How To Cut Abs Pipe

Cutting ABS pipe can be a daunting task, especially for those who are new to plumbing or DIY projects. However, with the right techniques and preparation, it can be a straightforward process. To achieve professional-looking results, it's essential to understand the importance of preparation, cutting techniques, and post-cutting procedures. In this article, we will delve into the world of ABS pipe cutting, exploring the key steps to take before making the cut, the various techniques to use when cutting, and the necessary procedures to follow after the cut has been made. By mastering these three crucial aspects, you'll be well on your way to cutting ABS pipe like a pro. So, let's start with the foundation of successful ABS pipe cutting: preparation is key.

Preparation is Key

Preparation is key to achieving success in various aspects of life, including DIY projects, sports, and even business ventures. When it comes to DIY projects, having the right mindset and preparation can make all the difference between a successful outcome and a disastrous one. To ensure a smooth and safe experience, it is essential to choose the right tool for the job, measure twice and cut once to avoid costly mistakes, and wear protective gear to prevent injuries. By doing so, individuals can minimize risks, save time and resources, and achieve their desired results. In this article, we will explore the importance of preparation in DIY projects, starting with the crucial step of choosing the right tool for the job.

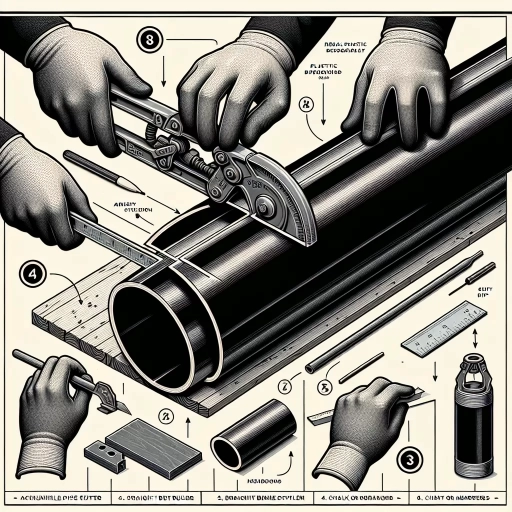

Choose the Right Tool for the Job

When it comes to cutting ABS pipe, having the right tool for the job is crucial. A good quality pipe cutter or hacksaw is essential for making clean, precise cuts. A pipe cutter is a specialized tool designed specifically for cutting plastic pipes, and it works by scoring the pipe and then breaking it off. This is the best option for cutting ABS pipe, as it produces a clean, smooth cut with minimal risk of cracking or shattering. A hacksaw can also be used, but it requires more effort and can be more prone to errors. It's also important to choose a tool that is suitable for the size and type of pipe you are working with. For example, a pipe cutter with a smaller blade may be better suited for smaller pipes, while a larger blade may be needed for larger pipes. Additionally, it's a good idea to have a deburring tool on hand to remove any rough edges or burrs that may be left after cutting. By choosing the right tool for the job, you can ensure a successful and safe cutting process.

Measure Twice, Cut Once

The age-old adage "measure twice, cut once" is a timeless wisdom that holds immense significance in various aspects of life, including DIY projects, carpentry, and even everyday decision-making. This simple yet profound phrase serves as a poignant reminder of the importance of meticulous planning, attention to detail, and patience. When it comes to cutting ABS pipe, this mantra is particularly relevant, as a single misstep can lead to costly mistakes, wasted materials, and frustration. By taking the time to measure twice, you ensure that your cuts are accurate, precise, and tailored to your specific needs. This, in turn, saves you from the hassle of re-cutting, re-measuring, and re-fitting, ultimately streamlining your workflow and yielding professional-grade results. Moreover, the "measure twice, cut once" approach fosters a mindset of diligence and responsibility, encouraging you to think critically and consider the potential consequences of your actions. By embracing this philosophy, you'll not only become a more skilled and confident DIY enthusiast but also develop a valuable skillset that can be applied to various areas of your life. So, the next time you're about to cut that ABS pipe, remember: measure twice, cut once, and reap the rewards of precision, efficiency, and pride in your work.

Wear Protective Gear

Wearing protective gear is a crucial step in preparing to cut ABS pipe. This type of pipe is made from a rigid plastic material that can be brittle and prone to cracking, which can lead to sharp edges and flying debris when cut. To protect yourself from these hazards, it's essential to wear the right gear. Start with safety glasses or goggles that have a wraparound lens to prevent debris from entering your eyes from the side. A face mask or respirator can also help prevent inhalation of dust and particles that can be released during the cutting process. Additionally, wear long sleeves, gloves, and pants to protect your skin from cuts and abrasions. A dust mask can also be worn to prevent inhalation of dust and particles. Steel-toed boots or shoes with slip-resistant soles can help prevent foot injuries from heavy objects or slippery surfaces. By wearing the right protective gear, you can minimize the risk of injury and ensure a safe and successful ABS pipe cutting experience.

Cutting Techniques for ABS Pipe

When it comes to cutting ABS pipe, having the right techniques is crucial for a successful project. Whether you're a seasoned plumber or a DIY enthusiast, mastering the art of cutting ABS pipe can make all the difference in the quality of your work. In this article, we'll explore three essential cutting techniques for ABS pipe: using a miter saw for clean cuts, utilizing a pipe cutter for precise cuts, and applying a hacksaw for tough cuts. By understanding these techniques, you'll be able to tackle even the most challenging ABS pipe projects with confidence. From making precise angled cuts to navigating complex pipe configurations, these techniques will help you achieve professional-grade results. So, let's dive in and start with the first technique: using a miter saw for clean cuts.

Using a Miter Saw for Clean Cuts

Using a miter saw for clean cuts is a great way to achieve precise and professional-looking results when working with ABS pipe. A miter saw is a specialized power tool designed specifically for making precise angled cuts in various materials, including plastic pipes. To use a miter saw for cutting ABS pipe, start by setting the saw to the desired angle, typically 90 degrees for a straight cut. Next, place the pipe on the saw's table, ensuring it is securely held in place by the saw's clamps or a non-slip mat. Slowly lower the saw blade through the pipe, applying gentle to moderate pressure, depending on the pipe's thickness and the saw's power. It's essential to maintain a steady and consistent motion to avoid applying too much pressure, which can cause the pipe to bind or the saw to kickback. As the saw blade cuts through the pipe, it will produce a clean and smooth edge, free from burrs or rough spots. To achieve the best results, use a high-quality miter saw with a sharp blade specifically designed for cutting plastic pipes. Additionally, always follow the manufacturer's instructions and safety guidelines when operating a miter saw, and wear protective gear, such as safety glasses and a dust mask, to prevent injury. By using a miter saw for clean cuts, you can ensure accurate and professional-looking results when working with ABS pipe, making it an ideal tool for various plumbing and DIY projects.

Utilizing a Pipe Cutter for Precise Cuts

When it comes to cutting ABS pipe, utilizing a pipe cutter is a highly effective method for achieving precise cuts. A pipe cutter is a specialized tool designed specifically for cutting through plastic pipes, including ABS, with ease and accuracy. To use a pipe cutter, simply place the pipe into the cutter's jaws, ensuring it is centered and secure. Then, tighten the cutter's handle to apply pressure, and slowly rotate the cutter around the pipe while maintaining consistent pressure. This will create a clean, smooth cut through the pipe. One of the key benefits of using a pipe cutter is its ability to produce precise cuts, which is essential for ensuring a secure and leak-free connection. Additionally, pipe cutters are often faster and more efficient than other cutting methods, making them an ideal choice for professionals and DIYers alike. By investing in a high-quality pipe cutter, individuals can achieve professional-grade results and ensure their ABS pipe projects are completed to the highest standards. Furthermore, pipe cutters are also versatile and can be used to cut a variety of pipe sizes and types, making them a valuable addition to any toolkit. Overall, utilizing a pipe cutter is a reliable and efficient method for cutting ABS pipe, and is an essential technique for anyone working with this type of material.

Applying a Hacksaw for Tough Cuts

When tackling tough cuts on ABS pipes, a hacksaw is often the go-to tool for many professionals and DIYers alike. To apply a hacksaw effectively, start by ensuring the pipe is securely clamped in place to prevent any movement during the cutting process. Next, select the correct blade for the job, choosing one with a high tooth count (around 18-24 teeth per inch) for a smoother cut. Position the hacksaw at a 45-degree angle to the pipe, with the blade facing the direction you want the pipe to fall. Hold the saw firmly, but not too tightly, and begin to make slow, steady strokes, applying gentle to moderate pressure. As you cut, maintain a consistent pace and avoid applying too much pressure, which can cause the blade to bind or the pipe to crack. To make the cut even smoother, use a lubricant such as oil or wax on the blade, and consider using a pipe cutter or miter box to help guide the saw and ensure a straight cut. By following these steps and using the right technique, you can make tough cuts on ABS pipes with ease and accuracy using a hacksaw.

Post-Cutting Procedures

When it comes to post-cutting procedures, there are several crucial steps that must be taken to ensure the quality and safety of the cut pipe. After cutting a pipe, it is essential to follow a series of procedures to prepare it for assembly and use. Three key post-cutting procedures that are often overlooked but are vital to the overall quality of the pipe are deburring the cut edge, inspecting the cut for smoothness, and preparing the pipe for assembly. Deburring the cut edge is a critical step that involves removing any sharp edges or burrs that may have formed during the cutting process. This is important because sharp edges can be hazardous and can also affect the overall performance of the pipe. By deburring the cut edge, you can ensure a smooth and safe surface for assembly and use. In fact, deburring the cut edge is the first step in the post-cutting process, and it is essential to get it right to ensure the quality of the pipe.

Deburring the Cut Edge

Deburring the cut edge is a crucial step in the post-cutting process of ABS pipe. It involves removing any rough or sharp edges that may have formed during the cutting process. This is important because sharp edges can be hazardous and can also cause damage to other components or fittings that the pipe will be connected to. Deburring can be done using a variety of tools, including deburring tools, files, or sandpaper. The goal is to smooth out the edge and remove any burrs or rough spots. It's also important to inspect the edge after deburring to ensure that it is smooth and even. A smooth edge is not only safer, but it also helps to ensure a secure and leak-free connection when the pipe is assembled. Additionally, deburring the cut edge can also help to prevent the growth of bacteria and other microorganisms that can thrive in rough or porous surfaces. By removing the rough edges, you can help to create a clean and smooth surface that is less conducive to bacterial growth. Overall, deburring the cut edge is an important step in the post-cutting process of ABS pipe, and it's essential to do it correctly to ensure a safe and secure connection.

Inspecting the Cut for Smoothness

Here is the paragraphy: Inspecting the cut for smoothness is a crucial step in the post-cutting procedure. A smooth cut is essential for ensuring a secure and leak-free connection. To inspect the cut, hold the pipe up to a light source and visually examine the cut edge. Check for any signs of roughness, burrs, or debris. If the cut is not smooth, it can cause the pipe to leak or become damaged during the connection process. Use a deburring tool or a file to smooth out any rough edges or burrs. This will help to create a secure and reliable connection. Additionally, a smooth cut will also make it easier to connect the pipe to fittings or other pipes, reducing the risk of leaks or damage. By taking the time to inspect the cut and smooth out any rough edges, you can ensure a safe and reliable connection.

Preparing the Pipe for Assembly

Preparing the pipe for assembly is a crucial step in the process of working with ABS pipes. After cutting the pipe to the desired length, it is essential to prepare the cut end for assembly. This involves deburring the pipe to remove any sharp edges or burrs that may have formed during the cutting process. Deburring can be done using a deburring tool or a file, and it is crucial to remove all sharp edges to ensure a smooth and secure connection. Additionally, the pipe should be cleaned to remove any debris or residue that may have accumulated during the cutting process. This can be done using a soft cloth and a mild cleaning solution. Once the pipe is clean and free of debris, it can be assembled with the desired fittings, such as couplings, elbows, or tees. It is essential to follow the manufacturer's instructions for assembly and to use the recommended type and amount of cement and primer to ensure a strong and durable bond. By properly preparing the pipe for assembly, you can ensure a secure and leak-free connection that will withstand the test of time.