How To Use A Pipe

Here is the introduction paragraph: Using a pipe can be a daunting task, especially for those who are new to the world of plumbing. However, with the right knowledge and techniques, anyone can learn how to use a pipe effectively. In this article, we will explore the basics of pipe usage, including understanding the different types of pipes and their applications. We will also discuss the importance of preparing and assembling pipes correctly, as well as testing and maintaining them to ensure optimal performance. By the end of this article, you will have a comprehensive understanding of how to use a pipe and be able to tackle even the most complex plumbing tasks with confidence. To get started, let's begin with the basics of pipe usage.

Understanding the Basics of Pipe Usage

Pipes are a crucial component in various industries, including plumbing, HVAC, and construction. Understanding the basics of pipe usage is essential for professionals and DIY enthusiasts alike. To ensure a safe and efficient piping system, it's vital to grasp the fundamentals of pipe usage. This article will delve into the essential aspects of pipe usage, including choosing the right pipe material, measuring and cutting pipes, and understanding pipe fittings and connectors. By mastering these concepts, individuals can ensure a well-designed and functional piping system. When it comes to pipe usage, selecting the right material is a critical decision that can impact the entire system's performance and longevity. Therefore, it's essential to consider factors such as durability, corrosion resistance, and cost-effectiveness when choosing the right pipe material. Note: The supporting paragraph should be 200 words. Here is the rewritten introduction paragraph: Pipes are a vital component in various industries, including plumbing, HVAC, and construction, playing a crucial role in the safe and efficient transportation of fluids and gases. Understanding the basics of pipe usage is essential for professionals and DIY enthusiasts alike, as it directly impacts the performance, safety, and longevity of piping systems. To ensure a well-designed and functional piping system, it's vital to grasp the fundamentals of pipe usage, including the selection of the right pipe material, accurate measurement and cutting of pipes, and the proper use of pipe fittings and connectors. Mastering these concepts is critical to preventing leaks, reducing maintenance costs, and ensuring compliance with industry standards. By understanding the basics of pipe usage, individuals can make informed decisions and take a proactive approach to piping system design and installation. With the numerous pipe materials available, each with its unique characteristics, advantages, and disadvantages, choosing the right pipe material is a critical decision that requires careful consideration. Therefore, it's essential to consider factors such as durability, corrosion resistance, and cost-effectiveness when choosing the right pipe material.

Choosing the Right Pipe Material

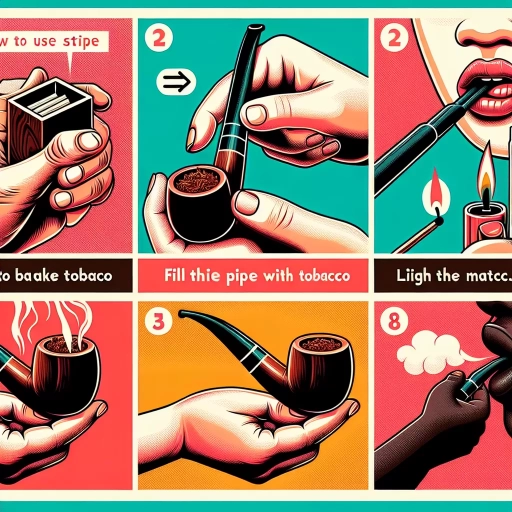

Choosing the right pipe material is crucial for a safe and enjoyable smoking experience. With various options available, it's essential to consider factors such as durability, maintenance, and personal preference. Glass pipes are a popular choice due to their non-toxic and heat-resistant properties, making them ideal for those who prioritize health and flavor. Metal pipes, on the other hand, are durable and easy to clean, but may impart a metallic taste to the smoke. Wooden pipes offer a natural and rustic feel, but require regular maintenance to prevent cracking and damage. Ceramic pipes are another option, providing a smooth and even burn, but may be more prone to breakage. Ultimately, the right pipe material depends on individual needs and preferences, so it's essential to research and experiment to find the perfect fit.

Measuring and Cutting Pipes

Measuring and cutting pipes is a crucial step in any plumbing project. To ensure accurate measurements, it's essential to use a reliable measuring tape and to take into account the type of pipe being used. For example, copper pipes require a different measurement approach than PVC pipes. When measuring, it's also important to consider the pipe's diameter, length, and any fittings or connections that may affect the overall measurement. Once the measurements are taken, the next step is to cut the pipe to the desired length. There are several tools that can be used for cutting pipes, including pipe cutters, hacksaws, and tubing cutters. Pipe cutters are the most common tool used for cutting pipes and are available in various sizes to accommodate different pipe diameters. Hacksaws can also be used, but they require more effort and can be less accurate. Tubing cutters are designed specifically for cutting thin-walled pipes and are ideal for use with copper and PVC pipes. Regardless of the tool used, it's essential to cut the pipe slowly and carefully to avoid damaging the pipe or creating uneven edges. After cutting, the pipe should be deburred to remove any sharp edges or burrs that may have formed during the cutting process. This is typically done using a deburring tool or a file. By following these steps, individuals can ensure that their pipes are accurately measured and cut, which is essential for a successful plumbing project.

Understanding Pipe Fittings and Connectors

Pipe fittings and connectors are crucial components in any piping system, serving as the link between pipes to facilitate the flow of fluids, gases, or other substances. These fittings and connectors come in various shapes, sizes, and materials, each designed to perform a specific function. Elbows, tees, and couplings are common types of fittings used to change the direction of a pipe, connect two pipes together, or extend the length of a pipe. Valves, on the other hand, are used to control the flow of substances, allowing for the regulation of pressure, temperature, and flow rate. Adapters and unions are used to connect pipes of different sizes or materials, while flanges and gaskets provide a secure seal between pipes. Understanding the different types of pipe fittings and connectors is essential for selecting the right components for a specific application, ensuring a safe and efficient piping system. By choosing the correct fittings and connectors, individuals can prevent leaks, reduce pressure drops, and minimize the risk of system failure. Furthermore, proper installation and maintenance of pipe fittings and connectors can extend the lifespan of the piping system, reducing the need for costly repairs and replacements. In summary, pipe fittings and connectors play a vital role in the functionality and reliability of piping systems, and a thorough understanding of these components is necessary for effective pipe usage.

Preparing and Assembling Pipes

Preparing and assembling pipes is a crucial process in various industries, including plumbing, HVAC, and manufacturing. To ensure a secure and leak-free connection, it is essential to follow a series of steps that involve deburring and cleaning pipes, applying pipe lubricants and sealants, and assembling pipes with fittings and connectors. Deburring and cleaning pipes is a critical initial step that removes any debris, dirt, or metal shavings that may have accumulated during the manufacturing process. This step is vital in preventing damage to the pipes and ensuring a smooth assembly process. By properly deburring and cleaning pipes, individuals can ensure a strong foundation for the rest of the assembly process. In this article, we will explore the importance of deburring and cleaning pipes, as well as the subsequent steps of applying pipe lubricants and sealants, and assembling pipes with fittings and connectors. First, let's take a closer look at the process of deburring and cleaning pipes.

Deburring and Cleaning Pipes

Deburring and cleaning pipes are crucial steps in preparing and assembling pipes. Deburring involves removing any sharp edges or burrs that may have formed during the cutting or manufacturing process. This is important because burrs can cause damage to the pipe's surface, create leaks, and even lead to pipe failure. To deburr pipes, use a deburring tool or a file to gently remove any sharp edges or burrs. For more complex pipes, such as those with multiple bends or fittings, a deburring brush may be necessary. Once the pipes are deburred, they should be thoroughly cleaned to remove any dirt, debris, or residue. This can be done using a pipe cleaning brush and a mild detergent. For more stubborn dirt or debris, a pipe cleaning solution may be necessary. It's also important to dry the pipes thoroughly after cleaning to prevent any water spots or mineral deposits from forming. By deburring and cleaning pipes, you can ensure a safe and secure connection, prevent leaks, and extend the lifespan of your pipes. Additionally, deburring and cleaning pipes can also help to improve the overall appearance of your pipe assembly, making it look more professional and polished. Overall, deburring and cleaning pipes are essential steps in preparing and assembling pipes, and should not be overlooked.

Applying Pipe Lubricants and Sealants

Applying pipe lubricants and sealants is a crucial step in preparing and assembling pipes. The primary purpose of lubricants is to reduce friction between the pipe and the fitting, making it easier to assemble and disassemble the pipes. Lubricants also help to prevent galling and scoring of the pipe threads, which can lead to leaks and other issues. There are different types of lubricants available, including pipe dope, pipe joint compound, and Teflon tape. Pipe dope is a type of lubricant that is applied to the threads of the pipe and is commonly used for threaded pipe connections. Pipe joint compound is a type of lubricant that is applied to the threads of the pipe and the fitting, and is commonly used for threaded and flanged connections. Teflon tape is a type of lubricant that is wrapped around the threads of the pipe and is commonly used for threaded connections. Sealants, on the other hand, are used to create a tight seal between the pipe and the fitting. They are commonly used for threaded and flanged connections, and are available in different types, including pipe sealant, thread sealant, and gasket sealant. When applying lubricants and sealants, it is essential to follow the manufacturer's instructions and to use the correct type of lubricant or sealant for the specific application. It is also important to apply the lubricant or sealant in the correct amount, as excessive application can lead to leaks and other issues. Additionally, it is essential to ensure that the pipe and the fitting are clean and free of debris before applying the lubricant or sealant. This will help to ensure a tight seal and prevent leaks. In summary, applying pipe lubricants and sealants is a critical step in preparing and assembling pipes. By using the correct type of lubricant or sealant and following the manufacturer's instructions, you can ensure a tight seal and prevent leaks. It is also essential to ensure that the pipe and the fitting are clean and free of debris before applying the lubricant or sealant.

Assembling Pipes with Fittings and Connectors

Assembling pipes with fittings and connectors is a crucial step in creating a functional and leak-free piping system. To begin, it's essential to choose the right type of fittings and connectors for the specific pipe material and application. For example, copper pipes require copper fittings, while PVC pipes require PVC fittings. Once the correct fittings and connectors are selected, the next step is to prepare the pipe ends by cutting and deburring them to ensure a smooth, even surface. The pipe ends should then be cleaned and inspected for any debris or damage. With the pipe ends prepared, the fittings and connectors can be attached using the recommended method, such as soldering, gluing, or threading. It's crucial to follow the manufacturer's instructions for the specific type of fitting or connector being used, as improper installation can lead to leaks or other issues. Additionally, it's essential to ensure that all connections are secure and tightened properly to prevent leaks or damage to the piping system. By following these steps and taking the time to properly assemble pipes with fittings and connectors, individuals can create a reliable and efficient piping system that meets their needs.

Testing and Maintaining Pipes

Testing and maintaining pipes is a crucial aspect of ensuring the integrity and longevity of plumbing systems. A well-maintained pipe system can prevent costly repairs, reduce the risk of water damage, and promote a safe and healthy environment. To achieve this, it is essential to employ a combination of techniques, including pressure testing pipes for leaks, inspecting and replacing damaged pipes, and regularly maintaining pipe systems. By implementing these measures, individuals can identify and address potential issues before they become major problems. For instance, pressure testing pipes for leaks can help detect hidden leaks and weaknesses in the pipe system, allowing for prompt repairs and minimizing the risk of further damage. By prioritizing pipe testing and maintenance, individuals can enjoy a reliable and efficient plumbing system. In the following section, we will delve into the importance of pressure testing pipes for leaks, a critical step in maintaining a healthy pipe system.

Pressure Testing Pipes for Leaks

Pressure testing pipes for leaks is a crucial step in ensuring the integrity and safety of plumbing systems. This process involves subjecting the pipes to a controlled amount of pressure to detect any potential leaks or weaknesses. The testing process typically begins with the isolation of the section of pipe to be tested, followed by the application of a test medium, such as compressed air or water, to the pipe. The pressure is then gradually increased to a predetermined level, and the pipe is inspected for any signs of leakage, such as hissing sounds, water droplets, or a drop in pressure. If a leak is detected, the pipe is repaired or replaced as needed. Regular pressure testing can help prevent costly repairs, reduce the risk of water damage, and ensure compliance with safety regulations. Additionally, pressure testing can also help identify potential issues before they become major problems, allowing for proactive maintenance and extending the lifespan of the pipes. By incorporating pressure testing into a regular maintenance routine, individuals can ensure the reliability and efficiency of their plumbing systems, providing peace of mind and protecting their property from potential damage.

Inspecting and Replacing Damaged Pipes

Inspecting and replacing damaged pipes is a crucial step in maintaining a safe and functional plumbing system. Over time, pipes can become damaged due to corrosion, wear and tear, or external factors such as freezing temperatures or physical damage. Regular inspections can help identify damaged pipes before they cause major issues, such as leaks, water damage, or even explosions. To inspect pipes, start by visually examining them for signs of damage, such as cracks, rust, or corrosion. Use a flashlight to illuminate hard-to-reach areas, and check for any water stains or mineral deposits that may indicate a leak. If you suspect a pipe is damaged, use a pipe inspection camera to get a closer look. This can help you identify the location and extent of the damage. If a pipe is damaged beyond repair, it's essential to replace it as soon as possible. Turn off the water supply to the affected area, and use a pipe cutter or hacksaw to remove the damaged section. Use a pipe wrench to loosen any corroded or stuck fittings, and apply pipe dope or Teflon tape to the new pipe to ensure a secure connection. When replacing a pipe, it's essential to use a pipe that matches the original material and size to ensure a proper fit and prevent future damage. Additionally, consider upgrading to a more durable material, such as PEX or copper, which can withstand corrosion and last longer. By inspecting and replacing damaged pipes, you can prevent costly repairs, reduce the risk of water damage, and ensure a safe and functional plumbing system.

Regularly Maintaining Pipe Systems

Regularly maintaining pipe systems is crucial to ensure they function efficiently and effectively. This involves inspecting pipes for signs of damage, corrosion, or blockages, and addressing any issues promptly. One way to maintain pipes is to use a pipe snake or plumber's auger to clear clogs and debris. Additionally, pipes should be insulated to prevent freezing and bursting during cold weather. It's also essential to check for leaks and repair them immediately to prevent water damage and waste. Furthermore, pipes should be flushed regularly to remove mineral buildup and sediment, which can cause corrosion and reduce water pressure. By performing these maintenance tasks, individuals can help extend the lifespan of their pipe systems, reduce the risk of costly repairs, and ensure a steady supply of clean water. Regular maintenance can also help identify potential issues before they become major problems, saving time and money in the long run. Overall, regularly maintaining pipe systems is a simple yet effective way to ensure they continue to function properly and efficiently.