How To Pack A Shipping Container

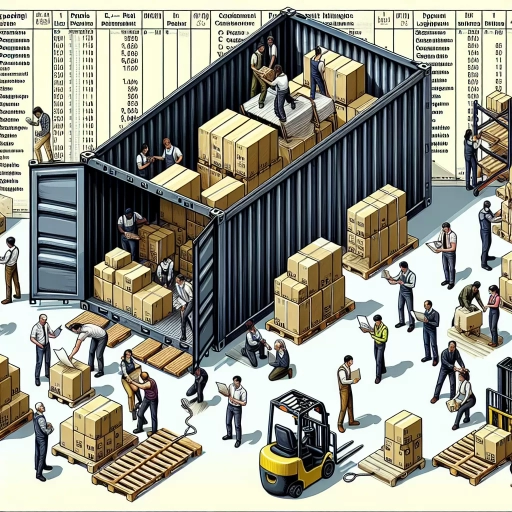

In a world constantly on the move, understanding how to effectively pack a shipping container is a vital skill that can save time, energy, and costs. But successful packing goes beyond simply arranging items skillfully; it encompasses a broad spectrum that includes understanding logistics, selecting suitable materials, and following shipping regulations. This engaging and comprehensive guide will shed light on these critical facets. First, we will delve into 'Understanding the Logistics: A Quick Guide to Shipping Container Packing', explaining how to strategize and optimize space within your container. Next, the importance of 'Appropriate Materials: Picking the Right Packaging for Your Items' will be explored, focusing on protecting your goods throughout transit. Lastly, we’ll venture into 'Maintaining Compliance: Navigations through Shipping Regulations and Standards', a critical segment that will help you bypass potential pitfalls and headaches associated with non-compliance. Now, let's embark on our informative journey by taking a deep dive into the logistics of shipping container packing.

In a world constantly on the move, understanding how to effectively pack a shipping container is a vital skill that can save time, energy, and costs. But successful packing goes beyond simply arranging items skillfully; it encompasses a broad spectrum that includes understanding logistics, selecting suitable materials, and following shipping regulations. This engaging and comprehensive guide will shed light on these critical facets. First, we will delve into 'Understanding the Logistics: A Quick Guide to Shipping Container Packing', explaining how to strategize and optimize space within your container. Next, the importance of 'Appropriate Materials: Picking the Right Packaging for Your Items' will be explored, focusing on protecting your goods throughout transit. Lastly, we’ll venture into 'Maintaining Compliance: Navigations through Shipping Regulations and Standards', a critical segment that will help you bypass potential pitfalls and headaches associated with non-compliance. Now, let's embark on our informative journey by taking a deep dive into the logistics of shipping container packing.Understanding the Logistics: A Quick Guide to Shipping Container Packing

In the complex world of logistics, understanding the process of shipping container packing is essential. This comprehensive guide will take you on a journey through three significant aspects that need careful consideration - the science of container space utilization, understanding weight distribution in container packing, and the art of securing your items in the shipping container. The first matter of business, the science of container space utilization, takes into account how each inch of space in the container can be effectively used to ensure optimal capacity. Moving on, we'll delve into the intricate details of weight distribution in container packing, which plays an indispensable role in maintaining the stability and safety during transport. Lastly but certainly not least, we will explore the creative yet analytical art of securing your items within the shipping container to prevent damage or loss during transit. By mastering these areas, one can ensure the entire logistics process is smoother, cost-effective, and efficient. The initial step, understanding container space utilization, may seem like a numbers game, but it is rather a pivotal science that contributes to successful shipping container packing.

The Science of Container Space Utilization

Understanding the science behind container space utilization plays a pivotal role when it comes to packing a shipping container effectively and efficiently. The concept, which may seem rudimentary at first glance, is deeply rooted in mathematical and physics principles. Optimizing space utilization in container packing facilitates not only the transportation of more goods but also ensures the safety and security of products during transit. Primarily, container packing rests on the principles of geometry. It involves knowing and understanding the container's dimensions – length, width, and height – and meticulously arranging items to maximize this predefined space. This process is similar to solving a three-dimensional puzzle wherein each piece must fit accurately and compactly. A well-executed packing plan considers this intricate relation between the container's volume and the load's dimensions, ensuring every inch contributes to the process. Secondly, it's not just about stuffing the container to its brim. The tenets of physics also come into play. It involves understanding the weight distribution, stability, and load handling. Ideally, heavy items must be placed at the bottom, distributed equally to balance the container's weight. Also, considering the container will undergo movements during the course of its journey, it's critical to pack items with foresight to mitigate any damage that can emanate from these actions. Additionally, utilizing the container space effectively brings significant cost benefits. It means fewer containers will be needed to transport the same quantity of goods. This results in considerable savings in freight costs and associated overheads like handling charges and storage fees. It also contributes to a lower carbon footprint, aligning with the global emphasis on sustainable logistics. However, despite these scientific principles involved in container packing, there's an amalgamation of art in this process as well. It requires an analytical mind and visual skills to envision the best possible way to pack goods into the container. This amalgamation of science and art in container space utilization elevates packing from a mere routine activity to a strategic exercise that can influence the entire logistics cycle. By understanding the science of container space utilization, individuals and businesses can not only enhance their logistical efficiency and cost-effectiveness, but they can also ensure their goods are transported safely and securely. Hence, it's safe to say that a solid understanding of container space utilization is a cornerstone in the broader framework of logistics.

Understanding Weight Distribution in Container Packing

Understanding the principle of weight distribution is a fundamental aspect of effective container packing. It plays a pivotal role in ensuring the safety and stability of the shipment as well as efficient utilization of the container's capacity. For the optimal equilibrium, heavy items should ideally be placed at the bottom and evenly spread. Essentially, this lowers the center of gravity, thereby stabilizing the container on uneven surfaces and high seas. Imbalance or incorrect weight distribution can result in a dangerous tilt or a cumbersome shift, which not only endangers the item in transit but also poses significant safety risks to dockworkers and shipping crew. Severe consequences of improper weight distribution such as toppling or capsizing of the vehicle or the ship underpin the need for due diligence in container packing. Furthermore, unequal weight distribution can lead to inefficient space utilization, as it may limit the placement of additional items. Therefore, careful planning and precise execution of the packing process are required to maximize the payload without compromising the safety or integrity of the shipment. Efficient weight distribution also extends to the category of items being shipped. For instance, hazardous materials should never be placed over food items or delicate goods to avoid potential contamination or damage. Similarly, fragile or valuable items should not bear the burden of heavier items. Knowledge of weight distribution, therefore, necessitates familiarity with the nature of the items being shipped. To facilitate better understanding, digital tools and software can be used that provide 3D visualizations of optimal weight distribution within containers, making this complex task more manageable. In a nutshell, mastering weight distribution in container packing not just safeguards your shipment but also liberates space, thereby translating into significant cost-savings. In the comprehensive world of logistics, understanding weight distribution in shipping container packing is thus, not just a prerequisite, but a mechanism geared towards achieving efficiency, cost-effectiveness, safety, and successful deliveries. So, as you delve into the world of shipping and logistics, remember that understanding weight distribution is much more than mere arrangement - it's a science in itself.

The Art of Securing Your Items in the Shipping Container

Securing your items adequately in a shipping container is undoubtedly an art that requires industry insights, careful planning, and meticulous execution. It's not just about filling up the container; it's about strategic arrangement, weight distribution, and embracing different cushioning and reinforcing elements to ensure maximum security during the transit. When it comes to the strategic arrangement of items, the key principle is to place heavier objects at the bottom and lighter items at the top. It essential to ensure balance within the container and minimize the risk of items shifting during transportation. This precise allocation of weight results in stability, a crucial requirement when your cargo is navigating choppy sea waves or uneven road terrain. Your artful packing methods should also encompass the use of cushioning materials. While objects nicely snug into each other offer less room for unnecessary movements, it's always a wise step to add a further layer of protection. Fill empty spaces with bubble wrap, foam, or other cushioning substances to reduce the likelihood of damage from abrupt movements or possible external pressure. Beyond cushioning, securing your items also call for efficient reinforcing methods. Standard procedures include strapping items down or constructing custom-built braces and supports. These procedures ensure that the contents stay intact, preventing unforeseen incidents like toppling over, even with the biggest jolts during the journey. Finally, remember that successful shipping container packing isn't a rushed process. It requires patience, time, and a certain artfulness in coming up with the best configuration for your cargo's safe journey. Each item, depending on its specifics, might need a unique way of packing and positioning – a responsible task that draws heavily on your creativity and forward-thinking ability. In essence, the art of securing your items in a shipping container is pivotal for smooth logistics. It's a defining piece of the puzzle in 'Understanding the Logistics: A Quick Guide to Shipping Container Packing.' When you master this art, you not only ensure a safer transit for your goods but also lay a firm foundation for effective and efficient shipping container utilization.

Appropriate Materials: Picking the Right Packaging for Your Items

Choosing the right packaging for your items is not a trivial task; it requires meticulous consideration, especially looking in terms of material durability, creative use of buffer materials, and the advantages of resorting to customized packing solutions. First and foremost, material durability gains immense relevance in shipping container packing. Robust packaging plays an integral role in preserving your products' state, especially during harsh transportation conditions. Buffer materials, on the other hand, are an essential ally in maximizing your product's protection and minimizing damage. These materials act as a shock absorber, reducing any impact the items might receive during transit. Lastly, the integration of customized packing solutions into your logistical strategies can enhance the overall safety of your goods. These solutions are tailored specifically to your product's dimension, weight, and fragility level, ensuring the utmost protection. Let's delve further into our first key component, understanding the relevance of material durability in shipping container packing.

The Relevance of Material Durability in Shipping Container Packing

Material durability carries significant relevance when considering packing methods for a shipping container. When shipping goods across varying climates and conditions, the protective packaging used plays a pivotal role in preserving the integrity of the items. Choosing the right material for packaging is not merely a matter of appearance, it questions the security and protection of the enclosed goods. High-grade materials such as corrugated cardboard and sturdy plastic are commonly used for their robustness and ability to withstand environmental pressures. Corrugated cardboard boxes, for instance, offer layers of protection. The embedded grooves in these boxes create a cushioning effect that helps absorb shocks and impacts during transit, thereby reducing the risk of damage. On the other hand, plastic has the advantage of being resistant to moisture, reducing the risk of water damage to products during shipping. The durability of these materials ensures that they remain uncompromised even under extreme weather conditions and rough handling. Yet, it's not enough just to have strong and durable packaging. Consideration of the nature of the item being shipped is also crucial - fragile items may need additional padding and support while perishable items require packaging that prevents spoilage. Moreover, using the right-size boxes and materials can prevent accidental slips and falls, offering the necessary support and reducing wastage. Admittedly, the cost is a likely concern when opting for high-quality materials. However, the slightly higher initial cost is compensated for by the reduced replacements and returns from damaged goods, maintaining customer satisfaction, and brand reputation. Furthermore, many durable materials like corrugated cardboard are often recyclable, contributing to both environmental responsibility and potential cost savings. In all, the relevance of material durability in shipping container packing is indisputable. As part of the broader issue of picking appropriate packaging for items, the quest for durability should not be compromised. Investing in robust packing solutions is not just a choice, but a requirement in today's logistics and shipping landscape. The potential loss from damaged goods during transit far outweighs the costs incurred in acquiring durable materials for packaging. Each decision made in the packaging process should mirror the company's commitment to delivering quality and value to its customers. With the right materials, businesses can ensure the safe arrival of products while bolstering consumer trust and loyalty.

Using Buffer Materials: Maximizing Protection and Minimizing Damage

Using buffer materials is an essential part of ensuring that your items get to their destination in the same condition they left in. Implementing these materials in your packaging can maximize protection and minimize potential damage during transit. Buffering materials can be anything that offers extra protection to your goods inside a shipping container, often acting as shock absorbers to prevent unwanted movement or cushion against impacts. Among the most popular buffering substances are Bubble Wrap, foam inserts, peanuts or packing paper. Bubble Wrap is a universal favorite owing to its excellent shock absorption qualities and customization capabilities. It can be easily cut and shaped to fit around any item, offering a comforting shield that can confidently withstand the rigors of transportation. Foam inserts provide a structured shield – they can be custom-fitted round the item, creating a safe nest within the packaging that holds the product securely. Meanwhile, packing peanuts are used to fill the extra space within packages, creating a buffer zone that restricts unwanted movement. On the other hand, packing paper is great for wrapping and padding the items, particularly those with irregular shapes. Another environmentally friendly and affordable option is crumpled newsprint or brown paper. These are easy to maneuver and offer good utility in filling gaps and providing an additional layer of cushioning. However, choosing the right buffer material isn't just about purchasing a random assortment of packing materials and stuffing them into your boxes. It requires careful thought about the item's size, weight, shape, fragility, and value. For instance, heavy-duty items might require more robust materials like polystyrene foam blocks. Simultaneously, fragile products might benefit from air pillows or bubble wrap that offer softer, more sensitive protection. Moreover, the choice of buffer material should also resonate with your brand's environmental philosophy. Biodegradable or recycled materials can be used to echo your brand's responsible and environmentally-conscious ethos. In conclusion, buffer materials play a significant role in packaging for shipping. By picking the appropriate material and using it effectively, you could ensure your items are well-protected during transit. This way, the likelihood of customer satisfaction rises — products reach safe and sound, preserving your business reputation and boosting customer trust even further. Absolutely, the attention you show in packaging can significantly reflect the care you have for your products and customers alike, leading you on a sure path to business success.

The Benefits of Customized Packing Solutions

Customized packing solutions offer myriad benefits that can overhaul your business’s shipping and handling process, forming an integral part of our subtitle theme, "Appropriate Materials: Picking the Right Packaging for Your Items." Firstly, they provide an unprecedented level of protection. Unlike one-size-fits-all packages, custom solutions are meticulously designed according to the dimensions of your products. This ensures that your items are not loose within the package, thereby minimizing potential damage during transit. Secondly, customization accentuates the efficiency of your logistics. By crafting the box to fit the product, you can eliminate wasted space and consequently cut down transportation costs significantly. This advantage also extends to the environmental spectrum as it reduces packaging waste. Thirdly, customized packaging solutions offer incredible branding opportunities. They serve as an extension of your brand and offer an additional platform to market your product. This means your brand doesn’t stop at your logo, your packaging tells your brand story, setting the emotional stage for your customers before they even interact with the product. Lastly, custom packaging enhances the user experience. Unboxing is not merely the act of removing the items from the box; with the rise of social media, it has become a crucial interactive element that can either engage your customers or turn them off. By custom-tailoring your packaging, you’re able to enhance the unboxing experience and forge a deeper connection with your customers. Thus, the benefits of customized packing solutions are far-reaching: they boost protection, enhance efficiency, elevate branding potential, and significantly improve the customer experience. So when picking out the right packaging for your items, remember that custom packaging solutions provide not only the appropriate protective aspect but also have immense potential to contribute positively to your bottom line and enhance customer engagement. They are an efficient, profitable, and environmentally friendly way to ensure your products reach their destination safely while broadcasting your brand's distinct identity.

Maintaining Compliance: Navigations through Shipping Regulations and Standards

To fully grasp the complexities of the shipping industry, comprehending and adhering to its myriad standards and regulations is essential. Whether navigating domestic customs or international seas, understanding these rules can make the difference between a successful shipment and a costly consequence. This article serves to illuminate the path by focusing on three critical areas: The Importance of Knowing Global Shipping Rules and Regulations, Understanding Container Packing Safety Standards, and Avoiding Potential Delays and Additional Costs: Compliance is Key. In the realm of international trade, knowing the intricacies of global rules for shipping doesn't just add up to best practices—it contributes directly to your bottom line, as we'll explore in the following section on the Importance of Knowing Global Shipping Rules and Regulations. Mastery in this area means mitigating risk, avoiding costly delays, and ensuring efficient, compliant operations. From packing safety to cost efficiency, maintaining compliance in shipping is a journey worth embarking on.

The Importance of Knowing Global Shipping Rules and Regulations

Understanding the importance of global shipping rules and regulations is crucial for any business that desires to maintain its competitive advantage and standing in the global market. Failure to adhere to these rules can result in hefty fines, delays, and a damaged reputation. One of the most important aspects of shipping regulations is ensuring that you accurately declare your goods. Every item that crosses international borders is subject to scrutiny by customs officers. If your shipment is poorly described or wrongly classified, it can be held at customs until the information discrepancy is resolved. This could cost you both time and money, as storage fees can rapidly accumulate, and late deliveries can damage your customer relations and your company's reputation. Besides, you need to understand the import and export regulations of the countries you are doing business with to avoid unnecessary complications. Each country has its own set of rules regarding what can be imported or exported, and failing to comply with these laws can lead to severe penalties. Additionally, some countries have specific packaging and labelling requirements, or even physical restrictions on the types of containers that can be used. Understanding these regulations can help avoid having your cargo held up or even confiscated. Also, knowing the global shipping rules and regulations can make your logistics more efficient. By understanding the specific guidelines in play, you can better predict your shipping times, manage your inventory, and optimize your transportation costs. It ensures seamless coordination between various stakeholders like shipping companies, customs officials, and local authorities. In conclusion, knowing global shipping rules and regulations not only helps in maintaining compliance but helps to navigate through the complexities of international trade. It aides in strategic decision-making, reduces the risk of penalties and fosters a smoother and more efficient shipping process, propelling your business towards success in the global marketplace. With a diligent approach to understanding and following these rules and standards, businesses can ensure their overseas trading operations are both lawful and lucrative. Remember, the world of international trade is dynamic, and so are its rules and regulations. Hence, a commitment to continual learning and adaptation is a must in this domain to stay compliant and competitive.

Understanding Container Packing Safety Standards

Understanding container packing safety standards is crucial to maintaining compliance and successfully navigating through shipping regulations and standards. These standards are devised by International Maritime Organization (IMO) and serve as guiding protocols that promote safety, security, and accountability in the business of shipping. This subset of regulations specifically focuses on how to pack a shipping container properly to avoid harm to goods, personnel, and shipping materials. At the heart of these standards is the CTU Code – a comprehensive guide for packing cargo transport units, including containers. The code considers numerous factors such as the type and dimensions of the container, the physical properties of the cargo, use of proper loading devices, and even climatic conditions during transport. This helps ensure that the freight remains secure throughout the shipping process. One imperative aspect addressed under these standards is weight distribution. An uneven load can jeopardize the safety of a container. The focus is on packing heavier items towards the bottom and lighter items up top to maintain container stability. Likewise, the correct use of dunnage (loose materials used to support and protect cargo) is also emphasized under these safety standards. Dunnage can significantly prevent cargo movement that may lead to container imbalance, damage or even catastrophic shifts during transit. Moreover, these safety standards underline the importance of proper container sealing and labeling. This practice guarantees that the nature of the cargo being transported is completely visible and can be handled accordingly during checks and inspections. A thorough understanding of container packing safety standards is thus critical to mitigate the risks associated with container shipping. It ensures that cargo is immune to unnecessary damage, reducing the financial burden related to shipping losses and ensuring regulatory compliance. This regulation-oriented packing process, in the end, contributes towards efficient, accountable, and most importantly, safer maritime logistics. Implementation of these rules therefore, not just adheres to compliance but also shapes the shipper’s reputation as a responsible player in the global supply chain. For this reason, these standards are not just another procedure in shipping protocol, but a comprehensive system that attaches significant value to the overall shipping process and business growth.

Avoiding Potential Delays and Additional Costs: Compliance is Key

Avoiding Potential Delays and Additional Costs: Compliance is Key Staying compliant with shipping regulations and standards is pivotal in ensuring the timely and efficient delivery of goods, and ultimately, the satisfaction of customers. In fact, non-compliance can lead to potential delays and additional costs, which can threaten the stability of the shipping process, and by extension, the profitability of your business. Understanding the international shipping regulations and standards is the first step towards compliance. These regulations are designed to guarantee safety, security, and efficiency concerning the movement of goods. For instance, specific rules pertain to the packaging and handling of hazardous materials, stringent weight limitations exist, and certain paperwork is required. Ignorance of these standards can result in penalties, additional shipping charges, or even seizure of the cargo by customs officials. Next, keeping up-to-date with ever-changing trade policies and laws is equally important. In today's volatile global landscape, trade policies can quickly change due to political or economic shifts. Businesses that are not agile enough to meet these specifications can find themselves facing delays, additional costs, or even sanctions. To avoid these pitfalls, investing in professional guidance can be beneficial. Experts in this field are equipped with the knowledge and understanding required to navigate the complex web of shipping compliance. By involving professionals, businesses can ensure they continue to meet regulatory changes and mitigate potential risks or challenges. Additionally, technology is revolutionizing the shipping industry, and utilizing these advancements can further streamline the process. Advanced software solutions designed for shipping compliance can highlight potential issues before they develop into more significant problems, saving companies both time and money. Therefore, the key to maintaining efficient shipping operations and avoiding unnecessary costs lies in compliance. It's not merely about transporting goods from point A to B; it involves understanding and applying appropriate procedures, laws, and standards while embracing the technological advancements aimed at simplifying such processes. By being proactive rather than reactive, you can effectively minimize the potential for substantial operational hiccups, ultimately avoiding potential delays and additional costs. Compliance is, without a doubt, key to successful shipping.