How To Remove Deep Scratches From Stainless Steel

Stainless steel is a popular material for various applications, including kitchen appliances, cookware, and decorative items, due to its durability and resistance to corrosion. However, it's not immune to scratches, which can be particularly noticeable on its shiny surface. Deep scratches can be especially challenging to remove, but with the right techniques and materials, it's possible to restore your stainless steel items to their original condition. To successfully remove deep scratches from stainless steel, it's essential to understand the importance of preparation, the various removal methods available, and the necessary post-removal care and maintenance. Preparation is key to ensuring a smooth and effective removal process, and it's crucial to start by understanding the type of scratch and the material you're working with. By doing so, you'll be able to choose the most suitable removal method and achieve the best possible results. With that in mind, let's begin by discussing the importance of preparation.

Preparation is Key

Preparation is key to a successful repair job. When it comes to fixing a scratch on a surface, having the right mindset and materials is crucial. To ensure a seamless repair, it's essential to assess the scratch, clean the area, and gather necessary materials. By doing so, you'll be able to determine the best course of action and avoid any costly mistakes. Assessing the scratch will help you understand the extent of the damage and what type of repair is needed. This initial step will set the tone for the rest of the repair process, making it essential to get it right. So, let's start by assessing the scratch.

Assess the Scratch

Assessing the scratch is the first step in removing it. To do this, you'll need to examine the scratch carefully and determine its depth, length, and location. Check if the scratch is only on the surface or if it has penetrated the metal. If the scratch is shallow and only affects the surface, you may be able to remove it with a simple polishing compound. However, if the scratch is deeper or longer, you may need to use a more aggressive method, such as sanding or using a scratch remover. Additionally, consider the location of the scratch. If it's in a high-traffic area or a spot that's prone to moisture, you may need to take extra steps to ensure the repair lasts. By assessing the scratch, you'll be able to determine the best course of action and choose the right tools and techniques to remove it effectively.

Clean the Area

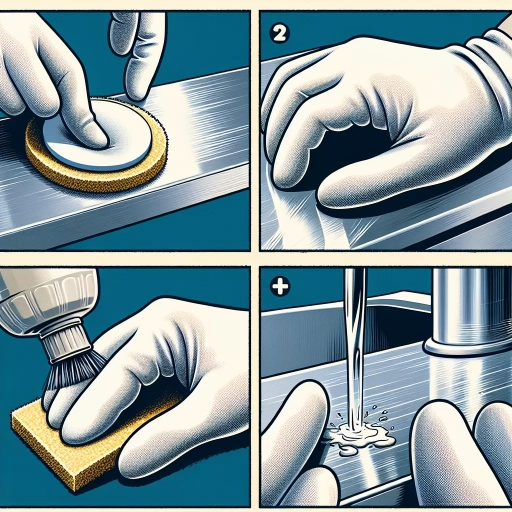

Cleaning the area around the scratch is crucial before attempting to remove it. Start by wiping down the stainless steel surface with a soft, dry cloth to remove any debris, dust, or dirt that may be accumulated. This will prevent any scratches or marks from getting worse during the removal process. Next, mix a solution of mild soap and warm water, and dip a soft cloth into it. Wring out the cloth thoroughly to avoid any excess moisture, and gently wipe down the area around the scratch. This will help loosen any dirt or grime that may be embedded in the scratch. Avoid using any harsh chemicals or abrasive cleaners, as they can damage the stainless steel surface. Once you've cleaned the area, dry it thoroughly with a soft cloth to prevent any water spots from forming. This will give you a clean slate to work with, and ensure that your scratch removal methods are effective.

Gather Necessary Materials

To effectively remove deep scratches from stainless steel, it is crucial to gather the necessary materials beforehand. This includes a variety of tools and supplies that will aid in the process. First and foremost, you will need a stainless steel scratch remover or a metal polish specifically designed for stainless steel. These products contain mild abrasives that help to remove scratches without damaging the surface. Additionally, you may need a soft cloth, such as a microfiber cloth, to apply the remover or polish and to buff the surface. A clean, soft-bristled brush can also be useful for applying the remover or polish to small, intricate areas. Furthermore, a stainless steel cleaning solution or a mixture of equal parts water and white vinegar can be used to clean the surface before and after the scratch removal process. It is also recommended to have a clean, dry cloth on hand to wipe away any excess remover or polish and to dry the surface. Optional materials may include a scratch removal kit, which usually includes a series of progressively finer abrasives, or a power buffer, which can be used to buff the surface to a high shine. By gathering all the necessary materials, you will be well-prepared to tackle the task of removing deep scratches from stainless steel.

Removal Methods for Deep Scratches

When it comes to dealing with deep scratches on surfaces, it's essential to have the right techniques and tools to restore the original appearance. Fortunately, there are several effective removal methods that can help eliminate these unsightly marks. Three popular approaches include using a scratch remover, applying a stainless steel polish, and utilizing a DIY scratch removal kit. Each of these methods has its unique benefits and can be tailored to specific types of scratches and surfaces. For instance, a scratch remover can be a quick and easy solution for minor scratches, while a stainless steel polish can provide a more thorough restoration for deeper scratches. On the other hand, a DIY scratch removal kit can offer a cost-effective and customizable approach. In this article, we will explore these methods in more detail, starting with the simplest and most convenient option: using a scratch remover.

Using a Scratch Remover

Using a scratch remover is a popular method for removing deep scratches from stainless steel surfaces. These products are specifically designed to fill in and blend scratches with the surrounding metal, making them nearly invisible. To use a scratch remover, start by cleaning the scratched area thoroughly with a mild detergent and water to remove any dirt or debris. Next, apply a small amount of the scratch remover to the affected area using a soft cloth, following the manufacturer's instructions. Gently rub the product into the scratch in a circular motion, applying moderate pressure. Continue to rub the area until the scratch is no longer visible or has significantly faded. Depending on the severity of the scratch, you may need to repeat the process several times to achieve the desired results. It's also important to note that not all scratch removers are created equal, and some may be more effective than others. Be sure to read reviews and follow the manufacturer's instructions carefully to ensure the best possible outcome. Additionally, some scratch removers may leave a residue or affect the finish of the stainless steel, so be sure to test a small area first to ensure compatibility. By using a scratch remover, you can effectively remove deep scratches from stainless steel surfaces and restore their original appearance.

Applying a Stainless Steel Polish

Applying a stainless steel polish is a crucial step in removing deep scratches from stainless steel surfaces. This process involves using a specialized polish that is designed to restore the metal's original shine and remove minor scratches. To apply a stainless steel polish, start by cleaning the scratched area thoroughly with a soft cloth and mild soap to remove any dirt or debris. Next, apply a small amount of polish to a clean, soft cloth and rub it into the scratched area in a circular motion. Be sure to follow the manufacturer's instructions for the recommended amount of polish to use and the desired level of shine. Continue to rub the polish into the scratched area until it is fully covered and the scratch is no longer visible. Finally, use a clean, dry cloth to buff the area and remove any excess polish, revealing a scratch-free and shiny surface. It's essential to note that not all stainless steel polishes are created equal, and some may be more effective than others at removing deep scratches. Therefore, it's crucial to choose a high-quality polish that is specifically designed for removing scratches from stainless steel surfaces. By following these steps and using the right polish, you can effectively remove deep scratches from your stainless steel surfaces and restore their original shine.

Utilizing a DIY Scratch Removal Kit

Utilizing a DIY scratch removal kit is a cost-effective and efficient way to remove deep scratches from stainless steel surfaces. These kits usually include a combination of polishing compounds, scratch removers, and applicators that can be used to restore the surface to its original condition. To use a DIY scratch removal kit, start by cleaning the scratched area thoroughly with a mild detergent and water to remove any dirt or debris. Next, apply the scratch remover or polishing compound to the affected area using the provided applicator, following the manufacturer's instructions. Gently rub the compound into the scratch using a circular motion, applying moderate pressure. Continue to rub the compound into the scratch until it is no longer visible, then wipe away any excess with a clean cloth. Depending on the depth and severity of the scratch, you may need to repeat the process several times to achieve the desired results. It's also important to note that DIY scratch removal kits may not be effective on very deep or severe scratches, and in such cases, it may be necessary to seek the help of a professional. However, for most minor to moderate scratches, a DIY scratch removal kit can be a convenient and effective solution.

Post-Removal Care and Maintenance

Proper post-removal care and maintenance are crucial to ensure the longevity and appearance of your newly restored surface. After removing stubborn stickers, decals, or adhesives, it's essential to follow a few simple steps to prevent damage and maintain the surface's quality. Regular cleaning and drying, applying a protective coating, and avoiding future scratches are all vital components of post-removal care. By incorporating these practices into your maintenance routine, you can prevent dirt and grime from accumulating, protect the surface from environmental factors, and reduce the risk of scratches and damage. To start, regular cleaning and drying are essential to remove any remaining residue and prevent water spots from forming.

Regular Cleaning and Drying

Regular cleaning and drying are crucial steps in maintaining the appearance and longevity of stainless steel surfaces, especially after removing deep scratches. To clean stainless steel, use a soft, lint-free cloth or sponge and a mild detergent solution. Avoid using abrasive materials, bleach, or harsh chemicals, as they can damage the surface or leave streaks. For tougher stains or grime buildup, a stainless steel cleaner or a mixture of equal parts water and white vinegar can be used. After cleaning, dry the surface thoroughly with a clean towel to prevent water spots. Regular cleaning and drying will help prevent the formation of new scratches and maintain the surface's shine and durability. Additionally, cleaning and drying can help prevent the growth of bacteria and other microorganisms that can thrive in moist environments, making it an essential step in maintaining hygiene and cleanliness. By incorporating regular cleaning and drying into your maintenance routine, you can ensure your stainless steel surfaces remain in excellent condition and continue to look their best.

Applying a Protective Coating

Applying a protective coating is a crucial step in maintaining the integrity and appearance of stainless steel surfaces after removing deep scratches. A protective coating serves as a barrier against environmental factors, such as moisture, salt, and chemicals, that can cause corrosion and damage. There are various types of protective coatings available, including wax, oil, and ceramic-based products. When selecting a protective coating, consider the level of protection required, the surface finish, and the environmental conditions the stainless steel will be exposed to. For example, a wax-based coating may be suitable for indoor applications, while a ceramic-based coating may be more suitable for outdoor or high-traffic areas. It is essential to follow the manufacturer's instructions for application and drying times to ensure a strong bond between the coating and the stainless steel surface. Regular reapplication of the protective coating is necessary to maintain its effectiveness, typically every 6-12 months, depending on the environmental conditions. Additionally, cleaning the stainless steel surface regularly with a mild detergent and water can help maintain the coating's integrity and prevent damage. By applying a protective coating, you can extend the lifespan of your stainless steel surface, prevent future scratches and damage, and maintain its original appearance.

Avoiding Future Scratches

To avoid future scratches on your stainless steel surface, it's essential to establish a regular cleaning and maintenance routine. Start by wiping down the surface with a soft, dry cloth after each use to remove any debris or residue. For more thorough cleaning, use a mild detergent and warm water, but avoid using abrasive materials or harsh chemicals that can damage the surface. Regularly drying the surface, especially after exposure to water or moisture, can also help prevent water spots and mineral deposits that can lead to scratches. Additionally, consider applying a stainless steel cleaner or polish to create a protective barrier against scratches and fingerprints. When cleaning, always use a soft, non-abrasive cloth or sponge, and avoid using circular motions that can create scratches. Instead, clean in straight lines, following the grain of the metal. By following these simple steps, you can help maintain the appearance of your stainless steel surface and prevent future scratches from occurring.