How To Apply Teflon Tape

Here is the introduction paragraph: When it comes to plumbing, pipefitting, and other industrial applications, Teflon tape is an essential tool for creating a watertight seal. However, many individuals struggle with applying Teflon tape correctly, leading to leaks, damage, and costly repairs. To ensure a successful application, it's crucial to understand the basics of Teflon tape, its uses, and the step-by-step process of applying it. In this article, we'll delve into the world of Teflon tape, exploring the importance of preparation, providing a step-by-step guide to application, and troubleshooting common issues that may arise. By the end of this article, you'll be equipped with the knowledge and skills necessary to apply Teflon tape like a pro. So, let's start by laying the foundation: Preparation is Key: Understanding Teflon Tape and Its Uses.

Preparation is Key: Understanding Teflon Tape and Its Uses

Here is the introduction paragraph: When it comes to ensuring a secure and leak-free connection in various applications, preparation is key. One crucial component that plays a significant role in achieving this goal is Teflon tape. Also known as plumber's tape or thread seal tape, Teflon tape is a versatile and essential tool that has been widely used in various industries, including plumbing, HVAC, and automotive. However, to maximize its effectiveness, it is essential to understand the different types of Teflon tape available, how to choose the right one for your specific needs, and the necessary precautions to take when handling it. In this article, we will delve into the world of Teflon tape, exploring what it is and how it works, the various types of Teflon tape and how to select the right one, and the precautions to take when handling it. By the end of this article, you will have a comprehensive understanding of Teflon tape and its uses, enabling you to make informed decisions and ensure a secure and leak-free connection in your next project. So, let's start by understanding what Teflon tape is and how it works.

What is Teflon Tape and How Does it Work?

. Here is the paragraphy: Teflon tape, also known as PTFE tape or plumber's tape, is a type of adhesive tape made from a non-stick, synthetic polymer called polytetrafluoroethylene (PTFE). This versatile tape is widely used in various industries, including plumbing, HVAC, and automotive, due to its unique properties. Teflon tape is designed to create a watertight seal on threaded connections, preventing leaks and ensuring a secure fit. When applied to a threaded pipe or fitting, the tape fills in the microscopic gaps between the threads, creating a smooth, non-stick surface that prevents water, air, or other fluids from escaping. The tape's non-stick properties also make it easy to remove and reapply, without leaving residue or damaging the threads. Additionally, Teflon tape is resistant to corrosion, chemicals, and extreme temperatures, making it an ideal solution for a wide range of applications. By understanding the properties and uses of Teflon tape, individuals can ensure a secure and leak-free connection, saving time and money in the long run.

Choosing the Right Type of Teflon Tape for Your Needs

. Here is the paragraphy: Choosing the right type of Teflon tape for your needs is crucial to ensure a successful application. With various types of Teflon tapes available in the market, it can be overwhelming to decide which one to use. The most common types of Teflon tapes are PTFE (Polytetrafluoroethylene) tape, FEP (Fluorinated Ethylene Propylene) tape, and PFA (Perfluoroalkoxy) tape. PTFE tape is the most widely used and is suitable for most applications, including pipe threading, gasket sealing, and electrical insulation. FEP tape, on the other hand, is more flexible and is often used in applications where a high level of conformability is required, such as in wire and cable wrapping. PFA tape is the most chemical-resistant and is typically used in high-temperature and high-pressure applications. Additionally, there are also specialized Teflon tapes, such as anti-static and high-temperature tapes, that are designed for specific applications. When choosing a Teflon tape, consider the temperature range, chemical resistance, and level of conformability required for your application. It's also important to check the thickness and density of the tape, as well as its compatibility with the materials it will be used with. By selecting the right type of Teflon tape, you can ensure a reliable and long-lasting seal.

Precautions to Take When Handling Teflon Tape

. When handling Teflon tape, it's essential to take certain precautions to ensure safe and effective use. First and foremost, it's crucial to handle the tape in a clean and dry environment to prevent contamination and damage. Always wash your hands before and after handling the tape to prevent the transfer of oils and dirt. Additionally, avoid touching the adhesive side of the tape, as the oils from your skin can compromise its effectiveness. When cutting the tape, use a sharp utility knife or scissors to prevent fraying and ensure a clean cut. It's also important to store the tape in a cool, dry place, away from direct sunlight and moisture, to maintain its adhesive properties. Furthermore, when applying the tape, avoid stretching or pulling it too tightly, as this can cause it to lose its shape and compromise its seal. Finally, always follow the manufacturer's instructions for use and take necessary safety precautions, such as wearing gloves and safety glasses, to prevent injury. By taking these precautions, you can ensure a safe and successful application of Teflon tape.

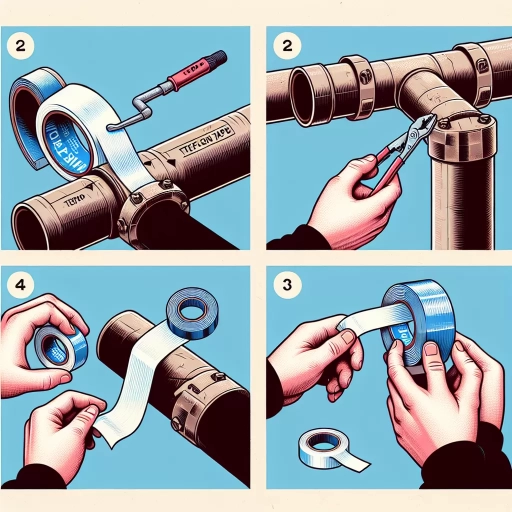

Step-by-Step Guide to Applying Teflon Tape

Applying Teflon tape is a crucial step in various plumbing and piping applications, requiring attention to detail to ensure a secure and leak-free seal. A well-applied Teflon tape can make all the difference in preventing costly repairs and ensuring the longevity of your pipes. To achieve this, it's essential to follow a step-by-step guide that covers the entire process, from preparation to application. This article will walk you through the process, starting with the importance of cleaning the surface for a secure bond, followed by the correct technique for wrapping the Teflon tape, and finally, ensuring a tight seal with the right amount of tension. By following these steps, you'll be able to apply Teflon tape like a pro and enjoy a leak-free plumbing system. So, let's begin by exploring the first crucial step: cleaning the surface for a secure bond.

Cleaning the Surface for a Secure Bond

. Cleaning the surface for a secure bond is a crucial step in the Teflon tape application process. A clean surface ensures that the tape adheres properly, creating a strong and durable seal. To clean the surface, start by removing any dirt, grime, or old adhesive using a soft cloth or brush. For more stubborn stains, a mild detergent and water solution can be used, but be sure to rinse the surface thoroughly to prevent any residue from interfering with the tape's adhesion. Next, use a lint-free cloth or paper towel to dry the surface, paying extra attention to any crevices or grooves where moisture may collect. If the surface is particularly rough or porous, a gentle sanding or filing may be necessary to create a smooth surface for the tape to bond to. Once the surface is clean and dry, inspect it carefully for any remaining imperfections or debris. A clean and prepared surface is essential for a secure bond, so take the time to ensure that the surface is free from any contaminants or obstructions. By following these simple steps, you can create a strong and reliable seal with your Teflon tape, ensuring that your pipes, threads, or other applications remain leak-free and secure.

Wrapping the Teflon Tape Correctly for Maximum Effectiveness

correctly. Wrapping the Teflon tape correctly is crucial for maximum effectiveness. To achieve this, start by holding the tape at a 45-degree angle to the pipe or fitting, with the tape's edge aligned with the thread's starting point. Begin wrapping the tape in a clockwise direction, applying gentle to moderate pressure to ensure the tape adheres evenly. It's essential to maintain a consistent overlap of about half the tape's width to prevent gaps and ensure a watertight seal. As you wrap, make sure to keep the tape taut, but not too tight, as this can cause the tape to bunch up or create air pockets. For threaded connections, apply 2-3 wraps of tape, depending on the thread's coarseness and the desired level of seal. For smooth connections, a single wrap may be sufficient. When wrapping around fittings or valves, use a gentle, sweeping motion to maintain even pressure and prevent creasing the tape. Finally, use a utility knife or scissors to trim the excess tape, leaving about 1/8 inch of tape exposed. By following these steps and taking the time to wrap the Teflon tape correctly, you can ensure a reliable, long-lasting seal that withstands the rigors of plumbing and piping applications.

Ensuring a Tight Seal with the Right Amount of Tension

. Ensuring a tight seal with the right amount of tension is crucial when applying Teflon tape. Too little tension can result in a loose seal, allowing leaks to occur, while too much tension can damage the threads or the tape itself. To achieve the perfect balance, start by wrapping the tape around the threaded area in a clockwise direction, applying gentle pressure. As you wrap, maintain a consistent tension, making sure not to pull the tape too tight. A good rule of thumb is to apply enough tension to compress the tape by about 50% of its original thickness. This will ensure a snug fit without over-tightening. It's also essential to avoid overlapping the tape, as this can create a weak point in the seal. Instead, wrap the tape in a smooth, continuous motion, making sure to cover the entire threaded area. By applying the right amount of tension and following these guidelines, you can ensure a tight, leak-free seal that will last.

Troubleshooting Common Issues with Teflon Tape Application

When it comes to applying Teflon tape, many individuals assume it's a straightforward process. However, common issues can arise, leading to frustration and wasted time. One of the most prevalent problems is dealing with air leaks and inadequate seals, which can compromise the integrity of the connection. Additionally, removing excess Teflon tape without damaging the surface can be a delicate task. Furthermore, preventing the tape from unraveling or coming loose over time is crucial to ensure a long-lasting seal. In this article, we will delve into these common issues and provide practical solutions to help you troubleshoot and overcome them. By understanding the causes and consequences of these problems, you'll be better equipped to apply Teflon tape effectively and efficiently. Let's start by examining the first common issue: dealing with air leaks and inadequate seals.

Dealing with Air Leaks and Inadequate Seals

like a pro. Dealing with Air Leaks and Inadequate Seals Air leaks and inadequate seals are common issues that can arise when using Teflon tape, particularly in applications where a high level of sealing is required. To address these problems, it's essential to identify the root cause of the issue. One common reason for air leaks is the use of insufficient tape or applying it too loosely, which can lead to gaps and openings that allow air to escape. To resolve this, ensure that you apply the recommended amount of tape and wrap it tightly around the threads. Another possible cause is the use of low-quality Teflon tape that may not provide a sufficient seal. In this case, consider switching to a high-quality tape that is specifically designed for your application. Additionally, make sure to clean the threads thoroughly before applying the tape to remove any dirt, oil, or other contaminants that may interfere with the seal. If the issue persists, you may need to reapply the tape or consider using a different type of sealant, such as pipe dope or a sealant specifically designed for your application. By taking these steps, you can effectively deal with air leaks and inadequate seals, ensuring a reliable and long-lasting connection.

Removing Excess Teflon Tape Without Damaging the Surface

like a pro. When it comes to removing excess Teflon tape without damaging the surface, it's essential to exercise caution and patience. The first step is to identify the type of surface you're working with, as this will determine the best removal method. For most surfaces, including pipes, fittings, and threads, a gentle approach is recommended. Start by carefully peeling off the excess tape, working from one edge and moving slowly towards the other. If the tape is stubborn, you can use a soft cloth or a credit card to gently pry it loose. Avoid using harsh chemicals, abrasive materials, or excessive force, as these can damage the surface or leave residue behind. For more delicate surfaces, such as glass or ceramic, it's best to use a specialized adhesive remover or a gentle solvent, such as acetone or mineral spirits. Apply the remover to the excess tape, let it sit for a few minutes, and then carefully wipe it away with a soft cloth. In some cases, you may need to repeat the process several times to completely remove the excess tape. Once the excess tape is removed, inspect the surface for any remaining residue or debris. If necessary, use a mild soap and water solution to clean the surface, and then dry it thoroughly with a soft cloth. By following these steps, you can safely remove excess Teflon tape without damaging the surface, ensuring a secure and leak-free connection.

Preventing Teflon Tape from Unraveling or Coming Loose

. To prevent Teflon tape from unraveling or coming loose, it is essential to apply it correctly and use the right techniques. One of the most common mistakes people make when applying Teflon tape is not wrapping it tightly enough, which can cause it to unravel over time. To avoid this, make sure to wrap the tape tightly around the pipe or fitting, overlapping each layer by about half the width of the tape. This will help to create a secure seal and prevent the tape from coming loose. Another technique to prevent unraveling is to use a small amount of tape and apply it in a consistent, smooth motion. This will help to prevent air pockets from forming, which can cause the tape to lift and unravel. Additionally, it's crucial to ensure the surface is clean and dry before applying the tape, as any dirt, oil, or moisture can compromise the adhesive properties of the tape. By following these simple tips and techniques, you can ensure a secure and long-lasting seal with your Teflon tape application. Furthermore, it's also recommended to use a high-quality Teflon tape that is specifically designed for the application you are using it for, as this will help to ensure the best possible results. By taking the time to apply the tape correctly and using the right techniques, you can prevent Teflon tape from unraveling or coming loose, and ensure a reliable and leak-free seal.