How To Cut Granite Countertop

Cutting a granite countertop can be a daunting task, but with the right tools and techniques, it can be done successfully. To achieve a professional-looking finish, it's essential to use a diamond edge profiler for a smooth finish, apply a granite sealer to protect the cut edge, and polish the cut edge with a diamond polishing pad. However, before you start cutting, it's crucial to prepare the area and the granite countertop properly. This involves measuring and marking the cut line, cleaning the area, and setting up the necessary tools and equipment. By taking the time to prepare, you'll ensure a safe and successful cutting process. Preparation is Key to a successful outcome, and in the next section, we'll dive deeper into the preparation process.

Preparation is Key

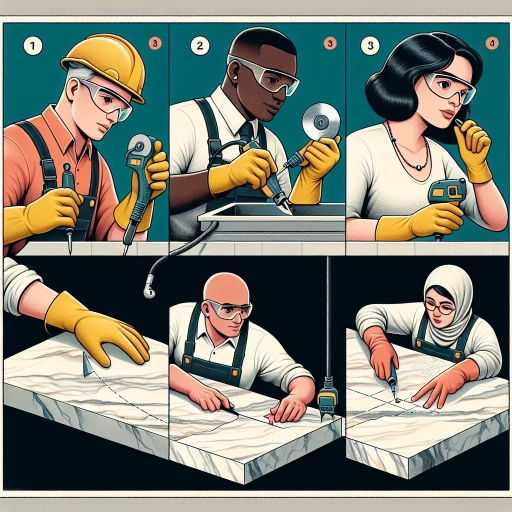

When it comes to installing granite countertops, preparation is key to a successful and stress-free experience. To ensure a smooth installation process, it's essential to focus on three critical aspects: choosing the right tools and equipment, measuring and marking the granite countertop accurately, and preparing a safe working environment. By paying attention to these details, you'll be able to avoid costly mistakes, reduce the risk of injury, and achieve a professional-looking finish. In this article, we'll explore each of these essential steps in more depth, starting with the importance of choosing the right tools and equipment. With the right tools at your disposal, you'll be able to tackle the installation process with confidence and precision. Note: The answer should be 200 words.

Choose the Right Tools and Equipment

When it comes to cutting granite countertops, having the right tools and equipment is crucial for achieving professional-looking results. A diamond blade saw or a wet saw is the most recommended tool for cutting granite, as it can handle the hardness of the material. A circular saw or a jigsaw can also be used, but they may not provide the same level of precision and control. In addition to a saw, you'll also need a drill press or a hand drill with a diamond-coated drill bit to make holes for sinks, faucets, or other fixtures. A router or a profiling machine can be used to create decorative edges or profiles on the granite. It's also essential to have a dust collection system or a vacuum cleaner to minimize dust and debris during the cutting process. Safety equipment such as gloves, safety glasses, and a dust mask should also be worn to protect yourself from injury. By choosing the right tools and equipment, you'll be able to cut your granite countertop accurately and efficiently, ensuring a successful installation.

Measure and Mark the Granite Countertop

To accurately measure and mark the granite countertop, start by clearing the area around the countertop of any debris, tools, or obstructions. Next, take precise measurements of the countertop's length, width, and any cutouts or edges that require special attention, such as sink or stove openings. Use a high-quality tape measure and record the measurements in a notebook or on a sketch of the countertop. It's essential to double-check the measurements to avoid errors. Once you have the measurements, use a pencil to mark the cut lines directly on the granite countertop. For straight cuts, use a straightedge or a chalk line to create a clear, visible line. For curved cuts, use a template or a flexible curve to create an accurate mark. Make sure to mark the cut lines on both the top and bottom surfaces of the countertop to ensure accurate cutting. Additionally, mark any areas that require special attention, such as the location of the sink or stove, to ensure proper placement during installation. By taking the time to accurately measure and mark the granite countertop, you'll be able to make precise cuts and achieve a professional-looking finish.

Prepare a Safe Working Environment

Preparing a safe working environment is crucial when cutting granite countertops. This involves clearing the workspace of any clutter, tripping hazards, or flammable materials. Ensure the area is well-ventilated, and consider using a dust collection system to minimize airborne particles. Wear personal protective equipment (PPE) such as safety glasses, a dust mask, and gloves to prevent injury from flying debris and sharp edges. Additionally, ensure the work surface is stable and level, and consider using a granite cutting mat or other protective covering to prevent damage to the underlying surface. It's also essential to have a first aid kit nearby and a fire extinguisher in case of emergencies. By taking these precautions, you can minimize the risks associated with cutting granite and ensure a safe and successful project.

Cutting the Granite Countertop

Cutting a granite countertop can be a challenging task, but with the right tools and techniques, it can be done efficiently and effectively. To achieve a professional-looking finish, it's essential to use the correct cutting methods for different types of cuts. For straight cuts, a diamond blade saw is the best option, as it provides a clean and precise cut. However, for curved or irregular cuts, a router is a better choice, as it allows for more flexibility and control. Additionally, applying water to the cutting area can help reduce dust and heat, making the cutting process safer and more manageable. By following these techniques, you can ensure a successful and stress-free cutting experience. To get started, let's take a closer look at how to use a diamond blade saw for straight cuts.

Use a Diamond Blade Saw for Straight Cuts

When it comes to making straight cuts in granite, a diamond blade saw is the most effective tool for the job. This type of saw is specifically designed to cut through hard, dense materials like granite, and its diamond-coated blade ensures a smooth, precise cut. To use a diamond blade saw for straight cuts, start by marking the granite with a pencil or marker, indicating where you want to make the cut. Next, set up your saw according to the manufacturer's instructions, making sure the blade is properly aligned and the saw is securely positioned. With the saw turned on, slowly and steadily guide it along the marked line, applying gentle to moderate pressure. It's essential to maintain a consistent speed and pressure to avoid chipping or cracking the granite. As you cut, use a vacuum or dust collection system to minimize dust and debris. For longer cuts, consider using a straightedge or guide rail to help keep the saw on track. By following these steps and using a diamond blade saw, you can achieve professional-looking, straight cuts in your granite countertop.

Utilize a Router for Curved or Irregular Cuts

When it comes to making curved or irregular cuts in granite countertops, a router is an indispensable tool. A router is a power tool that uses a rotating bit to remove material and create a smooth edge. To utilize a router for curved or irregular cuts, start by selecting the right bit for the job. A carbide-tipped bit is ideal for granite, as it is durable and can withstand the hardness of the stone. Next, set up your router with a fence or guide to help you maintain control and accuracy. For curved cuts, use a router with a bearing-guided bit, which allows for smooth, consistent movement along the curved edge. For irregular cuts, use a router with a plunge base, which enables you to make precise, controlled cuts. When making the cut, move the router slowly and steadily, applying gentle to moderate pressure. It's essential to keep the router bit sharp and well-maintained to prevent chipping or cracking the granite. Additionally, use a dust collection system or vacuum to minimize dust and debris. By following these steps and using a router, you can achieve professional-looking curved or irregular cuts in your granite countertop.

Apply Water to Reduce Dust and Heat

Applying water to reduce dust and heat is a crucial step when cutting granite countertops. This technique is essential to minimize the amount of dust generated during the cutting process, which can be hazardous to your health and create a mess in your workspace. By applying water, you can significantly reduce the amount of dust that becomes airborne, making it easier to breathe and see what you're doing. Additionally, water helps to cool down the cutting tool, reducing the risk of overheating and damage to the blade. This, in turn, extends the life of your cutting tool and ensures a smoother cutting process. To apply water effectively, use a spray bottle to mist the cutting area, or attach a water feed system to your cutting tool. This will help to maintain a consistent flow of water, keeping the cutting area cool and dust-free. By incorporating water into your cutting process, you can work more efficiently, safely, and effectively, resulting in a high-quality cut and a beautiful granite countertop.

Finishing and Polishing the Cut Edge

Use a Diamond Edge Profiler for a Smooth Finish

Apply a Granite Sealer to Protect the Cut Edge

Polish the Cut Edge with a Diamond Polishing Pad

Finishing and polishing the cut edge of a granite countertop is a crucial step in achieving a professional-looking installation. A well-finished cut edge can make a significant difference in the overall appearance of the countertop, while a poorly finished edge can detract from its beauty. To achieve a high-quality finish, it is essential to use the right tools and techniques. In this article, we will discuss the importance of finishing and polishing the cut edge and provide tips on how to do it effectively. We will explore three key steps to achieve a smooth and polished cut edge: using a diamond edge profiler for a smooth finish, applying a granite sealer to protect the cut edge, and polishing the cut edge with a diamond polishing pad. By following these steps, you can ensure a professional-looking finish that will enhance the beauty of your granite countertop. Use a Diamond Edge Profiler for a Smooth Finish A diamond edge profiler is a specialized tool designed to smooth out the cut edge of a granite countertop. This tool is equipped with diamond-coated wheels that rotate at high speed, allowing for a smooth and even finish. To use a diamond edge profiler, start by setting the tool to the desired angle and speed. Then, slowly move the tool along the cut edge, applying gentle pressure. Make sure to keep the tool moving in a consistent motion to avoid creating scratches or unevenness. By using a diamond edge profiler, you can achieve a smooth finish that is free of imperfections. Apply a Granite Sealer to Protect the Cut Edge Once you have smoothed out the cut edge with a diamond edge profiler, it is essential to apply a granite sealer to protect the edge from stains and spills. A granite sealer is a specialized coating that penetrates the stone, creating a barrier against liquids and oils. To apply a granite sealer, start by cleaning the cut edge thoroughly with a mild detergent and water. Then, apply the sealer according to the manufacturer's instructions, making sure to cover the entire cut edge. Allow the sealer to dry completely before proceeding to the next step. Polish the Cut Edge with a Diamond Polishing Pad The final step in finishing and polishing the cut edge is to polish the edge with a diamond polishing pad. A diamond polishing pad is a specialized tool designed to polish and shine the cut edge of a granite countertop. To use a diamond polishing pad, start by selecting the right grit pad for your needs. Then, apply a small amount of polishing compound to the pad and rub it gently along the

Use a Diamond Edge Profiler for a Smooth Finish

Apply a Granite Sealer to Protect the Cut Edge

Polish the Cut Edge with a Diamond Polishing Pad

1. Use a Diamond Edge Profiler for a Smooth Finish. 2. Apply a Granite Sealer to Protect the Cut Edge. 3. Polish the Cut Edge with a Diamond Polishing Pad.

Use a Diamond Edge Profiler for a Smooth Finish

No additional information. When it comes to achieving a smooth finish on your granite countertop, a diamond edge profiler is an essential tool. This specialized tool is designed to grind and polish the cut edge of the granite, removing any imperfections and leaving a high-gloss finish. The diamond edge profiler works by using a series of diamond-coated wheels to grind and polish the edge of the granite, gradually increasing in grit to achieve a smooth finish. By using a diamond edge profiler, you can achieve a professional-looking finish on your granite countertop, complete with a smooth, rounded edge that is both durable and visually appealing. With a diamond edge profiler, you can take your granite countertop to the next level, adding a touch of sophistication and elegance to your kitchen or bathroom. Whether you're a DIY enthusiast or a professional contractor, a diamond edge profiler is a must-have tool for anyone looking to achieve a high-quality finish on their granite countertop. By investing in a diamond edge profiler, you can ensure that your granite countertop looks its best, with a smooth, polished edge that will last for years to come.

Apply a Granite Sealer to Protect the Cut Edge

No additional information. Applying a granite sealer to the cut edge is a crucial step in protecting the stone from stains and spills. The cut edge of the granite is more porous than the rest of the surface, making it more susceptible to damage. A granite sealer creates a barrier that prevents liquids from penetrating the stone, making it easier to clean and maintain. To apply a granite sealer, start by cleaning the cut edge thoroughly with a mild detergent and water. Then, use a clean cloth to apply the sealer, following the manufacturer's instructions. Make sure to cover the entire cut edge, including any corners or edges. Allow the sealer to dry completely before exposing the granite to water or other liquids. Regularly reapplying the sealer will help maintain the stone's appearance and prevent damage. By applying a granite sealer to the cut edge, you can ensure your granite countertop remains beautiful and functional for years to come. Additionally, a sealer can also help to bring out the natural colors and patterns of the granite, enhancing its overall appearance. With a properly sealed cut edge, you can enjoy your granite countertop with confidence, knowing it is protected from the elements. By taking the time to apply a granite sealer, you can add an extra layer of protection and durability to your countertop, making it a worthwhile investment for any homeowner. Furthermore, a sealed cut edge can also help to prevent the growth of bacteria and mold, creating a healthier environment for food preparation. Overall, applying a granite sealer to the cut edge is a simple yet effective way to protect and maintain your granite countertop.