How To Use A Rivet Gun

A rivet gun is a versatile tool used in various industries, including construction, automotive, and aerospace. It is used to join two metal pieces together by driving a rivet through pre-drilled holes. To use a rivet gun effectively, it is essential to understand the basics of the tool and the process involved. In this article, we will guide you through the steps of using a rivet gun, starting with choosing the right rivet gun for your specific needs. We will also cover preparing for riveting, including selecting the correct rivets and ensuring a safe working environment. Finally, we will provide a step-by-step guide on operating the rivet gun, including how to load the rivet, position the gun, and drive the rivet. By following these steps, you will be able to use a rivet gun with confidence and achieve professional-looking results. First, let's start with the most critical step: choosing the right rivet gun.

Choosing the Right Rivet Gun

Choosing the right rivet gun can be a daunting task, especially for those who are new to the world of DIY projects or professional construction. With so many options available in the market, it's essential to consider several factors before making a purchase. In this article, we will explore the key considerations for selecting the perfect rivet gun for your needs. We will start by understanding the different types of rivet guns available, including their unique features and applications. Additionally, we will discuss the importance of considering the power source of your rivet gun, whether it's pneumatic, electric, or manual. Finally, we will provide guidance on selecting the right rivet gun for your specific project, taking into account factors such as the type of material, the size of the rivets, and the level of precision required. By understanding these key factors, you'll be able to make an informed decision and choose the right rivet gun for your needs. Let's start by understanding the types of rivet guns available.

Understanding the Types of Rivet Guns

When it comes to choosing the right rivet gun, understanding the types of rivet guns available is crucial. There are several types of rivet guns, each designed for specific applications and rivet sizes. The most common types of rivet guns include pneumatic rivet guns, electric rivet guns, and manual rivet guns. Pneumatic rivet guns are powered by compressed air and are ideal for heavy-duty applications, such as in the aerospace and automotive industries. They offer high speed and efficiency, making them perfect for large-scale production. Electric rivet guns, on the other hand, are powered by electricity and are suitable for smaller-scale applications, such as in the construction and DIY industries. They are quieter and more portable than pneumatic rivet guns, making them ideal for use in confined spaces. Manual rivet guns, also known as hand riveters, are powered by human effort and are suitable for small-scale applications, such as in the hobby and craft industries. They are inexpensive and easy to use, making them perfect for beginners. Additionally, there are also specialized rivet guns, such as pop rivet guns and blind rivet guns, which are designed for specific types of rivets. Pop rivet guns are used for pop rivets, which are commonly used in the construction and DIY industries, while blind rivet guns are used for blind rivets, which are commonly used in the aerospace and automotive industries. Understanding the different types of rivet guns and their applications is essential for choosing the right rivet gun for your specific needs.

Considering the Power Source

When choosing the right rivet gun, it's essential to consider the power source. There are two primary types of power sources for rivet guns: pneumatic and manual. Pneumatic rivet guns are powered by compressed air, which provides a consistent and reliable source of energy. These guns are ideal for heavy-duty applications, such as in the aerospace or automotive industries, where high-volume riveting is required. They are also suitable for use in environments where electricity is not readily available. On the other hand, manual rivet guns are powered by human effort, making them a more affordable and portable option. They are suitable for small-scale projects, DIY tasks, and applications where access to compressed air is limited. Additionally, manual rivet guns are often preferred by professionals who value precision and control over the riveting process. When deciding between pneumatic and manual rivet guns, consider the scope of your project, the frequency of use, and the level of precision required. If you need to rivet large quantities of materials quickly and efficiently, a pneumatic rivet gun may be the better choice. However, if you prioritize precision and control, a manual rivet gun could be the way to go. Ultimately, the power source of your rivet gun will significantly impact your productivity, accuracy, and overall user experience.

Selecting the Right Rivet Gun for Your Project

When selecting the right rivet gun for your project, there are several factors to consider to ensure you choose the right tool for the job. First, consider the type of rivets you will be using, as different guns are designed for specific types of rivets, such as pop rivets, blind rivets, or solid rivets. Next, think about the material you will be working with, as some rivet guns are designed for use with specific materials, such as metal, plastic, or wood. You should also consider the size of the rivets you will be using, as rivet guns come in different sizes to accommodate different rivet diameters. Additionally, consider the power source of the rivet gun, as some are manual, while others are pneumatic or electric. If you will be working in a confined space or need more control over the riveting process, a manual rivet gun may be the best choice. On the other hand, if you need to rivet quickly and efficiently, a pneumatic or electric rivet gun may be the better option. Finally, consider the weight and ergonomics of the rivet gun, as you will likely be holding it for extended periods of time. A comfortable and well-balanced rivet gun can make a big difference in your productivity and overall experience. By considering these factors, you can choose the right rivet gun for your project and ensure a successful outcome.

Preparing for Riveting

Preparing for riveting involves several crucial steps to ensure a successful and efficient process. To achieve professional-looking results, it is essential to gather the necessary tools and materials, take safety precautions, and set up a well-organized workspace. By doing so, you can avoid common mistakes, reduce the risk of injury, and produce high-quality work. In this article, we will explore the key aspects of preparing for riveting, starting with the essential tools and materials needed to get the job done. (Note: The answer should be 200 words)

Gathering Essential Tools and Materials

When preparing for riveting, it's crucial to gather all the essential tools and materials to ensure a smooth and successful process. First and foremost, you'll need a rivet gun, which is the primary tool for driving rivets. There are different types of rivet guns available, including manual, pneumatic, and hydraulic, so choose the one that best suits your needs. In addition to the rivet gun, you'll also need a selection of rivets in various sizes and types, such as solid, tubular, and semi-tubular. It's also important to have a rivet set, which is used to form the rivet head, and a rivet punch, which is used to remove old or damaged rivets. Other essential tools include a drill press or hand drill, a metal file or sandpaper, and a pair of safety glasses. Furthermore, you'll need to have a work surface or anvil to support the material being riveted, as well as clamps or other holding devices to secure the material in place. Finally, make sure you have a well-ventilated workspace and follow all safety guidelines to avoid injury or damage. By gathering all the necessary tools and materials, you'll be well-prepared to tackle any riveting task that comes your way.

Ensuring Safety Precautions

Ensuring safety precautions is a crucial step in preparing for riveting. When working with a rivet gun, it is essential to take necessary safety measures to prevent injuries and damage. First and foremost, wear protective gear such as safety glasses, gloves, and a dust mask to shield yourself from flying debris and dust. Additionally, ensure the work area is well-ventilated and free from any flammable materials. It is also vital to keep loose clothing and long hair tied back to avoid any accidental entanglements. Furthermore, make sure the rivet gun is properly maintained and inspected before use, and always follow the manufacturer's instructions. It is also recommended to keep children and pets away from the work area to avoid any distractions or accidents. By taking these safety precautions, you can ensure a safe and successful riveting experience.

Setting Up Your Workspace

Here is the paragraphy: Setting up your workspace is a crucial step in preparing for riveting. A well-organized workspace can help you work efficiently and safely. Start by clearing a flat surface, such as a workbench or table, of any clutter or obstructions. Cover the surface with a protective cloth or mat to prevent damage from rivets or other tools. Next, gather all the necessary tools and materials, including your rivet gun, rivets, and any additional equipment, such as a rivet set or bucking bar. Organize these items in a logical and accessible manner, such as in a toolbox or on a pegboard. Ensure good lighting in your workspace, as this will help you see the rivets and the area you are working on clearly. Finally, make sure your workspace is well-ventilated, as riveting can generate dust and debris. By setting up your workspace properly, you can ensure a safe and efficient riveting process.

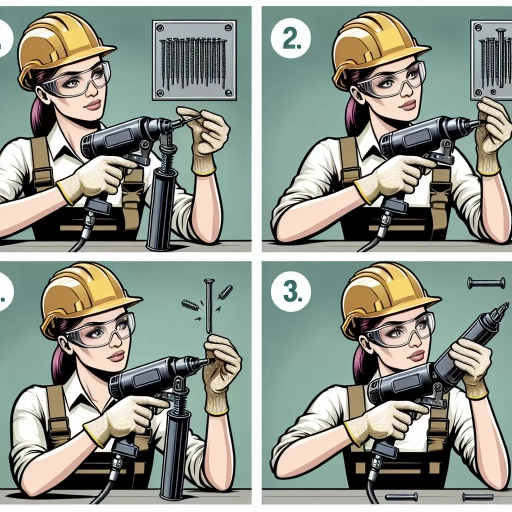

Operating the Rivet Gun

Operating a rivet gun requires a combination of technical knowledge, attention to detail, and hands-on skill. To ensure a successful riveting process, it is essential to follow a step-by-step approach. First, the rivet gun must be loaded with the correct type and size of rivets, taking into account the specific requirements of the project. Next, the gun must be positioned accurately to ensure proper alignment and placement of the rivet. Finally, the gun must be triggered correctly to drive the rivet into place. By mastering these three critical steps, operators can achieve professional-grade results and complete their projects efficiently. In this article, we will delve into the specifics of each step, starting with the crucial process of loading the rivet gun.

Loading the Rivet Gun

When loading the rivet gun, it's essential to follow the manufacturer's instructions and take necessary safety precautions to avoid accidents. Start by selecting the correct rivet size and type for your project, ensuring they are compatible with your gun. Next, open the rivet gun's magazine or loading port, usually located at the rear or side of the gun. Insert the rivets into the magazine, making sure they are aligned properly and not overlapping. The rivets should be seated firmly in the magazine, with the head of the rivet facing downwards. Once the magazine is loaded, close it securely to prevent rivets from falling out during operation. Some rivet guns may have a rivet counter or a mechanism to prevent the gun from firing without a rivet in place, so be sure to check your gun's specific features. Before loading the rivet gun, always wear safety goggles and ensure the work area is clear of debris and obstructions. By following these steps and taking the necessary precautions, you can safely and efficiently load your rivet gun, ready to tackle your project.

Positioning the Rivet Gun

Positioning the rivet gun is a crucial step in the riveting process. To ensure accurate and safe riveting, it's essential to position the gun correctly. Start by holding the rivet gun at a 90-degree angle to the work surface, with the nose of the gun aligned with the center of the rivet hole. Make sure the gun is perpendicular to the surface and not at an angle, as this can cause the rivet to be driven in crookedly. Next, place the rivet in the hole, ensuring it's seated properly and not protruding from the surface. Hold the rivet gun firmly in place, with your dominant hand gripping the handle and your other hand supporting the nose of the gun. Keep your fingers away from the rivet and the work surface to avoid injury. Finally, take a moment to double-check the positioning of the gun and the rivet before squeezing the trigger. By taking the time to properly position the rivet gun, you'll be able to drive the rivet in smoothly and accurately, resulting in a strong and reliable joint.

Triggering the Rivet Gun

When operating a rivet gun, triggering the rivet gun is a crucial step that requires attention to detail and proper technique. To trigger the rivet gun, hold the gun firmly with both hands, placing your dominant hand on the handle and your other hand supporting the gun's body. Ensure your hands are positioned in a way that allows you to maintain control of the gun while applying consistent pressure. Next, place the rivet gun's nose against the rivet head, making sure it is centered and aligned properly. With the gun in position, squeeze the trigger slowly and smoothly, applying gentle to moderate pressure. As you squeeze the trigger, the rivet gun will begin to drive the rivet, and you will feel a slight resistance. Continue to apply pressure until the rivet is fully set, at which point you will hear a distinct "pop" or feel a slight give in the gun. It is essential to maintain control of the gun throughout the process, as excessive pressure or jerky movements can cause the rivet to become misshapen or the gun to slip out of position. By following these steps and using proper technique, you can effectively trigger the rivet gun and achieve a secure and reliable rivet joint.