How Long Does A Pump Last

Understanding the Lifespan of a Pump

The Natural Lifespan of Different Types of Pumps

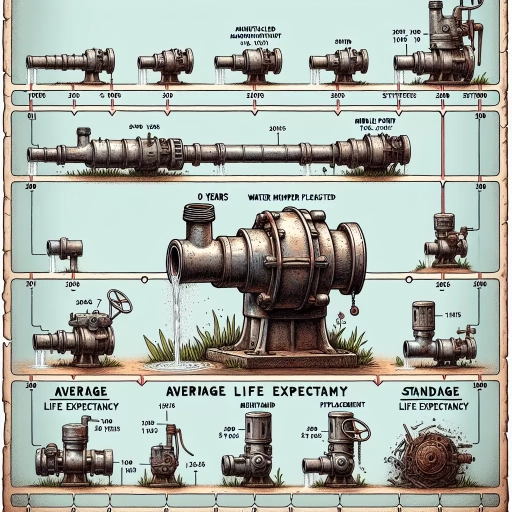

The lifespan of a pump will depend on several factors, and one prominent factor is the type of the pump. Various forms of pumps exist in the market, each designed for a specific function, and therefore, each has a different lifespan. For instance, standard centrifugal pumps that are probably the most common and versatile kinds of pumps can last between 10 to 15 years if maintained properly. On the other hand, well-made and reliably serviced submersible pumps, used extensively for waterworks, can last up to 25 years. The variety ensures that there's a pump for almost every need, but it also means the consumer needs to be well-informed about what to expect regarding the pump's durability.

Factors Influencing Pump Lifespan

Aside from the kind of pump being used, several other factors can influence how long a pump lasts. First on the list is the quality of installation. Improper installation can lead to poor performance and can significantly shorten the expected lifespan of your pump. Other factors include the nature of the material being pumped, how often the pump is used, and the conditions under which it operates. A pump that deals with abrasive or corrosive materials or that is subjected to extreme temperatures or high levels of vibration will generally not last as long as one that experiences more moderate usage.

Maintenance Practices and Pump Longevity

Lastly, but very significantly, the frequency and quality of maintenance that a pump receives will greatly affect its lifespan. Regular preventive maintenance is crucial in extending the life expectancy of a pump system. This involves checking the system's components for wear and tear, leaks, and other potential issues. With good preventive maintenance, potential problems can be detected and rectified before they evolve into severe, costly damages. Further, regular maintenance can also lead to making improvements in the pump system, which can enhance its longevity.

Maximizing the Lifespan of Your Pump

Invest in Quality Pumps and Materials

When it comes to pump longevity, quality counts. Investing in a good quality pump from a reputable manufacturer can likely increase the lifespan of your pump. High-quality pumps are typically made with superior materials and engineering which aids in their durability. Similarly, it's worth investing in high-quality pipes, fittings, and other system components. These components will be exposed to a considerable amount of wear and tear over time, so quality materials will pay off in the long run.

Proper Installation and Setup

The right installation of the pump system plays a vital role in its lifespan. The setup should be done by a knowledgeable and experienced technician who understands the requirements and workings of the pump system. Improper or faulty setup can not just decrease the lifespan of the pump, but it may also increase the running costs and efficiency issues. Therefore, investing in professional installation can ensure that your pump is set up correctly, thus improving its lifespan and operational efficiency.

Regular Preventive Maintenance

Ideally, pump maintenance isn't just about fixing issues as they arise, but about preventing potential issues from becoming problematic. This requires regular check-ups and monitoring. Regular maintenance should include checking for signs of wear, seal performance, vibration levels, and temperature to catch and resolve issues early. Specifically, routine lubrication, balancing, alignment, and inspection of fasteners, seals, and bearings should not be neglected. Adhering to a preventive maintenance schedule can extend the life of a pump significantly, reduce future costs, and improve efficiency.

Overview of Pump Replacement

Signs Your Pump Needs Replacement

Knowing when to replace a pump is as important as knowing how to extend its lifespan. Some of the key signs that your pump might require replacement include a significant drop in performance, unusual noises or vibrations, corrosion, or recurrent breakdowns. Moreover, leakages within the pump system, especially involving hazardous materials, are often a sign that the pump may need to be replaced. By recognizing these signs early, you can prevent safety hazards, and it can also save you from high replacement or repair costs.

Choosing the Right Replacement Pump

Once you understand that your pump needs to be replaced, it's necessary to choose the right replacement. This decision should be based on the same criteria you'd use when purchasing a new pump. Consider the pump type, its intended application, the conditions under which the pump will operate, and the quality and reputation of the manufacturer. Additionally, consider the age of the rest of your pump system and whether other components might also need replacement.

Professional Assistance

When it comes to replacing a pump, it's essential to seek professional help. They can guide you to understand whether repair or replacement is the right option. Also, they can provide valuable recommendations on the right pump type for your specific requirements. While pumps may seem simple in operation, they are quite complex in nature and design, and therefore, require expert assistance for proper installation or replacement.