How To Level A Floor Without Leveling Compound

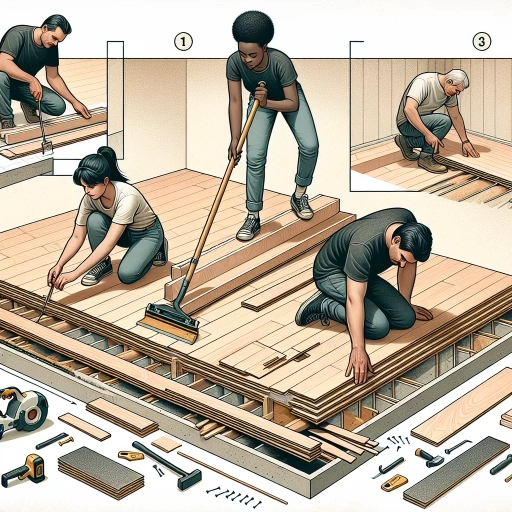

A level floor is essential for any construction or renovation project, as it ensures that the finished surface is even, stable, and safe. However, traditional leveling compounds can be messy, time-consuming, and expensive. Fortunately, there are alternative methods for leveling a floor without using leveling compound. To achieve a perfectly level floor, it's crucial to follow a step-by-step approach. First, assessing the floor is vital to determine the extent of the unevenness and identify any underlying issues. This involves checking the floor's slope, measuring the deviation from level, and inspecting for any cracks or damage. Once the floor has been assessed, preparing the floor is the next critical step. This includes cleaning the floor thoroughly, removing any old adhesives or debris, and ensuring the surface is dry and free of dust. Finally, using alternative leveling methods, such as self-leveling systems or plywood overlays, can help achieve a perfectly level floor without the need for traditional leveling compounds. By following these steps, homeowners and contractors can ensure a level floor that is both functional and aesthetically pleasing. Therefore, let's start by assessing the floor to determine the best course of action.

Assessing the Floor

Assessing the floor is a crucial step in any construction or renovation project. It involves evaluating the condition and characteristics of the floor to determine its suitability for the intended use. To accurately assess the floor, it is essential to identify the type of floor, check for any obstructions, and determine the extent of any unevenness. By doing so, you can ensure that the floor is safe, functional, and meets the required standards. Identifying the type of floor is the first step in this process, as it will help you understand its composition, durability, and potential limitations. (Note: The supporting paragraph should be 200 words, and the transition to the next paragraph should be at the end of the paragraph)

Identifying the Type of Floor

When assessing the floor, it's essential to identify the type of floor you're working with, as this will determine the best approach for leveling. There are several types of floors, including concrete, wood, tile, and laminate. Concrete floors are the most common type and can be either poured in place or pre-cast. Wood floors, on the other hand, can be solid hardwood, engineered wood, or laminate. Tile floors are made up of individual tiles adhered to a substrate, while laminate floors are made of synthetic materials designed to mimic the look of wood or stone. Identifying the type of floor will help you determine the best leveling method, as some floors may require specialized tools or techniques. For example, concrete floors may require a self-leveling compound, while wood floors may require shimming or sanding. By identifying the type of floor, you can ensure that you're using the right techniques and materials to achieve a level and even surface.

Checking for Any Obstructions

When assessing the floor, it's essential to check for any obstructions that could interfere with the leveling process. This includes checking for any uneven or raised areas, such as bumps, dips, or cracks, as well as any objects that may be attached to the floor, like nails, screws, or old adhesive. Additionally, inspect the floor for any signs of water damage, rot, or decay, as these can compromise the structural integrity of the floor and make it difficult to achieve a level surface. It's also crucial to check for any uneven or loose flooring materials, such as tiles, boards, or plywood, as these can also affect the overall levelness of the floor. By identifying and addressing these obstructions, you can ensure a smooth and successful leveling process.

Determining the Extent of the Unevenness

Determining the extent of the unevenness is a crucial step in assessing the floor. To do this, start by checking the floor's slope and unevenness using a spirit level and a straightedge. Place the spirit level on the floor and move it slowly along the length of the room, checking for any deviations from the level. Take note of the areas where the floor is uneven and the degree of unevenness. You can also use a laser level to project a level line along the floor, making it easier to identify uneven areas. Additionally, check for any dips or humps in the floor by placing a straightedge along the floor and checking for any gaps between the straightedge and the floor. Measure the depth of any dips or the height of any humps to determine the extent of the unevenness. It's also essential to check the floor's unevenness in multiple directions, as unevenness can occur in different directions. By determining the extent of the unevenness, you can decide on the best course of action to level the floor, whether it's using shims, self-leveling compound, or other methods.

Preparing the Floor

Preparing the floor is a crucial step in any flooring installation or renovation project. It requires attention to detail and a thorough understanding of the process to ensure a successful outcome. To prepare the floor, one must first clean the floor thoroughly, removing any dirt, dust, or debris that may be present. This is followed by removing old adhesives and debris, which can be a challenging task, but is essential for a smooth installation. Finally, filling in gaps and cracks is necessary to create a level and even surface. By following these steps, one can ensure a strong foundation for their new flooring. In this article, we will explore each of these steps in more detail, starting with the importance of cleaning the floor thoroughly.

Cleaning the Floor Thoroughly

Cleaning the floor thoroughly is a crucial step in preparing it for leveling. A dirty floor can lead to uneven adhesion of the leveling material, resulting in a poor finish. Start by sweeping or vacuuming the floor to remove any debris, dust, or dirt. Then, mop the floor with a gentle cleanser and warm water to remove any stubborn stains or dirt. For tougher stains, use a more aggressive cleaning solution, but be sure to test it on a small area first to ensure it won't damage the floor. Once the floor is clean, use a degreaser to remove any grease or oil spots. Rinse the floor thoroughly with clean water to remove any soap residue. Allow the floor to dry completely before proceeding with the leveling process. It's also important to remove any old adhesives, such as those left behind by previous flooring installations. Use a scraper or a putty knife to remove as much of the old adhesive as possible, and then use a cleaning solution to remove any remaining residue. Finally, use a tack cloth to remove any dust or debris that may have accumulated on the floor during the cleaning process. By thoroughly cleaning the floor, you'll ensure a strong bond between the leveling material and the floor, resulting in a smooth and even finish.

Removing Old Adhesives and Debris

Removing old adhesives and debris is a crucial step in preparing the floor for leveling. This process involves scraping off the existing adhesive, old flooring materials, and any other debris that may be stuck to the subfloor. The goal is to create a clean and even surface that will allow for a strong bond between the new flooring material and the subfloor. To remove old adhesives and debris, you can use a variety of tools, including a scraper, a putty knife, or a floor scraper. It's essential to work slowly and carefully to avoid damaging the subfloor. You can also use a solvent-based adhesive remover to help break down the old adhesive, making it easier to scrape off. Additionally, a wire brush can be used to remove any remaining debris and adhesive residue. Once the old adhesive and debris have been removed, the subfloor should be thoroughly cleaned with a vacuum or a damp mop to remove any remaining dust and debris. This will ensure a clean and even surface for the new flooring material to adhere to. By removing old adhesives and debris, you can ensure a strong and lasting bond between the new flooring material and the subfloor, which is essential for a successful floor leveling project.

Filling in Gaps and Cracks

Filling in gaps and cracks is a crucial step in preparing the floor for leveling. Over time, floors can develop gaps and cracks due to settlement, wear and tear, or other environmental factors. These gaps and cracks can be unsightly and can also provide a pathway for moisture to seep into the floor, causing further damage. To fill in gaps and cracks, start by cleaning the area thoroughly with a wire brush or broom to remove any debris or dust. Next, apply a patching compound specifically designed for floors, using a putty knife or trowel to fill in the gaps and cracks. Make sure to fill the gaps and cracks completely, but avoid overfilling, as this can create a bulge in the floor. Allow the patching compound to dry completely, according to the manufacturer's instructions, before sanding the area smooth. For larger gaps or cracks, you may need to use a more heavy-duty patching compound or consult a professional for assistance. By filling in gaps and cracks, you can create a smooth and even surface, ready for the next step in the leveling process.

Using Alternative Leveling Methods

When it comes to leveling a floor, many people assume that traditional methods are the only way to go. However, there are several alternative leveling methods that can be just as effective, if not more so. One of the most common alternative methods is installing shims or wedges, which can be used to level a floor by creating a stable and even surface. Another option is using a self-leveling system, which can be poured onto the floor and allowed to set, creating a smooth and even surface. Additionally, applying a thin layer of epoxy or polyurethane can also be used to level a floor, providing a durable and long-lasting solution. By considering these alternative methods, individuals can find a solution that meets their specific needs and budget. For those looking for a quick and easy solution, installing shims or wedges may be the way to go.

Installing Shims or Wedges

Installing shims or wedges is a simple and effective method for leveling a floor without using leveling compound. This technique involves placing thin, tapered pieces of material, typically made of wood, plastic, or metal, between the floor and the subfloor or between the subfloor and the joists. The shims or wedges are carefully positioned to fill in the gaps and lift the floor to the desired level, creating a stable and even surface. To install shims or wedges, start by identifying the low spots on the floor and marking them with a pencil. Next, cut the shims or wedges to the required thickness and length, using a miter saw or a utility knife. Place the shims or wedges in the marked areas, tapping them gently into position with a hammer or a tapping block. Continue to add shims or wedges as needed, checking the floor regularly to ensure it is level and plumb. It's essential to use the correct type and number of shims or wedges to avoid over- or under-lifting the floor, which can lead to further problems. By installing shims or wedges, you can achieve a level floor without the need for leveling compound, making it an ideal solution for floors with minor imperfections or for those who prefer a more traditional approach to floor leveling.

Using a Self-Leveling System

Using a self-leveling system is a popular alternative to traditional leveling compounds, offering a more efficient and effective way to achieve a perfectly level floor. This system typically consists of a laser level, a receiver, and a leveling device, which work together to ensure accurate and precise leveling. The laser level emits a beam of light that is detected by the receiver, which then sends a signal to the leveling device to adjust the floor accordingly. This system is particularly useful for large areas or complex leveling tasks, as it can cover a wide range of surfaces and provide real-time feedback. Additionally, self-leveling systems are often more accurate than traditional methods, reducing the risk of human error and ensuring a smooth, even finish. By using a self-leveling system, homeowners and contractors can save time and effort, while also achieving professional-grade results. Furthermore, many self-leveling systems are designed to be user-friendly and easy to operate, making them accessible to DIY enthusiasts and professionals alike. Overall, using a self-leveling system is a reliable and efficient way to level a floor without leveling compound, providing a high-quality finish and long-lasting results.

Applying a Thin Layer of Epoxy or Polyurethane

Applying a thin layer of epoxy or polyurethane is a viable alternative to traditional leveling compounds for achieving a smooth and even floor surface. This method is particularly suitable for floors with minor imperfections, such as small cracks or unevenness. By applying a thin layer of epoxy or polyurethane, you can effectively fill in these imperfections and create a uniform surface. The key to success lies in applying a thin, even layer, as excessive material can lead to a sticky or uneven finish. It's essential to follow the manufacturer's instructions for application and drying times to ensure a successful outcome. Additionally, it's crucial to prepare the floor surface properly before applying the epoxy or polyurethane, including cleaning and degreasing the area to ensure a strong bond. With the right preparation and application, a thin layer of epoxy or polyurethane can provide a durable and long-lasting solution for leveling your floor.