieces. In this article, we will explore each of these methods in detail, starting with the versatility and convenience of using a reciprocating saw.

Using a Reciprocating Saw

Using a reciprocating saw is a popular method for cutting rebar, especially in tight spaces or when working with curved or irregularly shaped rebar. This versatile power tool is designed for heavy-duty cutting and demolition work, making it an ideal choice for cutting through rebar. To use a reciprocating saw, start by selecting the right blade, which should be specifically designed for cutting metal. A bi-metal or carbide-tipped blade is recommended, as they offer the best combination of durability and cutting performance. Next, ensure the saw is properly assembled and the blade is securely attached. When cutting rebar, it's essential to use a slow and controlled motion, applying gentle to moderate pressure. This will help prevent the blade from binding or kicking back. It's also crucial to keep the saw blade perpendicular to the rebar to achieve a clean and accurate cut. Additionally, use a steady and consistent motion to maintain control and avoid applying too much pressure, which can cause the saw to vibrate or lose its cutting efficiency. When cutting through thicker rebar, it may be necessary to use a slower speed and more gentle pressure to avoid overheating the blade or damaging the saw. By following these guidelines and using the right blade, a reciprocating saw can be an effective and efficient tool for cutting rebar in a variety of applications.

Using a Circular Saw

Here is the paragraphy: Using a circular saw is a popular method for cutting rebar due to its speed and efficiency. To use a circular saw, start by selecting the correct blade, which should be specifically designed for cutting metal. A diamond-coated blade or a blade with tungsten carbide teeth is ideal for cutting rebar. Next, ensure the saw is set to the correct speed, typically between 3,000 to 4,000 RPM. Wear protective gear, including safety glasses and a dust mask, to prevent injury from flying debris. Hold the saw firmly and place the blade on the rebar, applying gentle to moderate pressure. Move the saw slowly and steadily along the cutting line, using a consistent motion to maintain control. It's essential to keep the saw blade perpendicular to the rebar to avoid binding or kickback. As the saw cuts through the rebar, use a broom or vacuum to remove the metal shavings and dust, ensuring a clean and safe working environment. Regularly inspect the blade for wear and tear, replacing it as needed to maintain optimal performance. By following these steps and taking necessary safety precautions, using a circular saw can be an effective and efficient method for cutting rebar.

Using Bolt Cutters

Using bolt cutters is a common method for cutting rebar, especially for smaller diameters. Bolt cutters are handheld tools that use a leveraged cutting action to sever the rebar. They are available in various sizes, ranging from 12 to 42 inches, and are suitable for cutting rebar up to 1 inch in diameter. To use bolt cutters, place the rebar in the jaws of the cutter, making sure it is centered and secure. Squeeze the handles together, applying steady pressure until the rebar is cut. It's essential to use the correct size of bolt cutters for the rebar diameter to avoid damaging the tool or the rebar. Additionally, bolt cutters can be used to cut rebar in tight spaces, making them a convenient option for projects with limited accessibility. However, bolt cutters may not be the most efficient method for cutting large quantities of rebar or for rebar with a larger diameter, as they can be time-consuming and physically demanding. Nevertheless, bolt cutters remain a popular choice for many construction and DIY projects due to their portability, ease of use, and affordability.

Post-Cutting Safety and Cleanup

When it comes to post-cutting safety and cleanup, there are several crucial steps that individuals must take to prevent accidents and ensure a safe working environment. After completing a cutting task, it is essential to dispose of cut rebar properly, clean the workspace thoroughly, and store cutting tools safely. By following these steps, individuals can minimize the risk of injury and maintain a clean and organized workspace. Proper disposal of cut rebar is particularly important, as it can be a significant hazard if not handled correctly. This is why it is vital to focus on disposing of cut rebar properly, starting with the removal of any sharp edges and points. By doing so, individuals can prevent accidents and ensure a safe working environment. Dispose of Cut Rebar Properly is the first step to ensure post-cutting safety and cleanup.

Dispose of Cut Rebar Properly

Here is the post: When cutting rebar, it's essential to dispose of the cut pieces properly to prevent injuries and maintain a safe working environment. Dispose of cut rebar by collecting the pieces in a designated container or bin, making sure they are not scattered around the work area. This will prevent tripping hazards and make it easier to clean up the site. It's also crucial to wear protective gear, such as gloves and safety glasses, when handling cut rebar to prevent puncture wounds and eye injuries. Additionally, ensure that the cut rebar is not mixed with other materials, such as concrete or debris, as this can make it difficult to recycle or dispose of properly. By disposing of cut rebar properly, you can prevent accidents, reduce waste, and maintain a clean and organized work site. Furthermore, it's recommended to label the container or bin with the contents and the date it was filled, making it easier to track and manage the disposal process. This will also help to ensure that the cut rebar is disposed of in accordance with local regulations and guidelines. Overall, proper disposal of cut rebar is a critical aspect of post-cutting safety and cleanup, and it's essential to take the necessary steps to ensure a safe and efficient work environment.

Clean the Workspace

Cleaning the workspace is a crucial step in the post-cutting safety and cleanup process. After cutting rebar, the workspace can become cluttered with debris, dust, and metal shavings, posing a significant risk to the safety of the workers and the quality of the project. Cleaning the workspace involves removing all debris, dust, and metal shavings from the area, including the floor, workbenches, and equipment. This can be done using a broom, dustpan, and a vacuum cleaner. It is also essential to wipe down all surfaces with a damp cloth to remove any remaining dust and debris. Additionally, cleaning the workspace helps to prevent accidents and injuries caused by slipping or tripping over debris. It also helps to prevent damage to equipment and tools, which can be costly to replace. Furthermore, a clean workspace promotes a safe and healthy working environment, reducing the risk of respiratory problems caused by inhaling dust and debris. Moreover, cleaning the workspace helps to maintain the quality of the project by preventing contamination of the rebar and other materials. It also helps to ensure that the workspace is organized and efficient, allowing workers to focus on the task at hand. In summary, cleaning the workspace is an essential step in the post-cutting safety and cleanup process, promoting a safe, healthy, and efficient working environment.

Store Cutting Tools Safely

Here is the paragraphy: When it comes to storing cutting tools safely, it's essential to prioritize organization, protection, and accessibility. After completing a rebar cutting project, ensure that all tools are cleaned and dried to prevent rust and damage. Store cutting tools in a designated area, such as a toolbox or storage bin, to keep them organized and out of the way. Use dividers or compartments to separate tools and prevent them from getting damaged or mixed up. Label each tool and its corresponding storage location to facilitate easy identification and retrieval. Consider storing cutting tools in a dry, climate-controlled environment to prevent moisture from accumulating and causing damage. Additionally, keep cutting tools out of reach of children and pets to prevent accidents and injuries. Regularly inspect and maintain cutting tools to ensure they remain in good working condition and are safe to use. By storing cutting tools safely and efficiently, you can prolong their lifespan, prevent accidents, and ensure a smooth workflow for future projects.