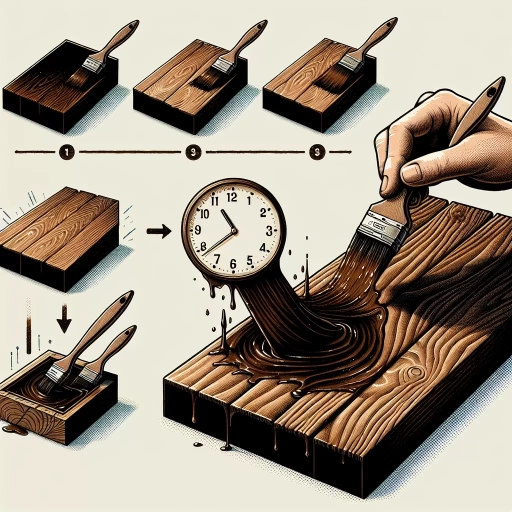

How Long Does Wood Stain Take To Dry

Wood stain is a popular finish for wood surfaces, offering protection and aesthetic appeal. However, one of the most common questions among woodworkers and DIY enthusiasts is how long does wood stain take to dry. The answer to this question is not straightforward, as it depends on several factors. In this article, we will explore the factors that affect wood stain drying time, provide general guidelines for drying times, and offer best practices for speeding up the process. Understanding these factors is crucial to achieving a successful finish. Factors such as temperature, humidity, and type of stain can significantly impact drying time. By considering these factors, you can plan your project accordingly and avoid delays. So, what are the key factors that affect wood stain drying time?

Factors Affecting Wood Stain Drying Time

When it comes to achieving a professional-looking finish with wood stain, one of the most critical factors to consider is the drying time. A slow-drying stain can lead to a tacky, uneven finish, while a stain that dries too quickly can result in a brittle, cracked surface. Several factors can affect the drying time of wood stain, including humidity and temperature, the thickness of the stain application, and the type of wood and stain used. Understanding these factors is crucial to achieving a smooth, even finish. For instance, high humidity and temperature can significantly impact the drying time of wood stain, as they can slow down the evaporation of solvents and affect the stain's ability to penetrate the wood evenly. In this article, we will explore the impact of humidity and temperature on wood stain drying time, as well as the effects of thickness of the stain application and type of wood and stain used. First, let's take a closer look at how humidity and temperature can affect the drying time of wood stain.

Humidity and Temperature

Humidity and temperature are two crucial factors that significantly impact the drying time of wood stain. When it comes to humidity, a relative humidity (RH) of 50-60% is considered ideal for wood stain drying. If the RH is too high, above 70%, the stain will take longer to dry, as the excess moisture in the air slows down the evaporation process. On the other hand, if the RH is too low, below 40%, the stain may dry too quickly, leading to uneven color and finish. Temperature also plays a vital role in the drying process. Most wood stains dry best in temperatures between 60°F and 80°F (15°C and 27°C). If the temperature is too high, above 90°F (32°C), the stain may dry too quickly, causing it to become brittle and prone to cracking. Conversely, if the temperature is too low, below 50°F (10°C), the stain may take longer to dry, or may not dry properly at all. It's essential to maintain a consistent temperature and humidity level to ensure the wood stain dries evenly and within the recommended time frame. By controlling these factors, you can achieve a professional-looking finish and ensure the longevity of your wood project.

Thickness of the Stain Application

The thickness of the stain application is a crucial factor in determining the drying time of wood stain. A thicker application of stain will take longer to dry than a thinner one. This is because the stain needs to penetrate deeper into the wood, and the excess stain on the surface needs to evaporate before the stain can fully dry. If the stain is applied too thickly, it can take several days or even weeks to fully dry, depending on the type of stain and environmental conditions. On the other hand, a thin application of stain will dry much faster, usually within a few hours or overnight. It's essential to follow the manufacturer's instructions for the recommended application thickness to ensure optimal drying time and a professional-looking finish. Additionally, using a foam brush or cloth to apply the stain can help to achieve a more even and thinner application, which can also aid in faster drying times.

Type of Wood and Stain Used

The type of wood and stain used can significantly impact the drying time of wood stain. Different types of wood have varying densities and porosities, which affect how quickly the stain is absorbed and dried. For example, hardwoods like oak and maple tend to dry faster than softwoods like pine and fir, as they have a denser grain structure. On the other hand, woods with high resin content, such as cedar and cypress, may take longer to dry due to the natural oils present in the wood. The type of stain used also plays a crucial role in determining the drying time. Oil-based stains, which contain solvents like mineral spirits or turpentine, tend to dry faster than water-based stains, which rely on evaporation to dry. Additionally, the color and finish of the stain can also impact the drying time, with darker colors and glossier finishes taking longer to dry than lighter colors and matte finishes. Furthermore, some stains may contain additives or conditioners that can affect the drying time, such as UV blockers or wood conditioners. Understanding the type of wood and stain used is essential to accurately estimate the drying time and ensure a successful staining project.

General Guidelines for Wood Stain Drying Time

When it comes to wood stain drying time, there are several factors to consider, including the type of stain, environmental conditions, and the surface preparation of the wood. Generally, wood stains can be categorized into three main groups based on their drying times: fast-drying stains, standard drying stains, and slow-drying stains. Fast-drying stains typically take between 1-2 hours to dry, making them ideal for projects that require quick turnaround times. Standard drying stains take around 2-4 hours to dry, while slow-drying stains can take 4-6 hours or more to fully dry. Understanding the drying time of your wood stain is crucial to achieve the desired finish and avoid any potential issues. In this article, we will explore the general guidelines for wood stain drying time, starting with fast-drying stains, which can be ready to recoat or finish in as little as 1-2 hours.

Fast-Drying Stains (1-2 hours)

Fast-drying stains are a popular choice for woodworkers and DIYers who want to complete their projects quickly. These stains are formulated to dry within 1-2 hours, depending on the specific product and environmental conditions. Fast-drying stains are usually water-based or oil-based with a high solvent content, which allows them to evaporate quickly. They are ideal for projects that require a fast turnaround, such as furniture making, woodturning, or refinishing. However, it's essential to note that fast-drying stains may not provide the same level of color depth and richness as slower-drying stains. Additionally, they may require multiple coats to achieve the desired color, which can increase the overall drying time. To ensure the best results with fast-drying stains, it's crucial to follow the manufacturer's instructions and apply the stain in a well-ventilated area. It's also recommended to test the stain on a small, inconspicuous area before applying it to the entire project. This will help you determine the optimal drying time and ensure that the stain doesn't dry too quickly or unevenly. Overall, fast-drying stains are a convenient option for woodworkers who need to complete their projects quickly, but they may require some compromise on color quality and drying time.

Standard Drying Stains (2-4 hours)

Standard drying stains are the most common type of wood stain and typically take between 2-4 hours to dry. These stains are usually oil-based or water-based and are designed to provide a rich, even color to the wood. The drying time for standard drying stains can vary depending on the specific product, environmental conditions, and the type of wood being stained. In general, oil-based stains take longer to dry than water-based stains, and stains applied in high humidity or low temperatures may take longer to dry than those applied in ideal conditions. It's essential to follow the manufacturer's instructions and wait the recommended amount of time before applying a second coat or sealing the wood. Applying a second coat too soon can result in uneven color or a sticky finish, while sealing the wood too soon can trap moisture and cause the stain to peel or flake off. By allowing the standard drying stain to dry for the recommended 2-4 hours, you can ensure a professional-looking finish and a durable, long-lasting result.

Slow-Drying Stains (4-6 hours or more)

Slow-drying stains, which take 4-6 hours or more to dry, are typically oil-based and contain solvents that evaporate slowly. These stains are often used on dense hardwoods, such as oak and maple, and are ideal for projects that require a rich, deep color. The slow-drying process allows the stain to penetrate deeper into the wood, resulting in a more even and consistent color. However, this longer drying time can be a drawback for projects with tight deadlines. It's essential to plan ahead and allow sufficient time for the stain to dry completely before applying a finish or sealant. Factors such as temperature, humidity, and air circulation can also impact the drying time of slow-drying stains, so it's crucial to follow the manufacturer's instructions and take necessary precautions to ensure optimal drying conditions. By understanding the characteristics of slow-drying stains, woodworkers and DIYers can achieve professional-looking results and avoid common mistakes that can lead to uneven color and finish.

Best Practices for Speeding Up Wood Stain Drying Time

When it comes to working with wood stain, one of the most frustrating aspects can be waiting for it to dry. Whether you're a seasoned professional or a DIY enthusiast, speeding up the drying time can be a game-changer for your project. Fortunately, there are several best practices that can help you achieve faster drying times without compromising the quality of your finish. By applying thin coats, using a fan or dehumidifier, and working in a well-ventilated area, you can significantly reduce the time it takes for your wood stain to dry. One of the most effective ways to speed up the drying process is to apply thin coats of stain, allowing each layer to dry before adding the next. This approach not only helps to prevent pooling and uneven drying but also ensures a smooth, even finish. By applying thin coats, you can achieve a professional-looking result while minimizing the risk of delays and setbacks.

Applying Thin Coats

Applying thin coats is a crucial best practice for speeding up wood stain drying time. When you apply thin coats, you allow the stain to dry faster and more evenly. This is because thin coats have less material to dry, reducing the overall drying time. Additionally, thin coats help prevent the stain from pooling or running, which can lead to uneven drying and a longer drying time. To apply thin coats, use a clean, lint-free cloth or foam brush to apply the stain in smooth, even strokes. Work in small sections, about 4 feet by 4 feet, to maintain even coverage and prevent the stain from drying out before you can wipe off any excess. Apply the stain in a thin, uniform layer, using long, smooth strokes to cover the entire section. Use a clean cloth to wipe off any excess stain, feathering the edges to blend the stain into the surrounding area. By applying thin coats, you can significantly reduce the drying time of your wood stain, allowing you to move on to the next step in your project more quickly. As a general rule, apply no more than 1-2 coats of stain per day, allowing each coat to dry completely before applying the next. This will help prevent the stain from becoming too thick and slow to dry. By following this best practice, you can achieve a beautiful, professional-looking finish on your wood project, while also saving time and effort.

Using a Fan or Dehumidifier

Using a fan or dehumidifier can significantly speed up the wood stain drying process. A fan can help circulate the air, allowing the stain to dry faster and more evenly. Position the fan to blow air directly onto the stained surface, but be cautious not to blow too hard, as this can create uneven drying patterns. On the other hand, a dehumidifier can remove excess moisture from the air, creating an environment that is conducive to faster drying. By reducing the humidity levels, you can prevent the stain from taking longer to dry due to excess moisture in the air. It's essential to note that using a dehumidifier is particularly effective in humid environments or during the summer months when the air is naturally more humid. By combining the use of a fan and dehumidifier, you can create an optimal drying environment that will help your wood stain dry faster and more evenly.

Working in a Well-Ventilated Area

Working in a well-ventilated area is crucial when working with wood stain, as it helps to speed up the drying process and ensures a safe working environment. Good airflow allows the solvents in the stain to evaporate quickly, reducing the drying time and preventing the buildup of fumes. A well-ventilated area also helps to prevent the growth of mold and mildew, which can occur when moisture becomes trapped in the air. To ensure good ventilation, open windows and doors, and use fans to circulate the air. If working in a confined space, consider using a respirator or mask to protect yourself from inhaling fumes. Additionally, keep the workspace clean and clear of clutter to allow for good airflow and prevent accidents. By working in a well-ventilated area, you can ensure a safe and efficient staining process, and achieve professional-looking results.