How To Bend Wood

Wood bending is a fascinating and rewarding woodworking technique that allows craftsmen to create unique and complex shapes from wood. By applying heat, moisture, and pressure, wood can be bent into various forms, from simple curves to intricate designs. However, bending wood requires a deep understanding of the process, as well as careful preparation and attention to safety. To master the art of wood bending, it's essential to start with the basics, understanding the fundamental principles of how wood responds to different bending techniques. This includes knowing the types of wood that are best suited for bending, the importance of grain direction, and the role of moisture in the bending process. With a solid foundation in the basics, you can then move on to preparing your wood for bending, selecting the right tools and materials, and applying the necessary techniques to achieve the desired shape. By following these steps and taking the necessary safety precautions, you can unlock the full potential of wood bending and create truly remarkable pieces. Understanding the basics of wood bending is the first step in this journey, and it's where we'll begin.

Understanding the Basics of Wood Bending

Wood bending is a fascinating technique that allows craftsmen to create unique and intricate designs from wood. To master this skill, it's essential to understand the basics of wood bending, including the types of wood suitable for bending, the importance of understanding wood grain, and the basic tools and equipment needed for the process. Different types of wood have varying levels of flexibility, and some are more suitable for bending than others. Understanding the characteristics of different wood species is crucial in selecting the right wood for a project. Additionally, the grain of the wood plays a significant role in determining its flexibility and stability. Knowing how to work with the grain can make a huge difference in the success of a wood bending project. Furthermore, having the right tools and equipment is vital in achieving the desired shape and form. By understanding these fundamental aspects of wood bending, craftsmen can unlock the full potential of this technique and create stunning pieces of art. With this in mind, let's start by exploring the types of wood suitable for bending.

Types of Wood Suitable for Bending

Wood suitable for bending can be categorized into several types, each with its unique characteristics and properties. One of the most popular types is hardwood, which is denser and heavier than softwood. Hardwoods like oak, maple, and ash are ideal for bending due to their strength and stability. They can withstand the stress and pressure of bending without breaking or cracking. Softwoods, on the other hand, are less dense and more prone to splitting, making them less suitable for bending. However, some softwoods like pine and spruce can still be used for bending, especially when steamed or heated to increase their flexibility. Another type of wood suitable for bending is engineered wood, which is made from layers of wood fibers or strands pressed together. Engineered wood is often used for curved furniture and architectural features due to its stability and resistance to warping. Lastly, some exotic hardwoods like ebony and rosewood are also suitable for bending, but they can be more expensive and challenging to work with due to their density and hardness. Ultimately, the type of wood chosen for bending depends on the specific project requirements, the desired level of flexibility, and the level of expertise of the woodworker.

Understanding Wood Grain and Its Impact on Bending

Understanding wood grain is crucial when it comes to bending wood, as it directly affects the wood's ability to bend and its overall appearance. Wood grain refers to the pattern of wood fibers that run along the length of a tree trunk. There are two main types of wood grain: straight grain and irregular grain. Straight grain wood has fibers that run parallel to each other, while irregular grain wood has fibers that twist and turn in different directions. When bending wood, it's essential to work with the grain, as bending against the grain can cause the wood to crack or break. The direction of the grain also affects the wood's strength and stability, with wood bent in the direction of the grain being stronger and more stable than wood bent against the grain. Furthermore, the type of wood grain can also impact the appearance of the bent wood, with straight grain wood producing a more uniform and smooth curve, while irregular grain wood can create a more unique and rustic look. By understanding the characteristics of different wood grains, woodworkers can better predict how their wood will behave when bent, allowing them to achieve the desired shape and appearance.

Basic Tools and Equipment Needed for Wood Bending

To successfully bend wood, you'll need a few basic tools and equipment. A heat source, such as a steam box or a heat gun, is essential for softening the wood and making it pliable. A bending iron or a metal strap can be used to shape the wood into the desired curve. A strongback or a bending form is necessary to hold the wood in place while it cools and sets. Clamps, such as bar clamps or pipe clamps, are used to secure the wood to the strongback or bending form. A thermometer is also useful for monitoring the temperature of the wood and ensuring it reaches the optimal temperature for bending. Additionally, a moisture meter can be used to check the moisture content of the wood, which is important for achieving successful bending. Safety equipment, such as gloves and safety glasses, should also be worn to protect yourself from burns and other injuries. A workbench or a stable surface is also necessary for supporting the wood and the bending equipment. Finally, a mallet or a hammer can be used to tap the wood into place and ensure it is securely fastened to the strongback or bending form.

Preparing Wood for the Bending Process

Preparing wood for the bending process is a crucial step in creating curved or bent wood components for various applications, including furniture making, woodworking, and construction. To achieve successful bending, wood must be properly prepared to increase its flexibility and reduce the risk of cracking or breaking. There are several methods to prepare wood for bending, including steaming, chemical treatments, and designing and cutting the wood to optimize its bending capabilities. Steaming wood is a popular method that involves exposing the wood to high temperatures and humidity to increase its flexibility. Chemical treatments, on the other hand, involve applying specialized chemicals to the wood to enhance its flexibility. Designing and cutting the wood to optimize its bending capabilities is also essential, as it allows woodworkers to create curved components with precision and accuracy. By understanding these methods, woodworkers can prepare wood for bending and create complex curved components with ease. Steaming wood, in particular, is a highly effective method that can increase wood flexibility, making it an ideal choice for many woodworking applications.

Steaming Wood to Increase Flexibility

Steaming wood is a popular method used to increase flexibility in wood, making it easier to bend and shape into desired forms. This process involves exposing the wood to high-temperature steam, which helps to break down the lignin, a natural glue that holds the wood fibers together. As the lignin breaks down, the wood becomes more pliable and flexible, allowing it to be bent and shaped without cracking or breaking. The steaming process typically involves placing the wood in a steam box or chamber, where it is exposed to steam for a period of time, usually ranging from 30 minutes to several hours. The length of time the wood is steamed will depend on the type of wood, its thickness, and the desired level of flexibility. Once the wood has been steamed, it is removed from the steam box and immediately bent into the desired shape, while it is still warm and pliable. The wood is then held in place with clamps or other holding devices, allowing it to cool and set in its new shape. Steaming wood is a highly effective method for increasing flexibility, and is often used in woodworking applications such as furniture making, boat building, and musical instrument construction.

Using Chemical Treatments to Enhance Wood Flexibility

Using chemical treatments is a common method to enhance wood flexibility, making it more pliable and easier to bend. One of the most popular chemical treatments is steaming, which involves exposing the wood to high-temperature steam to break down the lignin, a natural glue that holds the wood fibers together. This process makes the wood more flexible and receptive to bending. Another chemical treatment is the use of ammonia, which is applied to the wood to break down the lignin and increase its flexibility. The ammonia treatment is often used in combination with heat to enhance its effectiveness. Chemical treatments can be applied to various types of wood, including hardwoods and softwoods, and can be used to achieve different levels of flexibility depending on the desired outcome. However, it's essential to note that chemical treatments can also affect the wood's color, texture, and strength, so it's crucial to carefully consider the type of treatment and its potential effects on the wood before applying it. Additionally, chemical treatments may require specialized equipment and safety precautions, so it's recommended to seek professional guidance or follow established protocols to ensure safe and effective treatment. By using chemical treatments, woodworkers can achieve the desired level of flexibility and create complex curved shapes that would be difficult or impossible to achieve through other methods.

Designing and Cutting Wood to Optimize Bending

Designing and cutting wood to optimize bending is a crucial step in the wood bending process. To achieve a successful bend, it's essential to consider the wood's grain direction, moisture content, and thickness. The grain direction should be parallel to the bend, as this allows the wood to flex more easily. The moisture content should be between 6-12%, as this range provides the optimal balance between flexibility and stability. The thickness of the wood should be consistent, as uneven thickness can cause the wood to bend unevenly. When cutting the wood, it's best to use a sharp blade and a precise cutting technique to minimize waste and prevent damage to the wood. The cutting pattern should be designed to minimize the number of cuts, as each cut can create a weak point in the wood. A curved cutting pattern can help to reduce the number of cuts and create a smoother bend. Additionally, using a template or jig can help to ensure accurate cuts and a consistent bend. By carefully designing and cutting the wood, you can optimize the bending process and achieve a strong, stable, and visually appealing curved wood piece.

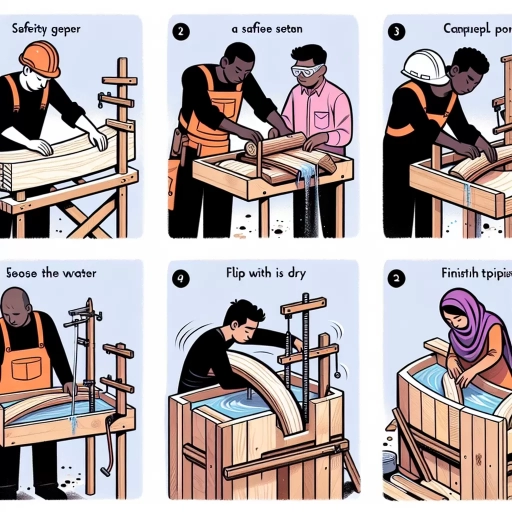

Techniques and Safety Precautions for Bending Wood

Bending wood is a delicate process that requires precision, patience, and attention to safety. To achieve professional-looking results, woodworkers must employ the right techniques and take necessary precautions. Three essential methods for bending wood include using a wood bending iron for precise control, applying even pressure with a bending form, and ensuring safety with protective gear and workspace setup. By mastering these techniques, woodworkers can create intricate designs and shapes with confidence. One of the most critical aspects of wood bending is achieving precise control over the bending process, which is where a wood bending iron comes into play. With its ability to heat and shape wood with precision, a wood bending iron is an indispensable tool for any woodworker looking to create complex curves and bends. By using a wood bending iron, woodworkers can achieve the level of control and accuracy needed to produce high-quality, professional-looking results.

Using a Wood Bending Iron for Precise Control

Using a wood bending iron is a technique that requires precision and control to achieve the desired shape and curve. A wood bending iron is a specialized tool that uses heat to soften the wood, making it pliable and easier to bend. To use a wood bending iron effectively, it's essential to understand the principles of heat transfer and the properties of the wood being bent. The iron should be heated to the optimal temperature, usually between 200°F to 300°F, depending on the type of wood and the desired curve. The wood should be slowly and carefully bent, using a combination of gentle pressure and controlled heat, to achieve the precise shape and curve. It's crucial to monitor the temperature and the wood's moisture content to avoid overheating or underheating, which can cause the wood to crack or become brittle. By using a wood bending iron with precise control, woodworkers can create intricate and complex curves, making it an essential tool for furniture making, woodworking, and other crafts that require curved wood components.

Applying Even Pressure with a Bending Form

When applying even pressure with a bending form, it's essential to ensure that the wood is evenly supported throughout the bending process. This can be achieved by using a combination of cauls, straps, and wedges to distribute the pressure uniformly. Cauls are flat, rigid pieces of material that are placed on either side of the wood to prevent it from becoming misshapen or developing uneven pressure points. Straps, on the other hand, are used to hold the wood in place and maintain even pressure along the length of the bend. Wedges can be used to fine-tune the pressure and make adjustments as needed. By using these tools in conjunction with a well-designed bending form, you can apply even pressure to the wood and achieve a smooth, consistent curve. It's also important to monitor the wood's moisture content and adjust the pressure accordingly, as wood that is too dry or too wet may not bend evenly. Additionally, it's crucial to work slowly and carefully, making gradual adjustments to the pressure as needed, to avoid applying too much pressure and causing the wood to crack or break. By taking the time to set up the bending form correctly and applying even pressure, you can achieve professional-looking results and create beautiful, curved wood pieces.

Ensuring Safety with Protective Gear and Workspace Setup

Ensuring safety is a crucial aspect of bending wood, as it involves working with sharp tools, hot equipment, and potentially hazardous materials. To minimize the risk of injury, it is essential to wear protective gear and set up a safe workspace. A dust mask or respirator should be worn to prevent inhalation of wood dust and other airborne particles. Safety glasses or goggles protect the eyes from flying debris and chemical splashes. A first aid kit should be readily available in case of accidents. A well-ventilated workspace is also vital, as it helps to remove fumes and particles from the air. The workspace should be clear of clutter and tripping hazards, with a stable and heat-resistant surface for working on. A fire extinguisher and a bucket of sand or a heat-resistant mat should be nearby in case of emergencies. Additionally, it is recommended to wear long sleeves, gloves, and closed-toe shoes to prevent skin contact with chemicals and hot equipment. By taking these precautions, woodworkers can ensure a safe and successful bending process.