How Is Rubber Made

Durable, stretchy, and waterproof, rubber is an exceptional material that surrounds us in our daily existence. Ever wondered how this multi-functional component went from being a tropical tree secretion to a crucial element in our modern world? This intriguing transformation involves a series of fascinating steps, from the historical discovery and harvesting process, to contemporary industrial production techniques that have elevated rubber into a versatile product. But this journey doesn't stop there, as we explore the various applications of rubber and its sustainability. This article will peel back the layers on the riveting world of rubber, starting with its rich history and harvesting methods. Unraveling the roots of this industry gives us a perceptual insight into its significance and sheds light on the dedicated effort behind each rubber product we use today. The tale of rubber is a testament to man's relentless push for innovation and mastery over nature. So, let's dive into the first chapter: The Origins of Rubber - From History to the Harvesting Process.

Durable, stretchy, and waterproof, rubber is an exceptional material that surrounds us in our daily existence. Ever wondered how this multi-functional component went from being a tropical tree secretion to a crucial element in our modern world? This intriguing transformation involves a series of fascinating steps, from the historical discovery and harvesting process, to contemporary industrial production techniques that have elevated rubber into a versatile product. But this journey doesn't stop there, as we explore the various applications of rubber and its sustainability. This article will peel back the layers on the riveting world of rubber, starting with its rich history and harvesting methods. Unraveling the roots of this industry gives us a perceptual insight into its significance and sheds light on the dedicated effort behind each rubber product we use today. The tale of rubber is a testament to man's relentless push for innovation and mastery over nature. So, let's dive into the first chapter: The Origins of Rubber - From History to the Harvesting Process.The Origins of Rubber: From History to the Harvesting Process

The Origin of Rubber: From History to Harvesting Process is a comprehensive analysis of the wondrous material we ubiquitously encounter in our daily lives. This engaging article intricately narrates the historical context of rubber discovery, delves into the basics and significance of the rubber tree, and elucidates the fascinating process of rubber harvesting. The journey to the past rediscovering the origins of rubber begins with the looming trees in the ancient tropical forests where indigenous cultures first discovered its versatility. Cherished by various civilizations, from pre-Columbian tribes to European colonizers, the understanding and usage of rubber have evolved incredibly over the centuries. The pivotal recognition of the rubber tree's significance in the natural world and as a cornerstone in our modern society will be another significant element of this narrative. The piece will also invite the reader to marvel at the fascinating harvesting process of natural rubber by delving into the traditional method of tapping. An artisanal and eco-friendly process, tapping is a significant contributor to the sustainable production of natural rubber, a material that continues to play an indispensable role in the world of manufacturing. Moving forward, we explore the historical context of rubber discovery and utilization, a fascinating narrative marked by different cultures, progressive innovations, and significant relevance in today's world.

The Historical Context of Rubber Discovery and Utilization

The Historical Context of Rubber Discovery and Utilization tells a fascinating narrative of ingenuity and adaptation. The story of rubber begins nearly 3,500 years ago in Mesoamerica, where the indigenous Olmec civilization first found ways to extract and use this incredible natural resource. The Olmec would harvest the sap from the Hevea brasiliensis trees, more commonly known as the rubber tree. Using their unique methods, they fashioned rubber into balls for their ceremonial games, bands for their clothing, and even containers to store goods. In the following centuries, utilization of rubber would evolve across different cultures and continents. Christopher Columbus is credited with introducing rubber to Europe after encountering it during his voyages to the New World. However, it wasn't until Charles Goodyear accidentally discovered vulcanization in 1839, that rubber became a game-changer in the industrial world. This process, which involves heating rubber with sulfur, transformed rubber into a durable and weather-resistant material. This made it useful in a wide range of applications, from waterproof shoes and clothing to the tires we see on vehicles today. Rubber's resilience and flexibility made it an essential element for industrial development during the Industrial Revolution. Whether used as insulation for telegraph wires in the 19th century or its role in the production of automobile tires in the 20th century, rubber has been an integral part of industries worldwide. Its impact is also felt in our day-to-day lives, as it is integral to numerous household objects, medical devices, and other essential tools we take for granted. The story of rubber is one of exploration, discovery, and relentless innovation. It's a testament to the ingenuity of our ancestors, their ability to harness the natural world around them, and our continued efforts to adapt and improve upon their original applications. By understanding the historical context of rubber discovery and utilization, we can gain a better appreciation for its role in our modern world and the harvesting process that brings it from tree to tool. A truly remarkable journey that serves as an inspiration for future innovations and sustainable practices.

Natural Rubber Tree: Basics and Significance

Natural Rubber Tree: Basics and Significance The significance of the Natural Rubber Tree is integral to the broader narrative of how rubber is made. It is here in the story of the rubber production process where we see the origins of rubber manifest their important history. Native to South America, Hevea Brasiliensis, more commonly referred to as the Rubber Tree, holds a place of inestimable value in the production of natural rubber. This tree is nature's providing hand, gifting us a milky-latex that can be collected and turned into rubber. Today, rubber tree plantations stretch through huge swathes of the equatorial tropics, dominated by countries like Thailand, Indonesia, Vietnam, and Malaysia. These rubber-military nations understand well the value of this resource and the economic profit it can bring. Yet, the wonders of the Rubber Tree go far beyond its economic worth. This majestic and robust deciduous tree, which can grow up to 30 meters high, is a living testimony to nature's provision. It serves as a primary habitat for countless fauna and flora species, showing the symbiosis of life in well-balanced ecosystems. The history of the Rubber Tree is nothing short of fascinating, evidenced by the fact that it initially found popularity in Europe in the early 19th century. Henry Wickham transported 70,000 rubber tree seeds from Brazil to England's Kew Gardens in 1876, paving the way for a rabid expansion of cultivated rubber outside of South America. This marked a significant event in the journey of rubber production, prompting its commercial cultivation on a large scale. The cultivation involves tapping the tree's bark to expose the latex vessels, a process that presents no harm to the tree, further testament to the sustainability of rubber production. Harvesting rubber from the Rubber Tree is an art steeped in tradition. Practiced by local tappers, it is a skill that has been meticulously refined over generations. The raw natural latex that the tree yields is utilized in a wide variety of applications, ranging from automobile tires to medical supplies. In the big picture of rubber production, the Natural Rubber Tree doesn't just speak of economic growth and commercial possibilities. It tells a particular story of resilience, survival, and the interconnectedness of life on our planet. It demonstrates how a single tree species can significantly shape our lives and technological development as we know it today. From the tapping of the bark to the final product, the Rubber Tree stands at the heart of humanity's advancement, underlining its inherent and undeniable significance in the larger course of our shared history and innovation.

Harvesting Natural Rubber: The Tapping Process

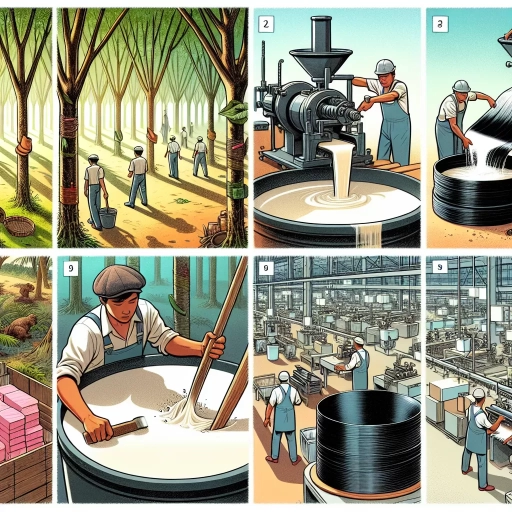

Rubber, one of the most commonly used materials globally, traces its roots back to ancient times. However, it is the intriguing journey of transformation from a latex-fluid to an unyielding material that truly grasps attention. The harvesting process of natural rubber, particularly the tapping process, serves as an essential procedure that shapes rubber's very existence. Tapping refers to the delicate operation of extracting the latex, a milky fluid, from the Hevea brasiliensis – the rubber tree. Ideally commencing before sunrise, as the internal pressure within the tree is the highest, tappers skillfully slice a thin layer of bark to expose the latex vessels without causing substantial harm to the tree. This diagonal groove allows the latex to overflow and trickle along the downward channel into a collection cup. A single tapping can produce latex for up to 6 hours post-incision, with each tree possessing the potential to be tapped every alternate day for nearly three decades. Natural rubber's charm lies in its renewable characteristic, with tapping offering a non-destructive method of harvesting. Generally, an adult rubber tree starts producing latex three to five years after planting and can continue to do so for twenty-five to thirty years. To enhance latex flow, chemical stimulants may sometimes be applied to the tap's cut surface. Despite the advent of modern technology, the tapping process remains largely manual, relying on the deftness of expert tappers. The collected latex, featuring a composition of 30-40% rubber hydrocarbons, proteins, and water, is then processed further to remove impurities and water to create the distinctive raw rubber. Understanding this critical stage of tapping in the rubber harvesting process offers intriguing insights into how versatile and resilient this material is. As consumers, it invites us to appreciate the intricate journey a single rubber band or car tire undertakes - from a rubber tree in a tropical plantation to the tools and commodities we casually utilize in everyday life. In its essence, the tapping process embodies a harmonious fusion of nature's bounty, human skill, and ingenuity - giving life a more flexible edge.

The Industrial Production: From Raw Material to a Multi-Purpose Product

Industrial production is a critical aspect of a functioning economy, transforming raw materials into multi-purpose products. This process is a perfect fusion of innovation, technique, and diligent quality control. One such manifestation of this process is the transformation of raw rubber into a versatile product. Our exploration begins with the initial stages of 'Raw Rubber Processing: Preparatory Stages and Techniques,' which is vital because it sets the stage for the whole process. Then, we delve into the fascinating world of 'The Vulcanization of Rubber: Process and Importance.' Essentially, this is the transformational point where natural rubber acquires its renowned strength and elasticity properties, signifying a significant milestone in rubber production. Lastly, to ensure that the end product is not just valuable but also safe, efficient and up to quality standards, we explore 'Quality Control in Rubber Production: Ensuring Safety and Efficiency.' Let's embark on this exciting journey, starting with understanding the preparatory stages and techniques involved in processing raw rubber.

Raw Rubber Processing: Preparatory Stages and Techniques

Raw rubber processing involves a range of preparatory stages and techniques that are both meticulous and complex, instrumental for transforming this raw material into a versatile, multi-purpose product. Initially, after the raw latex is sourced from the rubber trees, it undergoes coagulation - a process which encourages the latex to solidify into sheets or blocks. This is typically achieved by adding formic acid to the mixture, prompting the latex particles to cluster together, a process akin to milk curdling. The block of rubber is then further processed using a series of methods to remove non-rubber components and impurities. This phase, called 'purification,' employs techniques such as squeezing it through high-pressure rollers or subjecting it to a lever-press to expel excess water. In other instances, the raw rubber is masticated using mechanical devices that operate like large-scale kitchen mixers, aimed at reducing the natural hardness and elasticity of the raw rubber. The rubber then enters the compounding stage—where the beauty of raw rubber's versatility truly shines. It is mixed with a bespoke blend of chemicals, curated to imbue it with the desired traits based on its end use. For instance, rubber meant for aircraft tires would require a different chemical compound compared to that intended for rubber ducks. The material is then heated using methods such as hot air, steam heating, or infrared radiation, in a process known as 'vulcanization.' Ultimately, the aforementioned preparatory stages and techniques illustrate the intricate journey of raw rubber from its unprocessed state to becoming an integral part of countless industries ranging from automotive to healthcare. This process is a testament to the incredible transformation it undergoes, from being tapped from a tree in the form of latex, advancing via a series of complex and fine-tuned steps to playing an invaluable role in modern industrial production, proving its reputation as a truly multi-purpose product.

The Vulcanization of Rubber: Process and Importance

Vulcanization of rubber, a pivotal process in the evolution of rubber production, serves as an integral part in the chapter of industrial production: from raw material to a multi-purpose product. Since its accidental discovery by Charles Goodyear in 1839, the process of vulcanization has revolutionized the rubber industry, effectively transforming raw rubber into a durable and versatile substance with countless applications in modern life. The vulcanization process involves treating raw rubber with sulfur at high temperatures, typically ranging from 130 to 140 degrees Celsius. This procedure forms cross-links between the long chains of polymeric rubber molecules, resulting in greatly enhanced physical properties. Post vulcanization, the rubber acquires improved strength, elasticity, and resistance to factors like abrasion, solvents, and temperature changes, making it suitable for industrial applications that require high durability and resilience. The significant role that vulcanized rubber plays in various industries cannot be overstated. It has become an essential material in the automotive industry, used in the manufacture of tires, engine mounts, and hoses. Beyond this, it’s extensively used in the production of seals and gaskets in plumbing systems, conveyor belts in manufacturing plants, footwear soles, and even in waterproof clothing and gloves. The high-degree resilience, superior strength, and overall versatility demonstrated by vulcanized rubber are the reasons behind its extensive implementation. In essence, the process of rubber vulcanization underscores the transformative power of industrial production methods. It illuminates how a simple raw material like rubber can be refined and evolved into a substance with a plethora of functional, multi-purpose applications. By maximizing the potential of raw materials through innovative techniques, our industries continue to shape the world around us, demonstrating the profound impacts of human ingenuity.

Quality Control in Rubber Production: Ensuring Safety and Efficiency

Quality Control in Rubber Production: Ensuring Safety and Efficiency Quality Control is an integral part of rubber production, implementing a series of checks and balances to guarantee the safety and efficiency of the end product. Over the years, the rubber industry has acknowledged the necessity for stringent quality control measures to guarantee the highest grade of rubber. This procedure, much like the journey of rubber from a raw material to a multi-purpose product, follows a stringent path ensuring every step meticulously checks for quality, safety, and performance. At the core of quality control lies the imperative task of testing the raw latex. This includes checking for impurities and variations in consistency, essential to ensure the final product's reliability. Further into the process, the rubber undergoes several treatments where quality control becomes critical. One such treatment involves vulcanization, a process where rubber is heated with sulfur to improve its durability and elasticity. It's vital to maintain precision during vulcanization because even slight deviations can negatively affect the rubber's properties. Additionally, manufacturers use advanced machinery to shape and mold rubber into various products, from tires to gloves, demanding rigorous quality checks for each mold. Any defects in the mold can lead to a structurally weak product, underscoring the pivotal role of quality control. Moreover, the completion of each phase, from raw material handling to rubber preparation for molding and vulcanization, requires a strict inspection process to ensure consistency in texture and durability. What elevates the importance of quality control in rubber production further is the eventual use of these rubber products. Their application in critical industries like healthcare and automotive requires the utmost quality assurance. For instance, in the healthcare sector, rubber gloves must comply with stringent safety standards, as such products directly affect human health. Similarly, rubber's role in the automotive industry, primarily in tires, necessitates top-tier quality control due to the direct influence on vehicle safety. Quality Control, therefore, doesn't merely ensure that rubber products meet the minimum safety and efficiency requirements, but rather shapes the process of rubber production itself. It filters out inefficiencies, hones the production process’s precision, and enhances the durability and reliability of the final product. As a result, quality control in rubber production becomes more than a routine check – it transforms into a strategic component in the transition of rubber from a raw material to a versatile product that permeates nearly every industry. By intertwining safety and efficiency seamlessly into the production process, quality control is not only ensuring the rubber's reliability, but also its resilience in the face of wide-ranging applications – a testament to rubber's journey from a humble raw material to a multi-purpose product.

Rubber Uses and Sustainability: Environmental Impact and Alternatives

Rubber, a material with vast utility and versatility, exhibits its prowess in household items to industrial machinery. Yet, its environmental impact and the search for sustainable alternatives is a narrative often overlooked. This article aims to shed light on the multifaceted aspects of rubber use and sustainability. Outlined in three sections, we will first delve into the common and industrial uses of rubber and its impact on society and economy. This chapter will explore how rubber has driven entire industries, sparking economic growth, yet paradoxically challenging communities in its path. Next, we venture into the realm of rubber substitutes, examining the potential of materials ranging from silicone to an array of synthetic chemicals. This conversation will underscore how innovation can reconcile human need and ecological responsibility. Lastly, we dissect rubber's environmental footprint and scrutinize timely solutions. Here we make a case for sustainable rubber production, as the world grapples with the repercussions of environmental negligence. Together, these three segments will help construct a comprehensive understanding of rubber's role in our lives, the economy, and the environment, starting with the manifold uses of this indispensable material.

Common and Industrial Uses of Rubber: Impact on Society and Economy

Rubber, despite its simplicity, plays a monumental role in various industries and significantly contributes to both society and the economy. Its versatility can be witnessed in a range of sectors such as manufacturing, consumer goods, automotive, and construction. In the manufacturing industry, rubber serves as an integral component in producing items such as seals, gaskets, and hoses that are essential for machinery operation. In the varied realm of consumer goods, rubber proffers flexibility, shock absorption, and water resistance, features which have been leveraged to manufacture a plethora of everyday items, from rubber bands and gloves to shoes and mattresses. The automotive sector arguably places rubber into the limelight. With nearly 70% of global natural and synthetic rubber used in manufacturing tires, its impact on economy and society is unmistakable. Tires enable mobility and contribute to the efficiency of transportation systems, bolstering economic activity and societal development. Beyond tires, rubber is used in producing car parts like belts, mounts, seals, sound insulators and technical parts, emphasizing its indispensable role in automotive technology. In the construction realm, rubber's elasticity makes it an ideal sealant, providing weatherproof solutions that protect buildings from the elements while also acting as an effective sound insulator. Additionally, the use of recycled rubber in construction repurposes millions of used tires each year, promoting sustainability and positively impacting the economy. The economic impact of rubber production is profound, especially in countries where rubber tree plantations are abundant. It provides livelihoods for millions of people in the developing world, contributes to GDP and presents new market opportunities. The societal benefits, although less quantifiable, are equally impactful. From offering safe travels due to car tires, enabling good health through rubber medical gloves, to encouraging sport and fitness activities with rubber-made sports equipment, rubber's various applications contribute to an enhanced quality of life. This synopsis underpins the significance of the "Rubber Uses and Sustainability" discourse, a crucial component in the broader conversation around the manufacturing process and the environmental implications of rubber usage.

Viable Rubber Alternatives: From Silicone to Synthetic Substitutes

As we delve into the duality of rubber usage and its environmental implications, it's imperative to explore viable rubber alternatives without compromising quality, durability, and versatility. From silicone to synthetic substitutes, the global scientific community takes significant strides in developing eco-conscious alternatives that are as reliable and effective as the conventional rubber. Silicone, a synthetic polymer made from silicon, oxygen, carbon, and hydrogen, is an outstanding candidate for replacing conventional rubber. What sets silicone apart from other alternatives is its combination of superior properties, including thermal stability, low chemical reactivity, and resistance to UV, ozone, and weathering. Therefore, silicone stands as a powerful replacement for automotive parts, medical devices, and household products where quality and safety are paramount. Exploring further, synthetic substitutes like styrene-butadiene rubber (SBR), acrylonitrile butadiene rubber (NBR), and ethylene propylene diene monomer (EPDM) promise similar performance characteristics as natural rubber. SBR, predominantly used in tire manufacturing, offers good abrasion resistance and aging stability. NBR, known for its superior oil and fuel resistance, is ideal for automotive fuel and oil handling hoses. EPDM, resistant to weathering, heat, and ozone, is widely used for window seals, roofing membranes, and water system seals. Shifting towards these alternatives is not just an environmental endeavor, but also a cost-effective move. The fluctuation in the price of natural rubber attributed to its unpredictable supply matrix makes synthetic alternatives a more stable and economical choice. However, the transition towards these alternatives is a process that needs the collective effort of policymakers, businesses, and consumers. Encouraging research, adopting recycling practices, and promoting sustainable consumption pave the way for a future where rubber usage becomes synonymous with sustainability. After all, the goal is to reach a point where the rubber we use doesn't leave an indelible mark on the environment, but it does in our lives. In the pursuit of this goal, exploring viable rubber alternatives like silicone and synthetic substitutes are indispensable.

Rubber and the Environment: Concerns and Sustainable Approaches

Rubber, both synthetic and natural, plays a huge role in our modern world, facilitating mobility and supporting countless industries. However, its production and disposal pose significant environmental challenges that demand urgent attention. It is thus crucial that we examine the impact and potential solutions more closely to ensure a sustainable future for rubber production. Intensive rubber tree plantations were mainly developed in the 19th and 20th century in response to booming demand, and have severely impacted biodiversity. Native forests in regions like Southeast Asia have been replaced with monoculture plantations, leading to habitat loss and triggering local extinction of some species. Moreover, the process of extracting latex involves the use of harmful chemicals like ammonia, posing threats to both environment and workers. Synthetic rubber isn't off the hook either. Derived primarily from petroleum, its production contributes to air pollution, climate change and is resource-intensive. The widespread use of rubber in tires creates its own problems with microplastics becoming a massive environmental concern. As tires wear out, they shed particles that end up in the soil and water bodies, harming aquatic life and contaminating food chains. Yet, in the face of these troubling aspects, there is also a wave of sustainable approaches coming to the fore. A concept called "agroforestry" is helping mitigate the impact of rubber tree plantations by integrating them with other crops and trees, creating a more balanced ecosystem. Innovations are happening on the synthetic side as well, with researchers exploring more sustainable raw materials like guayule and Russian dandelion. Rubber recycling is gaining momentum too, converting old tires into rubber crumb for use in road construction, playground surfaces, and synthetic turf. Additionally, tire manufacturers are investing in "green tires", made of eco-friendly materials and designed to minimize rolling resistance, thus improving fuel efficiency. By spotlighting these concerns and solutions, we can navigate the path to rubber sustainability conscientiously. Innovation in rubber production and recycling, coupled with stricter regulations and public awareness, will be instrumental in reducing the environmental footprint of rubber and securing its place in a sustainable future.