How Does A Plasma Cutter Work

Plasma cutters are versatile tools used in various industries, including metal fabrication, automotive, and construction. They offer a precise and efficient way to cut through metal, making them an essential piece of equipment for many professionals. But have you ever wondered how a plasma cutter works? The principle of operation, key components, and working process of a plasma cutter are crucial to understanding its functionality. In this article, we will delve into the inner workings of a plasma cutter, starting with the principle of operation, which is the foundation of its cutting ability. By understanding how a plasma cutter works, you will be able to appreciate its capabilities and limitations, and use it more effectively in your work. So, let's begin by exploring the principle of operation of a plasma cutter.

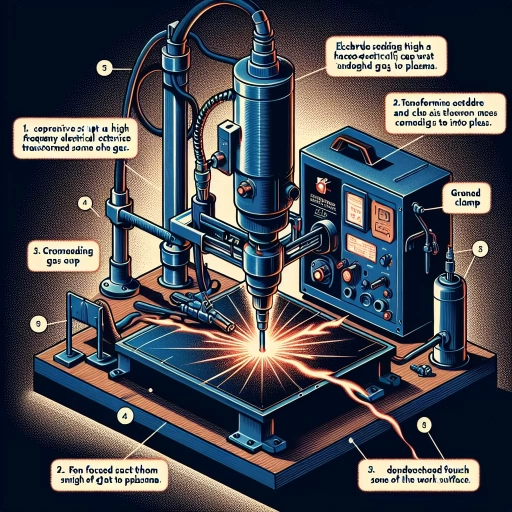

Principle of Operation

The principle of operation of a plasma cutting system is based on the creation of a high-temperature plasma arc that is used to cut through conductive materials. This process involves several key stages, including the ionization process, plasma arc formation, and heat transfer mechanism. The ionization process is the initial stage, where a high-voltage electrical discharge is used to create a conductive pathway of ionized gas. This pathway is then used to create a plasma arc, which is sustained by the continuous flow of electrical energy. The plasma arc is then used to cut through the material, with the heat transfer mechanism playing a crucial role in the cutting process. In this article, we will explore each of these stages in more detail, starting with the ionization process.

Ionization Process

The ionization process is a crucial step in the operation of a plasma cutter, as it enables the creation of a conductive plasma arc that can cut through metal. During this process, the gas, typically air or an inert gas such as argon or nitrogen, is ionized, meaning that its atoms or molecules are stripped of their electrons, resulting in the formation of ions and free electrons. This ionization occurs when the gas is heated to extremely high temperatures, typically in the range of 10,000 to 20,000 Kelvin, which is hotter than the surface of the sun. As the gas is ionized, it becomes electrically conductive, allowing it to carry an electrical current. The ionized gas, now a plasma, is then accelerated through the nozzle of the plasma cutter, where it is focused into a narrow, high-velocity jet that can cut through metal with incredible precision and speed. The ionization process is sustained by the electrical energy supplied to the plasma cutter, which maintains the high temperatures and ionization levels necessary to support the plasma arc. Overall, the ionization process is a critical component of the plasma cutting process, enabling the creation of a high-energy plasma arc that can efficiently cut through metal.

Plasma Arc Formation

Plasma arc formation is a complex process that involves the ionization of a gas, typically air or an inert gas, to create a conductive plasma arc. The process begins with the creation of a high-frequency spark, typically in the range of 10-100 kHz, which is generated by the plasma cutter's power supply. This spark is directed at the workpiece, where it creates a small, localized arc. The arc is then sustained and intensified by the flow of gas, which is typically compressed air or an inert gas such as argon or helium. As the gas flows through the arc, it is heated and ionized, creating a plasma of highly energetic particles. The plasma is then accelerated by the electromagnetic field created by the power supply, which causes it to expand and form a stable arc. The arc is then maintained by the continuous flow of gas and the electromagnetic field, allowing the plasma cutter to cut through the workpiece with high precision and accuracy. The plasma arc formation process is a critical component of the plasma cutting process, as it allows the cutter to generate the high temperatures and energy densities needed to cut through a wide range of materials.

Heat Transfer Mechanism

The heat transfer mechanism in a plasma cutter is a complex process that involves the transfer of thermal energy from the plasma arc to the workpiece. The plasma arc, which is a high-temperature, high-energy gas, is generated by the electrical discharge between the electrode and the nozzle. As the plasma arc comes into contact with the workpiece, it transfers its thermal energy to the metal through a process called conduction. The heat is then distributed throughout the workpiece through convection and radiation, causing the metal to melt and vaporize. The molten metal is then blown away by the high-velocity gas flow, creating a clean cut. The heat transfer mechanism is influenced by several factors, including the temperature of the plasma arc, the velocity of the gas flow, and the thermal conductivity of the workpiece. Understanding the heat transfer mechanism is crucial for optimizing the cutting process and achieving high-quality cuts.

Key Components of a Plasma Cutter

A plasma cutter is a powerful tool used for cutting through metal and other materials with high precision and accuracy. The key components of a plasma cutter work together to produce a high-temperature plasma arc that can cut through even the toughest materials. Three essential components of a plasma cutter are the power supply unit, plasma torch, and cooling system. The power supply unit is the heart of the plasma cutter, providing the necessary energy to generate the plasma arc. The plasma torch is responsible for directing the plasma arc onto the workpiece, while the cooling system helps to prevent overheating and maintain optimal performance. In this article, we will explore each of these components in more detail, starting with the power supply unit, which is the foundation of a plasma cutter's operation.

Power Supply Unit

A power supply unit (PSU) is a crucial component of a plasma cutter, responsible for converting AC power from the mains to DC power that the cutter can use. The PSU is essentially the heart of the plasma cutter, providing the necessary energy to generate the plasma arc. A typical PSU consists of a rectifier, a filter, and a high-frequency inverter. The rectifier converts the AC power to DC power, while the filter smooths out any ripples or fluctuations in the DC output. The high-frequency inverter then converts the DC power to a high-frequency AC signal, which is used to generate the plasma arc. The PSU also includes a control circuit that regulates the output voltage and current, ensuring that the plasma arc is stable and consistent. In addition, the PSU often includes features such as overvoltage protection, overcurrent protection, and thermal protection to prevent damage to the plasma cutter. A high-quality PSU is essential for reliable and efficient plasma cutting, as it directly affects the quality of the cut and the lifespan of the cutter.

Plasma Torch

A plasma torch is a crucial component of a plasma cutter, responsible for generating the high-temperature plasma arc that cuts through metal. The plasma torch consists of a nozzle, electrode, and swirl ring, which work together to create a stable and efficient plasma arc. The nozzle is typically made of a heat-resistant material, such as copper or ceramic, and is designed to withstand the high temperatures generated by the plasma arc. The electrode is usually made of a tungsten or copper alloy and is responsible for initiating the plasma arc. The swirl ring is a critical component that helps to create a stable and consistent plasma arc by swirling the gas around the electrode. The plasma torch is also equipped with a cooling system, which helps to prevent overheating and prolong the lifespan of the torch. The plasma torch is connected to a power source, which provides the electrical energy needed to generate the plasma arc. The power source is typically a high-frequency generator that produces a high-voltage, low-current output. The plasma torch is also connected to a gas supply, which provides the shielding gas needed to protect the plasma arc from atmospheric gases. The shielding gas is typically a mixture of argon and hydrogen, which helps to maintain a stable and consistent plasma arc. Overall, the plasma torch is a critical component of a plasma cutter, and its design and construction play a crucial role in determining the quality and efficiency of the cutting process.

Cooling System

The cooling system is a crucial component of a plasma cutter, responsible for regulating the temperature of the cutting process. It works by circulating a coolant, typically compressed air or water, through the system to absorb heat generated by the electrical arc. This heat is then dissipated, preventing overheating and damage to the equipment. The cooling system consists of a pump, hoses, and a heat exchanger, which work together to maintain a stable temperature. In some plasma cutters, a cooling system is integrated into the power supply, while in others, it is a separate unit. The cooling system plays a vital role in maintaining the plasma cutter's performance, longevity, and safety, allowing for precise cuts and minimizing the risk of equipment failure. By controlling the temperature, the cooling system enables the plasma cutter to operate at optimal levels, resulting in high-quality cuts and increased productivity.

Working Process of a Plasma Cutter

A plasma cutter is a powerful tool used to cut through metal with precision and accuracy. The working process of a plasma cutter involves several key stages that work together to achieve a clean and efficient cut. The process begins with the initial arc ignition, where a high-voltage electrical discharge is used to create a plasma arc. This arc is then sustained through the plasma arc sustainment stage, where the plasma is maintained and controlled to achieve the desired cutting performance. Finally, the cutting process stage is where the plasma arc is used to cut through the metal, resulting in a precise and accurate cut. In this article, we will explore each of these stages in more detail, starting with the initial arc ignition.

Initial Arc Ignition

The initial arc ignition is a crucial step in the plasma cutting process. It involves the creation of a high-voltage electrical arc between the electrode and the workpiece, which is necessary to ionize the gas and create the plasma. The initial arc is typically generated by a high-frequency spark, which is produced by a high-voltage power source. This spark creates a conductive path between the electrode and the workpiece, allowing the electrical current to flow and the plasma to form. The initial arc is usually very short-lived, lasting only a few milliseconds, but it is essential for initiating the plasma cutting process. Once the plasma is established, the cutting process can begin, and the plasma cutter can be moved along the desired cutting path to produce a precise and accurate cut. The initial arc ignition is a critical component of the plasma cutting process, and it plays a key role in ensuring the quality and accuracy of the cut.

Plasma Arc Sustainment

Plasma arc sustainment is a critical component of the plasma cutting process, as it enables the continuous flow of plasma gas and electrical energy to the cutting arc. This sustainment is achieved through a combination of electrical and thermal energy, which maintains the ionization of the gas and allows the arc to remain stable and consistent. The plasma arc is sustained by a high-frequency pilot arc, which is generated by a high-voltage electrical discharge. This pilot arc creates a conductive path for the plasma gas to flow through, allowing the arc to be sustained and the cutting process to continue. The plasma arc is also sustained by the thermal energy generated by the cutting process itself, which helps to maintain the ionization of the gas and keep the arc stable. As the plasma arc cuts through the metal, it creates a molten pool of metal that is blown away by the high-velocity plasma gas, allowing the cutting process to continue. The plasma arc sustainment is controlled by the plasma cutter's power supply, which regulates the electrical energy and plasma gas flow to maintain a consistent and stable cutting arc. By sustaining the plasma arc, the plasma cutter is able to maintain a high level of cutting precision and accuracy, making it an ideal tool for a variety of metal cutting applications.

Cutting Process

The cutting process of a plasma cutter involves several key steps that work together to produce a precise and efficient cut. First, the plasma cutter is positioned at the desired location on the workpiece, and the operator sets the desired cutting parameters, such as the cutting speed, voltage, and gas flow rate. Once the parameters are set, the plasma cutter is activated, and a high-frequency electrical arc is generated between the electrode and the nozzle. This arc ionizes the gas, creating a plasma arc that is hot enough to melt the metal. The plasma arc is then directed at the workpiece, where it melts the metal and creates a kerf, or cut. The molten metal is then blown away from the cut area by the gas flow, leaving a clean and precise cut. The cutting process is typically controlled by a computer or CNC system, which allows for precise control over the cutting parameters and ensures a high-quality cut. Throughout the cutting process, the plasma cutter is constantly monitoring the cutting conditions and adjusting the parameters as needed to maintain optimal cutting performance. This ensures that the cut is accurate, efficient, and of high quality. Overall, the cutting process of a plasma cutter is a complex and highly controlled process that requires careful attention to detail and precise control over the cutting parameters.