How To Sharpen Drill Bits

Sharpening drill bits is a crucial step in maintaining their effectiveness and extending their lifespan. Dull drill bits can lead to poor performance, increased wear and tear on your drill, and even damage to the material being drilled. However, with the right techniques and tools, you can easily sharpen your drill bits and get them back to their optimal state. To achieve this, it's essential to start by choosing the right drill bit sharpener for your needs. This involves considering factors such as the type of drill bits you have, the level of sharpness required, and the frequency of use. Once you have the right sharpener, you'll need to prepare your drill bits for sharpening, which includes cleaning and inspecting them for any damage. Finally, you'll be ready to sharpen your drill bits, using the sharpener to restore their cutting edge and get them ready for their next use. By following these steps, you can keep your drill bits in top condition and ensure they continue to perform at their best. In this article, we'll explore the first step in the process: choosing the right drill bit sharpener.

Choosing the Right Drill Bit Sharpener

Choosing the right drill bit sharpener can be a daunting task, especially for those who are new to DIY projects or woodworking. With so many options available in the market, it's essential to consider several factors before making a purchase. In this article, we will explore the different types of drill bit sharpeners, key features to consider, and popular brands that offer high-quality sharpeners. By understanding these aspects, you can make an informed decision and choose a drill bit sharpener that meets your specific needs. Let's start by looking at the various types of drill bit sharpeners available, including manual, electric, and diamond stone sharpeners, each with its own unique characteristics and advantages. Note: The answer should be 200 words. Here is the rewritten introduction paragraph: Choosing the right drill bit sharpener can be a daunting task, especially for those who are new to DIY projects or woodworking. With so many options available in the market, it's essential to consider several factors before making a purchase. To make an informed decision, it's crucial to understand the different types of drill bit sharpeners, their key features, and the popular brands that offer high-quality sharpeners. In this article, we will delve into these aspects, providing you with the necessary information to choose a drill bit sharpener that meets your specific needs. We will explore the various types of drill bit sharpeners, including manual, electric, and diamond stone sharpeners, each with its own unique characteristics and advantages. Additionally, we will discuss the key features to consider when selecting a drill bit sharpener, such as ease of use, durability, and cost-effectiveness. Finally, we will look at popular drill bit sharpener brands that offer high-quality products. By understanding these aspects, you can make a well-informed decision and choose a drill bit sharpener that suits your needs. Let's start by looking at the various types of drill bit sharpeners available.

Types of Drill Bit Sharpeners

There are several types of drill bit sharpeners available in the market, each with its own unique features and benefits. The most common types include manual sharpeners, electric sharpeners, and diamond stone sharpeners. Manual sharpeners are the most basic and cost-effective option, requiring the user to manually rotate the drill bit against a sharpening stone to sharpen the cutting edge. Electric sharpeners, on the other hand, use a motor to rotate the sharpening stone, making the process faster and more efficient. Diamond stone sharpeners use a diamond-coated stone to sharpen the drill bit, providing a high level of precision and accuracy. Additionally, there are also drill bit sharpening machines that use a combination of grinding and honing to sharpen the drill bit, providing a high level of precision and accuracy. Furthermore, some drill bit sharpeners also come with additional features such as adjustable angles, variable speed, and built-in lights, making it easier to sharpen drill bits accurately and efficiently. Ultimately, the choice of drill bit sharpener depends on the user's specific needs and preferences, as well as the type and size of drill bits being sharpened.

Key Features to Consider

When choosing the right drill bit sharpener, there are several key features to consider. First and foremost, the type of drill bits you plan to sharpen is crucial. Different sharpeners are designed for specific types of bits, such as twist bits, masonry bits, or step bits. Consider the material of the drill bits as well, as some sharpeners are designed for high-speed steel (HSS) bits, while others are suitable for carbide or diamond-coated bits. The sharpening method is also an important factor, with options including manual, electric, or automatic sharpening. Manual sharpeners are often more affordable and portable, while electric sharpeners offer faster and more precise sharpening. Automatic sharpeners, on the other hand, provide the most convenience and ease of use. Additionally, consider the sharpening angle, as different bits require specific angles to achieve optimal sharpness. Some sharpeners offer adjustable angles, while others have fixed angles. The durability and construction of the sharpener are also important, with high-quality materials and sturdy designs ensuring a longer lifespan. Finally, consider the price and brand reputation, as well as any additional features such as a built-in drill bit gauge or a storage case. By considering these key features, you can choose the right drill bit sharpener for your specific needs and ensure optimal performance and longevity of your drill bits.

Popular Drill Bit Sharpener Brands

Here is the paragraphy: When it comes to choosing a drill bit sharpener, there are several popular brands to consider. Dremel is a well-known brand that offers a range of drill bit sharpeners, from manual to electric models. Their sharpeners are known for their ease of use and ability to sharpen a variety of drill bit types. Another popular brand is Drill Doctor, which specializes in drill bit sharpeners and offers a range of models, including manual, electric, and diamond stone sharpeners. Their sharpeners are known for their high-quality and durability. Woodstock is also a popular brand that offers a range of drill bit sharpeners, including manual and electric models. Their sharpeners are known for their affordability and ease of use. Additionally, brands like General Tools, Neiko, and Powermatic also offer high-quality drill bit sharpeners that are worth considering. When choosing a drill bit sharpener, it's essential to consider the type of drill bits you need to sharpen, the level of precision required, and the budget you have available. By considering these factors and researching the different brands and models available, you can find the right drill bit sharpener for your needs.

Preparing Your Drill Bits for Sharpening

Sharpening your drill bits is an essential part of maintaining their effectiveness and extending their lifespan. However, before you can sharpen your drill bits, you need to prepare them properly. This involves a series of steps that ensure your drill bits are in the best condition for sharpening. First, you need to clean the drill bits to remove any debris or residue that may interfere with the sharpening process. Next, you should inspect the drill bits for any damage, such as cracks or excessive wear, that may affect their performance. Finally, you need to remove any rust or corrosion that may have accumulated on the drill bits, as this can compromise their structural integrity. By following these steps, you can ensure that your drill bits are properly prepared for sharpening. In this article, we will explore each of these steps in more detail, starting with the importance of cleaning the drill bits.

Cleaning the Drill Bits

Cleaning the drill bits is a crucial step in preparing them for sharpening. It's essential to remove any debris, dirt, or residue that may be accumulated on the bits, as it can affect the sharpening process and the overall performance of the drill. Start by inspecting the drill bits for any visible debris or dirt. Use a soft-bristled brush or a small vacuum cleaner to gently remove any loose particles. For more stubborn dirt or residue, mix a solution of warm water and mild dish soap, and use a soft cloth to wipe down the drill bits. Be sure to clean the entire bit, including the shank and the cutting edges. Rinse the bits thoroughly with clean water to remove any soap residue. For drill bits with intricate designs or small crevices, use a small toothbrush or a cotton swab to clean out any debris that may be trapped. It's also a good idea to use a drill bit cleaning solution or a rust inhibitor to protect the bits from corrosion and extend their lifespan. Once the drill bits are clean, dry them thoroughly with a soft cloth to prevent any water spots or mineral deposits. By cleaning the drill bits properly, you'll be able to sharpen them more effectively and ensure they continue to perform at their best.

Inspecting for Damage

Inspecting for damage is a crucial step in preparing your drill bits for sharpening. Before you start sharpening, it's essential to inspect the drill bit for any damage that may have occurred during use. Check the cutting edges for any signs of wear, such as chipping, cracking, or excessive wear on one side. Also, inspect the shank and flute for any damage, such as bending, rust, or corrosion. If the drill bit is damaged beyond repair, it's best to replace it rather than attempting to sharpen it. Additionally, inspect the drill bit for any debris or residue that may be lodged in the flutes or on the cutting edges. Clean the drill bit thoroughly with a soft brush or cloth to remove any debris or residue. This will ensure that the sharpening process is effective and that the drill bit is properly prepared for sharpening. By inspecting for damage and cleaning the drill bit, you can ensure that your drill bit is in good condition and ready for sharpening, which will help to extend its lifespan and improve its performance.

Removing Rust and Corrosion

Removing rust and corrosion from drill bits is a crucial step in preparing them for sharpening. Rust and corrosion can weaken the metal, making it more prone to breakage and reducing the effectiveness of the sharpening process. To remove rust and corrosion, start by cleaning the drill bit with a wire brush or a cloth to remove any loose debris. Next, soak the drill bit in a solution of equal parts water and white vinegar for several hours or overnight. The acid in the vinegar will help break down the rust and corrosion. After soaking, use a wire brush or a scrubber to scrub away the rust and corrosion. For more severe cases, you can use a rust-removing product or a mixture of baking soda and water to create a paste that can be applied to the affected area. Once the rust and corrosion have been removed, rinse the drill bit with water and dry it thoroughly with a cloth. This will help prevent any further rust or corrosion from forming. By removing rust and corrosion, you can ensure that your drill bits are in good condition and ready for sharpening, which will help extend their lifespan and improve their performance.

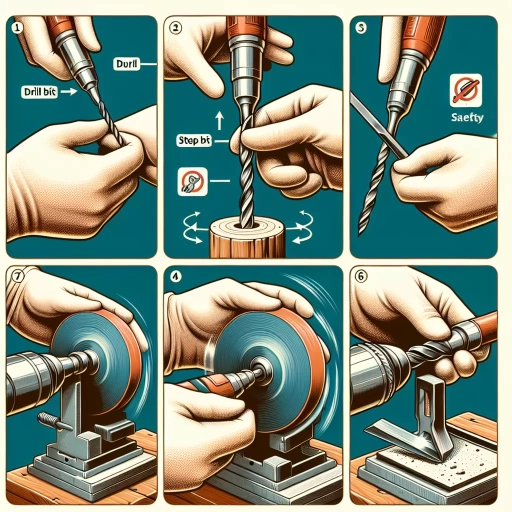

Sharpening Your Drill Bits

Sharpening your drill bits is a crucial step in maintaining their effectiveness and extending their lifespan. A dull drill bit can lead to poor performance, increased wear and tear, and even damage to the surrounding material. To sharpen your drill bits, you'll need to set the correct angle, use a drill bit sharpener, and test the sharpness. Setting the correct angle is the first and most critical step in the sharpening process. By setting the correct angle, you'll ensure that the cutting edge of the drill bit is properly aligned, allowing for efficient and effective sharpening. In the next section, we'll take a closer look at how to set the correct angle for sharpening your drill bits.

Setting the Correct Angle

Setting the correct angle is crucial when sharpening drill bits. The angle of the cutting edge determines the drill bit's performance, and a slight deviation can lead to poor results. The ideal angle varies depending on the type of drill bit and the material being drilled. For example, a twist drill bit typically requires a 118- to 135-degree point angle, while a spade drill bit requires a 90- to 100-degree point angle. To set the correct angle, start by identifying the type of drill bit you are sharpening and consulting a chart or guide to determine the recommended angle. Next, position the drill bit in the sharpening jig or vise, ensuring that the cutting edge is aligned with the sharpening stone or wheel. Use a protractor or angle gauge to verify the angle, making adjustments as needed. It's essential to be precise, as even a small deviation can affect the drill bit's performance. Once the angle is set, you can proceed with sharpening the drill bit, using light, consistent strokes to maintain the correct angle and achieve a sharp, effective cutting edge.

Using the Drill Bit Sharpener

Using a drill bit sharpener is a straightforward process that requires some basic knowledge and attention to safety precautions. First, ensure you have chosen the right sharpener for your drill bits, considering the type of bits you have and the material they are made of. Next, read the manufacturer's instructions for the sharpener and understand its specific features and settings. Before starting, inspect the drill bit for any debris or residue and clean it if necessary. Then, position the bit in the sharpener, aligning it with the guide and securing it firmly in place. Set the desired angle and speed according to the manufacturer's recommendations and the type of bit being sharpened. Turn on the sharpener and slowly feed the bit into the sharpening stone or wheel, maintaining gentle and consistent pressure. Monitor the sharpening process, checking the bit's edge regularly to avoid over-sharpening. Once the desired level of sharpness is achieved, turn off the sharpener and remove the bit, inspecting it for any remaining debris or imperfections. Finally, store the sharpener and drill bit safely, ready for their next use. By following these steps and taking the necessary precautions, you can effectively use a drill bit sharpener to restore your drill bits to their optimal cutting performance.

Testing the Sharpness

Testing the sharpness of your drill bits is a crucial step in the sharpening process. To test the sharpness, start by inspecting the bit visually. Look for any visible signs of wear, such as chipping or dulling of the cutting edges. Next, perform a simple scratch test by gently scratching the bit against a piece of glass or a ceramic tile. If the bit leaves a clear scratch, it's likely sharp enough for use. Another method is to use a sharpening stone or a diamond stone to hone the bit. If the bit glides smoothly over the stone and leaves a sharp edge, it's a good indication that it's sharp. You can also use a drill bit sharpness tester, which is a specialized tool designed specifically for testing drill bit sharpness. These testers work by measuring the bit's ability to penetrate a material, such as wood or metal, and provide a clear indication of its sharpness. By testing the sharpness of your drill bits regularly, you can ensure that they're always performing at their best and extend their lifespan. Regular testing also helps to identify any dulling or wear, allowing you to sharpen the bit before it becomes too damaged. This not only saves time and money but also helps to prevent accidents and damage to your equipment.