How Much Platinum Is In A Catalytic Converter

Platinum is a rare and highly valuable precious metal used in various industrial applications, including the automotive industry. One of the most significant uses of platinum is in catalytic converters, which are essential components of vehicle exhaust systems. Catalytic converters play a crucial role in reducing harmful emissions and pollutants from vehicles, and platinum is a key component in their construction. But have you ever wondered how much platinum is actually in a catalytic converter? The answer to this question is not straightforward, as it depends on various factors such as the type of vehicle, the age of the converter, and the manufacturer's specifications. In this article, we will delve into the world of platinum in catalytic converters, exploring the platinum content in these devices, the extraction and recycling processes, and the market dynamics that influence the use of platinum in this industry. We will begin by examining the platinum content in catalytic converters, which is a critical factor in understanding the value and significance of these devices.

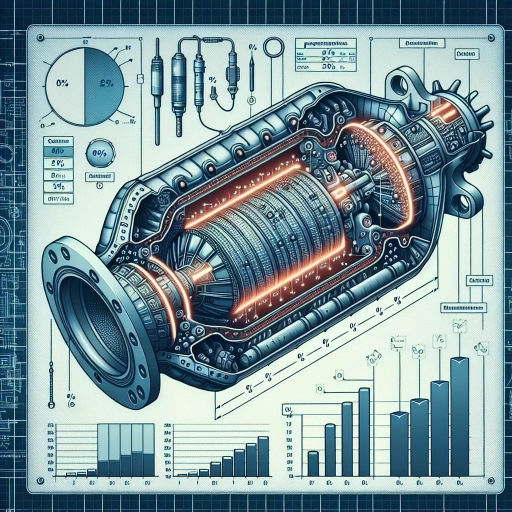

Platinum Content in Catalytic Converters

Platinum content in catalytic converters is a crucial aspect of the automotive industry, playing a significant role in reducing emissions and improving air quality. The amount of platinum used in these converters can vary greatly, depending on several factors. In this article, we will delve into the world of platinum content in catalytic converters, exploring typical platinum loadings in modern converters, the factors that affect platinum content, and a comparison of platinum content in different types of converters. By understanding these aspects, we can gain a deeper appreciation for the importance of platinum in catalytic converters and its impact on the environment. So, let's start by examining the typical platinum loadings in modern catalytic converters.

Typical Platinum Loadings in Modern Catalytic Converters

Typical platinum loadings in modern catalytic converters vary depending on the application, vehicle type, and emissions standards. Generally, a typical catalytic converter contains between 2-12 grams of platinum, with an average loading of around 4-6 grams. However, some high-performance vehicles or those designed for specific emissions standards may have higher platinum loadings, up to 20 grams or more. The platinum loading is usually distributed across multiple catalysts, including the front and rear converters, as well as the diesel oxidation catalyst (DOC) and diesel particulate filter (DPF). The platinum content is typically measured in grams per cubic foot (g/ft³) of catalyst volume, with a typical range of 0.5-2.5 g/ft³. The actual platinum loading can vary depending on the manufacturer, model year, and specific emissions requirements.

Factors Affecting Platinum Content in Catalytic Converters

The platinum content in catalytic converters can be influenced by several factors, including the type of vehicle, engine size, and emissions standards. Typically, gasoline-powered vehicles have higher platinum content than diesel-powered vehicles, as they require more platinum to meet stricter emissions regulations. Additionally, vehicles with larger engines tend to have more platinum in their catalytic converters, as they produce more emissions and require more catalyst to reduce them. The age of the vehicle can also impact platinum content, with newer vehicles often having more advanced catalytic converters that use less platinum. Furthermore, the type of catalyst used can also affect platinum content, with some catalysts using more platinum than others to achieve the same level of emissions reduction. Overall, the platinum content in catalytic converters can vary significantly depending on these factors, making it difficult to determine a standard amount of platinum in a catalytic converter.

Comparison of Platinum Content in Different Types of Catalytic Converters

The platinum content in different types of catalytic converters can vary significantly, depending on the specific application, vehicle type, and manufacturer. Generally, three-way catalytic converters, which are the most common type, contain between 2-7 grams of platinum per unit. These converters are designed to reduce emissions of carbon monoxide, hydrocarbons, and nitrogen oxides, and are typically used in gasoline-powered vehicles. In contrast, diesel oxidation catalysts (DOCs), which are used in diesel-powered vehicles, typically contain between 1-3 grams of platinum per unit. These converters are designed to reduce emissions of particulate matter, carbon monoxide, and hydrocarbons. Selective catalytic reduction (SCR) systems, which are used in some diesel-powered vehicles, may contain up to 10 grams of platinum per unit. These systems use a catalyst to reduce emissions of nitrogen oxides. Finally, two-way catalytic converters, which are less common, typically contain between 1-2 grams of platinum per unit. These converters are designed to reduce emissions of carbon monoxide and hydrocarbons, but not nitrogen oxides. Overall, the platinum content in catalytic converters can vary widely, depending on the specific application and type of converter.

Extraction and Recycling of Platinum from Catalytic Converters

The extraction and recycling of platinum from catalytic converters have become increasingly important due to the growing demand for this precious metal in various industries, including automotive, jewelry, and electronics. The recycling of platinum from spent catalytic converters is a complex process that involves several challenges and limitations. However, with the development of emerging technologies, the efficiency of platinum recovery from catalytic converters is improving. This article will discuss the methods for extracting platinum from spent catalytic converters, the challenges and limitations in platinum recycling, and the emerging technologies for efficient platinum recovery. By understanding these aspects, we can better appreciate the importance of platinum recycling and the efforts being made to improve the process. One of the primary steps in platinum recycling is the extraction of platinum from spent catalytic converters, which will be discussed in the next section.

Methods for Extracting Platinum from Spent Catalytic Converters

The extraction of platinum from spent catalytic converters is a complex process that requires careful consideration of various methods to ensure maximum recovery and minimal environmental impact. One of the most common methods is the pyrometallurgical process, which involves heating the converters to high temperatures to melt the platinum and other precious metals, allowing for their separation and extraction. Another method is the hydrometallurgical process, which uses a combination of chemicals and water to dissolve the platinum and other metals, making it easier to extract and separate them. Additionally, some companies use a combination of both pyrometallurgical and hydrometallurgical processes to achieve higher recovery rates. Other methods include the use of bioleaching, which uses microorganisms to break down the platinum and other metals, and the use of electrochemical processes, which use an electric current to extract the platinum. Each method has its own advantages and disadvantages, and the choice of method depends on the specific characteristics of the spent catalytic converters and the desired level of platinum recovery.

Challenges and Limitations in Platinum Recycling from Catalytic Converters

The recycling of platinum from catalytic converters is a complex process that poses several challenges and limitations. One of the primary challenges is the extraction of platinum from the ceramic or metallic substrate, which requires the use of high-temperature furnaces and specialized equipment. Additionally, the presence of other precious metals such as palladium and rhodium in the catalytic converter can make the extraction process more complicated. Furthermore, the recycling process also generates hazardous waste, including toxic chemicals and heavy metals, which requires proper handling and disposal. Another limitation is the economic viability of the recycling process, as the cost of extracting platinum from catalytic converters can be higher than the cost of mining primary platinum. Moreover, the recycling process also requires a significant amount of energy, which can contribute to greenhouse gas emissions. Despite these challenges and limitations, many companies and researchers are working to develop more efficient and sustainable methods for recycling platinum from catalytic converters. For instance, some companies are using hydrometallurgical processes that use aqueous solutions to extract platinum, which can be more energy-efficient and environmentally friendly. Researchers are also exploring the use of microbial leaching, which uses microorganisms to extract platinum from catalytic converters. These innovative approaches aim to overcome the challenges and limitations of platinum recycling and make the process more economically viable and environmentally sustainable.

Emerging Technologies for Efficient Platinum Recovery from Catalytic Converters

The recovery of platinum from catalytic converters has become increasingly important due to the growing demand for this precious metal in various industries. Emerging technologies are being developed to improve the efficiency of platinum recovery, reducing the environmental impact and costs associated with traditional methods. One such technology is hydrometallurgical processing, which involves the use of aqueous solutions to extract platinum from catalytic converters. This method has shown promising results, with high recovery rates and minimal waste generation. Another emerging technology is bioleaching, which utilizes microorganisms to break down the catalytic converter material and release the platinum. This method is considered more environmentally friendly and cost-effective compared to traditional smelting and refining processes. Additionally, advanced sensor technologies and machine learning algorithms are being developed to optimize the platinum recovery process, enabling real-time monitoring and control of the extraction process. These emerging technologies have the potential to significantly improve the efficiency and sustainability of platinum recovery from catalytic converters, reducing the environmental footprint of the industry while meeting the growing demand for this valuable metal.

Market Dynamics and Economic Factors Influencing Platinum in Catalytic Converters

The market dynamics and economic factors influencing platinum in catalytic converters are complex and multifaceted. The demand for platinum in catalytic converters is driven by the need to reduce emissions and meet stringent environmental regulations. However, the high cost of platinum and fluctuations in global demand can impact prices and affect the overall market. The supply chain and market trends also play a crucial role in determining the platinum content in catalytic converters. Furthermore, the economic benefits and challenges of using platinum in catalytic converters must be carefully considered. As the global demand for platinum in catalytic converters continues to rise, it is essential to understand the impact of this trend on prices and the overall market. In this article, we will explore the global demand for platinum in catalytic converters and its impact on prices, examining the factors that drive demand and the resulting effects on the market.

Global Demand for Platinum in Catalytic Converters and Its Impact on Prices

The global demand for platinum in catalytic converters has been a significant driver of the metal's price in recent years. As governments worldwide implement stricter emissions regulations, the demand for platinum-based catalytic converters has increased, leading to a surge in platinum prices. The automotive industry is the largest consumer of platinum, accounting for over 40% of total demand, with catalytic converters being the primary application. The increasing adoption of hybrid and electric vehicles, however, is expected to impact platinum demand in the long term. Nevertheless, the current demand for platinum in catalytic converters remains robust, driven by the need for cleaner emissions and the lack of viable alternatives. As a result, platinum prices have been volatile, influenced by fluctuations in demand, supply chain disruptions, and geopolitical tensions. The price of platinum has been particularly sensitive to changes in the automotive industry, with prices rising in response to increased demand and falling when demand slows. The impact of global demand for platinum in catalytic converters on prices is expected to continue, with the metal's price likely to remain volatile in the face of changing market dynamics and economic factors.

Supply Chain and Market Trends Affecting Platinum Content in Catalytic Converters

The increasing demand for cleaner vehicles and stricter emissions regulations have led to a surge in the use of platinum in catalytic converters. As a result, the supply chain for platinum has become a critical component in the automotive industry. Market trends indicate that the demand for platinum is expected to continue growing, driven by the increasing adoption of hybrid and electric vehicles, which require more advanced emissions control systems. However, the supply of platinum is limited, and the market is heavily reliant on a few major producers, including South Africa, Russia, and Canada. This concentration of supply creates risks, including price volatility and potential disruptions to the supply chain. Furthermore, the recycling of platinum from spent catalytic converters is becoming increasingly important, as it provides a secondary source of supply and helps to reduce the environmental impact of platinum mining. As the demand for platinum continues to grow, the industry is likely to see increased investment in recycling technologies and closed-loop production systems. Additionally, the development of alternative emissions control technologies, such as palladium-based systems, may also impact the demand for platinum in the future. Overall, the supply chain and market trends affecting platinum in catalytic converters are complex and multifaceted, requiring careful management and planning to ensure a stable and sustainable supply of this critical material.

Economic Benefits and Challenges of Using Platinum in Catalytic Converters

The use of platinum in catalytic converters has significant economic benefits and challenges. On the one hand, platinum-based catalytic converters are highly effective in reducing emissions, which leads to cost savings for governments and industries through reduced environmental damage and healthcare costs. Additionally, the high demand for platinum in catalytic converters drives the global platinum market, creating jobs and stimulating economic growth in platinum-producing countries such as South Africa and Russia. Furthermore, the recycling of platinum from spent catalytic converters provides a valuable source of revenue for the automotive and recycling industries. On the other hand, the high cost of platinum is a significant challenge, making catalytic converters more expensive to produce and maintain. The volatility of platinum prices also poses a risk to the automotive industry, as fluctuations in price can impact production costs and profitability. Moreover, the increasing demand for platinum in emerging markets, such as China and India, is driving up prices and creating supply chain challenges. Overall, the economic benefits and challenges of using platinum in catalytic converters highlight the need for sustainable and cost-effective solutions to meet the growing demand for clean air technologies.