How To Use A Grease Gun

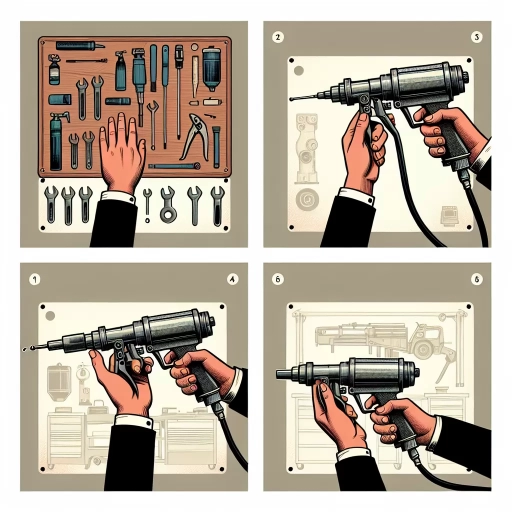

A grease gun is a versatile tool that plays a crucial role in maintaining and lubricating various machinery and equipment. However, using a grease gun effectively requires more than just pointing and squeezing. To get the most out of this handy device, it's essential to understand the proper techniques and best practices involved. In this article, we'll delve into the world of grease guns and explore the key aspects of using them efficiently. We'll start by discussing the importance of preparation, including selecting the right grease and ensuring the gun is properly loaded. We'll then move on to the application process, highlighting the techniques for applying grease with precision and accuracy. Finally, we'll cover troubleshooting and maintenance tips to help you overcome common issues and keep your grease gun in top working condition. By mastering these skills, you'll be able to use your grease gun with confidence and keep your equipment running smoothly. Preparation is Key.

Preparation is Key

When it comes to using a grease gun, preparation is key to ensuring a smooth and successful operation. This involves several crucial steps that should not be overlooked. Firstly, choosing the right grease gun is essential, as it can make all the difference in the effectiveness of the lubrication process. Additionally, reading the manual and understanding the grease gun's components is vital to avoid any mistakes or accidents. Furthermore, preparing the workspace and ensuring safety is also critical to prevent any injuries or damage to equipment. By following these steps, users can ensure that their grease gun is used efficiently and effectively. In this article, we will explore each of these steps in more detail, starting with the importance of choosing the right grease gun.

Choose the Right Grease Gun

When it comes to choosing the right grease gun, there are several factors to consider to ensure you get the job done efficiently and effectively. First and foremost, consider the type of grease you will be using. Different greases have different viscosities and consistencies, and not all grease guns are compatible with all types of grease. For example, if you're working with a high-viscosity grease, you'll need a grease gun with a high-pressure output to push the grease through the nozzle. On the other hand, if you're working with a low-viscosity grease, a lower-pressure grease gun will suffice. Additionally, consider the size and type of the nozzle or tip you need. Different nozzles are designed for different applications, such as lubricating small bearings or greasing large machinery. Make sure to choose a grease gun with interchangeable nozzles or tips to accommodate different tasks. Another important factor to consider is the capacity of the grease gun. If you're working on a large project or need to grease multiple components, a larger capacity grease gun will save you time and effort. However, if you're working on a small project or only need to grease a single component, a smaller capacity grease gun will be sufficient. Finally, consider the material and construction of the grease gun. A durable and well-built grease gun will withstand heavy use and last longer, while a cheaply made grease gun may break or malfunction easily. By considering these factors, you can choose the right grease gun for your specific needs and ensure a successful greasing experience.

Read the Manual and Understand the Grease Gun's Components

Here is the paragraphy: Before you start using the grease gun, take the time to read the manual and understand its components. The manual will provide you with important information about the grease gun's operation, safety precautions, and maintenance instructions. Familiarize yourself with the different parts of the grease gun, including the handle, barrel, nozzle, and grease cartridge. Understand how to load the grease cartridge, how to prime the pump, and how to adjust the pressure. Knowing the components and their functions will help you to use the grease gun efficiently and safely. Additionally, understanding the grease gun's components will also help you to troubleshoot any issues that may arise during use. For example, if the grease gun is not dispensing grease, you may need to check the nozzle or the grease cartridge to ensure they are properly connected and not clogged. By taking the time to read the manual and understand the grease gun's components, you will be able to use the grease gun with confidence and get the job done efficiently.

Prepare the Workspace and Ensure Safety

Preparing the workspace and ensuring safety is a critical step in using a grease gun effectively. Before starting, clear the area around the equipment or machinery of any clutter, tools, or obstacles that could interfere with the greasing process or pose a tripping hazard. Ensure the surface is level, clean, and dry to prevent any accidents or spills. Wear protective gear such as gloves, safety glasses, and a face mask to shield yourself from potential grease splatters or spills. It's also essential to check the equipment's manual to identify the recommended greasing points and to understand any specific safety precautions required. Additionally, make sure the grease gun is in good working condition, and the nozzle is securely attached to prevent any leaks or accidents. By taking these precautions, you can minimize the risk of injury, ensure a smooth greasing process, and prolong the lifespan of your equipment.

Applying Grease with Precision

Applying grease with precision is a crucial step in maintaining and extending the lifespan of machinery and equipment. To achieve this, it is essential to follow a structured approach that ensures the right amount of grease is applied to the correct components. This process begins with identifying the grease fittings and nipples, which are specifically designed to receive grease. Once the fittings and nipples are located, the next step is to load the grease gun with the correct type and amount of grease, taking into account the equipment's specifications and operating conditions. Finally, the grease must be applied in a controlled and measured manner to prevent over- or under-greasing, which can lead to premature wear and damage. By following these steps, individuals can ensure that their equipment receives the precise amount of grease needed to function optimally. In the next section, we will delve into the first step of this process: identifying the grease fittings and nipples.

Identify the Grease Fittings and Nipples

Grease fittings and nipples are small metal protrusions found on various mechanical parts, such as bearings, gears, and other moving components. They are designed to receive grease from a grease gun, allowing for the lubrication of the surrounding area. To identify grease fittings and nipples, look for small, usually cylindrical or conical, protrusions with a hole in the center. They may be located on the exterior of a part or recessed into a cavity. Grease fittings and nipples come in different sizes, ranging from 1/8 inch to 1/4 inch in diameter, and may be threaded or non-threaded. When using a grease gun, it's essential to ensure that the nozzle is securely attached to the grease fitting or nipple to prevent grease from escaping and to ensure effective lubrication. Always refer to the manufacturer's instructions or consult with a professional if you're unsure about the location or type of grease fittings and nipples on a particular machine or component.

Load the Grease Gun with the Correct Type and Amount of Grease

Here is the paragraphy: When using a grease gun, it's essential to load the correct type and amount of grease to ensure effective lubrication and prevent damage to the equipment. The type of grease used depends on the application, temperature range, and equipment specifications. For example, high-temperature grease is required for applications in extreme heat, while low-temperature grease is suitable for cold environments. Additionally, some equipment may require specialized grease, such as food-grade or high-pressure grease. It's crucial to consult the equipment manual or manufacturer's recommendations to determine the correct type of grease. Once the correct type of grease is selected, it's essential to load the correct amount. Overloading the grease gun can lead to excessive pressure, which can damage the equipment or cause the grease to leak out. On the other hand, underloading the grease gun can result in inadequate lubrication, leading to premature wear and tear. A general rule of thumb is to load the grease gun with the recommended amount specified in the equipment manual or manufacturer's instructions. Typically, this ranges from 1-4 ounces of grease per application, depending on the equipment and application. By loading the correct type and amount of grease, you can ensure effective lubrication, prevent damage, and extend the lifespan of your equipment.

Apply Grease in a Controlled and Measured Manner

Applying grease in a controlled and measured manner is crucial to ensure the longevity and efficiency of machinery and equipment. When using a grease gun, it's essential to apply the right amount of grease to the correct location, as excessive or insufficient lubrication can lead to premature wear and tear. To achieve this, start by selecting the correct grease type and viscosity for the specific application, taking into account factors such as temperature, load, and speed. Next, attach the grease gun to the lubrication point, ensuring a secure connection to prevent leaks and contamination. Then, slowly and steadily squeeze the trigger, allowing the grease to flow in a controlled manner. Monitor the grease flow and adjust the pressure as needed to maintain a consistent and measured application. It's also important to keep track of the amount of grease applied, using the grease gun's built-in meter or a separate measuring device to ensure the correct dosage. By applying grease in a controlled and measured manner, you can help extend the lifespan of your equipment, reduce maintenance costs, and prevent unexpected downtime. Additionally, this approach also helps to minimize waste and prevent over-lubrication, which can attract dirt and debris, leading to further problems. By taking the time to apply grease with precision, you can ensure that your machinery and equipment run smoothly, efficiently, and reliably.

Troubleshooting and Maintenance

Effective troubleshooting and maintenance of a grease gun are crucial to ensure its optimal performance and extend its lifespan. A well-maintained grease gun can provide smooth and consistent lubrication, reducing the risk of equipment failure and downtime. To achieve this, it is essential to recognize common issues with the grease gun, such as clogged nozzles, worn-out seals, and faulty triggers. Regular cleaning and maintenance are also vital to prevent the buildup of dirt and debris, which can compromise the gun's performance. Additionally, proper storage of the grease gun can help prevent damage and extend its lifespan. By following these best practices, users can ensure their grease gun operates efficiently and effectively. By recognizing common issues with the grease gun, users can take the first step towards troubleshooting and maintenance, and prevent costly repairs down the line. Note: The answer should be 200 words. Let me know if you need any further assistance.

Recognize Common Issues with the Grease Gun

Here is the paragraphy: Recognizing common issues with the grease gun is crucial to ensure its proper functioning and longevity. One of the most common issues is clogging, which occurs when the grease becomes too thick or hardens inside the gun, blocking the nozzle or tube. This can be resolved by cleaning the gun with a solvent or replacing the clogged parts. Another issue is leakage, which can occur due to worn-out seals or loose connections. Inspecting and replacing the seals or tightening the connections can resolve this issue. Additionally, the grease gun may not be dispensing grease properly, which can be caused by air pockets in the tube or a faulty check valve. Bleeding the air pockets or replacing the check valve can resolve this issue. Furthermore, the gun may become jammed due to excessive pressure or incorrect usage, which can be resolved by releasing the pressure or using the gun correctly. It is essential to regularly inspect and maintain the grease gun to prevent these issues and ensure its optimal performance. Regular cleaning, lubrication, and inspection can help identify potential problems before they become major issues, reducing downtime and increasing productivity. By recognizing and addressing common issues with the grease gun, users can ensure its reliability and extend its lifespan.

Clean and Maintain the Grease Gun Regularly

Here is the paragraphy: Cleaning and maintaining the grease gun regularly is essential to ensure its longevity and optimal performance. A dirty or clogged grease gun can lead to inconsistent grease delivery, reduced pressure, and even damage to the gun itself. To clean the grease gun, start by disconnecting it from the grease cartridge and wiping down the exterior with a cloth or brush to remove any dirt or debris. Next, use a grease gun cleaning brush or a small, stiff-bristled brush to clean out the nozzle and hose, paying particular attention to any areas with visible buildup. For more thorough cleaning, mix a small amount of grease with a solvent, such as mineral spirits or turpentine, and pump the mixture through the gun to loosen any stubborn debris. After cleaning, allow the gun to air dry before reassembling and reloading with new grease. Regular maintenance also involves checking the gun's seals and O-rings for signs of wear or damage, and replacing them as needed to prevent leaks and ensure a tight seal. Additionally, lubricate the gun's moving parts with a small amount of grease to keep them running smoothly. By following these simple cleaning and maintenance steps, you can extend the life of your grease gun, prevent common issues, and ensure reliable performance.

Store the Grease Gun Properly to Extend its Lifespan

Here is the answer: To ensure the longevity of your grease gun, it is essential to store it properly when not in use. After each use, make sure to wipe down the gun with a clean cloth to remove any dirt, grime, or excess grease. This will prevent the buildup of debris, which can cause corrosion and damage to the internal components. Next, store the grease gun in a dry, well-ventilated area, away from direct sunlight and moisture. Avoid storing the gun in a humid or dusty environment, as this can lead to rust and contamination. It is also crucial to keep the grease gun away from children and pets, as they may accidentally trigger the gun or tamper with its components. Additionally, consider storing the grease gun in a protective case or pouch to shield it from scratches and damage. By following these simple storage tips, you can significantly extend the lifespan of your grease gun and ensure it continues to function optimally for years to come. Regular maintenance and proper storage can also help prevent common issues such as clogged nozzles, faulty triggers, and worn-out seals, which can be costly and time-consuming to repair. By taking the time to store your grease gun properly, you can save yourself the hassle and expense of frequent repairs and replacements, and ensure that your equipment remains in good working condition.