How To Adjust Front Derailleur

Navigating the world of bike servicing can seem like a complex labyrinth, especially when it comes to adjusting the integral parts like the front derailleur. This underrated component plays a pivotal role in ensuring your bike operates smoothly, and mastering its intricate mechanism can significantly enhance your biking experience. This comprehensive guide aims to help every bicycling aficionado decode the mysterious functioning of a front derailleur, elucidate the methodical steps encompassing its proper adjustment, and provide ingenious tips and tricks for maintaining an efficient front derailleur. By sinking your teeth into these topics, you'll solve the puzzle of working with front derailleurs. We'll start the journey by understanding the mechanics of a front derailleur and unravelling its architectural genius. Who knows, after this, you might become the go-to bicycle repair specialist in your cycling community! Let's embark on this journey, shifting our gears towards 'Understanding the Mechanics of a Front Derailleur'.

Navigating the world of bike servicing can seem like a complex labyrinth, especially when it comes to adjusting the integral parts like the front derailleur. This underrated component plays a pivotal role in ensuring your bike operates smoothly, and mastering its intricate mechanism can significantly enhance your biking experience. This comprehensive guide aims to help every bicycling aficionado decode the mysterious functioning of a front derailleur, elucidate the methodical steps encompassing its proper adjustment, and provide ingenious tips and tricks for maintaining an efficient front derailleur. By sinking your teeth into these topics, you'll solve the puzzle of working with front derailleurs. We'll start the journey by understanding the mechanics of a front derailleur and unravelling its architectural genius. Who knows, after this, you might become the go-to bicycle repair specialist in your cycling community! Let's embark on this journey, shifting our gears towards 'Understanding the Mechanics of a Front Derailleur'.Understanding the Mechanics of a Front Derailleur

Understanding the Mechanics of a Front Derailleur is vital for any cycling enthusiast or casual bike user, as it's one of the essential components responsible for smooth transitions between gear ratios. This article will take a deep dive into the inner workings of the Front Derailleur, breaking down the anatomy of this critical bicycle component to equip you with the knowledge you need. We will start by explaining The Basic Structure and Function of a Front Derailleur, highlighting what makes it instrumental in the efficient functioning of a bike. We then tackle Common Issues and Their Causes, offering insights into potential hitches you may face and their underlying reasons. Lastly, we will guide you through Preliminary Steps Before Making Adjustments, ensuring you are well-prepared before you commence any modifications. Let's start with the core foundation: The Basic Structure and Function of a Front Derailleur, setting the pace for a comprehensive understanding of this complex, yet crucial part of your bicycle.

The Basic Structure and Function of a Front Derailleur

The working principle of a front derailleur is indeed fascinating. Serving as a paramount connectivity node between the rider's power and the bicycle's speed, the front derailleur plays an essential role in any bike's functionality. It's a mechanism composed of a metal cage, order that the shifts the chain from one chainring to another. To do so, the derailleur moves side to side, triggered by a wire that’s manipulated by the gear shifter on the bicycle's handles. It starts with the foundation—the derailleur hanger. This small metal piece, typically made of aluminum, serves as the interface between the frame of the bicycle and the derailleur. It's designed to be weaker than the frame and the derailleur, allowing it to bear any accidental brunt, thus protecting the rest of the mechanism from potential damage. The body of the derailleur, largely comprised of the parallelogram, pivot points, and linkages, creates the next layer of structure. Getting the right tension on these pivot points is crucial; they need to move smoothly for accurate gear shifting but also provide enough resistance to hold the chain in place. The linkages tie these movement pieces together, choreographing the fluid shifting of gears. The hardware, consisting of the clamp, limit screws, and tension adjustment, determines how much modulation the derailleur can offer. The clamp holds the derailleur onto the frame and the limit screws define the farthest movement to either side, preventing the chain from slipping off the largest and smallest chainrings. The tension adjustment, controlled by the gear shifter, moves the derailleur in calculated increments, allowing the chain to shift accurately between gears. Lastly, the leverage arm and the guide pulley enact the finale of function - making the shift happen. The leverage arm, connected to the shifting cable, moves the derailleur based on the gear selected. The guide pulley, integral yet often overlooked, maintains a close proximity with the chain, guiding it onto the new gear. Understanding these basic structures and functions of a front derailleur simplifies the process of mastering the art of smooth gear shifting. Comprehending how each piece collaborates with the others helps to diagnose any issues that might arise, thus empowering the cyclist to maximize their ride efficiency and the lifecycle of their bicycle. The front derailleur may be a complex interplay of components, but with careful attention and practice, its management can become second nature to the rider.

Common Issues and Their Causes

Understanding the common issues that can affect a bicycle's front derailleur and their root causes is crucial to better grasp the mechanics involved. This inquiry is similar to comprehending the rudimental map of a complex city. The first common issue is difficulty in shifting gears. This problem may be due to a stretched or worn-out cable. Cables exposed to regular wear and tear or harsh weather conditions tend to expand over time, affecting the tension that's necessary for accurate gear shifts. Shifting problems could also result from an incorrect limit screw setting, which controls the movement range of the derailleur. Another common issue is chain rub. This usually happens when there's misalignment between the derailleur cage and the chain, causing an annoying scratchy sound during a ride. A third frequently noticed problem is chain drop. A chain may fall off the chainring due to the derailleur not moving the chain far enough onto the ring. This issue often occurs because of an incorrectly set high limit (H) screw. The front derailleur cage's improper height or angle could also lead to this derailment. A well-adjusted front derailleur should be parallel to the chainrings and about 1-3mm above the large chainring. Lastly, one of the crucial issues cyclists face is the poor shifting of the front derailleur due to lack of lubrication. This affects both, shifting up or down between chainrings. Regular lubrication is essential to maintain the smooth functioning of a front derailleur and keep it free from dirt, grime and rust. Understanding these common problems and what causes them is key to diagnosing and fixing issues as they appear. Furthermore, familiarizing yourself with these pain points could even help you implement preventative measures to avoid such problems in the future, making your rides more efficient and enjoyable. Keep in mind that the practical knowledge of bicycle mechanics significantly enhances the overall cycling experience. After all, a well-maintained bike is key to a seamless ride.

Preliminary Steps Before Making Adjustments

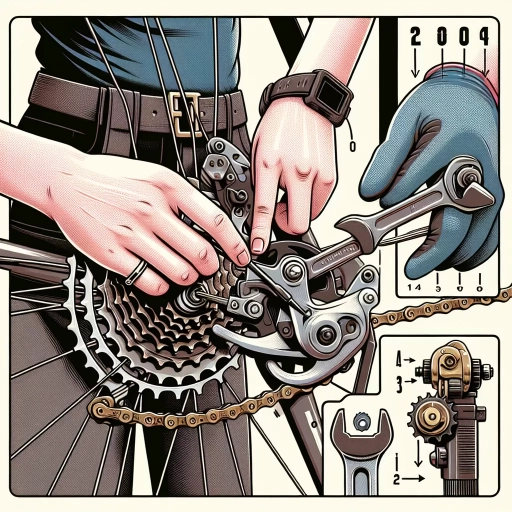

Before one dives headfirst into the process of adjusting a front derailleur, it is imperative to consider several preliminary steps to ensure the process runs smoothly and effectively. A derailleur is a sophisticated bicycle component and understanding its mechanics is critical in order to carry out adjustments that enhance the bike's performance and longevity. Firstly, keen observation is key. Take time to study and understand how your bicycle's front derailleur works. You will notice that it strategically moves the bicycle's chain from one chainring to another, an action that is activated by the shift lever. Look at its current adjustment, how the derailleur interacts with the chain, and its position in relation to other components. Familiarity with this overview is essential for making any necessary changes. Secondly, keep in mind the importance of regular maintenance. This is the primary preventative measure against severe mechanical complications. Routine checks on your derailleur's limit screws, cleanliness and lubrication will sustain the bike's efficient operation and pave the way for any needed adjustments. Next, gather all the necessary tools for adjustment. These typically include crosshead and flathead screwdrivers, an Allen key set, and possibly pliers for handling the derailleur cables. The troubleshooting process can be impeded or even halted by the absence of these tools, hence, securing them beforehand is vital. Another integral step, which might seem more technical, is understanding the gear index setting. This encompasses recognising the front derailleur’s neutral gear and its highest and lowest gear positions. This knowledge allows for effective tuning of the gears, resulting in a frictionless shifting experience when on the move. Lastly, remember to follow any manufacturer guidelines that may be specific to your bike model or derailleur type. These manuals typically contain important details that are catered to your bicycle's unique make-up and thus shouldn't be ignored. After taking all these preliminary steps into account, you'll be more than ready to accurately and confidently adjust your front derailleur. Addressing these steps before jumping to the actual adjustment ensures you uphold the integrity and performance of your bicycle mechanics, promising a fluid and enjoyable ride every time.

How to Properly Adjust Your Front Derailleur

The art of bicycle maintenance transcends just cleaning and greasing: intricate adjustments like fine-tuning your front derailleur are integral to maintaining your cycle's excellent performance. In the following subsections, we'll guide you through the detailed process of effectively adjusting your front derailleur. Firstly, we'll delve into how to correctly adjust the height and angle of the derailleur, ensuring optimal functionality of your bike and reduction of pesky gear skipping. The next critical step will involve setting the correct limit screws, a measure that effectively prevents the chain from derailing while shifting up or down, consequently extending the longevity of your drive-train. Lastly, but importantly, we will explore the procedure of tightening or loosening your derailleur cable - a tuning that can make the difference between smooth and frustrating gear transitions. So, let's kick start this journey by focusing on the first critical step: adjusting the height and angle of your front derailleur to properly position it for maximum efficiency and smooth operation.

Adjusting the Height and Angle

Adjusting the height and angle of your front derailleur is a critical step in ensuring optimal bicycle performance. Not only does it promote a smooth ride, it also prevents chain derailment, saving you from any unexpected disruptions during your journey. The height of the derailleur should be set so the outer plate of the derailleur cage, the part closest to the pedal, is 1-3 mm above the largest chainring. Anything more or less can lead to sub-optimal performance. This is due to the chain failing to engage properly with the derailleur, causing mis-shifts and chain noises. To adjust the height, loosen the derailleur mount and slide it up or down accordingly. Once you find the sweet spot, tighten it back into place to maintain the position. The derailleur's angle, on the other hand, plays a significant role in how accurately and efficiently gears are shifted. It should be aligned parallel to the chain rings. An inappropriate angle can lead to inefficient gear shifting or the chain rubbing against the derailleur. Moreover, it can cause unnecessary wear and tear to your entire drivetrain. To rectify this, you will need to loosen the derailleur's clamp bolt and adjust it manually, being cautious not to strain any of the connectors. These adjustments can seem minor, but they contribute significantly to the overall performance and longevity of your bicycle. Confirming the precise height angle contributes to a longer life and better ride. The process can be complex and meticulous, as the changes in performance are seen incrementally. But with patience and ongoing minor tweaks, perfect adjustment that ensures the best performance can be achieved. Remember; the art of fine-tuning is a journey, not a destination. That means regular checking and adjustment isn't just recommended, it's essential. Like any aspect of bicycle maintenance, a consistent sense of care and attention goes a long way. By investing this time and effort into adjusting the height and angle of your front derailleur, you will ensure a more balanced ride, improve the longevity of your cycling gear, and ultimately, enhance your overall cycling experience. Remember, each bike is unique, and what works for one might not work for another. It is fundamental to consult your bicycle's manual or seek professional help if needed. After all, the goal is more than just achieving the perfect adjustment - it's also about fostering an ongoing relationship with your bike that respects the meticulous engineering that has gone into it.

Setting the Correct Limit Screws

Setting the correct limit screws on your front derailleur is a crucial part of the adjustment process. They act as physical barriers that prevent the chain from going too far out onto the smallest or largest chainring, thus avoiding potential mechanical issues or chain loss. Understanding how to perfectly set these limit screws is an essential skill for any cyclist. The first step in setting the correct limit screws involves identifying them on your front derailleur. Typically, they are labeled "H" for high gear and "L" for low gear. The H-screw adjustment ensures the chain cannot move past the largest chainring to fall into the cranks, while the L-screw prevents the chain from being shifted past the smallest chainring into the frame. Once you have identified the limit screws, begin by shifting your bike into its largest gear at the front and smallest at the rear to set the H-screw. Adjust the screw until the outer plate of the derailleur aligns perfectly with the outer chainring. Following this, shift into the smallest front gear and largest rear gear to adjust the L-screw. Continue this process until the front derailleur chain guide is just clear of the chain. Remember, it is always better to make minor adjustments, test them, and then adjust again if needed. The key is to proceed with smaller changes rather than making one large, drastic adjustment. Following this method will prevent any damage to your gears and chain, and ensure a smooth and efficient gear system on your bike. Mastering the art of setting the correct limit screws not only bolsters your technical cycling skills but significantly improves your bike's performance, making your rides smoother and more enjoyable. Properly adjusted front derailleur limits can also reduce mechanical errors, saving you from potential inconveniences or accidents during your ride. Overall, setting the correct limit screws is an integral part of adjusting your front derailleur, ensuring a pleasant riding experience. As with any mechanical adjustment, it might seem challenging at first, but patience, precision, and consistent practice can make a huge difference. It's an essential skillset for all seasoned cyclists and an advanced step towards efficient self-maintenance of their prized possession.

Tightening or Loosening the Derailleur Cable

Tightening or loosening your derailleur cable is a critical step in properly adjusting your front derailleur. The derailleur, an essential part of the bike's transmission, is responsible for moving the bike chain between the chainrings. Without it, changing gears would be impossible. Therefore, ensuring that it is well adjusted and functioning properly can greatly enhance your biking experience. In order to adjust the derailleur, you'd have to understand the purpose and function of the derailleur cable. The cable is a strong, flexible metal wire that connects the derailleur to the shift lever. It plays a crucial role in moving the derailleur and helps in swift and accurate gear shifting. A well-tightened cable ensures prompt changes, while a loose one would result in sluggish or unresponsive gear changes. The adjustment should be perfect; a too-tight cable can lead to difficulties with low gears, while a too-loose cable can hinder shifting to higher gears. Adjusting the cable doesn't require special tools, and with following the appropriate steps, you should be able to perfect the cable tension. To tighten the cable, gently turn the barrel adjuster counterclockwise. This action effectively lengthens the housing and puts more tension on the cable, aiding the derailleur move to a larger chainring. Conversely, to loosen the cable, turn the barrel adjuster clockwise. The housing becomes shorter, and the tension on the cable decreases, making it easier to move to a lower chainring. A quarter-turn at a time is recommended to maintain precision in adjustment. Furthermore, remember that cables stretch over time, so small adjustments may be needed. If you find the derailleur not moving the chain to the desired chainring effectively, a slight turn of the barrel adjuster may quickly fix this. Fine-tuning the derailleur cable tension hence plays an incredibly significant role in the overall performance of your bike's gearing system. Whether you're an experienced cyclist or just starting out, having a well-adjusted derailleur can do wonders for your biking experience. It makes for smoother gear changes, less wear on components, minimal chain chatter, and a quiet, well-functioning bike that's enjoyable to ride. By understanding the technique of tightening or loosening the derailleur cable, you can maintain your bike in top shape and ensure an optimized riding experience.

Tips and Tricks for Maintaining an Efficient Front Derailleur

Whether you're a professional cyclist or a biking enthusiast, maintaining an efficient front derailleur is extremely important for a smooth and enjoyable ride. This article provides valuable tips and tricks on achieving just this, focusing on three vital aspects: Performing Regular Maintenance Checks, Identifying When Professional Help is Needed, and The Importance of Using Quality Parts and Tools. By understanding these elements, you'll not only reduce your overall bike maintenance costs but also extend the longevity of your derailleur. Ensuring regular upkeep goes a long way in preventing most derailleur-related issues before they even arise. And for those times when DIY solutions don't suffice, knowing how and when to consult a professional becomes essential. Lastly, using superior quality parts and the right tools will undoubtedly result in a higher functioning derailleur. So, without any further ado, let's dive into the first aspect - Performing Regular Maintenance Checks, as this is the preliminary step in sustaining an efficient front derailleur. From here onwards, the journey to attaining a perfectly tuned bike derailleur begins.

Performing Regular Maintenance Checks

Performing regular maintenance checks on your front derailleur is not only a key tip and trick for maintaining an efficient component, but it's also crucial for ensuring optimal functionality and longevity of your bicycle's overall gear system. Your front derailleur, the mechanical device shifting your ride’s chain between the high and low gears, is a crucial part that greatly influences your pedaling experience. Neglecting its upkeep may potentially lead to underperformance, gear slipping, or even damaging of other parts. Regular checks, set at appropriate intervals, ensure that you identify and rectify signs of premature wear and tear, maintaining the derailleur's efficiency. Start by inspecting the derailleur’s alignment. Proper alignment of the derailleur cage with the chainrings reduces the chances of your bike chain falling off while riding or switching gears, thereby enhancing ride stability and smooth operation. Regular inspection also includes checking for signs of contaminations, typically grit, grime, and more, that can impede its performance. Cleaning your derailleur, and the parts it interacts with, with suitable cleaning solutions is pivotal in the dissolution of this accumulated grime. Lubrication is another integral part of derailleur maintenance. Regular lubrication ensures that the moving parts operate smoothly and reduces the wearing effect of friction, thereby contributing to an efficient performance on the road. When lubricating, focus on areas with moving parts, such as pivot points. However, caution must be exercised to avoid overlubrication, which increases the chances of your derailleur attracting dirt and debris. Last but not least, checking cable tension regularly is crucial, as it significantly affects gear shifting. A bike with cable tension set too high or too low can give you a hard time shifting gears, thereby affecting your ride's efficiency. Regular checks allow for early diagnosis and timely adjustment, ensuring your ride's gear shifting system runs smoothly and efficiently. Performing regular maintenance checks on your front derailleur ensures you have a reliably efficient component, enhancing your ride’s quality while reducing C costly repair or replacement. To cap it all, regular maintenance checks help you master your machine better, giving you the confidence and peace to focus more on the trails ahead than worrying about impending mechanical failures.

Identifying When Professional Help is Needed

Identifying When Professional Help is Needed In the journey of maintaining an efficient front derailleur, it's essential to remember that not every issue can be resolved with DIY methods, no matter how many tricks you've learned. Understanding when to seek professional help is invaluable. While many maintenance tasks are achievable at home, certain signs indicate when it's time to consult a professional. For instance, if you consistently experience difficulty with shifting gears, despite making the necessary adjustments and replacements, it might indicate an underlying issue that requires an expert's attention. Sometimes, the derailleur does not sit at the correct height or angle, and while you can rectify this somewhat, only a certified technician can ensure it's perfectly aligned for optimum performance. Worn or distorted parts can also pave the way for more serious issues that demand professional intervention. Delayed shifting or unusually loud noises during the operation could also signal a problem. Persistent issues with chain rub, where the chain grates against the metal cage, can cause detrimental long-term damage if not correctly addressed by a professional. Moreover, if you have tried your DIY expertise and the problem persists, it's prudent to seek professional help. Not only should you focus on enhancements and maintenance, but acknowledging when professional help is needed can ultimately save you time, resources, and stave off further complications. Implementing this wisdom into your maintenance routine will ensure your front derailleur operates at its most efficient, providing smooth and seamless rides time after time.

The Importance of Using Quality Parts and Tools

Quality parts and tools are critical in maintaining an efficient front derailleur, and they play a vital role in ensuring a seamless and hassle-free ride. Understanding the importance of using quality parts and tools not only enhances the performance of your bike but also extends its longevity, save you from unnecessary expenses due to frequent repairs or part replacements. The overriding principle behind this is straightforward - quality begets quality. Superior parts and tools allow precise adjustments and offer a higher degree of sturdiness, longevity, and reliability. In essence, they are designed to withstand the challenges presented by the rough and frequently changing terrains, unlike their lower-quality counterparts, which can fail under stress leading to abrupt halts or even accidents. Beyond the physical implications, the use of quality parts and tools also correlate positively with the rider's experience. A well-maintained front derailleur, supported by top-notch parts, reduces instances of chain slips or misses. It makes gear shifting a breeze and contributes significantly to an effortless ride, irrespective of the trail's conditions. Quality shouldn't be a choice, rather a requirement. Standard tools can give you a false sense of savings at the outset but are costlier in the long run. They not only compromise the performance of your bike but could also lead to irreparable damages, thus increasing the overall cost of bike maintenance. On the other side, quality tools, known for their robust build and impeccable precision, can enhance the effectiveness of your maintenance rituals. They allow for exact adjustments, ensuring connectivity between the derailleur and the chainring is spot-on, decreasing the chances of mid-ride interruptions. Ultimately, by choosing quality parts and tools, one is investing in their bike's health. It's the safety net that keeps your rides smooth and consistent, enabling you to power through trails with confidence. With the right parts and tools in your maintenance kit, you're not only preserving your bike's functionality but also securing a joyful cycling experience each day. Therefore, focus on quality, and remember that every component of your bike, especially a part as essential as the front derailleur, deserves nothing but the best.