How Much Air Pressure Should Be In A Bladder Tank

Bladder tanks are a crucial component in various industrial and commercial applications, including fire suppression systems, water treatment, and HVAC systems. The air pressure within these tanks plays a vital role in their performance and longevity. However, determining the ideal air pressure for a bladder tank can be a daunting task, especially for those unfamiliar with their operation. To ensure optimal performance and prevent potential issues, it is essential to understand the basics of bladder tanks, determine the ideal air pressure, and be aware of the consequences of incorrect air pressure. In this article, we will delve into these critical aspects, starting with the fundamentals of bladder tanks. By grasping the basics, you will be better equipped to navigate the complexities of air pressure and make informed decisions about your bladder tank system. Understanding the basics of bladder tanks is the first step in ensuring their optimal performance and longevity.

Understanding the Basics of Bladder Tanks

Bladder tanks are a type of water storage tank that plays a crucial role in various industries, including firefighting, municipal water supply, and industrial processes. To understand the basics of bladder tanks, it is essential to know their function, components, and the importance of air pressure in their operation. A bladder tank consists of a flexible bladder surrounded by a steel or fiberglass shell, which stores water or other liquids under pressure. The components of a bladder tank, including the bladder, shell, and valves, work together to provide a reliable and efficient storage solution. The air pressure in a bladder tank is also critical, as it helps to maintain the pressure of the stored liquid and ensures the tank operates safely and effectively. By understanding these key aspects of bladder tanks, individuals can appreciate their importance in various applications. So, let's start by exploring what a bladder tank is and its function.

What is a Bladder Tank and Its Function

A bladder tank, also known as a captive air tank or a diaphragm tank, is a type of pressure vessel that stores water and compressed air in a single tank. The tank is divided into two compartments by a flexible bladder or diaphragm, which separates the water from the compressed air. The bladder is typically made of a durable, rubber-like material that is designed to withstand the pressure of the compressed air. The function of a bladder tank is to provide a consistent and reliable source of water pressure in a plumbing system, while also protecting the system from water hammer and other pressure-related issues. When the system demands water, the compressed air in the bladder tank pushes the water out of the tank and into the system, maintaining a consistent pressure. As the water is used, the bladder expands to fill the space, allowing the tank to refill with water. The bladder tank's ability to store both water and compressed air makes it an essential component in many plumbing systems, including well water systems, booster pump systems, and fire suppression systems. By providing a buffer against pressure fluctuations, bladder tanks help to ensure a steady and reliable water supply, while also reducing the risk of damage to pipes and other system components.

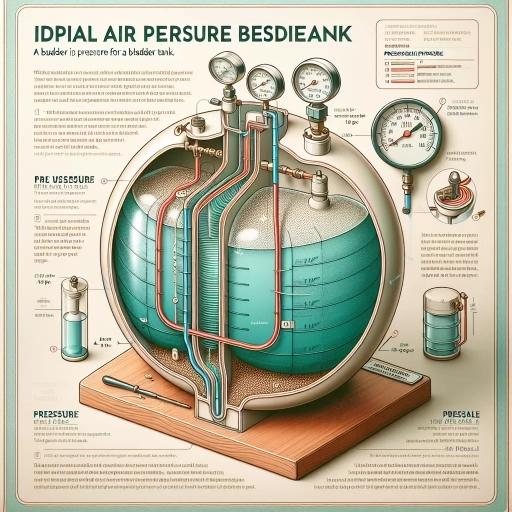

Components of a Bladder Tank

A bladder tank is a type of pressure vessel that consists of several key components, each playing a crucial role in its overall function. The bladder, also known as the diaphragm, is a flexible, airtight bag that separates the water chamber from the air chamber. The bladder is typically made of a durable, rubber-like material that is resistant to corrosion and abrasion. The water chamber, also known as the tank shell, is the outer casing of the bladder tank that holds the water. It is usually made of steel or fiberglass and is designed to withstand the pressure of the water and air inside the tank. The air chamber, also known as the air cell, is the compartment that holds the compressed air. It is typically located at the top of the tank and is separated from the water chamber by the bladder. The air valve is a critical component that allows air to enter and exit the air chamber, maintaining the desired pressure level. The pressure gauge is a device that measures the pressure of the air in the air chamber, providing a visual indication of the tank's pressure level. The drain valve is a component that allows water to be drained from the tank, usually for maintenance or repair purposes. The inlet and outlet connections are the points where the water supply lines connect to the tank, allowing water to flow in and out of the tank. Finally, the mounting hardware, such as brackets and straps, secures the tank to a wall or floor, ensuring stability and safety. By understanding the components of a bladder tank, users can better appreciate the importance of proper maintenance and operation to ensure optimal performance and longevity.

Importance of Air Pressure in Bladder Tanks

Air pressure plays a crucial role in the functioning of bladder tanks, which are widely used in various applications, including fire suppression systems, water supply systems, and industrial processes. The bladder tank's air pressure is responsible for maintaining the system's pressure and ensuring a consistent water supply. When the air pressure in the bladder tank is set correctly, it allows the system to operate efficiently, providing a reliable source of water or other fluids. Conversely, incorrect air pressure can lead to reduced system performance, increased energy consumption, and even equipment damage. Therefore, it is essential to understand the importance of air pressure in bladder tanks and ensure that it is set and maintained at the recommended levels to guarantee optimal system performance and longevity. By doing so, users can prevent potential issues, reduce maintenance costs, and ensure the overall reliability of their bladder tank system.

Determining the Ideal Air Pressure for a Bladder Tank

Determining the ideal air pressure for a bladder tank is crucial for its optimal performance and longevity. A bladder tank's air pressure affects its ability to store and supply water efficiently, making it essential to get it right. However, finding the ideal air pressure can be a complex task, as it depends on various factors. To determine the ideal air pressure, one must consider the factors affecting air pressure in bladder tanks, calculate the ideal air pressure for a specific bladder tank, and adhere to industry standards and recommendations. By understanding these key aspects, one can ensure that their bladder tank operates at its best. In this article, we will delve into the factors affecting air pressure in bladder tanks, exploring how temperature, tank size, and water pressure impact the ideal air pressure.

Factors Affecting Air Pressure in Bladder Tanks

The air pressure in a bladder tank is influenced by several factors, including the tank's size and material, the type of bladder used, the temperature of the surrounding environment, and the level of water in the tank. The size and material of the tank can affect the air pressure because larger tanks tend to have lower air pressure due to the increased volume, while tanks made of certain materials, such as steel, may be more prone to corrosion, which can impact air pressure. The type of bladder used is also a crucial factor, as different bladders have varying levels of elasticity and resistance to pressure, which can affect the overall air pressure in the tank. Temperature is another significant factor, as changes in temperature can cause the air in the tank to expand or contract, leading to fluctuations in air pressure. Finally, the level of water in the tank can also impact air pressure, as the weight of the water can compress the air in the tank, leading to increased pressure. Understanding these factors is essential for determining the ideal air pressure for a bladder tank and ensuring optimal performance and longevity.

Calculating the Ideal Air Pressure for a Specific Bladder Tank

Calculating the ideal air pressure for a specific bladder tank involves considering several factors, including the tank's size, material, and intended application. The ideal air pressure is typically determined by the manufacturer's recommendations, but it can also be calculated using the following formula: Ideal Air Pressure (PSI) = (Minimum System Pressure (PSI) x 1.1) + (Static Head (ft) x 0.433). The minimum system pressure is the lowest pressure required by the system, while the static head is the vertical distance from the tank to the highest point in the system. For example, if the minimum system pressure is 40 PSI and the static head is 50 ft, the ideal air pressure would be (40 x 1.1) + (50 x 0.433) = 44 + 21.65 = 65.65 PSI. It's essential to note that the ideal air pressure may vary depending on the specific application and the tank's design. Therefore, it's recommended to consult the manufacturer's instructions and consider factors such as the tank's size, material, and intended use when determining the ideal air pressure. Additionally, it's crucial to ensure that the air pressure is within the recommended range to prevent damage to the tank and ensure optimal performance.

Industry Standards and Recommendations for Air Pressure

The American Society of Mechanical Engineers (ASME) and the National Fire Protection Association (NFPA) provide industry standards and recommendations for air pressure in bladder tanks. According to ASME, the air pressure in a bladder tank should be set between 2-10 psi (14-69 kPa) above the minimum required pressure to ensure proper system operation. NFPA recommends that the air pressure be set at 10-20 psi (69-138 kPa) above the minimum required pressure to ensure adequate system performance. Additionally, the International Association of Plumbing and Mechanical Officials (IAPMO) recommends that the air pressure be set at 12-18 psi (83-124 kPa) above the minimum required pressure. It is essential to consult the manufacturer's instructions and local regulations to determine the specific air pressure requirements for a particular bladder tank application. Furthermore, regular maintenance and inspections are crucial to ensure the air pressure remains within the recommended range and the system operates efficiently and safely. By following industry standards and recommendations, users can ensure optimal performance, extend the lifespan of the bladder tank, and prevent potential hazards.

Consequences of Incorrect Air Pressure in Bladder Tanks

Incorrect air pressure in bladder tanks can have severe consequences on the overall performance and longevity of the system. Maintaining the correct air pressure is crucial to ensure the bladder tank operates efficiently and effectively. However, incorrect air pressure can lead to a range of problems, including over-pressurization and under-pressurization, which can have devastating effects on the system. Over-pressurization can cause the bladder to rupture, leading to costly repairs and downtime, while under-pressurization can result in reduced system performance and increased energy consumption. Furthermore, incorrect air pressure can also impact the overall system performance, leading to reduced water quality and increased maintenance costs. In this article, we will explore the risks of over-pressurization, under-pressurization, and the impact of incorrect air pressure on system performance. First, let's examine the risks of over-pressurization in bladder tanks.

Risks of Over-Pressurization in Bladder Tanks

Over-pressurization in bladder tanks poses significant risks to the entire system, including the tank itself, the surrounding infrastructure, and the people operating it. When the air pressure in the tank exceeds the recommended level, it can lead to a range of problems, including premature wear and tear on the bladder, increased risk of rupture, and damage to the tank's fittings and connections. Furthermore, over-pressurization can also cause the tank to become over-extended, leading to a loss of its ability to absorb pressure surges and shocks, which can have catastrophic consequences. In extreme cases, over-pressurization can even lead to a complete failure of the tank, resulting in costly repairs, downtime, and potential safety hazards. Therefore, it is essential to ensure that the air pressure in bladder tanks is maintained within the recommended range to prevent these risks and ensure the safe and reliable operation of the system.

Risks of Under-Pressurization in Bladder Tanks

Under-pressurization in bladder tanks poses significant risks to the overall performance and longevity of the system. When the air pressure in the tank is too low, it can lead to a range of problems, including reduced system efficiency, increased energy consumption, and premature wear on the tank and its components. One of the primary risks of under-pressurization is the potential for the tank to become waterlogged, which can cause the bladder to become damaged or even rupture. This can result in costly repairs, downtime, and even safety hazards. Furthermore, under-pressurization can also lead to a decrease in the tank's ability to provide a consistent and reliable water supply, which can have serious consequences for households, businesses, and industries that rely on a steady water supply. Additionally, under-pressurization can also cause the tank to become more susceptible to corrosion and contamination, which can compromise the quality of the water being stored. Overall, it is essential to ensure that the air pressure in bladder tanks is maintained at the recommended level to prevent these risks and ensure the optimal performance and longevity of the system.

Impact of Incorrect Air Pressure on System Performance

Incorrect air pressure in a bladder tank can significantly impact system performance, leading to a range of consequences that can compromise the efficiency, reliability, and longevity of the system. When the air pressure is too low, the tank may not be able to provide the necessary pressure to push water through the pipes, resulting in reduced water flow rates and pressure. This can lead to poor system performance, including decreased water pressure at fixtures, increased energy consumption, and reduced system capacity. On the other hand, if the air pressure is too high, it can cause the tank to become over-pressurized, leading to premature wear and tear on the tank and its components, as well as increased risk of tank rupture. Furthermore, incorrect air pressure can also affect the tank's ability to absorb pressure surges and shocks, leading to increased stress on the system and its components. Overall, maintaining the correct air pressure in a bladder tank is crucial to ensure optimal system performance, efficiency, and reliability.