How Much Does A Fridge Weigh

Dealing with refrigerators can be weighty business, especially when you're trying to figure out how much these cooling giants actually weigh. The answer to this question is more complex than it seems, as the weight of a refrigerator is influenced by multiple factors. In fact, the weight of a refrigerator can be understood through three key angles. Firstly, understanding the basic design and manufacturing process of refrigerators can provide insight into what contributes to their weight. Secondly, the weight spectrum differs vastly in various types of refrigerators, warranting an analysis of their respective weights. Finally, the weight of a refrigerator can directly impact its functionality and portability, making it an essential factor to consider during purchase or transit. By exploring these aspects, we can define the true scale of these weighty kitchen mainstays, starting by peeling back the layers of their intricate design and manufacturing process.

Dealing with refrigerators can be weighty business, especially when you're trying to figure out how much these cooling giants actually weigh. The answer to this question is more complex than it seems, as the weight of a refrigerator is influenced by multiple factors. In fact, the weight of a refrigerator can be understood through three key angles. Firstly, understanding the basic design and manufacturing process of refrigerators can provide insight into what contributes to their weight. Secondly, the weight spectrum differs vastly in various types of refrigerators, warranting an analysis of their respective weights. Finally, the weight of a refrigerator can directly impact its functionality and portability, making it an essential factor to consider during purchase or transit. By exploring these aspects, we can define the true scale of these weighty kitchen mainstays, starting by peeling back the layers of their intricate design and manufacturing process.Understanding the Basic Design and Manufacturing Process of Refrigerators

At the epicenter of every modern household stands a marvel of scientific innovation - the refrigerator. This vital appliance, often underappreciated, incorporates exemplary design and advanced manufacturing processes, peculiar to its function and efficiency. Our in-depth exploration takes us through three main facets of refrigerator production: the materials used in its construction, the steps involved in the production process, and the design parameters that impact its weight. To begin with, refrigerators are constructed from a variety of robust and efficient materials. These materials are specifically chosen to ensure the appliance's durability, energy efficiency, and aesthetic appeal. A peak into the construction phase will elaborate on the complexities involved in the assemblage of these materials. We will delve into how these materials are manipulated to form the final product, paying specific attention to how the design parameters affect the overall weight of the appliance. The meticulous planning and precision that goes into the design stage becomes evident here, as each parameter is carefully considered to balance the appliance's performance and manageability. These aspects combined create an exquisite balance of performance, function, and design that is emblematic of modern refrigerators. Stay with us as we embark on a thorough examination, beginning with the materials crucial to the construction of these indispensable household appliances.

1. Materials used in the Construction of Refrigerators

1.

Materials Used in the Construction of Refrigerators

The construction of refrigerators involves diverse materials that play a vital role in the overall function, efficiency, and lifespan of the appliance. These are chosen meticulously based not only on their durability but also on their thermal properties, cost-effectiveness, and environmental impacts. Primarily, the core of the refrigerator – the body, doors, and the interior paneling, are constructed using high-quality steel. This material is preferred due to its structural strength and robustness, essential attributes for an appliance expected to last for several years. Additionally, steel possesses excellent thermal properties, enabling it to maintain the desired temperature inside the refrigerator effectively. The insulation material sandwiched between the steel layers significantly enhances the energy efficiency of refrigerators. Polyurethane foam is predominantly used as it exhibits exceptional insulating properties and resistance to deformation over time. This foam fills every tiny space within the refrigerator's walls, ensuring virtually no air leaks and minimum heat transfer between the exterior and interior environments. Moreover, the interior shelves and compartments are typically made of high-strength glass and durable plastics. The glass shelves are often tempered, providing increased resilience against weight and impact. The plastic components, on the other hand, are commonly crafted from Acrylonitrile Butadiene Styrene (ABS), known for its toughness, hardness, gloss, and electrical insulation properties. The refrigerant, the heart of a refrigerator's cooling system, consists of a substance called hydrofluorocarbon (HFC), which facilitates cooling by absorbing and releasing heat. However, due to environmental concerns, there's a growing trend towards using natural refrigerants like hydrocarbons, particularly propane and isobutane. To bind these constituents together, adhesives like epoxy resins are used due to their high resistance against temperature changes and their superb mechanical and electric insulated properties. In conclusion, the assortment of different materials used in refrigerator construction collaboratively work to ensure longevity, energy efficiency, and optimal cooling performance. Keeping this information in mind places an intriguing perspective on the significant factors contributing to refrigerator design and weight.2. The Production Process

The Production Process

The production process of a refrigerator is both intricate and intricate, involving a fusion of cutting-edge technology and skilled craftsmanship. It all starts with meticulous design planning, where potential models are conceived and blueprints developed. This stage focusses on optimizing the design for energy efficiency, user accessibility, and durability while ensuring it aligns with the aesthetic and functional preferences of the target consumer demographic. Once the design is finalized, the manufacturing process commences. Initially, a coil of metal is cut and formed into the refrigerator's body and door panels. Advanced machinery then moulds these panels into their proper shapes, ensuring each bend and fold meet precision standards. In the next step, the distinctive exterior coating is applied to provide the refrigerator's desired appearance and offer durability against wear and tear. Inside the assembly line, the fridge's insulation process is put into motion. The chosen insulation material, often polyurethane foam, is meticulously inserted into the panel gaps to maximize the appliance's cooling efficiency. Simultaneously, essential electrical components like the compressor, condenser and evaporator coils are assembled and incorporated into the structure. Next, the refrigerator's inner cabinet is prepared. Metal racks and compartments are fastened securely, ensuring optimal space utilization and user convenience. The heart of the refrigerator, the cooling system, is expertly installed. This system involves a delicate balance of its compressor, condenser, expansion valve, and evaporator. They work in unison to ensure the fridge maintains a conducive environment for food preservation. The penultimate step in the production process is the addition of the refrigerator's control panel. This panel houses the appliance's thermostat and other control settings which allow users to manage the fridge's temperature and other functions effectively. Here, software and hardware are merged for user-friendly interaction and efficient performance. The final stage of the manufacturing process is rigorous quality control testing. Every refrigerator undergoes a spectrum of tests to ensure it satisfies performance benchmarks, safe operation protocols, and energy-efficiency ratings before being approved for shipment to retailers. Thus, the production process entails a harmonious marriage of sophisticated technology and impeccable workmanship, reflecting significant labor and resources. It all serves to uphold the refrigerator's attribute of being a household cornerstone— a reliable, efficient, and aesthetic presence that makes the kitchen feel complete.3. Design Parameters Impacting Weight

Design parameters significantly impact the overall weight of a refrigerator. First and foremost, the size of the fridge plays a considerable role. Larger models have more parts and materials, causing them to be considerably heavier. The scale of the refrigerator, including its width, height, and depth, directly correlates with its weight. For instance, larger French door and side-by-side models usually weigh more than compact or under-counter units. Second, the material composition of the refrigerator can also influence its weight. Commonly, fridges are constructed from heavy-duty materials like steel and hard plastic, which contribute significantly to the weight. Luxury models that feature glass doors or stainless steel interiors will be heavier due to the denser pieces involved. Thirdly, the fridge's additional features and systems can add to the weight. Factors such as ice maker units, water dispensers, and advanced cooling systems add up and influence the unit's overall weight. Complex refrigeration systems that involve multiple fans, large compressors, or intricate coolant lines will be heavier due to these additional parts. Overall, these design parameters combine to affect the final weight of the refrigerator. As consumers seek refrigerators with more features and larger capacities, the need for lightweight yet durable materials becomes even more critical. Manufacturers must strive to balance design needs and material availability with the inherent challenge of keeping appliance weight manageable. Through strategic design choices and innovative material use, manufacturers can create refrigerators that meet consumers' needs without becoming overly heavy or unwieldy. Ultimately, understanding the design parameters that influence fridge weight allows consumers to make more informed decisions when purchasing these essential appliances.

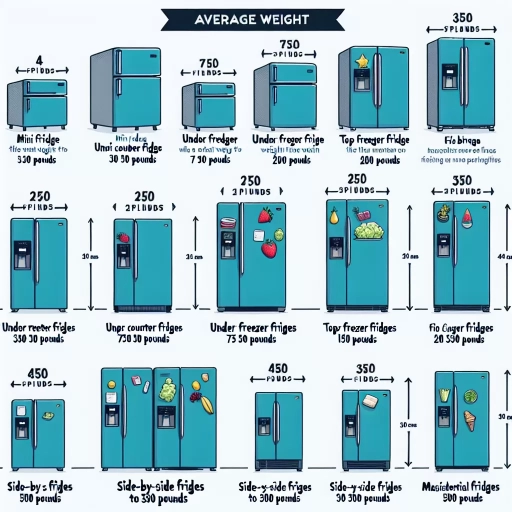

Analysing the Weight of Different Types of Refrigerators

Understanding the weight of different types of refrigerators enables consumers to make informed choices based on their specific needs and circumstances. Refrigerators, undoubtedly indispensable appliances in every household, come in a myriad of designs, each varying in weight due to size, materials used, and the technology embedded within. This article will delve into the weight analysis of three primary types of refrigerators - Single Door, Double Door, and Side-by-Side Refrigerators. These three models embody a wide spectrum of the market, each catering to varied consumer needs, and provide a compelling snapshot into the weight considerations that users should pay attention to when shopping for a refrigerator. Let's kick off our exploration with an in-depth study of the Single Door Refrigerators, the most compact and lightweight option among the three, and a favorite among those living alone or with limited space.

1. Single Door Refrigerators

Single door refrigerators are popular as they offer great efficiency and compact design, making them ideal for smaller households or areas where space is at a premium. In terms of weight, these refrigerators are generally lighter when compared to their double door or side-by-side counterparts. Single door refrigerators often weigh between 100 to 200 pounds, depending on the model and the features included. One of its main characteristics is the one-door design, where the freezer compartment is incorporated inside the main fridge area, reducing its overall weight. This design offers a unique advantage in terms of energy consumption, making single-door refrigerators more energy-efficient. Less cooling is lost since the freezer is not accessed frequently, which reduces the fridge's energy consumption. Though they may lack the storage capacity of larger models, they make up for it in less weight, lower energy consumption, and overall suitable for those on a budget. However, it’s important to note that a lot depends on the materials used in manufacturing the refrigerator, added features, and the overall size. For instance, some high-end single door refrigerators that feature glass shelving, metal bodies, sophisticated cooling technologies, and electronic interfaces might weigh more than the simpler plastic models. In terms of innovative additions, certain models include features like vegetable crispers, built-in water dispensers, quick freeze compartments, and advanced temperature control systems, all factors that could potentially add to the weight. Understanding the weight of a single door fridge is practical not just for delivery and installation reasons but also if you're considering the rigidity of your flooring or if you're planning to move. Those who live in upper-floor apartments or houses on pillars might prefer these lighter, more manageable models. It’s also a vital consideration when it comes to energy consumption, as heavier fridges tend to consume more power. Therefore, while single door refrigerators might lack space compared to other types, they compensate by being compact, lightweight, and energy-efficient. The exact weight of the refrigerator will vary from model to model, so users must do their research and decide what works best for their needs. This knowledge helps one in making informed decisions about the product that suits their lifestyle and requirements.

2. Double Door Refrigerators

Double Door Refrigerators are a popular type of fridge that have carved their niche in the kitchen appliance space for their combination of style and functionality. As part of the broader refrigerator family, they offer unique weight considerations in our analysis of the weight of different types of refrigerators. On average, a typical double door refrigerator can weigh anywhere between 180 to 350 pounds (roughly 80 to 160 kilograms). This weight range depends on several factors, including the refrigerator's size, materials used, technological features, and the type of cooling system installed. Double door refrigerators are known for their spaciousness. They usually feature a side-by-side or a top-and-bottom design, with separate doors for the fridge and freezer sections. This means they have a larger capacity compared to single-door units, accommodating more items and thereby influencing the appliance's overall weight. Additionally, the materials used in constructing these refrigerators, like high-grade steel, durable plastic, and insulation materials, also add substantial weight. Furthermore, double door refrigerators often come packed with advanced technological features. These might include water and ice dispensers, digital temperature controls, air filtration systems, and energy-saving mechanisms– all of which could add to the overall weight of the refrigerator. Overall, when examining the weight of double door refrigerators, it’s essential to account for the additional elements they bring to the table. While these refrigerators are heavier than their single-door counterparts, their ability to offer greater storage capacity, advanced features, and aesthetic appeal justifies their weight. Investing in a double door refrigerator not only beats the space constraints in your kitchen but also brings a modern edge, proving that their slightly heavier weight can be a worthy trade-off for the benefits they provide.

3. Side-by-Side Refrigerators

Side-by-side refrigerators are a popular choice among homeowners for their sleek design and functional capacities. They present a modern and sophisticated appearance, often adding a touch of class to the kitchen spaces they inhabit. Their defining feature is the vertical split design, creating two distinct sections - the freezer on one side and the refrigeration unit on the other. An average side-by-side refrigerator can hold between 20 to 29 cubic feet of space, making them one of the more spacious options when it comes to refrigerators. They are typically wider than traditional models and are more adept at storing large or irregular-shaped items. Examining the weight, side-by-side refrigerators are substantially heavier than their top-freezer or bottom-freezer counterparts. On average, they weigh anywhere between 250 to 350 lbs, depending on their size and the materials used in their construction. The heavier weight is often because these models come with more features such as water and ice dispensers, temperature-controlled compartments, and adjustable shelves and bins. The weight of a side-by-side refrigerator could potentially affect several aspects. For instance, it could influence the installation process as heavier models require more personnel or equipment to move and install. Also, the weight could impact the type of flooring suitable for the kitchen, as heavy appliances put more strain on the floor. However, consumers often overlook the weight in their buying decisions, prioritizing instead the benefits that a side-by-side refrigerator brings to their lifestyle. The unique configuration of these refrigerators allows for organized storage and easy accessibility. Frozen foods are at eye level and can be retrieved without bending down, a benefit appreciated by those with back issues. In the final analysis, while the weight of side-by-side refrigerators is greater than some other types of fridges, the bonus of improved functionality, organization, and design often justifies this additional weight. As a result, for those willing to accommodate the heavier apparatus, side-by-side refrigerators offer a compelling combination of style and efficiency.

How Does the Weight of a Refrigerator Impact its Functionality and Portability?

The interplay between a refrigerator's weight and its functionality and portability carries more implications than one might presume at first glance. Paramount among these are crucial factors such as energy efficiency, cooling capacity, and the overall mobility of the appliance. The weight of the refrigerator is not merely a dimension of size, but it is linked substantially with its energy consumption and efficiency. That is to say, heavier refrigerators may lean towards being more energy-intensive and less efficient. Likewise, it's essential not to overlook the strong relationship existing between a refrigerator's weight and its cooling capacity. This bond underpins the performance and effectiveness of your cooling machine fundamentally. Lastly, a weighty consideration hinges on the portability of your refrigerator. As a rule of thumb, heavier fridges are harder to move and transport, presenting a potential limitation for some consumers. As we sail into the depth of this discourse, our first port of call will be the intriguing correlation between weight and energy efficiency. Can more massive refrigerators really be energy guzzlers? Let's find out.

1. Correlation Between Weight and Energy Efficiency

Understanding the correlation between weight and energy efficiency in refrigerators is crucial in determining their functionality and portability. The weight of a fridge doesn't just dictate its size or capacity; it also significantly influences the fridge's overall energy efficiency. With the ever-increasing call for sustainable practices, manufacturers are putting their focus on producing lighter, energy-efficient models that guarantee optimal performance without overloading energy consumption. Energy efficiency is affected by several aspects of a refrigerator's construction, of which weight is a dominant factor. The absorption refrigeration process, used by many contemporary refrigerators, is particularly influenced by overall system weight. Refrigerators that are heavier tend to have larger compressors and insulation systems, which can lead to higher energy consumption. It is because these components need more power to maintain the refrigeration cycle, hence impacting the energy efficiency. On the other hand, lighter refrigerators are designed with compact and efficient components that operate using less power. The decreased weight comes from using advanced insulation materials, smaller but proficient compressors, and innovative techniques to optimize internal space. The result is an appliance that offers the necessary cooling services while minimizing energy consumption. It's worth noting that a lighter refrigerator doesn't necessarily guarantee energy-efficiency, though. It needs to stand up to other energy efficiency parameters. Notably, the lighter refrigerator can also enhance portability. Lower weight can often mean easier maneuverability and less strain on flooring, making relocation or transport significantly less troublesome. In conclusion, while choosing a refrigerator, understanding the correlation between weight and energy efficiency plays a vital role. Although there are other energy efficiency parameters to consider, the weight is a significant factor that contributes to the overall power efficiency, functionality, and more importantly, the fridge's portability. Manufacturers are therefore constantly innovating to strike a balance between these elements to provide appliances that meet consumer expectations and regulatory standards.

2. Weight Versus Cooling Capacity

When discussing the weight of a refrigerator, it is important to also consider its cooling capacity. These two factors are significantly linked; a larger cooling capacity often results in a heavier fridge. This is primarily because a refrigerator with a higher cooling capacity might need to have a more robust and heavier built compressor, larger heat exchanger systems, and intricate insulation mechanisms—all of which can contribute to the overall weight of the appliance. Furthermore, refrigerators are designed to keep the temperature consistent to preserve food for an extended period. This function demands a high level of energy efficiency. A heavy-duty fridge that can keep a large volume of food cool without constantly consuming energy needs to have a robust structure, including a thick door, high-quality insulation, and a sizable capacity compressor. All these elements inadvertently add to the refrigerator’s weight. Despite the increased weight, the upside of an enhanced cooling capacity is an improved performance. Larger refrigerators can maintain precision in temperature regulation and work efficiently in various environmental conditions. They also hold more substantial quantities of food, which can be beneficial for families. However, the increased weight can negatively impact the refrigerator's portability. A heavier fridge is difficult to maneuver and requires more effort when moving it either within your house or during relocation. This factor can discourage customers who prioritize ease of movability. Therefore, users must carefully balance their needs: if a high cooling capacity and energy efficiency are priorities, a heavier refrigerator may be worth the trade-off. In conclusion, the relationship between a refrigerator's weight and its cooling capacity tends to be directly proportional and influences various aspects of its functionality and portability. Considering these factors when purchasing a refrigerator could ensure your expectations align with the fridge's performance and ease of use.

3. The Effect of Weight on the Portability of a Refrigerator

In the examination of the overall functionality and portability of a refrigerator, the weight of the unit is a fundamental factor to consider. The impact of a refrigerator's weight on its portability can be quantified in different dimensions - moving within a household setting, transporting during a house move, or even shipping for a retailer or manufacturer. Firstly, in a household setting, a refrigerator's weight plays a crucial role. In scenarios like remodelling or reorganizing kitchen space, the weight of the fridge can significantly impact the ease or difficulty of the process. Lighter refrigerators can be swiftly relocated, facilitating an immediate transformation of one's kitchen layout. However, overly heavy refrigerators may require multiple individuals or professional assistance to move, adding to the task's complexity. Furthermore, during a house move, the impact of weight on a fridge's portability becomes highly relevant. The processes of packing, loading, transporting, unloading, and unpacking can be burdensome with heavier fridges. This impact could translate into increased physical effort, time consumption, and potentially higher moving costs. Therefore, homeowners keen on preserving their energy, time, and financial resources may opt for lighter fridge models that promise easier portability. Lastly, from the viewpoint of retailers and manufacturers, the weight of refrigerators affects their distribution and shipping. Decreased weight often implies decreased shipping costs - a key factor in maintaining competitive pricing in the market. On the other hand, heavier models may translate into higher logistical expenses, which can challenge profitability and market price competitiveness. Therefore, manufacturers and retailers are constantly innovating to design fridges that are light yet efficient. In conclusion, the weight of a refrigerator isn't just a specification in a product brochure, it has real-world implications on the product's portability and user experience. From remodeling a kitchen to planning a move, to the world of logistics and market competition, the weight of a fridge significantly impacts its functionality and portability.