How To Find Coefficient Of Friction

The coefficient of friction is a crucial concept in physics and engineering, playing a significant role in understanding the interaction between two surfaces in contact. It is a measure of the force that opposes motion between two surfaces, and its value can greatly impact the design and functionality of various systems and mechanisms. In this article, we will delve into the world of coefficient of friction, exploring its underlying concept, methods for measurement, and its applications and considerations. To begin, it is essential to grasp the fundamental concept of coefficient of friction, which will be discussed in the next section. By understanding the basics of coefficient of friction, we can then move on to explore the various methods for measuring it, and ultimately, examine its applications and considerations in real-world scenarios. Understanding the concept of coefficient of friction is the first step in unlocking its secrets, and it is to this topic that we now turn.

Understanding the Concept of Coefficient of Friction

The concept of coefficient of friction is a fundamental aspect of physics that plays a crucial role in understanding the behavior of objects in contact with each other. In this article, we will delve into the world of friction and explore its various facets. We will start by defining the coefficient of friction and its importance in real-world applications. Additionally, we will discuss the different types of coefficient of friction, including static and kinetic friction, and examine the factors that affect the coefficient of friction. By understanding these concepts, we can gain a deeper appreciation for the complex interactions between objects and the role that friction plays in shaping our daily experiences. With this foundation, let's begin by defining the coefficient of friction and its significance.

Defining Coefficient of Friction and Its Importance

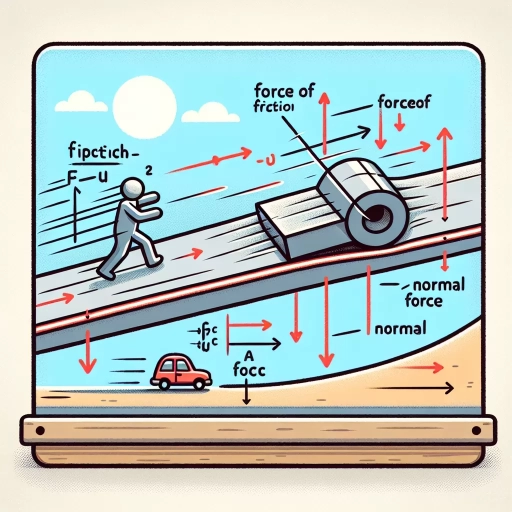

The coefficient of friction is a dimensionless quantity that describes the ratio of the force of friction between two surfaces to the normal force pressing the surfaces together. It is a measure of the amount of friction that occurs when two surfaces are in contact with each other. The coefficient of friction is usually denoted by the symbol μ (mu) and is a fundamental concept in physics and engineering. The coefficient of friction is important because it helps to predict the amount of friction that will occur in a given situation, which is crucial in designing and optimizing systems such as brakes, gears, and bearings. A higher coefficient of friction indicates a greater amount of friction, while a lower coefficient of friction indicates a lesser amount of friction. The coefficient of friction can be affected by various factors such as the surface roughness, temperature, and the presence of lubricants. Understanding the coefficient of friction is essential in various fields such as mechanical engineering, aerospace engineering, and materials science, where it plays a critical role in designing and optimizing systems to minimize friction and maximize efficiency.

Types of Coefficient of Friction: Static and Kinetic

The coefficient of friction is a crucial concept in physics that determines the amount of frictional force that opposes motion between two surfaces in contact. There are two primary types of coefficients of friction: static and kinetic. The static coefficient of friction, denoted by μs, is a measure of the force required to initiate motion between two stationary surfaces. It is the ratio of the maximum static frictional force to the normal force acting on the surfaces. The static coefficient of friction is typically higher than the kinetic coefficient of friction, as it takes more force to overcome the initial resistance and start moving an object. On the other hand, the kinetic coefficient of friction, denoted by μk, is a measure of the force required to maintain motion between two surfaces that are already moving. It is the ratio of the kinetic frictional force to the normal force acting on the surfaces. The kinetic coefficient of friction is usually lower than the static coefficient of friction, as less force is required to keep an object moving once it has started. Understanding the difference between static and kinetic coefficients of friction is essential in various fields, such as engineering, physics, and materials science, as it helps in designing and optimizing systems that involve frictional forces.

Factors Affecting Coefficient of Friction

The coefficient of friction is influenced by several factors, including the nature of the surfaces in contact, the normal force applied, the velocity of the moving object, and the temperature and humidity of the environment. The surface roughness and texture play a significant role in determining the coefficient of friction, as rougher surfaces tend to have a higher coefficient of friction due to the increased contact area and the resulting frictional forces. The normal force, or the force perpendicular to the surface, also affects the coefficient of friction, as an increase in normal force typically leads to an increase in the frictional force. Additionally, the velocity of the moving object can impact the coefficient of friction, with higher velocities often resulting in a decrease in the coefficient of friction due to the reduced contact time between the surfaces. Furthermore, environmental factors such as temperature and humidity can also influence the coefficient of friction, as changes in these conditions can alter the surface properties and the resulting frictional forces. For instance, a decrease in temperature can lead to an increase in the coefficient of friction, while an increase in humidity can result in a decrease in the coefficient of friction. Understanding these factors is crucial in accurately determining the coefficient of friction and predicting the behavior of objects in various scenarios.

Methods for Measuring Coefficient of Friction

The coefficient of friction is a crucial parameter in various fields, including engineering, physics, and materials science. It is essential to measure the coefficient of friction accurately to understand the behavior of materials and surfaces. There are several methods for measuring the coefficient of friction, each with its own advantages and limitations. Experimental methods, such as the inclined plane and horizontal pull, are widely used to measure the coefficient of friction. Additionally, mathematical formulas can be used to calculate the coefficient of friction, providing a more theoretical approach. Furthermore, tribometers are specialized instruments that can provide accurate measurements of the coefficient of friction. In this article, we will explore these methods in more detail, starting with experimental methods, specifically the inclined plane and horizontal pull.

Experimental Methods: Inclined Plane and Horizontal Pull

The experimental methods for measuring the coefficient of friction involve various techniques to determine the frictional force between two surfaces. Two common methods are the inclined plane and horizontal pull. The inclined plane method involves placing an object on a flat surface that is gradually tilted until the object starts to slide. The angle at which the object begins to slide is measured, and the coefficient of friction can be calculated using the tangent of this angle. This method is simple and effective, but it can be affected by the surface roughness and the weight of the object. The horizontal pull method, on the other hand, involves applying a horizontal force to an object until it starts to move. The force required to initiate motion is measured, and the coefficient of friction can be calculated by dividing this force by the normal force (the weight of the object). This method is more accurate than the inclined plane method, but it requires more sophisticated equipment. Both methods have their advantages and limitations, and the choice of method depends on the specific application and the desired level of accuracy.

Calculating Coefficient of Friction Using Mathematical Formulas

Calculating the coefficient of friction using mathematical formulas is a precise method that involves understanding the forces at play when two surfaces are in contact. The coefficient of friction (μ) is a dimensionless quantity that describes the ratio of the force of friction (F) to the normal force (N) between two surfaces. The formula to calculate the coefficient of friction is μ = F/N. To calculate the force of friction, we can use the formula F = μN, where μ is the coefficient of friction and N is the normal force. However, since we are trying to find μ, we need to rearrange the formula to solve for μ. This can be done by using the formula μ = F/N, where F is the force of friction and N is the normal force. Another formula that can be used to calculate the coefficient of friction is the angle of repose method, which states that μ = tan(θ), where θ is the angle of repose. The angle of repose is the angle at which an object will begin to slide down an inclined plane. By measuring the angle of repose, we can calculate the coefficient of friction using the formula μ = tan(θ). Additionally, the coefficient of friction can also be calculated using the formula μ = (2F)/(m \* g), where F is the force of friction, m is the mass of the object, and g is the acceleration due to gravity. This formula is commonly used in problems involving inclined planes and friction. Overall, calculating the coefficient of friction using mathematical formulas requires a good understanding of the forces involved and the ability to apply the correct formulas to solve for μ.

Using Tribometers for Accurate Measurements

Tribometers are specialized instruments designed to measure the coefficient of friction between two surfaces in contact. These devices are crucial in various industries, including manufacturing, automotive, and aerospace, where understanding frictional forces is essential for optimizing performance, safety, and efficiency. A tribometer typically consists of a stationary surface and a moving surface, with sensors to detect the frictional forces generated during the interaction. By carefully controlling the experimental conditions, such as the normal force, sliding speed, and surface roughness, tribometers can provide accurate and reliable measurements of the coefficient of friction. The data obtained from tribometers can be used to evaluate the performance of different materials, coatings, and lubricants, allowing researchers and engineers to make informed decisions about product design and development. Furthermore, tribometers can also be used to investigate the effects of environmental factors, such as temperature and humidity, on frictional behavior, providing valuable insights into the complex interactions between surfaces. Overall, tribometers are powerful tools for measuring the coefficient of friction, enabling the development of innovative solutions and improving the performance of various products and systems.

Applications and Considerations of Coefficient of Friction

The coefficient of friction is a crucial concept in physics and engineering, playing a vital role in various applications across different industries. It is essential to understand the coefficient of friction to design safe and efficient systems, optimize performance in sports and transportation, and minimize wear and tear in mechanical systems. In the context of designing safe and efficient systems, the coefficient of friction is particularly important in the development of brakes and gears. By understanding the coefficient of friction, engineers can design brakes that provide optimal stopping power while minimizing wear on the brake pads and rotors. Similarly, the coefficient of friction is critical in the design of gears, as it affects the efficiency and reliability of gearboxes. In this article, we will explore the applications and considerations of the coefficient of friction, starting with its role in designing safe and efficient systems, particularly in the context of brakes and gears.

Designing Safe and Efficient Systems: Brakes and Gears

Designing safe and efficient systems requires careful consideration of various components, including brakes and gears. When it comes to brakes, the coefficient of friction plays a crucial role in determining the stopping distance and overall safety of a vehicle. A higher coefficient of friction between the brake pads and the rotor or drum can lead to shorter stopping distances, but it can also increase the risk of wheel lockup and skidding. On the other hand, a lower coefficient of friction can result in longer stopping distances, but it can also provide more stable and controlled braking. To achieve a balance between safety and efficiency, engineers often use a combination of materials and designs, such as semi-metallic brake pads and ventilated rotors, to optimize the coefficient of friction. In addition to brakes, gears also rely on the coefficient of friction to function efficiently. The coefficient of friction between gear teeth and the surrounding material can affect the gear's ability to transmit power and withstand wear and tear. A higher coefficient of friction can lead to increased frictional losses and heat generation, while a lower coefficient of friction can result in reduced efficiency and increased risk of gear failure. To mitigate these issues, engineers often use specialized coatings and surface treatments to optimize the coefficient of friction and improve gear performance. By carefully designing and optimizing the coefficient of friction in brakes and gears, engineers can create safer and more efficient systems that meet the demands of various applications, from automotive and aerospace to industrial and consumer products.

Optimizing Performance in Sports and Transportation

The coefficient of friction plays a crucial role in optimizing performance in various fields, including sports and transportation. In sports, the right amount of friction can significantly impact an athlete's performance. For instance, in golf, the coefficient of friction between the club head and the ball affects the ball's trajectory and distance. A higher coefficient of friction can result in a more consistent and accurate shot. Similarly, in tennis, the friction between the racket and the ball influences the ball's speed and spin. In transportation, the coefficient of friction is critical for safety and efficiency. The friction between tires and the road surface affects a vehicle's acceleration, braking, and cornering capabilities. A higher coefficient of friction can improve traction, reducing the risk of skidding and accidents. However, excessive friction can lead to increased wear and tear on tires, reducing their lifespan. In the aerospace industry, the coefficient of friction is crucial for aircraft performance, particularly during takeoff and landing. The friction between the tires and the runway affects the aircraft's acceleration and braking capabilities, making it essential to optimize the coefficient of friction for safe and efficient operations. In the automotive industry, the coefficient of friction is also critical for the development of advanced safety features, such as anti-lock braking systems (ABS) and electronic stability control (ESC). By understanding and optimizing the coefficient of friction, manufacturers can improve vehicle safety and performance, reducing the risk of accidents and injuries. Overall, the coefficient of friction is a critical factor in optimizing performance in sports and transportation, and its importance cannot be overstated.

Minimizing Wear and Tear in Mechanical Systems

Minimizing wear and tear in mechanical systems is crucial to ensure optimal performance, reduce maintenance costs, and prolong the lifespan of components. One effective way to achieve this is by controlling the coefficient of friction, which is a measure of the force that opposes motion between two surfaces in contact. By reducing the coefficient of friction, mechanical systems can experience less wear and tear, resulting in smoother operation, reduced heat generation, and increased efficiency. This can be achieved through various means, such as applying lubricants, using surface coatings, or designing components with optimized geometries. For instance, in the automotive industry, lubricants are used to reduce friction between moving parts, such as engine components and gears, thereby minimizing wear and tear and improving fuel efficiency. Similarly, in the aerospace industry, surface coatings are applied to reduce friction and wear on moving parts, such as aircraft landing gear and engine components. By minimizing wear and tear, mechanical systems can operate more reliably, reduce downtime, and lower maintenance costs, ultimately leading to increased productivity and cost savings. Furthermore, reducing wear and tear can also help to minimize the environmental impact of mechanical systems, as it can lead to reduced energy consumption and lower emissions. Overall, controlling the coefficient of friction is a critical aspect of minimizing wear and tear in mechanical systems, and its importance cannot be overstated.