How To Make Concrete

Welcome to the world of concrete-making, a skill that harnesses the blend of science and practicality for constructing solid foundations! This article promises to take you on a pedagogical journey that aligns the ruggedness of concrete with a refined knowledge of its creation. Whether you're a novice DIY enthusiast or a practiced professional looking to refresh their knowledge, this guide intends to be your support. We will commence our exploration by understanding the basics of concrete, punctuating the constituent elements and their interplay in a mix. Along this path of discovery, we will walk through the sequential steps involved in making concrete, systematically unfolding the process for you. However, even a well-laid plan can face the perils of mistakes. To pre-empt the possibility of faltering, we'll delve into frequent pitfalls and offer proactive solutions to avoid them. Let's embark on this enlightening expedition by first unraveling the essentiality enveloping the basics of concrete. Evidently, the foundation of this explainer on creating concrete is as solid as the subject matter itself. Let's kick start with understanding the basics of concrete.

Welcome to the world of concrete-making, a skill that harnesses the blend of science and practicality for constructing solid foundations! This article promises to take you on a pedagogical journey that aligns the ruggedness of concrete with a refined knowledge of its creation. Whether you're a novice DIY enthusiast or a practiced professional looking to refresh their knowledge, this guide intends to be your support. We will commence our exploration by understanding the basics of concrete, punctuating the constituent elements and their interplay in a mix. Along this path of discovery, we will walk through the sequential steps involved in making concrete, systematically unfolding the process for you. However, even a well-laid plan can face the perils of mistakes. To pre-empt the possibility of faltering, we'll delve into frequent pitfalls and offer proactive solutions to avoid them. Let's embark on this enlightening expedition by first unraveling the essentiality enveloping the basics of concrete. Evidently, the foundation of this explainer on creating concrete is as solid as the subject matter itself. Let's kick start with understanding the basics of concrete.Understanding the Basics of Concrete

Concrete, mankind's essential building material, forms the backbone of our infrastructure, from towering skyscrapers to the homes we live in. As substantial as it is, understanding the basics of concrete is vital. This article will offer a comprehensive exploration into the realm of concrete, peeling back its layers of complexity to reveal its fundamental building blocks and importance to our world. Our first stop in this exploration will be delving into the 'Fundamentals of Concrete', where we'll uncover the secrets behind its unparalleled strength and resilience. Next, we'll step into the area of 'Different Types of Concrete and Their Uses', exposing the myriad of concrete types that find their use in various sectors of construction. Finally, we'll understand 'The Importance of Choosing the Right Concrete', where we will learn how the choice of the correct type is crucial for any project's success. Let's commence this exploration with our first topic, 'Fundamentals of Concrete', to uncover the qualities that make concrete the cornerstone of our built environment.

Fundamentals of Concrete

Fundamentals of Concrete Delving deeper into the subject, it's pivotal to comprehend the fundamentals of concrete, the lifeblood to many a construction project. At its core, concrete is a pragmatic blend of various ingredients, each with a vital role to play. The primary elements are often ordinary Portland cement, aggregate such as sand or gravel, and water. In this harmonious blend, cement acts as a binder, solidifying the mix and giving rise to the characteristic sturdiness of concrete. The aggregate lends mass and strength to the construct, a feature made possible because, unlike cement, it is virtually unaffected by water. The water, on the other hand, stimulates the cement's chemical reactions leading to the hardening process known as hydration. But these elements alone do not entirely capture the fundamentals of concrete. A key aspect also lies in the ratio of water to cement in the mix, often referred to as the water-cement ratio. This ratio holds immense significance as it directly influences the strength of the concrete. Lower water-cement ratios lead to highly durable, albeit difficult to mix, concrete. Similarly, a higher ratio might offer ease of mixing but results in lower strength and greater porousness. Another fundamental aspect of concrete is understanding its three key stages of setting. The initial setting phase where the mix starts losing its plasticity, the final setting phase where it attains a certain hardness to sustain some pressure but is still malleable for finishes, and finally the hardening stage where the concrete evolves into a robust material capable of withstanding the intended load. Moreover, the 'curing' of concrete is a fundamental process where maintained moisture levels and temperature allow the cement hydration process to continue for weeks, enhancing the durability and resistance of the structure. In essence, the quality of concrete largely depends upon this supervised 'curing' period. In conclusion, understanding the fundamentals of concrete goes much beyond its ingredients. It resides in the intricate knowledge of the ratio mix, ability to understand the various stages of setting and hardening, and the pivotal process of curing. Armed with this knowledge, one can truly grasp the towering strength behind those looming edifices of concrete.

Different Types of Concrete and Their Uses

Understanding the basics of concrete is fundamental when delving into the world of construction and home renovation, as it gives you a precise grasp on durable and efficient building materials. In this context, shedding light on different types of concrete and their uses becomes particularly significant. Concrete, a versatile material, is a blend of cement, aggregate, and water that hardens into a strong and durable structure. Broadly speaking, there are about five main types of concrete, each serving unique purposes based on their composition and properties. Firstly, there is Plain Concrete, the most basic form used in most constructions. It is made up of cement, sand, aggregates, and water. It is ideal for buildings and pavements that don't need high tensile strength but require a good degree of durability. The second type is Reinforced Concrete, stronger than its plain counterpart. It is made from the same basic elements but with the addition of reinforcement bars that significantly increase tension resistance. This concrete type is often used in connections where high tensile strength is required, such as in columns and bridges. The third type, known as Precast Concrete, is manufactured offsite in different shapes like beams or walls. Once cured, these parts are transported and assembled onsite. This type allows for higher-quality control, provides quick construction, and minimizes labor-intensive fieldwork. The fourth type is Prestressed Concrete. Particular high tensile steel wires are used to make this concrete, providing high resistance to tension. Prestressed concrete is typically used in constructions that bear heavy loads, fleets, and bridges. The fifth and final type is Lightweight Concrete. This less dense option is perfect for reducing the overall load of a structure or for thermal insulation. It’s often used in the constructions of partition walls and small homes. In conclusion, understanding these different types of concrete is essential in selecting the right material for your construction project. Whether it's a small home or a large bridge, the right choice of concrete can immensely influence the structure's durability and efficiency.

The Importance of Choosing the Right Concrete

The importance of selecting the right concrete cannot be overstated when discussing the basics of concrete. Concrete, a fundamental material in construction projects, possesses varying characteristics depending on its composition, and not all types will be suitable for every project. This choice plays a pivotal role in the longevity, sustainability, and aesthetic appeal of the structure being erected. The right concrete can significantly influence the strength of your structure. With different types of concrete available, such as high-strength, lightweight, or even air-entrained concrete, it is vital to recognize their unique qualities and how they can cater to specific project needs. For instance, high-strength concrete lends itself perfectly to structures that need to withstand high pressure, such as skyscrapers, dams, or bridges. On the other hand, lightweight concrete, though not as resilient, provides excellent thermal insulation and is often used in building walls, roofing, and raised floors for load reduction. Moreover, the choice of concrete also has sizable implications on the sustainability of the structure. Today, with increasing emphasis on environmental conservation, choosing eco-friendly concrete variants made from recycled materials can significantly reduce the carbon footprint of construction. For instance, utilizing recycled aggregate concrete helps conserve natural resources and reduce the amount of waste in landfills. Lastly, let’s not forget the aesthetic element. The right choice of concrete can also impact the visual appeal of the structure. Exposed aggregate concrete, stamped concrete, or colored concrete can offer interesting textures and color palettes that give a unique vibe to a structure, be it a simple walkway or a grand architectural feat. Ultimately, selecting the right concrete is a critical decision that will define the structure's performance and appeal. It demonstrates how concrete, often perceived as a plain and mundane material, hides considerable complexity beneath its grey surface. It's not just about mixing cement, water, and aggregate; it’s about understanding the specifics of your project, the environmental impact of your choices, and the resulting visual effect. Therefore, making an informed choice of concrete is not only crucial for structural reasons but also for the underlying narrative of your construction project.

Steps Involved in Making Concrete

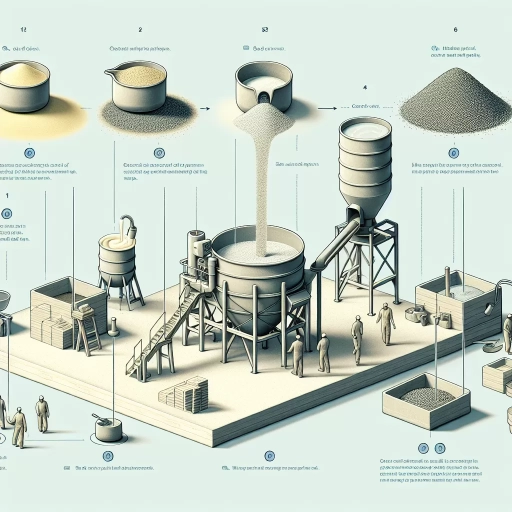

Concrete is a common construction material that’s incredibly versatile and relatively simple to make. This article will guide you through the specific steps involved in creating high-quality concrete. Key components discussed will include the materials necessary to produce concrete, the specifics regarding the right proportions and mixing techniques, and the safety measures one should enforce when pouring and curing the mixture. Understanding how each of these factors plays a pivotal role in the entire process will help you create strong and durable concrete at home or on your construction site. First, we delve into the Materials Needed in Creating Concrete - highlighting the crucial ingredients and where to source them properly. Read on to not only become familiar with the process but also to confidently handle concrete with the mastery of an experienced mason.

Materials Needed in Creating Concrete

Creating concrete is a relatively simple process that requires a few essential materials. These materials have been handpicked by experts in the field for their unique attributes that contribute to the production of high-quality concrete. Firstly, you would need a good supply of Portland cement. This vital ingredient contributes to the hardness of the finished product. Portland cement cannot be substituted with any other type of cement and is an industry standard across all concrete mix designs. Secondly, you would require aggregate, which is a broad term used to describe coarse materials like sand, gravel, and crushed stone. Aggregate provides volume and adds stability to your concrete mix. It is chosen for its strength and can widely influence the concrete's finished texture. Depending on the desired texture, you may need to select your aggregate carefully. Thirdly, water is crucial in the concrete mixing process. The water needs to be clean and free from impurities for the end product to have a strong, durable finish. The water's primary purpose is to react with the Portland cement in a process called hydration. Hydration is what causes the concrete to harden and gain strength over time. Lastly, but equally as essential are concrete additives or admixtures. These admixtures are chemicals that are added to the concrete to alter its properties. Some admixtures can make the concrete set faster, while others increase its strength or make it more resistant to harsh weather conditions. In other cases, these additives might reduce the amount of cement needed, making the process more cost-effective. In summary, the ingredients needed to make concrete; Portland cement, aggregate, water, and concrete admixtures each play distinctive roles in creating a perfect blend. Without these materials, the concrete may lack in key qualities such as durability, strength, texture, and cost-effectiveness. Securing these materials and using them correctly is the first step in producing high-grade concrete. The remaining step requires careful mixing, curing, and application, which will be comprehensively covered under the 'Steps Involved in Making Concrete' section.

Right Proportions and Mixing Techniques

Right Proportions and Mixing Techniques

When it comes to creating concrete, understanding the right proportions and mixing techniques are vital factors that contribute to the overall strength, durability, and performance of the final product. In the intricate process of making concrete, precision is key. Concrete, a robust and common material in construction, is typically composed of Portland Cement, water, and aggregates - coarse and fine, such as gravel and sand respectively. For an optimal blend, the standard ratio usually employed is 1:2:3 – one part cement, two parts sand, and three parts gravel. It is essential to maintain this ratio, as altering it can lead to changes in the workability, strength, and density of the concrete. An excess of water, for instance, can weaken the mix, while a deficit can cause it to be unworkable. Mixing technique is equally important. To ensure homogeneity and consistent quality, the ingredients should be added in the right order. Typically, half the water should initially be added to the mix, followed by the cement and sand, and then the gravel. The remaining water is then introduced while the mix is stirred. Stirring should continue until all elements are dispersed evenly, creating a uniform, paste-like substance. Care should be taken to not over mix as it can deteriorate the quality of the concrete, causing it to harden quickly and reducing its long-term durability. Let the mixer run for three to five minutes, check the consistency, and make adjustments as needed. It's all about balance – the ideal concrete mix should hold its shape when squeezed but should also be able to flow into corners and molds. The right proportions and mixing techniques in concrete-making significantly affect the resultant mixture’s performance in terms of compressive strength, ease of transport and application, economy, and overall aesthetics. By adhering to these guidelines, one can create a concrete mix that is both high in quality and suitable for its intended use.Precautions to Take When Pouring and Curing Concrete

One of the most crucial steps in the concrete making process is the act of pouring and curing it. This stage is vital because it ensures the final product has integrity and longevity. Specific precautions must be followed to ensure this outcome. First, before pouring the concrete, ensure the surface is well prepared. It should be firm, level, and capable of supporting the load without shifting or dishing. Whether you're creating a foundation, driveway, or sidewalk, incorporating a sub-base layer will add stability. The second precaution to heed when pouring concrete involves the mixing process. Achieving the perfect balance of cement, sand, aggregate and water is paramount. A well-mixed concrete should have a consistency similar to that of thick oatmeal. It should hold its shape when squeezed, but easily spread out with minimal effort. This balance helps prevent the occurrence of honeycombing, air pockets and water pooling, common issues that may lead to future structural weaknesses. Thirdly, weather conditions should be taken into account when pouring concrete. Avoid pouring in extremely cold or hot conditions as it can affect the curing process. In freezing temperatures, the water in the concrete mix can freeze and expand, causing cracking. On the extreme end of heat, the curing concrete can dry out too quickly, leading to brittle and weakened results. Lastly, keep an eye on the curing process. This process involves letting the concrete dry out slowly and fully hydrate to reach maximum strength. It generally takes about 28 days under normal conditions but in certain weather conditions, curing could take slightly longer. If incorrectly or hastily cured, the resulting concrete structure could exhibit surface dusting, lower surface hardness, decreased abrasion resistance, and increased susceptibility to cracking. Some additional steps could also be beneficial. Sealing the concrete after curing can provide additional protection against water penetration, freeze-thaw conditions, and chemical exposure. Plus, proper control joints placed at strategic intervals can help manage stress caused by shrinkage during curing and prevent unwanted cracks. Thus, these precautions of careful surface preparation, accurate mixing, weather consideration, patient curing, and optional sealing and control joints can ensure a successful and durable end product in your concrete creation journey. The stakes are high, but with meticulous execution and patience, the rewards are worth it since good quality concrete can last a lifetime.

Common Mistakes and How to Avoid Them

In the grueling world of concrete construction and repair, one misstep could cause a domino effect of issues leading to substantial loss of time, resources, and manpower. In this comprehensive guide, we've assembled the most prevalent mistakes and offer solutions you can cull from our batch of knowledge and experience. The first topic we tackle concerns the choosing and combining of crucial construction materials. Here, we'll explain what goes wrong when the wrong selection process is employed. Following that, we'll delve into the common errors that transpire during the pouring and curing process. These mistakes can greatly affect the final product if not addressed promptly. Lastly, we present an actionable guide on how to solve everyday concrete issues. On this journey of discovery and solutions, we aim to provide you a roadmap to navigate the construction terrain with fewer hitches, starting with understanding the heart of the problem - the elemental missteps in choosing and combining construction materials.

Mistakes in Choosing and Combining Materials

Choosing and combining materials for concrete may seem straightforward, but this process is often beset with mistakes that can harm the quality, aesthetics, and longevity of the resulting structure. It's imperative to understand that the success of your construction largely depends on the materials you choose and how you combine them. Often, incorrect proportions and unsuitable materials together form the basis of most errors. A common yet grave mistake is overlooking the importance of material quality. Aggregates, cement, and water are the basic ingredients of concrete, each having specific requirements. Using impure and poor-quality aggregates can lead to weak structures with low durability. Hence it is essential to buy aggregates from reputable sources and test them for impurities before using. Likewise, using stale or expired cement can significantly reduce the strength of the final product. So it's necessary to check cement for lumps and its manufacturing date. Erroneous water proportion is another mistake committed frequently. Water acts as the catalyst in the cement binding process, however, too much water can lead to pores and cracks in the concrete, weakening the structure. On the other hand, using too little water can prevent the cement from hydrating fully and hence, compromising its strength. Understanding the optimum water-cement ratio and carefully adding water during the mixing phase can help avoid this mistake. Using incompatible materials is yet another misstep in concrete production. Certain materials do not pair well with each other, resulting in chemical reactions detrimental to the concrete. For instance, an aggregate containing reactive silica can react with the alkalis in cement, causing 'Alkali Silica Reaction' which leads to cracks and distortion in concrete. Therefore, understanding the chemical composition of the materials being used is paramount to their successful combination. Direct sunlight is often considered a trivial factor but can cause rapid evaporation of water during the curing process, leading to shrinkage cracks in the concrete. Therefore, curing should be done under optimal conditions to retain moisture and achieve proper strength. In conclusion, choosing and combining materials for concrete require keen attention to details. Avoiding the common mistakes of over or under watering, using poor-quality materials or combining incompatible materials, and improper curing can help create strong, durable structures. With the right grading, proportioning, quality checking and curing controls, it's possible to create a concrete structure that stands the test of time. Hence, know the common mistakes in order to avoid them and achieve excellent results. Remember, in concrete making, even the smallest elements can make a big difference.

Errors During the Pouring and Curing Process

Pouring and curing concrete may seem like a straightforward task, but in reality, it's a meticulous process that requires precision and detailed knowledge. Mistakes made during these phases can compromise the integrity of the concrete and increase the risk of structural failure down the line. One common error during the pouring process is the improper preparation of the subgrade, the surface on which the concrete is poured. The subgrade must be thoroughly cleaned and compacted to ensure a flat, stable base for the concrete. If not, you could end up with a lumpy, uneven surface that can jeopardize the structural integrity of the final product. Besides, keeping the subgrade damp before the pour can help prevent it from absorbing water from the concrete, which could lead to curing problems. Another prevalent mistake is adding too much water to the mix. While it might make the concrete easier to pour, a high water-to-cement ratio can weaken the resulting structure and lead to cracks as it dries. The curing stage, often overlooked, is a vital part of the concrete manufacturing process, during which the concrete hardens and gains strength. Frequently, people rush this process, leading to weak and brittle concrete. Concrete needs an adequate amount of moisture and a suitable temperature to cure correctly. Consequently, not properly hydrating the concrete or exposing it to extreme weather conditions can stunt its strength development. Moreover, understanding the type of concrete you're working with is also crucial, as different types have varied curing durations. For instance, quick-setting concrete might need less time compared to other types. To avoid these errors, always prepare your subgrade well, measure your water-to-cement ratio accurately, and remain patient during the curing process. Keep the concrete damp and shielded from extreme weather conditions and remember - concrete is more of a science than an art, thus meticulous attention to detail can lead to a strong and durable structure. Understanding these common mistakes and how to avoid them can significantly improve the quality of your concrete production, saving you time, money, and potential frustrations in the long run.

Problem-solving: How to Fix Common Concrete Issues

Concrete issues are prevalent in daily life and can occur due to various reasons, which include inappropriate mixing procedures, inadequate curing periods, and the use of poor-quality materials. However, with proper insights and guidelines, these common problems can be easily rectified, leading to sturdy and long-lasting constructions. Incorrect water-cement ratio often results in concrete cracking - a common mistake that can be easily avoided. It is crucial to ensure that the concrete mixture isn't too wet or too dry, as both extremes can lead to significant faults like shrinkage cracking or decreased concrete strength. In order to avoid this, it's recommended to adopt the standard water-cement ratio guideline provided by the American Concrete Institute (ACI). This guideline suggests using the minimum amount of water to ensure workability while maintaining the correct consistency to deliver maximum strength. Another frequent mishap in concrete construction is the occurrence of efflorescence, a white crystal-like deposit found on the surface of concrete. It emerges due to the migration of soluble salts to the surface. While it doesn’t pose a structural threat to the material, it does compromise the aesthetic appearance of the structure. The best preventive measure against efflorescence is to use low alkali cement and ensuring proper curing. Concrete discoloration is another prevalent issue. This usually arises when non-uniform procedures are followed in batching, mixing, and applying cement. To prevent this, consistency is key. Ensure you use the same brand and type of cement, aggregate, and admixtures throughout the entire project. Also, make sure all the workers are trained to mix and apply concrete uniformly. Lastly, inadequate curing often leads to the weakening of concrete structures. Curing is a crucial process that helps to maintain the moisture content in concrete, ensuring it gains strength properly. It is advisable to allow adequate time for curing and use moistures retaining techniques such as ponding, water sprinkling, and wet coverings to prevent the concrete from drying out. In conclusion, the majority of these concrete issues and mistakes can be avoided by adhering to established concrete guidelines, maintaining consistency throughout the project, using high-quality materials, and applying proper curing methods. In doing so, one can ensure the creation of a robust, durable and aesthetically pleasing concrete structure that stands the test of time. Remember, problem-solving in concrete construction involves more than just fixing the manifesting issue - it involves discovering the root cause and rectifying it.