How Big Are Containers

In an ever-globalizing world, it's essential to understand the fundamental aspects, including containers, that drive our global commerce system. These monolithic structures, familiar sights in harbors and on cargo ships, play an integral role in the shipment and transportation of goods worldwide. But have you ever paused to ask yourself, how big are these containers? This article serves to strip away the mystery and provide a closer examination of containers and their dimensions. We'll delve into the basics and understand what containers in essence are, before journeying through the various dimensions that constitute different types of containers. Lastly, we’ll appreciate why the size of these containers matters in practical applications. Stick with us as we uncover the marvels of these hulking objects, starting with understanding what they are in the context of global logistics.

In an ever-globalizing world, it's essential to understand the fundamental aspects, including containers, that drive our global commerce system. These monolithic structures, familiar sights in harbors and on cargo ships, play an integral role in the shipment and transportation of goods worldwide. But have you ever paused to ask yourself, how big are these containers? This article serves to strip away the mystery and provide a closer examination of containers and their dimensions. We'll delve into the basics and understand what containers in essence are, before journeying through the various dimensions that constitute different types of containers. Lastly, we’ll appreciate why the size of these containers matters in practical applications. Stick with us as we uncover the marvels of these hulking objects, starting with understanding what they are in the context of global logistics.

The Basics: Understanding What Containers Are

Containers, as crucial tools in transportation and trade, encapsulate an intriguing narrative that transcends time and industries. This guide offers a thorough exploration into the world of containers starting from its rich historical evolution, its definition and usage in the landscape of commerce and transport, to the myriad comparative forms it has assumed over the decades. The historical evolution of containers provides an insight into how they have become core components of global trade, drastically altering our methods of transportation. By defining containers within the transportation and trade context, we understand how they function as vessels of enormous capacity, designed for efficiency and security. As we delve into the different types of containers, we underscore their diversity and versatility, each with unique features to accommodate various needs. As we embark on this journey, let's first look back to see how containers have grown from mere storage units into vital cogs in the global trading machinery. From their humble beginnings, we'll trace the triumphal march of containers that have transformed our world in ways hitherto unimagined. Prepare to delve into the exciting history of containers and discover how they've shaped our global trade narrative.

The Historical Evolution of Containers

The historical evolution of containers is as fascinating as it is intricate, heavily influencing the way we perceive and utilize these versatile units in the modern global supply chain. In essence, containers are essential tools in logistics, offering simplicity and standardization in transporting goods across vast distances, over land or sea. The origin of containers dates back to the mid 19th century when they were merely simple, wooden boxes for sea transportation. However, their design evolved over time due to the growing demand for more efficient modes of transport. During the early 20th century, 'lift-vans' were used to transfer goods in bulk but still lacked efficiency, requiring a significant number of workers and time for loading and unloading. The revolution truly began in 1956 when an American entrepreneur, Malcolm McLean, conceptualized and developed the modern shipping container. McLean's innovative design was an intermodal steel container, which offered strength, safety, and remarkable efficiency. His creation quickly gained momentum, and by the 1960s, the standardized shipping container had become the lifeblood of international trade. Over the decades, containers have witnessed several enhancements. With the introduction of the ISO (International Standards Organization) in 1961, uniform regulations were set for sizes and types of containers, further fueling their efficiency and global usage. Container vessels also evolved, becoming larger and more specialized, while various types of containers, such as refrigerated or open-top versions, were introduced to accommodate a wider array of goods. This evolution has laid the groundwork for a globalized economy where international trade is quicker, efficient, cost-effective, and more integrated than ever. Understanding the historical evolution of containers indeed helps in comprehending their vital role and the basics of how they function in contemporary logistics and supply chains. From their humble beginning as wooden boxes to becoming standardized vessels of globalization, the metamorphosis of containers is a testament to human innovation and advancements that aim to make the world a closer, accessible space. From this historical perspective, it's easier to grasp why containers are so integral to modern logistics and global commerce. Despite their relative simplicity, their impact is far from minimal. As their evolution continues, so too will their influence on how goods are moved worldwide, further emphasizing the need to understand what containers truly are, their functions, their types, and their future prospects.

Defining Containers in the Realm of Transportation and Trade

Defining Containers in the Realm of Transportation and Trade Incredibly versatile in their use, shipping containers are a pivotal facet of global transportation and trade. Originating during the mid-20th century, these standard-sized metallic boxes revolutionized the concept of smooth and efficient global trade. Their uniform design allows multiple containers to be stacked neatly and securely during transport by land or water, enhancing safety, reducing load time, and increasing haulage capacity. By design, a container is both a practical transport unit and a symbol of globalization, acting as the fundamental building block of international commerce. Ranging from 20 to 40 feet in length, their standardized size is meticulously designed to match global infrastructures like ships, trucks, trains, and cranes for seamless mobility. This regulated size, known as TEU (Twenty-foot Equivalent Unit), is universally adhered to across the globe to maintain streamlined operations in trade and transportation. The structural integrity of containers is formidable, constructed to withstand harsh environmental conditions during long-distance sea voyages. They are typically made from corrosion-resistant steel or aluminum, offering robust protection for the wide array of goods they carry, which can range from electronics, clothing, machinery to perishable items like food and pharmaceuticals. In today's digital world, containers have become more than just physical entities. They have permeated into the digital realm, particularly in terms of software applications. Much like their physical counterparts, digital containers 'encapsulate' an application and its dependencies into a single, self-sufficient unit that can run universally, enhancing the efficiency of software development and deployment. Expanding beyond their traditional usage, containers have also found a new lease of life in architectural contexts, transforming into trendy homes, offices, and pop-up retail shops. Their affordability, durability, and modular properties make them an ecological and flexible building option, further emphasizing their crucial role in modern society. From a seemingly mundane box to a symbol of globalization, a facilitator of trade, and a cornerstone of innovative architectural and digital revolutions, containers offer boundless potential. Thus, understanding the realm of containers helps to unravel the incredible journey from loading dock to destination, providing a fascinating insight into the intricacies of global commerce and beyond.

Exploring the Different Types of Containers

Exploring the different types of containers brings us to a world of diverse dimensions, designs and drawling specifications, making them incredibly versatile for various industries. Containers can broadly be categorized into dry storage, flat rack, open top, tunnel, open side, double doors, refrigerated, insulated or thermal, tanks, and half height containers. Each of these containers sports a particular size and functionality pertinent to the requirements of the business it supports. Take dry storage containers, popular for their standard sizes of 10ft, 20ft, and 40ft. These are commonly employed in the transportation of dry materials, offering extensive utility in the shipping industry. On the other hand, a flat rack container featuring collapsible sides becomes ideal for carrying large and heavy loads ranging from construction machinery to pipes. When it comes to containers with unusual dimensions such as lengthy pipes or logs, an open top container comes into play with its removable convertible top, providing the liberty to maximize the use of space. Similarly, tunnel and open side containers are synonymous with convenience and flexibility, the former hosting doors on both ends while the latter unfolding entirely on the side for wider space. Refrigerated or reefer containers, insulated, and thermal containers become invaluable in transporting perishable goods, ensuring optimum temperature control. There is also the impressive tank container, specifically designed to carry liquids, gases, and powders as bulk cargo. Rounding off with half-height containers, they become indispensable where smaller and heavier cargo like stones or coal needs shipping. There you have it, an overview of the different types of containers, each signifying innovation in the way we store and transport commodities. Remembering this diversity helps unravel the significance of containers, an integral chapter in the basics of understanding what containers are.

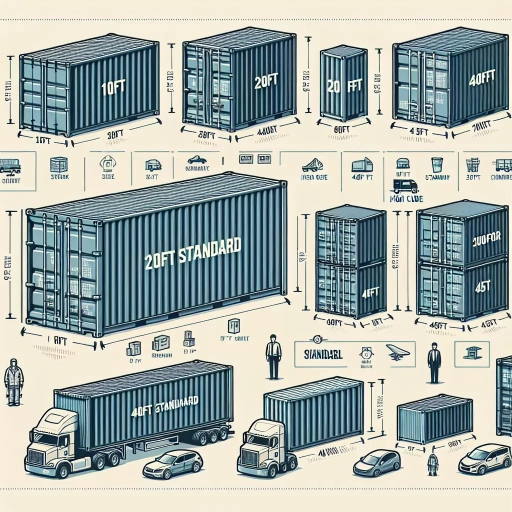

Size Matters: Dimensions of Different Types of Containers

In the world of shipping and logistics, as in life, size indeed matters. Choosing the appropriate container for your shipping requirements is pivotal for a successful operation, as it directly impacts cost, safety, and accuracy of delivery. Grasping a deep understanding of the myriad of containers available could become overwhelming without a convenient guide at your disposal. This examination will serve as your go-to resource on an assortment of container types: their diverse dimensions, distinct variations, and specialized versions. First, we will delve into the cornerstone of the industry, scrutinizing 'standard container' dimensions in exacting detail. Moving further, we’ll unpack the rich variety of other types, with special focus on high cube, pallet wide, and open top containers, offering you an impressible narrative into their functionalities. Lastly, we'll unravel the mystery behind special containers, specifically the tank, flat rack, and reefer containers, each playing a critical role in the global supply chain. As we embark on this journey, let's first set our sights on understanding the fabric of this industry - the standard dimension containers.

Details of the Standard Container Dimensions

Container dimensions play a crucial role in determining its usability and aptness for different types of cargo. The most common type of container used for cargo shipment across the globe is the 20-foot standard container. Its dimensions typically measure 20' length x 8' width x 8'6'' height. These dimensions allow for roughly 1,170 cubic feet of storage space, suiting the needs of most goods. However, other standard container sizes provide more flexibility. For instance, a 40-foot container, which measures 40' length x 8' width x 8'6'' height, nearly doubles the storage space offered by a 20-foot container. It provides approximately 2,390 cubic feet of storage, allowing for larger and bulkier cargo transportation. For higher loads and larger objects, the High Cube container is the ideal choice. It bears similar dimensions to the 40-foot standard container but stands taller with a height of 9'6''. Offering around 2,698 cubic feet of space, it serves to fulfill the demands of oversized or voluminous loads. Smaller containers also have their fair share of utilization, especially in the realm of small-scale shipments or storage. The 10-foot container, measuring 10' length x 8' width x 8'6'' height and providing around 585 cubic feet of space, happens to be a great fit for lesser amounts of cargo or for compact spaces. In choosing the right container, it's not a one-size-fits-all scenario. Size truly matters; with an understanding of standard container dimensions, one can make informed decisions and optimize cargo transportation or storage effectively. Understanding this allows for efficiency in logistics planning, as well as cost-effectiveness by preventing wasted space or overspending on unnecessary storage capacity. Hence, assuring an efficient logistic operation contingent upon a clear understanding of the dimensions of different types of containers.

The Variations: High Cube, Pallet Wide and Open Top Containers

The sizes and variations of shipping containers are paramount factors that often determine the choice of the container type to be used. Delving deeper into the various types, we encounter the High Cube, Pallet Wide, and Open Top Containers. These forms stand apart for their distinct capacities and utilities, proving that size indeed matters when it comes to container shipping. High Cube Containers are renowned for their additional interior height- around a foot taller than the standard containers. This feature greatly benefits transporting voluminous cargo, providing more vertical space to stack goods. Thus, high cube containers have superior load capacity even when the base square footage remains constant, enhancing logistics efficiency in transporting 'cubed-out' cargo where volume matters more than weight. On the other hand, the Pallet Wide Containers are an answer to a common industry problem. Frustration often arises when palletized goods cannot fit into standard containers efficiently, wasting crucial storage capacity. Pallet wide containers astutely resolve this issue with an extra couple of inches in their width, enabling maximum utilization of the floor space. Specifically designed to accommodate Euro-pallet sizes, these containers are a pivotal part of global trade in Europe. Lastly, the Open Top Containers bring a distinctive aspect by upending the paradigm of entry and exit in a container. The roof in these types can be completely removed, facilitating loading and unloading of cargo from the top. This feature is especially helpful for tall cargo that would not pass through the standard container’s doors. However, the absence of a solid roof doesn’t mean these containers are exposed; they come with a tarpaulin that can secure and protect the goods from the elements. In sum, High Cube Containers, Pallet Wide Containers, and Open Top Containers are variations that aptly highlight the 'one size doesn’t fit all' reality in container shipping. They are designed with specific needs in mind, providing innovative solutions to issues inherent in the logistics sector. Therefore, understanding the dimensions of different types of containers becomes a critical aspect of making informed choices in container shipping logistics.

Special Containers: Tank, Flat Rack and Reefer Containers

In the realm of shipping and logistics, understanding the dimensions and usability of different types of containers is crucial. When we dig deeper into the variety of these utility boxes, three specific types usually stand out - the Tank, Flat Rack, and Reefer Containers. Tank containers are made for the transportation of liquid cargo, such as oil, different types of chemicals, or even food products such as wine or juice. They are substantially different from the others due to their large cylindrical tanks situated within the container frame. The size of a tank container typically measures 20 feet in length, and due to the materials they're made from, usually steel and anti-corrosive materials, these containers can securely contain and transport various liquid products. Flat Rack containers, on the other hand, come with collapsible walls, and they are designed to carry oversized, heavy, or awkward cargoes. With standard lengths of 20 and 40 feet, Flat Racks can manage loads that challenge the size and shape of typical Containerized cargo. Their flexible structure makes them a preferred choice for items like large machinery, vehicles, or even prefabricated parts of new buildings. Flat Racks’ practicality and versatility in handling unconventional cargoes is a standout characteristic. Finally, Reefer Containers, short for Refrigerated Containers, serve a unique purpose in international trade of perishable commodities. Often chosen for transporting food products like fruits, vegetables, meat, or dairy products, Reefer Containers provide temperature controlled environment ranging from -65 to +40 degrees Celsius. They come in lengths of 20, 40, and even 53 feet, ensuring the freshness and quality of the goods during their sea or road journey. The value offered by container standardization is immense. It simplifies logistical complexities, ensures the safety of goods, and increases overall transportation efficiency. Whether it’s the Tank, Flat Rack, or Reefer, the containers are truly the unsung heroes of international trade and transport logistics, living proof that indeed, in this realm, size does matter.

Practical Implications: Why Container Sizes are Important

Container Sizes play a tremendous role in multiple facets of modern commerce - a reality that is often underestimated. Their importance is not restricted to basic functionality; it extends to impact aspects such as transport efficiency, space utilization, and cost management. In this enlightening discourse, we will delve into each of these three significant implications of container sizes. First, we'll investigate the role container sizes play in transport efficiency, evaluating their influence on the optimization of shipping and logistics operations. Additionally, we'll dissect the relationship between the dimensions of these containers and how they affect storage capacity and space utilization, a factor that directly impacts warehouse management and inventory costs. Lastly, we'll scrutinize the tie between container sizes and cost management, bearing in mind that the correct size choice can precipitate substantial savings or spiraling expenses. As we transition to our first point of discussion - the crucial association between container sizes and transport efficiency, it's crucial to remember that the effects of these variables are a domino-effect that directs the functionality and profitability of businesses worldwide.

The Role of Container Size in Transport Efficiency

Container size plays a pivotal role in transport efficiency, becoming a critical variable in both maritime and land logistics operations across the globe. When we talk about the size of a container, it is primarily a measure of its length, width, and height - dimensions that determine the volume of goods a single unit can accommodate. Notably, standardizing these sizes has proven to be an economic game-changer, a cornerstone of cost optimization and operational seamlessnes, underpinning global trade as we know it. The intricate calibration of container dimensions exhibits a direct relationship with the payload it can carry, thereby directly influencing transport cost dynamics. Larger containers translate to more cargo capacity which allows for economy of scale, reducing the cost per unit of goods being transported. In an increasingly cost-conscious market, this can be a vital factor contributing to a company’s competitiveness. However, it's not just about size - there's also the principle of 'size compatibility'. As global shipping norms dictate, containers need to be uniform to the standards established to integrate smoothly with different modes of transport such as ships, trains, and trucks. This uniformity enables streamlined, efficient system of loading and unloading processes, mitigating delays, and enhancing overall logistic productivity. Interestingly, the role of container size extends beyond operational efficiency itself. It also touches upon the environmental impact. Larger containers contribute to fewer trips in conveyance, consequently assisting in a reduction of greenhouse gas emissions. Thus, container size optimization warrants a more sustainable, eco-friendly transport process. However, the optimization of container dimensions isn't a straightforward task and the benefits of larger containers should also be contemplated against potential challenges. Constraints like infrastructure limitations or local regulations could impact container size selection. Furthermore, the preference for larger containers may not be the most cost-effective or applicable for all types of goods. In essence, understanding and attuning to appropriate container size has practical implications on transport efficiency which further spirals down to economical, operational, and environmental repercussions. It's all part of the pragmatic realty that reaffirms why the dimensions of containers are critically important in the sphere of global logistics.

Impacts of Container Size on Storage and Space Utilization

Understanding the impacts of container size on storage and space utilization goes beyond the simple consideration of dimensions. For efficient utilization of space in transportation, warehousing, or storage operations, the size of the container plays a significant role. This decisive factor often dominates the planning and execution stages, influencing cost and overall efficiency. Larger containers tend not only to occupy more physical space but also necessitate sophisticated handling equipment and larger storage areas. The footprint of a larger container could take up valuable real estate, thus reducing available room for other operations or equipment. However, large containers also present some advantages, including potentially lower relative handling costs per unit of cargo, increased protection for the cargo against external elements, and possible economies of scale. Conversely, smaller containers might be easier to handle, require less floor area, and could provide more flexibility in accommodating different types of cargo or navigating through constricted spaces. Additionally, smaller containers could also contribute to a lean inventory management strategy, avoiding potential wastage of space and money since goods could be managed efficiently. A competent understanding of a business's storage needs concerning the dimensions of the container can lead to optimizing both space and operations. Virtual computer-aided methods can further support businesses in foreseeing the impact and strategically planning their storage to optimally utilize space. In a digitized world, where space comes at a premium, prudent decision-making with regard to container size can play an instrumental role in managing costs and increasing productivity. Therefore, selecting container sizes should align with overall operational efficiency and business strategies rather than just physical availability of space. In short, while the size of a container directly impacts storage and space utilization, the longer-term implications for cost, productivity, and operational efficiency make it a crucial factor deserving serious consideration in operational planning. Simply put, the size of containers matters because it selflessly weaves itself into the operational fabric of businesses, impacting everything from space management to financial efficiency. As such, container sizes can be considered as an intrinsic part of strategic space and storage utilization in any aspect of trade and commerce.

Container Sizes and Their Influence on Cost Management

Container sizes significantly influence cost management in various industries, especially in shipping. The reason for this is simple; the container's size correlates directly with its capacity to house products. Logically, larger containers can accommodate a larger volume of goods, which can lead to cost-effectiveness in shipping larger batches. However, the implication here is not a one-size-fits-all solution but rather a matter of strategic planning based on business nature and needs. Consider this analogy: imagine you are filling a jar with sand. Smaller grains fit more efficiently into the available space, leaving less wasted room than larger grains. Similarly, choosing the right container size is akin to picking the ideal 'grain size.' Precise selection helps maximize utility and directly impacts cost management. Consistently making the most of the container's full potential minimizes unused 'white space,' effectively reducing waste and inefficiency. Optimal container usage translates into reduced shipping costs, which, in turn, impacts the overall economy of scale, driving down per-unit cost. This cost advantage can then be transferred down the line, benefiting consumers with more competitive pricing. Simultaneously, understanding container sizes extends beyond mere cost-saving. It also contributes to streamlining the supply chain management process. By making informed decisions about container sizes, businesses can manage their inventory more efficiently. They can decide when to ship, based on whether they can fill a container or should wait to avoid half-filled transport. This not only influences cost management but also affects other crucial dimensions like time management and environmental sustainability. Elsewhere, in warehousing, the container size is equally impactful. Right-sized containers can improve warehouse space utilization, contributing positively to inventory management, accessibility, and eventually operating costs. In conclusion, the significance of container sizes transcends its physical form and bears practical implications for robust cost management. Whether in shipping or storage, making smart choices about container sizes can result in superior operational efficiency, improved cost management, and enhanced customer satisfaction.