How Long To Dehydrate Beef Jerky

Dehydrating beef jerky is a culinary art that marries patience, technique and precision, delivering a savoury snack rich in taste and texture. Time-proven and enjoyed by generations worldwide, the creation of this delightful delicacy conceals secrets worth exploring. This comprehensive guide will enlighten you on the intriguing process that is dehydrating beef jerky, exploring the importance of time, technique, and a few tricks of the trade. Firstly, we will start by diving into the basics of dehydrating beef jerky, to understand the fundamental principles shaping its unique flavour profile. Afterwards, we'll delve into the pivotal role dehydration time plays in creating the perfect beef jerky texture, imbued with an optimal balance of moisture and crunch. Lastly, we'll reveal some invaluable tips to refine your beef jerky dehydration technique. Not for the faint-hearted, this craft demands patience and resilience. Rest assured, the reward is well worth the wait and effort. So, let's embark on this tantalizing journey, beginning with a comprehensive understanding of the basics of dehydrating beef jerky.

Dehydrating beef jerky is a culinary art that marries patience, technique and precision, delivering a savoury snack rich in taste and texture. Time-proven and enjoyed by generations worldwide, the creation of this delightful delicacy conceals secrets worth exploring. This comprehensive guide will enlighten you on the intriguing process that is dehydrating beef jerky, exploring the importance of time, technique, and a few tricks of the trade. Firstly, we will start by diving into the basics of dehydrating beef jerky, to understand the fundamental principles shaping its unique flavour profile. Afterwards, we'll delve into the pivotal role dehydration time plays in creating the perfect beef jerky texture, imbued with an optimal balance of moisture and crunch. Lastly, we'll reveal some invaluable tips to refine your beef jerky dehydration technique. Not for the faint-hearted, this craft demands patience and resilience. Rest assured, the reward is well worth the wait and effort. So, let's embark on this tantalizing journey, beginning with a comprehensive understanding of the basics of dehydrating beef jerky. Understanding The Basics Of Dehydrating Beef Jerky

Understanding the intriguing process of dehydrating beef jerky involves more than just leaving the meat out to dry. The innovative science behind dehydration, the need for essential equipment, and required preparation and safety protocols are key facets. To start with, we delve into the science propelling meat dehydration, shedding light on this old-age preservation technique, now adopted by jerky lovers worldwide. In this process, we take you through the intricate facets that aid in creating pieces of dried beef full of intense flavors. Next, curated specially for the aspiring chefs and culinary enthusiasts, we provide an enlightening guide about the essential equipment required for beef jerky dehydration. From a method as simple as sun-drying to using dehydrating machines, every tool adds a unique element to the process. Finally, we stress on the importance of maintaining stringent safety measures during this process. While dehydrating, maintaining the right temperature can not only preserve the quality of the beef but also ensure the final product is safe to consume. As we venture further into this enlightening exploration, we will first unravel the alluring science behind the dehydration process of meat, a venture that transforms a humble piece of beef into a tantalizing jerky treat. Delve in and immerse yourself in this gastronomical revelation.

The Science Behind The Dehydration Process Of Meat

Understanding the science behind the dehydration process of meat is crucial in making good quality beef jerky. Dehydration, at its core, is a drying process. The logic behind it is quite simple: dehydrators work by removing the moisture from meat, thus creating a hostile environment for bacteria, yeasts, and molds that could otherwise spoil the beef. This drying method has been used since the prehistoric age, with evidence of sun and wind-dried meats from various cultures. The dehydration process kicks off with heat and air. Beef jerky is typically dehydrated at a temperature between 130-170 degrees Fahrenheit. The heat gradually raises the meat's temperature, warming the water contained within it. However, it's not the heat alone that dehydrates the meat; it's the combination of heat and airflow. This duo speeds up the evaporation process, effectively drying out the jerky. But how exactly is water removed from the meat? As heat is applied, it triggers the water held within the meat to vaporize. This is where the importance of airflow comes in. The air in the dehydrator moves around, carrying away the moist, warm air surrounding the meat. In doing so, it makes room for more water to vaporize from the meat, preventing the process from halting. Here's where things get interesting— during dehydration, the meat's interior and exterior don't lose water at the same rate. The surface dries out faster and forms a semi-dry shell, while the interior remains relatively moist. This happens because water vapor has to navigate through the meat's tissue network to reach the surface. Ensuring your beef is not excessively thick will help achieve an even drying process. It's worth noting that dehydration does not cook the meat, contrary to what some may believe. However, in the case of beef jerky, we use a dehydrator that can reach 160 degrees Fahrenheit or above to kill potential pathogenic bacteria like Salmonella and E.coli. This is what makes beef jerky safe for consumption despite not technically being cooked. Understanding the dehydration process's science can enhance your jerky-making experience, ensuring safety, flavor, and efficiency. By controlling the elements of heat, air, and time, you can not only make dehydrated beef jerky - you can master it.

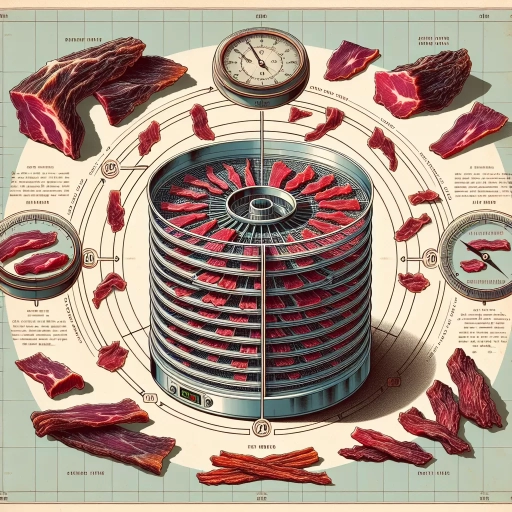

Essential Equipment For Beef Jerky Dehydration

Understanding the art of dehydrating beef jerky not only encompasses the processes, but it also dives deep into identifying the essential equipment needed for successful beef jerky dehydration. Paramount among these is a dehydrator, the technological backbone of the whole drying process. The dehydrator should come with efficient features to ensure the beef's moisture is removed gradually and at the right temperatures to prevent spoilage and maintain food safety. Quality dehydrators include the likes of Excalibur models, which have a thermostat for precise temperature control, adjustable shelves for convenience, and a fan for even air circulation. Next in line is a reliable, sharp knife. These aren't just regular kitchen knives but specifically tailored for meat cutting. Such knives should feature blades durable enough to cut through the meat and fat effortlessly, leaving you with thin strips ideal for dehydration. Additionally, the use of a jerky gun, specifically designed for ground meat, aids in giving the beef jerky its classic thin strip form. Marinating equipment cannot be overlooked in beef jerky dehydration. Here, zip-lock bags or vacuum-seal bags play an integral role in the marination process. The primary function of these bags is to ensure that the beef soaks up all the marination goodness evenly, which contributes substantially to the final taste profile of the jerky. Keeping these bags sealed for a given period enhances flavor absorption into the beef, making each jerky piece a burst of tantalizing taste. A kitchen scale is another critical tool when preparing beef jerky. The scale ensures a balanced meat-to-spice ratio, contributing to ideal taste and flavor retention. Similarly, a cooking thermometer will guarantee that your dehydrator is conducting heat at the right food-safe temperatures, thus eliminating any health concerns related to undercooked food. Lastly, let’s not forget about air-tight containers or vacuum-seal bags for proper storage of your beef jerky. In essence, these containers lock in the flavor and protect the jerky from moisture in the air, which could otherwise compromise freshness and induce spoilage. In conclusion, understanding the equipment essentials for beef jerky dehydration enables one to produce safe, delicious, and high-quality jerky. Each piece of equipment contributes to the major steps in the dehydration process; preparation, marination, dehydration, and storage. Well-dehydrated beef jerky is a gourmet delight and can easily be achieved with the right tools at hand.

Preparation and Safety Measures During Dehydration

In preparing and ensuring safety measures while dehydrating beef jerky, it's crucial to understand each step's significance. This process doesn't just call for the art of preserving food; it also demands a meticulous commitment to hygiene and food safety standards. First and foremost, source the best quality lean meat with minimal fat content. This is an essential tip as fat doesn't dehydrate and can cause the jerky to spoil quickly. Following the search for quality beef, one needs to prepare the meat by slicing it against the grain into thin, flat strips which are easier to dehydrate. Before drying, remove excess moisture by patting the slices dry. It’s imperative to ensure your hands and working area are thoroughly clean during preparation to avoid any foodborne diseases. At this stage, you can marinate the beef strips with your preferred seasoning. While taste should be a priority, it's also worth noting that the marinade plays a crucial role in killing bacteria. When dehydrating beef jerky, temperature is vital for safety and preservation purposes. Most food safety experts recommend heating the jerky to 160 to 165°F. At these temperatures, most bacteria that cause foodborne illnesses are eliminated. Therefore, it's best to use a dehydrator that can maintain consistent high temps. Time is another critical aspect – this process can take anywhere from 4 to 15 hours, depending on your dehydrator and the thickness of the meat. You’ll know the jerky is done when it bends and cracks, but doesn’t break. Finally, always store the dehydrated jerk in a cool, dry place. Monitoring all these aspects during dehydration can seem intimidating but adhering to these safety and preparation measures is vital for not only the taste and quality of your jerky, but also to ensure food safety. Taking these steps into account for dehydration will guarantee that your beef jerky is delicious, safe, and lasts as long as possible.

The Impact Of Dehydration Time On Beef Jerky

As a favored snack for outdoor enthusiasts and busy people in search of healthy, protein-rich food options, beef jerky garners quite an interest due to its taste and nutritional value. However, the process of making this delightful snack is more nuanced than most people realize, and factors such as dehydration time play a pivotal role in shaping the quality and flavor profile of beef jerky. This article unravels the intricate juncture of dehydration time and the resultant consistency of beef jerky, exploring key concepts like - The Relationship of Dehydration Time and Jerky Quality, Figuring Out The Optimal Dehydration Time For Different Beef Types, and Dehydrating Beef Jerky: Common Times and Temperatures. Each of these topics aims to unveil the science behind beef jerky preparation and help you understand how to optimize the dehydration time for different types of beef. To kick off our deep dive, let's first explore how dehydration time impacts the quality of jerky. With a clear understanding of this relationship, you can be well on your way to mastering the art of jerky preparation, thereby ensuring your savory snack is both appetizing and nutritional.

The Relationship Of Dehydration Time and Jerky Quality

Within the process of making beef jerky, dehydration time plays a pivotal role in determining the final quality of the jerky. It's a delicate balance to straddle — over-dehydrate the meat, and the jerky becomes brittle and harsh to chew; under-dehydrate, and you risk it being too soft or worse still, unsafe to consume due to potential bacterial contamination. Given that the quality of the jerky is ultimately reliant on the perfection of its moisture content, the dehydration time cannot be overlooked. Scientifically, dehydrating meat involves the expulsion of water content, which helps retard or cease bacterial growth and increases the shelf life of the jerky substantially. However, shift the balance just slightly, and you risk compromising on those crucial factors that make for good-quality beef jerky - optimum chewability, flavour retention, and longevity. Controlled and appropriate dehydration not only extends the lifecycle of the jerky but also enhances its inherent flavor considerably. The water removal process intensifies the flavors; hence a protracted dehydration time frame would give the jerky a more robust and richer flavor profile. But caution is always necessary because over-dehydration not only makes jerky tough but can also lead to a severe loss of volume and render it distasteful. Therefore, dehydration time is directly tied to the quality of the jerky and is an integral ingredient in your recipe for perfect beef jerky. Under-dehydration may result in a chewier but moist jerky, likely indicating it hasn't reached its full potential in terms of flavor, and is more susceptible to spoilage. Over-dehydration can lead to an overly dry, brittle texture losing its taste and enjoyment factor. Striking that balance is key to creating perfectly dehydrated jerky that marries the richness of flavor with the right texture and optimal safety criteria. In conclusion, adjusting the dehydration time accordingly and ensuring a controlled, steady dehydration process is essential to quality beef jerky; making it not only a culinary delight but also a safe, long-standing treat.

Figuring Out The Optimal Dehydration Time For Different Beef Types

Figuring out the optimal dehydration time for different beef types is both a science and an art. Not all beef cuts are the same; each type requires keen attention to detail to achieve the right consistency, flavour, and longevity in your beef jerky. One of the factors that heavily influence the dehydration process is the fat content in the meat. For instance, lean beef like sirloin tip or rump roast is generally quicker to dehydrate owing to its low fat content. Average dehydration time for these types ranges between 4 to 6 hours. Meanwhile, fattier cuts like beef brisket might take a longer time, around 8 to 10 hours due to the fat's high moisture content. Moreover, the thickness of your slicing plays an influential role here. Thinner slices dehydrate faster, while thicker ones need more time. From a culinary angle, adjusting dehydration time also affects the end product's texture. Shorter dehydration times result in a more chewy jerky, while longer periods offer a crisper finish. The balance lies in ensuring the meat dehydrates enough to inhibit bacterial growth while not reaching a state of over-dehydrated beef which can be akin to chewing on a leather belt. It's all about discovering a sweet spot to keep the jerky palatable. Remember, factors like local climate conditions and the type of dehydrator play a key role as well; the same beef cut might dehydrate in different periods under contrasting environmental conditions or devices. The entire process is a confluence of knowledge, precision, and experimentation. Optimal dehydration is crucial to maximise the beef jerky's lifespan and maintain the nuanced flavours that contribute to its savouriness. Understanding the impact of dehydration time on various beef types thus lays a sound foundation for crafting superior quality beef jerky. In essence, figuring out the optimal dehydration time for different beef types is about honouring the meat's natural characteristics while ensuring its preservation. As a craftsperson, it's about calibrating and recalibrating until perfection - or the closest one can get to it - is achieved.

Dehydrating Beef Jerky: Common Times and Temperatures

When dehydrating beef jerky, it is critical to pay close attention to the times and temperatures to achieve the desired results. The optimal temperature setting for most food dehydrators is between 130 to 160 degrees Fahrenheit. This temperature range is perfect for both safety and preservation. Your dehydrator's temperature needs to be high enough to fend off bacteria and pathogens, but not so high that it "cooks" the meat instead of dehydrating it. It's a fine balance that requires careful monitoring. Typically, dehydrating beef jerky takes about 4 to 6 hours but can take up to 15 hours depending on various factors. These factors include the thickness of the slices, meat's moisture content, dehydrator type, and relative humidity. Thinly sliced meat with a low moisture content in a modern dehydrator in a dry climate will dehydrate much faster than thick slices with high moisture in an older model dehydrator in a humid environment. Monitoring the dehydration process can impact the quality of the beef jerky significantly. Certain signs indicate when your jerky has dehydrated properly. It should be firm and dry, but still pliable, with no traces of moisture or pools of liquid fat. Carefully remove a piece from the dehydrator (be sure to let it cool first) and bend it. If it bends and cracks without breaking, it's perfect. If it's too brittle and cracks easily, it's been over-dried, but still edible. In summary, there's a direct correlation between dehydration time and the resulting quality of beef jerky. The temperature setting on your dehydrator plays a significant role in determining that time. Testing and tracking your results, adjusting as necessary, will lead to perfect beef jerky over time. It might involve a few trials and errors, but the end product will be worth the effort and patience.

Tips For Perfecting Your Beef Jerky Dehydration Technique

Perfecting the craft of beef jerky dehydration isn't just a process, it's an art. This article is oriented to help you do just that, providing expert guidance and practical tips that will guarantee to take your jerky preparation skills to new heights. From the crucial stage of marinating the beef - an important process that enhances and imprints flavour into the meat, to maintaining the right temperature during dehydration for supreme texture and to avoid unwanted spoiling. We'll even guide you on how to be sure that your jerky has achieved the optimal level of dehydration - a critical point that can make or break your jerky making experience. Let's step into this high-protein adventure starting with the first step that has a profound impact on your jerky's final taste - marinating the beef for enhanced flavor during dehydration.

Marinating Beef For Enhanced Flavor During Dehydration

In perfecting your beef jerky dehydration technique, one critical step that significantly enhances the flavor is marinating your beef before the dehydration process. Marination is far more than a mere pre-dehydration step; it's an exquisite art that strikes a balance between several flavours to give your jerky that distinct, memorable taste. Think about the beef marination process as a passage of flavor transformation, where raw beef is artistically infused with a rich blend of chosen spices, herbs, and sauces. Marination is not just about soaking meat in sauces; it is about understanding the natural flavors of the beef and choosing a marinade that complements these flavors, thereby making them stand out. This elaborate interplay of tastes is what gives beef jerky its unique, addictive taste. The type of ingredients in your marinade is not the only crucial factor; so is the marination timing. If you’re aiming for a rich and immersive flavor, it would be best to marinate your beef in the refrigerator for about 12 to 24 hours. This duration allows the marinade to deeply penetrate the beef, hence, intensifying the flavor. The role of acids, such as vinegar or lemon juice, in your marinade is also noteworthy as these ingredients help to break down protein in the beef, allowing for deeper and faster absorption of the marinade flavors. Remember that the marination process is directly linked to the dehydration process. The marinade also adds moisture to the beef, hence, the longer you marinate, the longer the dehydration process may take. Your timing should strike a balance between marination and dehydration timings to ensure you achieve that perfect chewable, flavorful beef jerky. Achieving a prime flavor in your beef jerky through marination is a trial and error process, encouraging you to invent and reinvent marinade concoctions till you hit that home run. So, don't hold back and let your imagination run free as you marinate your beef. As your creative juices flow, so too will the flavors in your jerky!

Maintaining The Right Temperature For Uniform Dehydration

Maintaining the Ideal Temperature for Uniform Dehydration In the journey of perfecting your beef jerky dehydration technique, maintaining the right temperature is of paramount importance. When it comes to dehydration, a uniform, steady temperature is key. Preserving the nutritional integrity and enhancing the natural flavor of the meat requires the mastery of heat regulation. Most professional dehydrators recommend a temperature of around 160°F (71°C) for meat dehydration. This temperature is considered optimal because it eradicates bacteria such as Salmonella and E.coli, which are often present in raw meat. Also, it is sufficient to extract the moisture without cooking or denaturing the meat. At this heat level, the meat undergoes a thorough drying process that helps to preserve it without losing its mouth-watering, jerky charm. However, maintaining this set temperature is not always as straightforward as it may seem. Slight fluctuations can lead to uneven dehydration, causing parts of the jerky to be overly dry, while others may still contain moisture—a breeding ground for bacteria. Uniform dehydration ensures a consistent texture and taste throughout the entire batch of beef jerky, which is what every jerky enthusiast strives for. One solution to overcome this problem is to intermittently shuffle the beef strips within the dehydrator. This strategy works exceptionally well for those using circular dehydrators as they tend to have a less controlled heat flow compared to box-shaped versions. Adapting digital temperature control can also help to maintain a consistent dehydration environment, allowing precision throughout the process. Some higher-end dehydrator models allow you to set the exact temperature, preventing chances of overheating or underheating, which can sabotage your jerky. There are plenty of elements involved in making the perfect beef jerky, and while it may seem a bit overwhelming initially, mastering the delicate art of temperature management is a massive leap towards achieving the perfect batch. This fine degree of control that you gain over the drying process will directly reflect in the quality of your final product—juicy, flavorsome beef jerky—with every bite resonating with the love and effort invested in nailing that impeccable dehydration technique. From this point forward, turn on your dehydrator with confidence, understanding that you're perpetuating a time-honored preservation technique while creating a nutritional, high-protein snack—that too, right at home. Embrace the process and savor the experience, for this is where the magic happens—culminating in gourmet-quality, homemade beef jerky.

How To Know If Your Beef Jerky Is Properly Dehydrated

After preparing your beef jerky in the marinade of your choice and setting it in your dehydrator, it's essential to determine when it's sufficiently dehydrated to ensure both optimal taste and food safety. The foremost indicator when ascertaining if your beef jerky has been correctly dehydrated is its texture. Dehydrated beef jerky should be tough but still pliable. If it's too flexible or spongy, that's a sign that it needs more time in the dehydrator. Contrastingly, if it's too brittle or crisp, it's likely you've over-dehydrated it, sacrificing its chewy quality. Another effective measure is checking the color. Appropriately dehydrated beef jerky is typically dark brown or black. A reddish or grey hue could imply that it's either under-dehydrated or possibly spoiled. In that case, additional time in the dehydrator may be necessary or, worse, you may have to discard the batch. Rehydrate a sample piece in warm water to give its interior a thorough check. Properly dried beef jerky will not retain any moisture inside and will be the same color all through. If you discover any pockets of moisture or patches of different color, it might mean that there are wet spots where bacteria could thrive. The ultimate tip is not to rush your dehydration process. Rushing could lead to an exterior 'crust,' making the jerky feels dry on the outside while retaining moisture within, potentially leading to spoilage later on. Remember, the goal is to systematically remove moisture all throughout the meat at a steady pace. This will not only preserve your jerky but also enhance its flavor profile, resulting in a tasty, long-lasting snack. Assessing your beef jerky's dehydration level rightly is an art that develops with experience. With these guiding tips, you're one step ahead to crafting perfectly dehydration beef jerky that is not just safe to eat but also packs a powerful flavor punch.