How To Dye Leather

Leather dyeing is a delicate process that requires patience, skill, and attention to detail. Whether you're looking to restore a worn-out leather item or give a new one a personalized touch, dyeing leather can be a rewarding experience. However, it's essential to approach the process with caution, as the wrong techniques or materials can damage the leather or result in uneven coloration. To achieve professional-looking results, it's crucial to break down the process into manageable steps. This article will guide you through the three essential stages of leather dyeing: preparation, application, and finishing. By understanding the importance of preparation, learning how to apply the dye effectively, and adding the perfect finishing touches, you'll be able to achieve a beautifully dyed leather item. So, let's start with the foundation of successful leather dyeing: preparation is key.

Preparation is Key

Preparation is key when it comes to working with leather. Whether you're a seasoned craftsman or a DIY enthusiast, having the right materials and tools is crucial for achieving professional-looking results. To ensure a successful project, it's essential to start with the basics. This includes choosing the right leather type, preparing the workspace and tools, and conditioning the leather if necessary. By taking the time to prepare, you'll be able to work efficiently and effectively, avoiding costly mistakes and achieving the desired outcome. With the right foundation in place, you can focus on bringing your creative vision to life. So, let's start with the first step: choosing the right leather type.

Choose the Right Leather Type

When it comes to dyeing leather, choosing the right leather type is crucial for achieving the desired results. Not all leathers are created equal, and some types are more suitable for dyeing than others. Aniline leathers, for example, are ideal for dyeing because they have not been treated with any finishes or coatings, allowing the dye to penetrate evenly. Semi-aniline leathers, on the other hand, have a light finish, which can affect the dye's ability to penetrate, but still produce good results. Pigmented leathers, however, are not recommended for dyeing as they have a thick finish that prevents the dye from penetrating. Suede and nubuck leathers are also not suitable for dyeing as they have a delicate nap that can be damaged by the dyeing process. Top-grain leathers, which are made from the strongest and most durable part of the hide, are generally the best choice for dyeing, as they have a smooth, even surface that allows for optimal dye penetration. By choosing the right leather type, you can ensure that your dyeing project turns out successful and looks great.

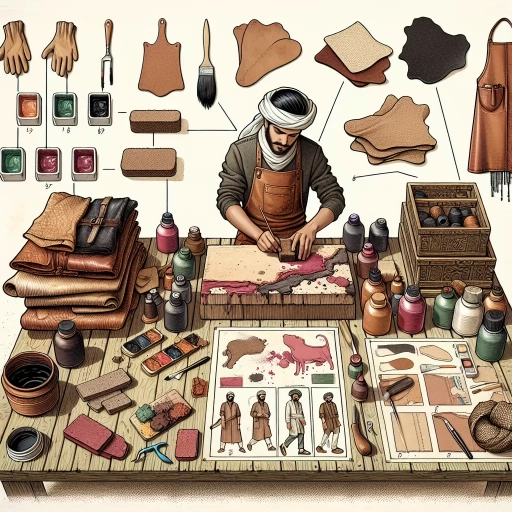

Prepare the Workspace and Tools

To prepare the workspace and tools for dyeing leather, start by covering your work surface with a drop cloth or old sheets to protect it from stains. Next, gather all the necessary tools and materials, including the leather dye, a foam brush or applicator, a clean cloth, and a pair of gloves. Make sure the workspace is well-ventilated and free from any distractions. If you're working with a large piece of leather, consider using a worktable or a large, flat surface to lay it out on. It's also a good idea to have a bucket of water and a mild soap nearby to clean your tools and wash your hands as needed. Additionally, have a clean, dry cloth on hand to blot any excess dye and prevent it from spreading. If you're using a leather dye kit, follow the instructions for preparing the dye and mixing it with any additional ingredients. Before starting the dyeing process, make sure to read the instructions carefully and understand the recommended application process, drying time, and any special precautions to take. By having a well-prepared workspace and tools, you'll be able to focus on achieving the desired color and finish for your leather project.

Condition the Leather (If Necessary)

If the leather is old, worn, or has a finish that's preventing the dye from penetrating evenly, it may be necessary to condition it before dyeing. Conditioning the leather helps to restore its natural moisture balance, making it more receptive to the dye. To condition the leather, start by applying a small amount of leather conditioner or leather oil to a clean, soft cloth. Gently rub the conditioner into the leather in circular motions, making sure to cover the entire surface evenly. Allow the conditioner to sit on the leather for about 15-20 minutes, or according to the manufacturer's instructions. Then, use a clean cloth to wipe away any excess conditioner, making sure not to leave any residue behind. This process helps to open up the leather's pores, allowing the dye to penetrate more evenly and resulting in a more consistent color. It's essential to note that not all leathers require conditioning, so it's crucial to check the manufacturer's instructions or consult with a professional if you're unsure. Additionally, some leathers, such as suede or nubuck, may require special conditioning products, so be sure to use the correct type of conditioner to avoid damaging the leather. By conditioning the leather, you'll be able to achieve a more even, vibrant color and ensure that your leather goods look their best.

Applying the Dye

Applying the dye is a crucial step in the leather dyeing process. To achieve professional-looking results, it's essential to follow a few key steps. First, applying a pre-dye treatment can help ensure the dye adheres evenly and consistently to the leather. Additionally, using a high-quality leather dye is vital, as it will provide the best color and durability. Finally, applying the dye evenly and consistently is critical to avoid any streaks or uneven coloration. By following these steps, you can achieve a beautiful, long-lasting finish. In this article, we'll explore each of these steps in more detail, starting with the importance of applying a pre-dye treatment.

Apply a Pre-Dye Treatment (If Necessary)

If you're working with a particularly stubborn or damaged piece of leather, you may need to apply a pre-dye treatment before proceeding with the dyeing process. This step is crucial in ensuring that the dye adheres evenly and penetrates the leather properly. A pre-dye treatment can help to open up the leather's pores, allowing the dye to penetrate more deeply and resulting in a more vibrant, consistent color. There are several types of pre-dye treatments available, including leather deglazers, which help to remove any existing finishes or waxes that may be interfering with the dye, and leather conditioners, which can help to moisturize and soften the leather, making it more receptive to the dye. When applying a pre-dye treatment, be sure to follow the manufacturer's instructions carefully, as different products may have specific application guidelines. Typically, you'll want to apply the treatment to the leather using a clean, lint-free cloth, working in small, circular motions to ensure even coverage. Allow the treatment to sit on the leather for the recommended amount of time before wiping off any excess with a clean cloth. Once the pre-dye treatment has been applied and allowed to dry, your leather should be ready for the dyeing process.

Use a High-Quality Leather Dye

When it comes to dyeing leather, using a high-quality leather dye is essential to achieve the desired color and finish. A good leather dye should be specifically formulated for the type of leather you are working with, whether it's aniline, semi-aniline, or pigmented leather. Look for a dye that is lightfast, meaning it won't fade quickly when exposed to sunlight, and has good color consistency. A high-quality leather dye will also be free of harsh chemicals and toxins, ensuring a safe and healthy working environment. Additionally, a good leather dye should be easy to apply and blend, allowing for a smooth and even finish. Some popular brands of high-quality leather dye include Fiebing's, Angelus, and Kiwi. These brands offer a wide range of colors and are known for their excellent colorfastness and durability. By using a high-quality leather dye, you can ensure that your leather project turns out with a rich, vibrant color that will last for years to come.

Apply the Dye Evenly and Consistently

To achieve a professional-looking finish, it's crucial to apply the dye evenly and consistently. Start by working in small sections, typically around 2-3 square inches, to maintain control and prevent the dye from spreading unevenly. Use a clean, lint-free cloth or applicator pad to apply the dye, working in smooth, even strokes to cover the entire section. Make sure to saturate the leather evenly, but avoid over-saturating, as this can cause the dye to pool or run. If using a spray dye, hold the can 6-8 inches away from the leather and spray in a steady, back-and-forth motion, moving the can slowly to maintain even coverage. For larger areas, consider using a foam brush or lambswool applicator to help distribute the dye evenly. To ensure consistency, apply the dye in the same direction as the leather's grain, working from one end of the section to the other. This will help prevent streaks and uneven coloration. If necessary, use a clean cloth to gently blot any excess dye and prevent it from spreading to adjacent areas. By taking the time to apply the dye evenly and consistently, you'll be rewarded with a rich, uniform color that enhances the natural beauty of the leather.

Finishing Touches

The finishing touches are the final steps in the leather dyeing process that can make all the difference in the appearance and durability of the leather. After applying the dye, it's essential to allow it to dry completely to prevent any unevenness or discoloration. This is a crucial step that sets the stage for the next two finishing touches: applying a leather finisher or topcoat to enhance the color and protect the leather, and inspecting and touching up any areas that may need it. By following these three steps, you can ensure that your leather goods look their best and last for years to come. Allow the Dye to Dry Completely is the first step in this process, and it's essential to get it right to achieve the desired results.

Allow the Dye to Dry Completely

When it comes to dyeing leather, one of the most crucial steps is allowing the dye to dry completely. This may seem like a straightforward process, but it's essential to get it right to achieve the desired results. If the dye is not given enough time to dry, it can lead to a range of issues, including uneven color, blotches, and a tacky finish. To avoid these problems, it's recommended to let the dye dry for at least 24 hours, depending on the type of leather and the ambient temperature and humidity. During this time, it's essential to keep the leather away from direct sunlight, heat, and moisture, as these can cause the dye to fade or become discolored. Once the dye is dry, you can proceed with the next steps, such as applying a finisher or conditioner to enhance the color and protect the leather. By allowing the dye to dry completely, you'll be able to achieve a rich, vibrant color that will last for years to come.

Apply a Leather Finisher or Topcoat

Applying a leather finisher or topcoat is the final step in the leather dyeing process, and it's essential to enhance the color, protect the leather, and give it a glossy finish. A leather finisher or topcoat is a clear liquid or cream that is applied to the leather surface to seal the dye and prevent it from fading or bleeding. It also helps to protect the leather from water, dirt, and other environmental factors that can cause damage. There are different types of leather finishers or topcoats available, including water-based, solvent-based, and wax-based, each with its own unique characteristics and benefits. When choosing a leather finisher or topcoat, consider the type of leather you are working with, the desired level of gloss, and the level of protection you need. Apply the finisher or topcoat according to the manufacturer's instructions, usually with a clean cloth or applicator pad, and allow it to dry completely before handling the leather. It's also important to test the finisher or topcoat on a small, inconspicuous area first to ensure it doesn't affect the color or texture of the leather. By applying a leather finisher or topcoat, you can achieve a professional-looking finish and extend the life of your leather goods.

Inspect and Touch Up (If Necessary)

Inspect and touch up (if necessary) is a crucial step in the leather dyeing process. After the dye has dried, inspect the leather carefully for any imperfections, uneven color, or areas where the dye may have missed. Check for any spots, streaks, or discolorations that may have occurred during the dyeing process. If you notice any of these issues, you can touch up the affected areas using a small brush and a matching dye color. Apply the dye sparingly and evenly, feathering it out towards the edges to blend with the surrounding color. Be cautious not to over-saturate the leather, as this can cause the dye to pool or become uneven. If the imperfections are minor, you can also use a leather touch-up pen or marker to quickly and easily correct the issue. These pens are specifically designed for leather and come in a range of colors, making it easy to find a match for your leather. By taking the time to inspect and touch up your leather, you can ensure a professional-looking finish and a beautiful, even color.