How To Make Blast Furnace

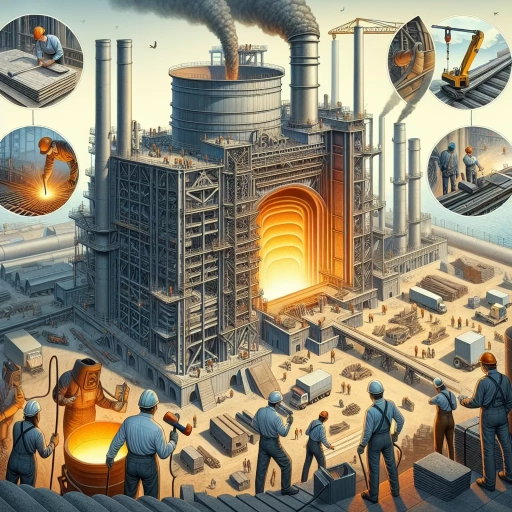

Creating a blast furnace, an essential tool in smelting and the production of iron, may seem like an intimidating task. However, with the right knowledge, resources, and safety precautions, it's definitely achievable. In this informative, engaging, and high-quality how-to guide, you will gain a comprehensive understanding of the intricacies involved in successfully constructing your personal blast furnace. The journey begins by delving into the 'Fundamentals of a Blast Furnace', a hidden world explored through the lens of science and engineering. With this foundation, we will then guide your hands in 'Constructing Your Own Blast Furnace', a step-by-step guide that offers practical and cost-effective solutions. Simultaneously, the paramount importance of safety cannot be overstated. Hence, our final section will highlight crucial 'Safety Precautions and Maintenance of a Blast Furnace.' By the end of this guide, you'll possess an actionable blueprint for constructing and maintaining your own blast furnace. Allow us to guide you into the fascinating world of metallurgy, starting with understanding the fundamentals of a blast furnace.

Creating a blast furnace, an essential tool in smelting and the production of iron, may seem like an intimidating task. However, with the right knowledge, resources, and safety precautions, it's definitely achievable. In this informative, engaging, and high-quality how-to guide, you will gain a comprehensive understanding of the intricacies involved in successfully constructing your personal blast furnace. The journey begins by delving into the 'Fundamentals of a Blast Furnace', a hidden world explored through the lens of science and engineering. With this foundation, we will then guide your hands in 'Constructing Your Own Blast Furnace', a step-by-step guide that offers practical and cost-effective solutions. Simultaneously, the paramount importance of safety cannot be overstated. Hence, our final section will highlight crucial 'Safety Precautions and Maintenance of a Blast Furnace.' By the end of this guide, you'll possess an actionable blueprint for constructing and maintaining your own blast furnace. Allow us to guide you into the fascinating world of metallurgy, starting with understanding the fundamentals of a blast furnace.Understanding the Fundamentals of a Blast Furnace

Understanding the fundamentals of a Blast Furnace is crucial for anyone working in heavy industries, particularly in metal processing. This powerful piece of machinery plays an integral role in the production of iron and steel, driving global economies with its prowess. To fully grasp the importance and mechanics of a Blast Furnace, one must delve into its basic structure, comprehend its operational methods, and understand the materials required building one. The structure of a Blast Furnace is a marvel in itself, designed to withstand extreme environments while ensuring optimal functionality. Furthermore, its operations consist of complex mechanisms that convert raw materials into molten iron. Even the choice of materials to build a Blast Furnace is a precise science that requires careful consideration. As we dive into the nitty-gritty of these substantial gadgets, we'll begin by scrutinizing its overall structure which is key to understanding a Blast Furnace's full potential. This will equip us with the necessary context before moving on to the operation methods and materials used in its construction. There’s an intriguing story behind each detail, which is both fascinating and enlightening.

The Basic Structure of a Blast Furnace

A blast furnace is an iconic structure in the world of metallurgy, serving as the vital lifeline for transforming raw materials into valuable fe products– like pig iron. This structure, a revered representative of industrial revolution, has been intricately designed to withstand harsh and extreme temperatures while maintaining an effortless functionality. Understanding its basic structure unveils the ingenious engineering involved in its creation and operation. At the heart of a blast furnace, standing proud and tall, is the stack. It's typically around 30 meters high, which allows ample space for several layers of raw materials - iron ore, coke, and limestone - to co-exist. The stack is lined with refractory bricks that are chemically and thermally resistant and enables it to withstand the intense heat produced within. The summit of the stack, known as the 'throat' takes in the raw materials. Following a methodical system, these materials are layered in, starting with coke at the bottom to create a high-heat environment, followed with alternating layers of iron ore and limestone. This carefully calculated stratification plays an essential role in the efficient operation of the blast furnace. As you move down, you reach the ‘belly’ and ‘bosh’. These areas see some of the most intense actions as temperatures here shoot much higher - almost up to 2000°C – forcing the raw materials to react with each other. Coke burns in the incoming hot air, producing carbon monoxide which then reacts with the iron ore, reducing it to molten iron. The lowest region of the blast furnace is the hearth, where the two major by-products, molten iron and slag, collect. These are periodically tapped from the hearth through tap holes. It’s important to note it's also in the hearth where the blast of air, crucial for the furnace’s operation, is introduced via tuyeres. Then we have the outer part - the shell, a steel casing that basically holds everything together. This part is not just a container, but it also acts as a heat insulator ensuring minimal heat loss from the furnace. To conclude, a blast furnace is an architectural marvel and emblem of human engineering skill. Understanding its basic structure reiterates how every inch and corner, every brick and layer, every air entry and exit, and every temperature variant within the furnace comes together to convert raw ores into a material that essentially kickstarted the industrial age –iron. While its name may suggest an alarming nature, the blast furnace is substantially a system of harmonious components working relentlessly in unison.

The Operations of a Blast Furnace

Blast furnaces are fundamental to the production of iron and steel, their operational mechanism harnessing a fascinating blend of science and engineering. The blast furnace is no ordinary furnace; it is a giant steel stack lined with refractory bricks engineered to withstand the searing temperatures generated. The furnace is filled with iron ore, coke, and limestone which act as vital elements in this intense chemical reaction that results in molten iron or pig iron. The function of the blast furnace is rooted in the smelting process. The iron ore, primarily iron oxide, is introduced into the furnace from the top, gradually descending into the hotter sections of the furnace. Simultaneously, jets of hot air, heaving with reducing elements like CO and H2, are blasted into the furnace bottom, hence the name 'blast furnace'. These air blasts ascend upwards, reacting with the descending iron ore and coke, reducing the iron ore into pure iron and emitting slag and gas in the process. Another critical element is the coke, a form of carbon obtained by heating coal. As it burns, the hot coke produces carbon monoxide. This carbon monoxide then reacts with the iron ore, reducing it to metallic iron. However, refining iron is not the sole purpose of coke. Its consistent granulated structure permits a free flow of gases through the charge, feeding the blast furnace with a steady stream of hot air. It also creates a strong physical structure for the load-bearing burden in the furnace, essentially holding everything in place. Limestone, the third ingredient, plays a pivotal role too. In the furnace, it decomposes to calcium oxide and carbon dioxide. The calcium oxide reacts with silicon oxide (impurities in the iron ore) to form calcium silicate, also known as slag. This slag, lighter than molten iron, floats above the molten iron and is outwardly drained from the furnace. The pig iron yielded from the blast furnace, while useful, still contains too much carbon and impurities for direct utilisation. So it continues its journey towards further refinement to become steel, embodying the persistence and resilience that steel signifies. Understanding the production processes of key materials like iron and steel through the operation of a blast furnace bridges the gap between esoteric science and its practical applications. After all, it’s not just a story of molten ore and fiery furnaces — this is the tale of human civilization's stride towards progress.

Materials Required to Build a Blast Furnace

High-quality, resilient materials are crucial in constructing a blast furnace, given its pivotal role in metallurgy. These furnaces operate under extreme conditions; they need to withstand not just the physical demands of housing the blast but also the severe heat produced during the extraction of iron from its ore. In the heart of the furnace construction is refractory brick, a particular kind of brick with an exceptional tolerance for heat. It forms the interior lining of the blast furnace and endures temperatures typically surpassing 2000 degrees Celsius. The external structure is built of steel, known for its impressive strength and durability required to support and encapsulate the internal components. Carbon blocks, also known as hearth blocks, are positioned at the bottom of the blast furnace, and these are subjected to the intense temperatures and corrosive elements. Thus, they are of superior quality to withstand this stress. The furnace also requires a complex system of pipes and valves created from robust steel and heat-resistant alloys. One cannot overlook the crucial role of the tuyeres, through which hot air is blasted into the furnace. These tuyeres are made of copper, possessing excellent heat transfer properties and resistance to corrosion. Lastly, the entire framework is insulated appropriately to ensure efficient operation and reduce the risk of heat leakage endangering the surroundings. This insulation layer typically incorporates ceramic materials due to their incredible heat resistance. To sum up, building a blast furnace is no small task. The materials required are carefully chosen for their capability to sustain the rigors of the blast furnace's environment, empowering continuous and efficient metal extraction. Without these specially selected materials, the goal of understanding and harnessing the power of the blast furnace would be impossible. Any aspiring metallurgist must appreciate the significance of these materials and their unique properties that make the blast furnace not merely conceivable, but a reality contributing immensely to modern manufacturing and infrastructure. The blast furnace stands as a testament to human ingenuity and our limitless potential for creating and shaping our world.

Constructing Your Own Blast Furnace

Constructing your own blast furnace can be a challenging, yet rewarding venture. It involves careful planning, efficient gathering of pertinent materials and tools, and a meticulous approach towards its actual construction. Initially, a proper layout plan for the blast furnace must be devised. This will serve as your blueprint in organizing the crucial elements and the physical space of the furnace. From the height, diameter, and shape of the furnace to its tuyeres and slag-tap arch, every structure has a strategic role. Acquisition of the necessary materials and tools follows suit. Appropriate choices of these instrumental factors could mean the difference between a highly functional blast furnace and an inefficient one. Materials range from heat-resistant bricks to a robust metallic base, while tools can include construction basics like hammer, chisel and marking tools. Finally, the actual steps in constructing your blast furnace must be carried out with precision and patience. Expect an iterative process as you adjust and tailor the furnace to ensure optimal functionality. Now let's delve into one of the most critical preliminary steps - planning the blast furnace layout.

Planning the Blast Furnace Layout

Planning the Blast Furnace Layout: As you embark on the journey of constructing your own blast furnace, it’s essential to meticulously plan the layout in advance. The blueprint of your furnace sets the groundwork for efficiency, productivity, and safety, and this stage demands attentive planning, research and precision. Begin by optimizing space usage and convenient placement of each major component. The heart of the unit, the hearth, is where molten iron and slag accumulate before their discharge. Its design should consider factors such as operating temperature, the desired volume of production, available space, and the provision for regular removal of waste. The bosh (where iron oxides are reduced to metallic iron), the stack (the upper furnace shaft) and the top-cone (chute for feeding input materials) also require strategic positioning. Nearer to the ground, the tuyeres—small pipes supplying the hot blast to the furnace—should be symmetrically placed around the hearth, maintaining a calculated distance from each other and the furnace wall to facilitate uniform heat distribution. Furthermore, consider accessibility for regular maintenance and safety precautions. Areas for inspection, like the taphole for releasing molten iron and slag, should be easy to reach and safe. Allow space for safety equipment and fire-resistant materials in the surrounding areas to minimize potential hazards. Implementing feedback control systems to monitor temperature, pressure, and the composition of raw materials and output can markedly improve furnace efficiency. Automated systems for the hot blast stoves (to preheat air blown into the furnace), raw material feed, and discharge of products also demand careful planning and place in the layout. Lastly, planning for environmental control is paramount. Techniques for waste heat recovery, dust collection, and efficient gas cleaning should be incorporated into the layout. Doing so reduces environmental impact and can turn waste into useful byproducts. In conclusion, planning the blast furnace layout is a meticulously strategic and critical step in your furnace construction, directly impacting its efficiency, safety, and environmental friendliness. And by fully understanding the function of each component, you'll be in a stronger position to decide their optimal placement within your furnace's blueprint.

Gathering Materials and Tools for Construction

Gathering the correct materials and tools for the construction of your own blast furnace is a critical step that should be approached with caution and serious consideration. Ensuring that you have everything required before you commence the project not only enables you to create a high-quality furnace but also leads to a smoother, more efficient construction process. To effectively construct a blast furnace, an array of both common and specialized materials are needed. These materials include bricks -preferably fire bricks due to their excellent heat resistance- and steel to form the furnace's structure. Specific heat-resistant materials like refractory cement are also essential for lining the furnace's interior to mitigate the impact of high temperatures. Besides, to facilitate the smelting process, you'll need a powerful air source. A typical choice is a leaf blower or an industrial blower, prized for their prolific air output, but remember to ensure it has feasible speed control. Crucibles made of graphite or other similar materials resistant to high temperature are additional necessities for safely containing the molten metal. As far as tools are concerned, you will require a comprised set that includes basic construction tools such as a trowel to apply the refractory cement, a protective pair of gloves for safety, and a brick saw or angle grinder for shaping your bricks. You might also need equipment for metalworking like a welding machine or metal cutters as your blast furnace takes shape. Larger or heavy-duty projects may require the use of advanced machinery or power tools. Consulting with an expert or conducting exhaustive research on handling such tools is always recommended to prevent any potentially harmful scenarios. Collecting adequate materials and tools gives you leverage to construct a durable, efficient blast furnace that can withstand the high heats produced during the smelting process and ensure safety. Managing the quality and type of materials, your choice of tools, and your overall approach in gathering them will decide the longevity and effectiveness of your furnace. By meticulously planning and obtaining the right resources, you're brightly paving the way for building a trustworthy and reliable blast furnace of your own, marking a significant step in your journey of understanding and appreciating the intricate workings of metallurgy.

Steps in Constructing a Blast Furnace

Constructing your own blast furnace requires a systematic and meticulous process, with an understanding of the various steps instrumental in ensuring optimal results. The first step in this complex procedure is the design phase. Here, a blueprint of the furnace is created, taking into consideration the furnace size, materials to be used, and the inherent technology requirements. Paramount in this stage is the analysis of the end goal- determining what materials will be smelted, thereby influencing the furnace's size and specifications. The second step involves the site selection and preparation. The blast furnace demands a site that can endure high temperatures and bear heavy loads. A foundational base is created, often from concrete, to guarantee stability and resilience. Also vital at this stage is the consideration of safety measures such as an efficient ventilation system and safety exits. The third phase of construction involves the assembly of the furnace. This is where the preciseness of the blueprint comes into play. The furnace is typically layered with a series of refractory bricks to tolerate the high heat. The furnace's heart, the crucible, is then assembled. It’s usually made from graphite or ceramic to withstand the inferno inside the furnace. The fourth step constitutes the construction of the air supply system. A blast furnace operates on the principle of extreme heat generated by forced air, aiding in melting down the charge. Hence, a powerful and efficient air blower is installed, capable of withstanding the furnace's demanding needs. Lastly, a cooling system is integrated to cool down the furnace post-operation. It often includes a water-cooling system that encircles the crucible. The system is designed to avoid any thermal shocks to the furnace due to rapid temperature changes. In conclusion, constructing a blast furnace is an intricate process that necessitates a deep understanding of the furnace's working principles and careful execution of each phase. Once constructed, the blast furnace can convert raw materials into pure and useful metals, a testament to the fruits of meticulous planning and diligent execution.

Safety Precautions and Maintenance of a Blast Furnace

Blast Furnaces are complex pieces of machinery that require careful handling. Their operation is not just a matter of controlling the temperature and the volume of materials; it is a complex process requiring a keen understanding of safety provisions and diligent maintenance. In this detailed guide, we dive deep into the critical safety precautions one must adhere to while using a blast furnace, the routine maintenance checks crucial for its functioning and longevity, and the precise technique of correctly shutting it down to avoid any possible hazards. Understanding and implementing these three aspects effectively will ensure you can operate a blast furnace smoothly and safely. We kick things off with the key safety measures, which forms the bedrock of any successful operation of a blast furnace.

Important Safety Measures While Using a Blast Furnace

Working with a blast furnace involves the handling of high temperatures, heavy metals, and other potentially dangerous elements, thus, following safety measures is not just a consideration, it's an absolute necessity. Each step in the operation of a blast furnace, from start-up to shutdown, requires a high level of care and attention to protective protocols, not only to prevent personal injury but also to avoid damage to the furnace itself. Primary among these precautions is the usage of personal protective equipment (PPE) like protective suits, gloves, and face shields. These pieces of protection prevent exposure to heat and prevent burns from molten material. Flame-retardant materials used in making PPE can provide substantial protection against extreme temperatures. Access to the area around the blast furnace should be restricted to trained personnel only, allowing for controlled movement that mitigates risks. To aid this, physical barriers, lock-out procedures, and signage can assist in steering clear of unauthorized personnel. Close monitoring of the internal temperature is another critical aspect. Various online thermal imaging systems and temperature monitoring tools should be leveraged for real-time monitoring. Deviations from the normal operating range could signal potential troubles that may lead to disastrous situations if not handled immediately. Maintenance routines for a blast furnace should be precisely planned and executed. Regular inspections are vital to flag and fix issues, avoiding larger problems down the line. These should include thorough checks on all parts of the furnace, looking for any signs of wear and tear and replacing parts as necessary. Employing and enforcing these safety measures goes hand in hand with the proper training of staff. Personnel should be well-versed in the correct operational procedures, emergency responses, and maintenance tasks. Understanding these measures and the potential consequences of negligence reduces the risk of both immediate and latent hazards. In short, the safe operation of a blast furnace calls for a judicious balance of precaution, vigilance, and training. When these elements work in sync, the chances of accidents dramatically reduce, ensuring the furnace's optimal performance while securing the environment for those involved.

Routine Maintenance Checks for a Blast Furnace

Understanding the safety precautions and maintenance steps for a blast furnace operation is crucial, and among them, routine maintenance checks stand out exceptionally. Regular monitoring and upkeep can help ensure the furnace's longevity, increase productivity, reduce unexpected breakdowns, and most importantly, ward off potentially hazardous situations. A blast furnace is a massive structure which involves a complex blend of different processes, designed to extract iron from its ore. The overall furnace's functionality relies heavily on the condition of its internal components, which need to be diligently maintained. The lack of frequent checks can lead to devastating malfunctions or dangerous reactions that could compromise people's safety and the efficiency of the operations. The heart of the routine maintenance check revolves around certain key areas. Firstly, checking the condition of the refractory lining is crucial as it works as a protective barrier to endure the extreme heat generated during the smelting process. It ensures the furnace walls are protected from wear-and-tear or any damage. Any weakening in this lining can expose the exterior parts of the furnace to higher temperatures, leading to a structural failure. Secondly, the appropriate maintenance of the furnace's tuyeres, which are water-cooled copper nozzles that inject a stream of air into the furnace, is essential. Regular maintenance checks need to ensure there is no blockage or damage to these components. Any complications can disrupt the blast of air, affecting the chemical reactions inside the furnace. A disrupted air supply can also lead to ineffective combustion and, ultimately, a drop in productivity. Further, the burden distribution at the top of the furnace, which refers to the layers of coke, flux, and iron ore, also needs to be keenly monitored. An irregular burden distribution can lead to inefficiencies, costing both time and resources. Lastly, monitoring the furnace’s gas cleaning system is crucial. This system removes particulate matter and harmful gases from the blast furnace, ensuring effective venting of the furnace gases and maintaining a safe working environment. Any disruptions in its efficient functioning could have severe environmental implications. It is important to remember that these are only some of the areas to consider during regular maintenance checks. Each blast furnace is unique and may require additional attention to specific components. A routine inspection and maintenance check is not an add-on but a necessity to ensure safety, efficiency, and long-term sustainability for your blast furnace operation. Regular training for teams, investment in automated control systems, and maintenance schedules should be an integral part of any blast furnace operation. Through diligent monitoring and maintenance, blast furnaces can prove to be both a profitable and safe component of the metals industry. This brief look into routine maintenance checks for a blast furnace stresses their importance within the full discussion on safety precautions and maintenance of a blast furnace. Continued operation and peak efficiency of a blast furnace can be ensured with the institution of structured maintenance procedures based on regular checks and timely interventions.

The Correct Way to Shut Down a Blast Furnace

The correct procedure for shutting down a blast furnace ensures not just its longevity, but also safeguards the entire workforce from potential hazards. This complex process, often referred to as 'blowing out', requires extensive pre-planning and meticulous execution. Essentially, a gradual decrease in the feed of raw materials is first initiated, followed by the closing off of the tuyeres - the vents through which hot air is injected into the furnace. However, this is just scratching the surface. Experience has proven that an abrupt halt can lead to significant repercussions. This includes the rupture of the furnace, due to pressure build-up, or damage to the interior lining due to sudden cooling. Hence, a mindful reduction in operations is instrumental. With the significant reduction in temperature and pressure, the contents of the furnace turn less volatile, reducing the risk of unpredictable reactions. But shutting down is only part of the story. Ensuring a safe cooling period is equally important. This procedure, known as 'banking', involves reducing the air blast and maintaining a low temperature to allow the furnace to cool slowly and prevent damage to the refractory brick lining. Constant monitoring of temperatures at various points within the furnace is vital during this stage. Any abnormal variations could signal complications that need to be addressed promptly. Maintenance of the blast furnace plays an equally crucial role during this phase. Depositing protective layers of specific materials like sand or dolomite can shield the inner lining from drastic temperature changes and prevent thermal shock. Moreover, the removal and disposal of residual slag, the byproduct of the process, must be done professionally to avert contamination hazards. Lastly, involving the entire workforce in the shutdown process is critical. Implementing regular training sessions can equip them with the knowledge to handle contingency situations. The utilization of protective equipment, adherence to safety protocols, and maintaining strict supervision during each step irons out the margin for errors, ensuring a safe and successful shutdown of the blast furnace.