How Does A Boiler Work

Boilers are a crucial part of many industrial and residential heating systems, providing a reliable source of hot water and steam. But have you ever wondered how they work? In this article, we will delve into the inner workings of a boiler, exploring its main components, the principles that govern its operation, and the importance of maintenance for optimal efficiency. We will start by examining the fundamental question: what is a boiler and what are its main components? By understanding the basic structure and function of a boiler, we can better appreciate the complex processes that occur within it. From there, we will move on to discuss the working principle of a boiler, including the flow of water, heat transfer, and steam generation. Finally, we will touch on the importance of boiler efficiency and maintenance, highlighting the steps that can be taken to ensure a boiler operates safely and effectively. What is a Boiler and Its Main Components?

What is a Boiler and Its Main Components

A boiler is a crucial piece of equipment in various industries, including power generation, heating, and manufacturing. It plays a vital role in converting water into steam, which is then used for different purposes. But have you ever wondered what a boiler is and how it works? In this article, we will delve into the world of boilers and explore their main components, types, and applications. We will start by defining what a boiler is and explaining its basic principles, followed by a detailed discussion of its main components, including the furnace, boiler tubes, and heat exchanger. Finally, we will examine the different types of boilers, such as fire-tube and water-tube boilers, and their various applications in different industries. By the end of this article, you will have a comprehensive understanding of boilers and their importance in modern industry. So, let's begin by defining what a boiler is and how it works.

Definition and Explanation of a Boiler

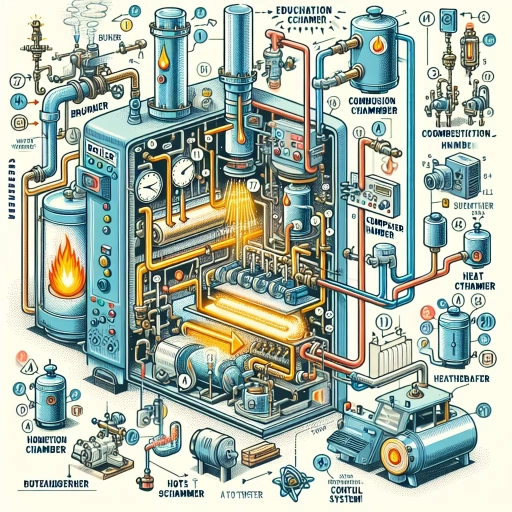

A boiler is a closed vessel in which water or other fluid is heated. The heated fluid or steam is used in various applications, including space and water heating, steam power generation, and process applications. Boilers are designed to withstand the high temperatures and pressures that occur during the heating process. The heat source for a boiler can be electricity, gas, oil, or solid fuels such as wood or coal. Boilers are classified into different types based on their design, fuel source, and application. The main components of a boiler include the furnace, where the fuel is burned to produce heat; the boiler tubes, where the water is heated; the heat exchanger, where the heat is transferred to the water; and the burner, which controls the amount of fuel that is burned. Boilers are an essential part of many industrial and commercial processes, and are also used in residential settings for heating and hot water supply.

Main Components of a Boiler System

A boiler system consists of several main components that work together to provide heat and hot water to a building. The first main component is the boiler itself, which is the central unit that heats the water or produces steam. The boiler is typically fueled by natural gas, oil, or electricity, and it uses a burner to ignite the fuel and generate heat. The heat is then transferred to the water or steam through a heat exchanger, which is usually a coiled tube or a series of tubes. The heated water or steam is then pumped through a network of pipes to the radiators or heating units, where it releases its heat and returns to the boiler to be reheated. Another key component is the control system, which regulates the boiler's operation and ensures that it runs safely and efficiently. This includes a thermostat, which monitors the temperature and adjusts the boiler's output accordingly, as well as safety devices such as pressure relief valves and low-water cutoffs. The system also includes a feedwater system, which supplies fresh water to the boiler to replace any water that is lost through evaporation or leakage. Finally, the system includes a drainage system, which removes any condensate or wastewater from the boiler and pipes. Overall, the main components of a boiler system work together to provide a reliable and efficient source of heat and hot water.

Types of Boilers and Their Applications

Boilers are classified into several types based on their design, fuel source, and application. The main types of boilers include fire-tube boilers, water-tube boilers, cast iron boilers, electric boilers, and condensing boilers. Fire-tube boilers are the most common type and are used in a wide range of applications, including residential, commercial, and industrial settings. They are simple in design and consist of a series of tubes that are heated by a furnace or burner, with the hot gases passing through the tubes to heat the water. Water-tube boilers, on the other hand, are more complex and are typically used in high-pressure applications, such as power plants and large industrial processes. They consist of a series of tubes that are heated by a furnace or burner, with the hot gases passing through the tubes to heat the water. Cast iron boilers are made from cast iron and are often used in residential and commercial settings. They are known for their durability and long lifespan. Electric boilers are a type of boiler that uses electricity to heat the water, rather than a fuel source. They are often used in small applications, such as residential heating systems. Condensing boilers are a type of boiler that uses the heat from the exhaust gases to pre-heat the water, making them more efficient than traditional boilers. They are often used in residential and commercial settings. In terms of applications, boilers are used in a wide range of industries, including power generation, chemical processing, food processing, and heating and cooling systems. They are also used in residential and commercial settings for space heating and hot water generation. Overall, the type of boiler used depends on the specific application and the requirements of the system.

The Working Principle of a Boiler

A boiler is a complex piece of equipment that plays a crucial role in various industrial and commercial applications. At its core, a boiler is a device that uses heat energy to convert water into steam, which can then be used for a variety of purposes, such as heating, power generation, and process applications. The working principle of a boiler involves a combination of heat transfer, water circulation, and steam generation, all of which are carefully controlled and monitored to ensure safe and efficient operation. In this article, we will delve into the intricacies of the boiler's working principle, exploring the heat transfer process, water circulation and steam generation, and the various controls and safety features that are in place to prevent accidents and ensure optimal performance. We will begin by examining the heat transfer process in a boiler, which is the foundation of the entire system.

Heat Transfer Process in a Boiler

The heat transfer process in a boiler is a complex phenomenon that involves the transfer of heat energy from the combustion of fuel to the water, resulting in the production of steam. The process occurs in three stages: convection, conduction, and radiation. Convection is the primary mode of heat transfer, where the hot flue gases produced by the combustion of fuel rise through the boiler, transferring their heat energy to the water through the boiler tubes. As the hot gases rise, they create a circulation of water, known as a convective cell, which helps to distribute the heat evenly throughout the boiler. Conduction occurs when the heat energy is transferred directly from the hot boiler tubes to the surrounding water, while radiation involves the transfer of heat energy through electromagnetic waves. The heat transfer process is influenced by various factors, including the design of the boiler, the type of fuel used, and the operating conditions. The efficiency of the heat transfer process is critical to the overall performance of the boiler, as it directly affects the amount of steam produced and the energy consumed. By optimizing the heat transfer process, boiler manufacturers can design more efficient and cost-effective boilers that meet the increasing demand for steam in various industries.

Water Circulation and Steam Generation

Water circulation and steam generation are two critical processes that occur within a boiler system. Water circulation refers to the continuous movement of water through the boiler's tubes, where it is heated and transformed into steam. This process is essential for maintaining the boiler's efficiency and preventing overheating. The water circulation system consists of a series of pumps, valves, and pipes that work together to circulate the water through the boiler's heat exchanger. As the water flows through the heat exchanger, it absorbs heat from the combustion gases, causing its temperature to rise. The heated water then rises to the top of the boiler, where it is separated from the steam. The steam is then collected and directed to the steam drum, where it is stored and distributed to the desired location. The water, now cooled, is then re-circulated back to the heat exchanger, where the process is repeated. This continuous circulation of water ensures that the boiler operates efficiently and safely. Steam generation, on the other hand, is the process by which the heated water is transformed into steam. This occurs when the water reaches its boiling point, typically around 212°F (100°C), and turns into vapor. The steam is then collected and used for various applications, such as heating, power generation, or industrial processes. The steam generation process is influenced by factors such as the boiler's design, fuel type, and operating conditions. By understanding the principles of water circulation and steam generation, boiler operators can optimize the performance of their boiler system, ensuring efficient and safe operation.

Boiler Controls and Safety Features

Boiler controls and safety features are crucial components of a boiler system, ensuring safe and efficient operation. The primary function of boiler controls is to regulate the boiler's temperature, pressure, and fuel supply to maintain optimal performance. This is achieved through a combination of sensors, controllers, and actuators that work together to monitor and adjust the boiler's operating conditions. For instance, temperature sensors detect changes in the boiler's temperature, sending signals to the controller, which then adjusts the fuel supply to maintain the setpoint temperature. Similarly, pressure sensors monitor the boiler's pressure, triggering the controller to adjust the steam release valve to prevent over-pressurization. Boiler controls also include features such as low-water cutoffs, which prevent the boiler from operating when the water level is too low, and high-limit switches, which shut off the boiler if the temperature exceeds a predetermined limit. Additionally, modern boilers often incorporate advanced safety features, such as flame failure detection, which shuts off the fuel supply if the flame is extinguished, and combustion air controls, which ensure proper air-fuel mixture to prevent incomplete combustion. These controls and safety features work in tandem to prevent accidents, reduce energy consumption, and prolong the boiler's lifespan. By ensuring the boiler operates within safe and efficient parameters, boiler controls and safety features play a vital role in maintaining a reliable and efficient heating system.

Boiler Efficiency and Maintenance

Boiler efficiency and maintenance are crucial aspects of ensuring the optimal performance of heating systems in various industries and residential settings. A well-maintained boiler not only reduces energy consumption but also minimizes environmental impact and prolongs its lifespan. However, several factors can affect boiler efficiency, including fuel quality, operating conditions, and design specifications. Regular maintenance tasks, such as cleaning and inspecting heat exchangers, monitoring water quality, and adjusting burner settings, are essential to prevent efficiency losses and ensure safe operation. Additionally, upgrading or retrofitting boilers with advanced technologies, such as condensing boilers or heat recovery systems, can significantly improve efficiency and reduce emissions. By understanding the factors that affect boiler efficiency and implementing regular maintenance tasks and upgrades, individuals and organizations can optimize their heating systems, reduce energy costs, and contribute to a more sustainable future. This article will explore the key factors affecting boiler efficiency, regular maintenance tasks, and upgrades and retrofits for improved efficiency, starting with the factors that impact boiler efficiency.

Factors Affecting Boiler Efficiency

Boiler efficiency is influenced by several factors, including fuel type, combustion air quality, and heat transfer surface area. The type of fuel used can significantly impact boiler efficiency, with natural gas and propane generally being more efficient than coal or oil. Combustion air quality also plays a crucial role, as inadequate air supply can lead to incomplete combustion, reducing efficiency. The heat transfer surface area, which includes the boiler's tubes, headers, and drums, affects the rate of heat transfer and, consequently, boiler efficiency. Additionally, factors such as boiler design, operating conditions, and maintenance practices can also impact efficiency. For instance, a well-designed boiler with a high turndown ratio can operate efficiently at varying loads, while regular maintenance, such as cleaning and inspecting heat transfer surfaces, can help maintain optimal efficiency. Furthermore, the use of advanced technologies, such as condensing boilers and economizers, can also enhance boiler efficiency by recovering heat that would otherwise be lost. Overall, understanding and addressing these factors is essential to optimizing boiler efficiency and minimizing energy waste.

Regular Maintenance Tasks for Boilers

Regular maintenance tasks for boilers are essential to ensure they operate efficiently, safely, and effectively. One of the most critical tasks is to check and replace the air filter regularly, as a dirty filter can reduce airflow and increase energy consumption. Additionally, the boiler's water level should be checked daily to ensure it is at the recommended level, as low water levels can cause the boiler to overheat and potentially lead to a breakdown. It is also crucial to inspect the boiler's burner and heat exchanger for any signs of wear or damage, as these components are prone to corrosion and can affect the boiler's performance. Furthermore, the boiler's temperature and pressure relief valve should be checked regularly to ensure it is functioning correctly, as a faulty valve can lead to a dangerous buildup of pressure. Moreover, the boiler's electrical connections and wiring should be inspected for any signs of wear or damage, as faulty electrical connections can cause the boiler to malfunction. Regular cleaning of the boiler's exterior and interior is also necessary to remove any dirt, dust, or debris that can accumulate and affect the boiler's performance. It is recommended to perform these maintenance tasks at least once a year, or as recommended by the manufacturer, to ensure the boiler operates efficiently and safely. By performing these regular maintenance tasks, homeowners can help extend the lifespan of their boiler, reduce energy consumption, and prevent costly repairs.

Upgrades and Retrofits for Improved Efficiency

Upgrades and retrofits can significantly improve the efficiency of a boiler system. One common upgrade is the installation of a new burner, which can provide a more efficient combustion process and reduce emissions. Another option is to install a heat recovery system, which can capture waste heat from the boiler's exhaust gases and use it to preheat the boiler's feedwater or provide additional heat to the building. Additionally, upgrading to a more efficient boiler control system can help optimize boiler performance and reduce energy consumption. Retrofits such as installing a new economizer or air preheater can also improve boiler efficiency by reducing heat loss and improving combustion air quality. Furthermore, implementing a boiler management system can help monitor and optimize boiler performance in real-time, allowing for quick identification and correction of any efficiency-reducing issues. By investing in these upgrades and retrofits, building owners and operators can improve the overall efficiency of their boiler system, reduce energy costs, and minimize their environmental impact.