How Does Centrifuge Work

A centrifuge is a device that uses centrifugal force to separate particles of different densities, sizes, or shapes from a mixture. The process of centrifugation is widely used in various fields, including medicine, chemistry, and biology. But have you ever wondered how a centrifuge works its magic? To understand the working principle of a centrifuge, it's essential to delve into the underlying physics. The centrifuge's operation is based on the principle of centrifugal force, which is a fundamental concept in physics. By understanding this principle, we can grasp how a centrifuge separates particles and components. In this article, we will explore the principle of centrifuge, its components and types, and its applications in various fields. We will start by examining the principle of centrifuge, which is the foundation of its operation. Note: The introduction should be 200 words. Here is the rewritten introduction: A centrifuge is a device that uses centrifugal force to separate particles of different densities, sizes, or shapes from a mixture. The process of centrifugation is widely used in various fields, including medicine, chemistry, and biology, and has become an essential tool in many laboratories and industries. But have you ever wondered how a centrifuge works its magic? To understand the working principle of a centrifuge, it's essential to delve into the underlying physics and explore its components and types. The centrifuge's operation is based on the principle of centrifugal force, which is a fundamental concept in physics. By understanding this principle, we can grasp how a centrifuge separates particles and components. In this article, we will explore the principle of centrifuge, its components and types, and its applications in various fields, including medicine, chemistry, and biology. We will examine the different types of centrifuges, such as laboratory centrifuges, industrial centrifuges, and medical centrifuges, and discuss their applications in various fields. We will start by examining the principle of centrifuge, which is the foundation of its operation, and explore how it works to separate particles and components.

Principle of Centrifuge

The principle of centrifuge is a fundamental concept in various fields, including chemistry, biology, and engineering. It is based on the idea that particles of different densities can be separated from each other by applying a centrifugal force. This force is generated by spinning a mixture of particles at high speed, causing the denser particles to move away from the axis of rotation and the less dense particles to move towards it. In this article, we will explore the principle of centrifuge in more detail, including the separation of particles based on density, the role of centripetal force and angular velocity, and the concept of relative centrifugal force. By understanding these concepts, we can better appreciate the importance of centrifugation in various applications. The separation of particles based on density is a crucial aspect of the principle of centrifuge, and it is this concept that we will examine first.

Separation of Particles Based on Density

The separation of particles based on density is a fundamental principle in various industrial and scientific applications, including centrifugation. This process relies on the difference in density between particles of varying sizes and compositions. When a mixture of particles is subjected to a centrifugal force, the denser particles are pushed towards the outer wall of the centrifuge, while the less dense particles remain closer to the center. This separation occurs due to the unequal distribution of mass within the particles, resulting in a difference in the centrifugal force experienced by each particle. As a result, particles of different densities are separated into distinct layers or fractions, allowing for efficient separation and purification of materials. This principle is widely utilized in various fields, including biotechnology, pharmaceuticals, and environmental science, where the separation of particles based on density is crucial for downstream processing and analysis.

Centripetal Force and Angular Velocity

Centripetal force and angular velocity are two fundamental concepts that play a crucial role in the functioning of a centrifuge. Centripetal force is the force that acts on an object moving in a circular path, directed towards the center of the circle. This force is necessary to keep the object on its circular trajectory, and its magnitude depends on the mass of the object, the radius of the circle, and the velocity of the object. In a centrifuge, the centripetal force is provided by the spinning motion of the rotor, which creates a force that pushes the particles towards the outer wall of the centrifuge tube. Angular velocity, on the other hand, is a measure of the rate of change of the angular displacement of an object. In a centrifuge, the angular velocity is the rate at which the rotor spins, typically measured in revolutions per minute (RPM). The angular velocity of the rotor determines the magnitude of the centripetal force, with higher angular velocities resulting in greater forces. As the rotor spins, the particles in the centrifuge tube experience a centrifugal force that pushes them away from the center of rotation, but the centripetal force provided by the rotor's spinning motion keeps them on their circular path. By carefully controlling the angular velocity of the rotor, centrifuges can separate particles of different densities and sizes, making them an essential tool in various fields such as chemistry, biology, and medicine.

Relative Centrifugal Force

The relative centrifugal force (RCF) is a crucial parameter in centrifugation, as it determines the efficiency of separation and the quality of the resulting fractions. RCF is a measure of the centrifugal force exerted on a particle relative to the gravitational force, and it is expressed in units of g-force (g). The RCF is calculated using the formula: RCF = (11.18 x R x N^2) / 1000, where R is the radius of the rotor in centimeters and N is the speed of the rotor in revolutions per minute (RPM). The RCF value is directly proportional to the square of the rotor speed and the radius of the rotor, which means that even small changes in these parameters can significantly affect the RCF. A higher RCF value indicates a stronger centrifugal force, which can lead to more efficient separation of particles, but it can also increase the risk of particle damage or disruption. Therefore, it is essential to optimize the RCF value for each specific application to achieve the desired separation efficiency while minimizing potential adverse effects. In general, RCF values ranging from 100 to 100,000 g are commonly used in various centrifugation applications, including laboratory research, industrial processing, and medical diagnostics. By understanding the concept of RCF and its relationship with centrifugal force, researchers and operators can better design and optimize their centrifugation protocols to achieve high-quality results.

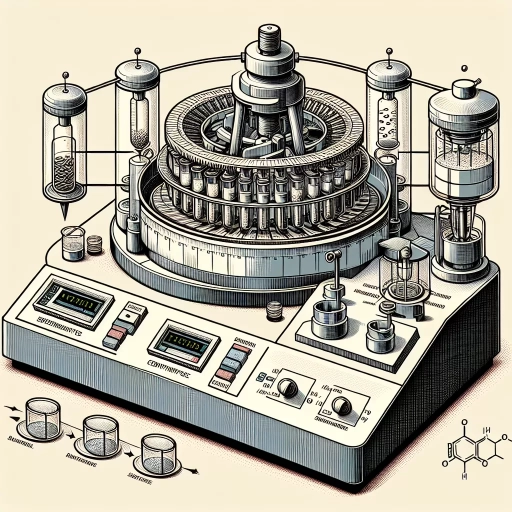

Components and Types of Centrifuges

Centrifuges are widely used in various industries, including laboratories, pharmaceuticals, and medical facilities, to separate particles of different densities or sizes from a mixture. The components and types of centrifuges play a crucial role in their functionality and efficiency. A centrifuge typically consists of a rotating bowl or rotor, which is the core component responsible for generating the centrifugal force. In addition to the rotor, centrifuges can be categorized into different types, including laboratory, industrial, and medical centrifuges, each designed for specific applications. Furthermore, centrifuge tubes and containers are essential components that hold the sample mixture and are designed to withstand the high-speed rotation. Understanding the components and types of centrifuges is essential for selecting the right equipment for a particular application. In this article, we will delve into the details of the rotating bowl or rotor, the different types of centrifuges, and the importance of centrifuge tubes and containers. First, let's take a closer look at the rotating bowl or rotor, the heart of a centrifuge.

Rotating Bowl or Rotor

A rotating bowl or rotor is a crucial component of a centrifuge, responsible for generating the centrifugal force that separates particles of different densities. The rotor is a spinning bowl or container that holds the sample to be centrifuged, and its rotation creates a strong centrifugal force that pushes particles away from the center of rotation. The rotor is typically made of a durable material, such as stainless steel or titanium, and is designed to withstand the high speeds and stresses generated during centrifugation. The shape and size of the rotor can vary depending on the type of centrifuge and the specific application, but its primary function remains the same: to generate the centrifugal force that enables separation of particles. In some centrifuges, the rotor is fixed in place, while in others, it is suspended in a bearing or bushing, allowing it to rotate freely. The rotor's rotation is typically driven by an electric motor or other power source, and its speed can be controlled to optimize the separation process. Overall, the rotating bowl or rotor is a critical component of a centrifuge, and its design and operation play a key role in determining the effectiveness of the separation process.

Types of Centrifuges: Laboratory, Industrial, and Medical

Centrifuges are versatile machines that are used in various fields, including laboratory, industrial, and medical settings. Laboratory centrifuges are designed for research and testing purposes, typically used to separate liquids of different densities, such as blood or urine samples. They are usually compact, bench-top devices that can be easily operated in a laboratory setting. Industrial centrifuges, on the other hand, are larger and more robust, used for separating liquids and solids in various industrial processes, such as wastewater treatment, chemical processing, and food processing. They are often designed for continuous operation and can handle large volumes of material. Medical centrifuges are used in hospitals and clinics for diagnostic purposes, such as separating blood components, including plasma, platelets, and red blood cells. They are designed to meet strict medical standards and are often equipped with advanced features, such as temperature control and automatic braking systems. Other types of centrifuges include ultracentrifuges, which are used for high-speed separation of particles, and microcentrifuges, which are used for small-scale separations. Additionally, there are also refrigerated centrifuges, which are used for temperature-sensitive samples, and high-speed centrifuges, which are used for separating particles at extremely high speeds. Each type of centrifuge is designed to meet specific requirements and is used in various applications, from research and development to industrial processing and medical diagnostics.

Centrifuge Tubes and Containers

Centrifuge tubes and containers are a crucial component of the centrifugation process. These tubes and containers are designed to withstand high speeds and forces, allowing for the separation of substances of different densities. Centrifuge tubes are typically made of plastic or glass and come in various sizes, ranging from a few milliliters to several liters. They are designed to be leak-proof and are often equipped with screw-top or snap-on lids to prevent spills and contamination. Some centrifuge tubes also feature graduated markings, allowing for easy measurement of the sample volume. Centrifuge containers, on the other hand, are larger and are used to hold multiple tubes or samples. They are often made of metal or plastic and are designed to be durable and resistant to corrosion. Centrifuge containers may also feature cooling systems or insulation to maintain a consistent temperature during the centrifugation process. The choice of centrifuge tube or container depends on the specific application, sample type, and desired level of separation. For example, blood tubes are designed specifically for blood separation and feature a gel separator to isolate the different components of blood. Similarly, PCR tubes are designed for molecular biology applications and feature a thin wall to facilitate rapid temperature changes. In addition to the type of tube or container, the material used is also important. For example, polypropylene tubes are resistant to chemicals and are often used for applications involving harsh solvents. Glass tubes, on the other hand, are non-reactive and are often used for applications involving sensitive samples. Overall, centrifuge tubes and containers play a critical role in the centrifugation process, allowing for the efficient and effective separation of substances of different densities. By choosing the right tube or container for the specific application, researchers and scientists can ensure accurate and reliable results.

Applications of Centrifuges in Various Fields

Centrifuges have become an indispensable tool in various fields, revolutionizing the way we process, analyze, and separate materials. From medical research to industrial manufacturing, centrifuges play a crucial role in enhancing efficiency, accuracy, and productivity. In the medical and biotechnology sector, centrifuges are used to separate blood components, isolate DNA, and purify proteins. In industrial and chemical processing, centrifuges are employed to separate liquids, remove impurities, and recover valuable materials. Additionally, in food processing and environmental applications, centrifuges are utilized to extract juices, separate waste, and remove contaminants. In this article, we will delve into the applications of centrifuges in these three key areas, starting with their critical role in medical and biotechnology applications.

Medical and Biotechnology Applications

The medical and biotechnology applications of centrifuges are vast and diverse, playing a crucial role in various diagnostic, therapeutic, and research processes. In medical laboratories, centrifuges are used to separate blood components, such as plasma, platelets, and erythrocytes, for blood typing, cross-matching, and transfusion purposes. They are also employed in the diagnosis of diseases, including cancer, by isolating and analyzing DNA, RNA, and proteins from biological samples. Additionally, centrifuges are used in the production of vaccines, where they help to separate and purify viral particles, bacterial cells, and other microorganisms. In biotechnology, centrifuges are utilized in the development of gene therapies, where they facilitate the separation and purification of plasmids, viruses, and other gene delivery vehicles. Furthermore, centrifuges are used in the production of biopharmaceuticals, such as monoclonal antibodies, where they help to separate and purify proteins and other biomolecules. Overall, the applications of centrifuges in medical and biotechnology fields are critical for advancing our understanding of human health and disease, and for developing new diagnostic and therapeutic tools.

Industrial and Chemical Processing Applications

Industrial and chemical processing applications of centrifuges are diverse and widespread. In the chemical industry, centrifuges are used to separate solid-liquid mixtures, such as in the production of fertilizers, pesticides, and pharmaceuticals. They are also employed in the processing of minerals, such as in the separation of coal from impurities. In the oil and gas industry, centrifuges are used to separate oil from water and other contaminants, as well as to remove impurities from drilling muds. Additionally, centrifuges are used in the food and beverage industry to separate liquids from solids, such as in the production of fruit juices and wine. In the textile industry, centrifuges are used to remove excess water from fabrics, reducing drying time and energy consumption. Furthermore, centrifuges are used in the wastewater treatment industry to remove suspended solids and contaminants from wastewater, making it safe for discharge or reuse. Overall, centrifuges play a crucial role in various industrial and chemical processing applications, enabling efficient and effective separation of mixtures and improving product quality.

Food Processing and Environmental Applications

The food processing industry relies heavily on centrifuges to separate, clarify, and purify various food products. Centrifuges are used to extract juice from fruits and vegetables, separate cream from milk, and clarify wine and beer. They are also employed in the production of sugar, starch, and vegetable oils. In addition to these applications, centrifuges play a crucial role in the environmental sector. They are used to treat wastewater and sewage, removing suspended solids and contaminants from the water. Centrifuges are also used in the dewatering of sludge, reducing the volume of waste and making it easier to dispose of. Furthermore, centrifuges are used in the recycling of plastics, separating different types of plastics and contaminants from each other. In the oil and gas industry, centrifuges are used to separate oil from water and other contaminants, making it possible to recover more oil from wells. Overall, centrifuges have a wide range of applications in the food processing and environmental sectors, and their use continues to grow as technology advances.