How Long Does Thermal Paste Last

Thermal paste, also known as thermal interface material (TIM), plays a crucial role in maintaining the optimal performance of electronic devices, particularly computers and laptops. It fills the microscopic gaps between the CPU or GPU and the heat sink, ensuring efficient heat transfer and preventing overheating. However, thermal paste is not a permanent solution and has a limited lifespan. The longevity of thermal paste depends on various factors, including its quality, usage, and environmental conditions. As thermal paste degrades over time, it can lead to reduced performance, increased temperatures, and potentially damage the device. It is essential to recognize the signs of thermal paste degradation and replace it when necessary to maintain optimal performance. Factors such as temperature, humidity, and usage patterns can significantly impact the lifespan of thermal paste, which will be discussed in the next section, Factors Affecting the Lifespan of Thermal Paste.

Factors Affecting the Lifespan of Thermal Paste

The lifespan of thermal paste, a crucial component in maintaining the optimal temperature of electronic devices, is influenced by several key factors. Understanding these factors is essential for ensuring the longevity and performance of devices. Three primary factors that affect the lifespan of thermal paste are temperature fluctuations, the quality of the thermal paste itself, and how it is used and handled. Temperature fluctuations can cause the paste to degrade faster, leading to reduced effectiveness in heat transfer. The quality of the thermal paste, including its composition and manufacturing process, plays a significant role in its durability and performance. Lastly, the way thermal paste is applied, stored, and maintained can also impact its lifespan. Among these factors, temperature fluctuations are particularly noteworthy, as they can significantly impact the paste's ability to maintain a stable thermal interface. Therefore, understanding the impact of temperature fluctuations on thermal paste lifespan is crucial for device reliability and performance.

Temperature Fluctuations

Temperature fluctuations can significantly impact the lifespan of thermal paste. When temperatures rise or fall, the thermal paste expands and contracts, which can cause it to break down and lose its effectiveness. This is because most thermal pastes are made from a mixture of materials with different coefficients of thermal expansion, which can lead to a loss of adhesion and a decrease in thermal conductivity. Furthermore, repeated temperature fluctuations can cause the thermal paste to degrade over time, leading to a decrease in its ability to transfer heat efficiently. In extreme cases, temperature fluctuations can even cause the thermal paste to dry out or become brittle, which can lead to a complete loss of thermal conductivity. As a result, it is essential to minimize temperature fluctuations in order to maximize the lifespan of thermal paste. This can be achieved by using a high-quality thermal paste that is designed to withstand temperature fluctuations, as well as by ensuring that the system is properly cooled and maintained. By taking these steps, users can help to extend the lifespan of their thermal paste and ensure optimal system performance.

Quality of the Thermal Paste

The quality of the thermal paste plays a significant role in determining its lifespan. High-quality thermal pastes are made from materials that have excellent thermal conductivity, such as silver, copper, or carbon-based compounds. These materials are able to efficiently transfer heat from the CPU or GPU to the heat sink, reducing the risk of overheating and prolonging the lifespan of the thermal paste. Additionally, high-quality thermal pastes are often formulated with additives that help to prevent drying out, cracking, or degradation over time. These additives can include moisture-absorbing agents, anti-oxidants, and other stabilizers that help to maintain the thermal paste's performance and extend its lifespan. In contrast, low-quality thermal pastes may be made from inferior materials that have lower thermal conductivity, leading to reduced performance and a shorter lifespan. Furthermore, low-quality thermal pastes may not contain the necessary additives to prevent degradation, resulting in a shorter lifespan and potentially causing damage to the CPU or GPU. Therefore, it is essential to choose a high-quality thermal paste to ensure optimal performance and a longer lifespan.

Usage and Handling

The usage and handling of thermal paste play a significant role in determining its lifespan. Proper application and handling techniques can significantly extend the lifespan of the thermal paste, while improper handling can lead to premature degradation. When applying thermal paste, it is essential to use the correct amount, as excessive paste can lead to a decrease in thermal conductivity. Additionally, the paste should be applied in a thin, even layer, ensuring that it covers the entire surface of the CPU or GPU die. It is also crucial to avoid touching the thermal paste, as the oils from human skin can contaminate the paste and reduce its effectiveness. Furthermore, thermal paste should be stored in a cool, dry place, away from direct sunlight and moisture, to prevent degradation. When handling thermal paste, it is recommended to use a credit card or similar tool to spread the paste, rather than fingers, to minimize the risk of contamination. By following proper usage and handling techniques, users can help extend the lifespan of their thermal paste and ensure optimal thermal performance.

Signs of Thermal Paste Degradation

Thermal paste is a crucial component in maintaining the optimal performance and longevity of electronic devices, particularly those that generate excessive heat such as computers and laptops. Over time, thermal paste can degrade, leading to a decrease in its effectiveness and potentially causing damage to the device. There are several signs that indicate thermal paste degradation, including increased CPU temperatures, visible drying or cracking, and reduced cooling efficiency. As the thermal paste breaks down, it can no longer effectively transfer heat away from the CPU, leading to increased temperatures. This can cause the CPU to throttle its performance, reducing the device's overall speed and efficiency. In extreme cases, overheating can cause permanent damage to the CPU, making it essential to monitor CPU temperatures and address any issues promptly. Therefore, it is essential to be aware of the signs of thermal paste degradation, starting with the most critical indicator: increased CPU temperatures.

Increased CPU Temperatures

Increased CPU temperatures can be a significant concern for computer users, as they can lead to reduced system performance, increased power consumption, and even damage to the CPU. When thermal paste degrades, it can no longer effectively transfer heat from the CPU to the heat sink, causing temperatures to rise. This can be particularly problematic for users who engage in resource-intensive activities such as gaming, video editing, or software development. As CPU temperatures increase, the system may slow down or throttle to prevent overheating, resulting in decreased productivity and performance. Furthermore, prolonged exposure to high temperatures can reduce the lifespan of the CPU and other system components, making it essential to monitor and address increased CPU temperatures promptly. In some cases, increased CPU temperatures can also be a sign of other underlying issues, such as dust buildup, poor airflow, or malfunctioning cooling systems, making it crucial to investigate and resolve the root cause of the problem. By recognizing the signs of thermal paste degradation, including increased CPU temperatures, users can take proactive steps to maintain their system's performance, reliability, and longevity.

Visible Drying or Cracking

Visible drying or cracking of the thermal paste is a clear indication of its degradation. Over time, the paste can lose its moisture and dry out, leading to a cracked or brittle appearance. This can be caused by exposure to high temperatures, air, or other environmental factors. As the paste dries out, it can lose its ability to effectively transfer heat, leading to increased temperatures and reduced system performance. In some cases, the drying or cracking of the thermal paste can be visible to the naked eye, while in other cases, it may require a closer inspection. If you notice any visible signs of drying or cracking, it's essential to replace the thermal paste as soon as possible to prevent any further damage to your system. Regular inspections and maintenance can help identify any issues before they become major problems, ensuring your system runs smoothly and efficiently.

Reduced Cooling Efficiency

Reduced cooling efficiency is a common sign of thermal paste degradation. As the thermal paste breaks down over time, it loses its ability to effectively transfer heat from the CPU or GPU to the heat sink. This can lead to increased temperatures, reduced system performance, and potentially even damage to the components. When the thermal paste is no longer able to fill the microscopic gaps between the CPU or GPU and the heat sink, heat is not dissipated efficiently, causing the system to run hotter. As a result, the system's cooling system may need to work harder to maintain a safe temperature, leading to increased fan noise, power consumption, and wear on the cooling components. In extreme cases, reduced cooling efficiency can cause the system to throttle or shut down to prevent overheating, resulting in lost productivity and potential data loss. Regular monitoring of system temperatures and performance can help identify reduced cooling efficiency as a sign of thermal paste degradation, allowing for prompt replacement and maintenance to prevent more severe consequences.

Replacing Thermal Paste for Optimal Performance

Replacing thermal paste is a crucial step in maintaining optimal performance in electronic devices, particularly in high-performance computing and gaming systems. Over time, thermal paste can degrade, leading to reduced heat transfer efficiency and increased temperatures. To ensure optimal performance, it is essential to replace thermal paste at regular intervals, choose the right replacement paste, and apply it correctly. In this article, we will explore the recommended replacement intervals, discuss the factors to consider when choosing the right replacement paste, and provide guidance on proper application techniques. By following these guidelines, you can ensure that your device runs at its best, with improved heat transfer efficiency and reduced risk of overheating. So, when should you replace your thermal paste? Let's start by discussing the recommended replacement intervals.

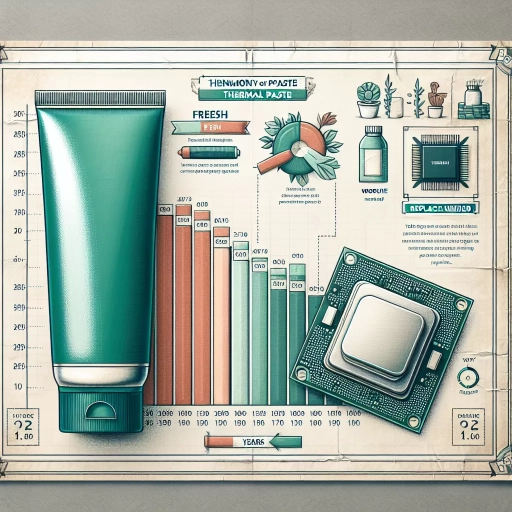

Recommended Replacement Intervals

The recommended replacement intervals for thermal paste vary depending on the type of paste, usage, and environmental conditions. Generally, most manufacturers recommend replacing thermal paste every 2-5 years, with some high-performance pastes lasting up to 7 years. However, if you notice a significant decrease in performance, overheating, or thermal throttling, it's best to replace the paste sooner. For heavy users, such as gamers, overclockers, or those running demanding applications, it's recommended to replace the paste every 1-2 years to maintain optimal performance. Additionally, if you live in a hot and humid climate, you may need to replace the paste more frequently, every 6-12 months, to prevent degradation. It's also important to note that some thermal pastes, such as those containing silver or copper, may degrade faster than others, requiring more frequent replacement. Ultimately, the best way to determine the replacement interval is to monitor your system's performance and temperature, and replace the paste when you notice a decline in performance or an increase in temperature.

Choosing the Right Replacement Paste

When choosing the right replacement paste, there are several factors to consider. First, consider the type of thermal paste you need. There are two main types: ceramic-based and metal-based. Ceramic-based pastes are suitable for most applications and are generally less expensive. Metal-based pastes, on the other hand, offer better thermal conductivity but are more expensive and may require special handling. Next, consider the thermal conductivity of the paste, which is measured in Watts per meter-Kelvin (W/mK). A higher thermal conductivity indicates better heat transfer. Look for a paste with a thermal conductivity of at least 3.5 W/mK. Additionally, consider the viscosity of the paste, which affects how easily it can be applied and spread. A paste with a lower viscosity is easier to apply but may not provide as good of a seal. Finally, consider the durability and lifespan of the paste. Look for a paste that is designed to last for a long time and can withstand high temperatures. Some popular brands of thermal paste include Arctic Silver, Noctua, and Thermal Grizzly. It's also important to read reviews and do research to find the best paste for your specific needs.

Proper Application Techniques

When it comes to replacing thermal paste, proper application techniques are crucial to ensure optimal performance and longevity. The first step is to clean the CPU die (the top surface of the processor) and the heat sink base thoroughly with a soft brush and a mild cleaning solution to remove any debris, dust, or old thermal paste. Next, apply a small pea-sized amount of thermal paste to the center of the CPU die, taking care not to touch the surrounding areas to prevent contamination. Using a credit card or a similar tool, gently spread the paste evenly across the CPU die, applying moderate pressure to ensure good contact. It's essential to avoid applying too much pressure, which can damage the CPU or push the paste out of the contact area. Once the paste is evenly spread, place the heat sink on top, ensuring it's centered and securely fastened. Finally, connect the fan and power cables, and boot up the system to test the thermal performance. By following these proper application techniques, you can ensure a strong bond between the CPU and heat sink, optimal heat transfer, and a significant reduction in temperatures, ultimately extending the lifespan of your thermal paste.