How Is Brandy Made

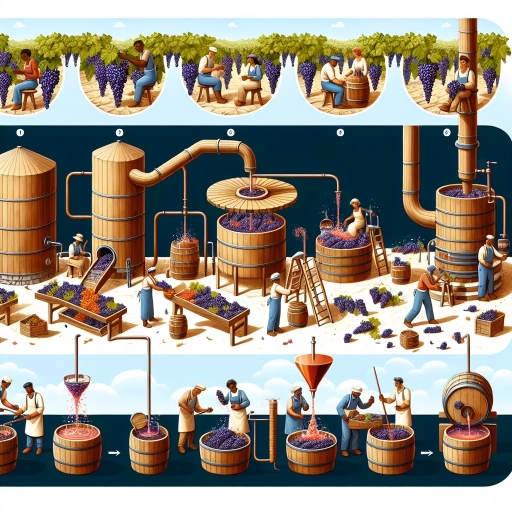

Brandy is a popular spirit made from distilled wine or fruit, with a rich history dating back to the 15th century. The production of brandy involves a multi-step process that requires great skill and attention to detail. From harvesting and preparing the grapes to fermentation and distillation, and finally, aging and blending, each stage plays a crucial role in shaping the final product. In this article, we will delve into the world of brandy production, exploring the intricacies of each step and what makes a high-quality brandy. We will begin by examining the first stage of the process: harvesting and preparing the grapes, which sets the foundation for the entire production process.

Harvesting and Preparing the Grapes

The process of harvesting and preparing grapes for winemaking is a meticulous and labor-intensive process that requires great care and attention to detail. From the moment the grapes are plucked from the vine to the moment they are transformed into a rich, full-bodied wine, every step is crucial in determining the final product's quality and character. The journey begins with hand-picking and sorting of grapes, where skilled laborers carefully select and separate the ripest, healthiest grapes from the rest. This is followed by crushing and de-stemming the grapes, which releases the juice and begins the process of extracting the flavors and aromas. Finally, a cold soak and maceration process is employed to extract even more flavors and tannins from the grape skins, resulting in a complex and balanced wine. In this article, we will delve into the first step of this process, hand-picking and sorting of grapes, and explore the importance of this labor-intensive task in producing high-quality wine.

Hand-picking and sorting of grapes

Hand-picking and sorting of grapes is a labor-intensive process that requires great care and attention to detail. This step is crucial in the production of high-quality brandy, as it allows for the selection of only the ripest and healthiest grapes. The process typically begins early in the morning, when the grapes are still cool from the night, and the pickers carefully hand-select the grapes from the vine. The grapes are then placed into small baskets or containers to prevent bruising and damage. Once the grapes are picked, they are taken to a sorting table where they are carefully sorted and cleaned to remove any leaves, stems, or unripe grapes. This process is usually done by hand, as it requires a great deal of precision and care. The sorted grapes are then crushed or pressed to release their juice, which is then fermented to produce the base wine that will eventually become brandy. The hand-picking and sorting process is time-consuming and labor-intensive, but it is essential for producing high-quality brandy that is rich in flavor and aroma.

Crushing and de-stemming the grapes

Crushing and de-stemming the grapes is a crucial step in the brandy-making process. After harvesting, the grapes are typically crushed to release their juice, which is then mixed with the skins and seeds. This process is called maceration, and it allows the juice to extract the flavors, colors, and tannins from the skins and seeds. The resulting mixture is called must. The de-stemming process involves removing the grape stems from the must, as they can impart a bitter flavor to the brandy. The crushed grapes are then transferred to a fermentation tank, where they undergo fermentation, which converts the sugars in the juice into ethanol. The fermentation process typically takes around 7-10 days, during which time the must is stirred regularly to prevent the skins from rising to the surface and forming a crust. After fermentation is complete, the must is pressed to separate the liquid from the solids, and the resulting liquid is called wine. The wine is then distilled to produce brandy. The quality of the grapes and the care taken during the crushing and de-stemming process can significantly impact the final flavor and quality of the brandy.

Cold soak and maceration to extract flavors

Cold soak and maceration are two techniques used to extract flavors and colors from grape skins during the brandy-making process. Cold soak involves submerging the grape skins in cold water or a cold grape juice solution for a period of time, usually several days, to extract the desired flavors and colors. This process helps to break down the cell walls of the grape skins, releasing the flavorful compounds and anthocyanins, which are responsible for the color and flavor of the brandy. Maceration, on the other hand, involves allowing the grape skins to steep in the grape juice or wine for a longer period, usually several weeks or even months, to extract even more flavors and colors. This process helps to break down the complex compounds in the grape skins, releasing a wider range of flavors and aromas into the brandy. Both cold soak and maceration are important steps in the brandy-making process, as they help to extract the desired flavors and colors from the grape skins, resulting in a high-quality brandy with a rich, complex flavor profile.

Fermentation and Distillation Process

The art of fermentation and distillation has been a cornerstone of human civilization for centuries, with various cultures developing unique techniques to create a wide range of spirits. From the smooth, rich flavors of whiskey to the crisp, refreshing taste of gin, the process of transforming raw ingredients into a refined spirit is a complex and fascinating one. At its core, the fermentation and distillation process involves three key stages: primary fermentation to convert sugars into alcohol, secondary fermentation to refine the flavor and aroma, and distillation in copper pot stills to concentrate the spirit. By understanding these stages, we can gain a deeper appreciation for the craftsmanship and expertise that goes into creating our favorite spirits. Let's start by exploring the first stage of this process: primary fermentation to convert sugars into alcohol.

Primary fermentation to convert sugars into alcohol

The primary fermentation process is a crucial step in the production of brandy, where the sugars present in the grape juice or wine are converted into alcohol. This process typically takes place in large, stainless steel tanks or oak barrels, where the grape juice or wine is mixed with yeast and other microorganisms. The yeast consumes the sugars, producing ethanol and carbon dioxide as byproducts. The primary fermentation process usually lasts for 7-14 days, during which time the mixture is regularly stirred and monitored to ensure optimal conditions for fermentation. The temperature, pH, and sugar levels are carefully controlled to promote healthy yeast growth and prevent the growth of unwanted bacteria or wild yeast. As the fermentation progresses, the mixture becomes more acidic, and the alcohol content increases, eventually reaching a level of around 8-10% ABV. The resulting liquid is then transferred to another tank or barrel for secondary fermentation, also known as malolactic fermentation, where the remaining sugars are converted into lactic acid, further refining the flavor and character of the brandy. Throughout the primary fermentation process, the winemaker or distiller closely monitors the progress, making adjustments as necessary to ensure the production of high-quality brandy.

Secondary fermentation to refine the flavor and aroma

Secondary fermentation, also known as malolactic fermentation, is a crucial step in the brandy-making process that refines the flavor and aroma of the wine. This process occurs after the primary fermentation, where the yeast converts the sugars into ethanol. During secondary fermentation, lactic acid bacteria convert the malic acid present in the wine into lactic acid, resulting in a smoother and more complex flavor profile. This process can take anywhere from a few weeks to several months, depending on factors such as temperature, pH levels, and the type of bacteria present. The secondary fermentation process can be induced naturally or artificially, with some winemakers choosing to add lactic acid bacteria to the wine to initiate the process. The benefits of secondary fermentation include a reduction in acidity, an increase in the wine's overall stability, and the development of a more refined and nuanced flavor profile. By allowing the wine to undergo secondary fermentation, brandy producers can create a more balanced and complex spirit that is better suited to aging and blending. Ultimately, the secondary fermentation process plays a critical role in shaping the final flavor and aroma of the brandy, and is an essential step in the production of high-quality brandy.

Distillation in copper pot stills to concentrate the spirit

Distillation in copper pot stills is a crucial step in the brandy-making process, allowing the spirit to be concentrated and refined. This traditional method involves heating the fermented wine in a copper pot still, causing the liquid to vaporize and rise into a condenser, where it cools and condenses back into a liquid. The resulting distillate is a clear, high-proof spirit that is rich in flavor and aroma compounds. Copper pot stills are preferred for distillation because they allow for a more nuanced and complex flavor profile to develop, as the copper reacts with the spirit to remove impurities and add subtle notes of sweetness and spice. The distillation process is typically repeated multiple times, with each run resulting in a higher concentration of the desired flavor and aroma compounds. The final distillate is then aged in oak barrels, where it matures and develops its characteristic color, flavor, and aroma. Throughout the distillation process, skilled distillers carefully monitor the temperature, pressure, and flow rate to ensure that the spirit is distilled to the perfect level of concentration and flavor. The art of distillation in copper pot stills requires great skill and attention to detail, as even small variations in the process can significantly impact the final quality of the brandy.

Aging and Blending the Brandy

The art of aging and blending brandy is a complex process that requires patience, skill, and attention to detail. To produce a high-quality brandy, distillers must carefully consider every step of the process, from aging in oak barrels to add color, flavor, and complexity, to blending different batches to achieve a consistent flavor profile, and finally, filtering and bottling the final product. Each of these steps plays a crucial role in shaping the final flavor and character of the brandy. By carefully controlling the aging process, distillers can coax out the full potential of the brandy, resulting in a rich, smooth, and full-bodied spirit. In this article, we will explore the first step in this process: aging in oak barrels to add color, flavor, and complexity.

Aging in oak barrels to add color, flavor, and complexity

Aging in oak barrels is a crucial step in the brandy-making process, as it allows the spirit to mature and develop its characteristic color, flavor, and complexity. Oak barrels impart a rich, velvety texture and a deep amber hue to the brandy, while also contributing subtle notes of vanilla, caramel, and toasted nuts. The aging process can last anywhere from a few months to several decades, depending on the type of brandy being produced. During this time, the brandy interacts with the oak, slowly extracting the desirable compounds that enhance its flavor and aroma. The type of oak used, whether it be French, American, or a combination of both, also plays a significant role in shaping the final product. French oak, for example, is known for its subtle, elegant flavors, while American oak imparts a bolder, more pronounced character. As the brandy ages, it undergoes a series of physical and chemical changes, including oxidation, evaporation, and the formation of new compounds. These changes contribute to the development of the brandy's complex flavor profile, which can include notes of dried fruit, spices, and even subtle hints of oak. Ultimately, the aging process is what sets brandy apart from other spirits, and it is this careful balance of time, oak, and patience that allows brandy to reach its full potential.

Blending different batches to achieve a consistent flavor profile

Blending different batches to achieve a consistent flavor profile is a crucial step in the brandy-making process. This technique involves combining brandies of varying ages, grape varieties, and production methods to create a harmonious and balanced flavor. By blending, distillers can compensate for the natural variations that occur between batches, ensuring that the final product meets the desired standards. The blending process typically begins with a thorough evaluation of each batch, where the distiller assesses the flavor profile, acidity, and overall character. They then select specific batches to combine, taking into account factors such as the type of grape, aging time, and level of oak influence. The blending ratio is carefully calculated to achieve the perfect balance of flavors, with some batches contributing fruitiness, while others add complexity and depth. The blended brandy is then left to mature for a period of time, allowing the flavors to integrate and harmonize. This process can be repeated multiple times, with the distiller continually tasting and adjusting the blend until the desired flavor profile is achieved. The art of blending is a delicate and nuanced process, requiring a deep understanding of the brandy's flavor components and a keen sense of taste. By mastering the art of blending, distillers can create a consistent and exceptional brandy that showcases the best qualities of the individual batches. Ultimately, the goal of blending is to produce a brandy that is greater than the sum of its parts, with a rich, complex, and refined flavor profile that delights the senses.

Filtering and bottling the final product

The final product of brandy production is filtered and bottled to ensure its quality and appearance. Filtration is a crucial step in the brandy-making process, as it removes any impurities or sediment that may have formed during the aging process. The type of filtration used can vary depending on the type of brandy being produced, but common methods include paper filtration, membrane filtration, and cold stabilization. Paper filtration involves passing the brandy through a paper filter to remove any particles or sediment, while membrane filtration uses a semipermeable membrane to separate the brandy from any impurities. Cold stabilization involves chilling the brandy to a very low temperature to precipitate out any impurities, which are then removed through filtration. Once the brandy has been filtered, it is bottled and prepared for distribution. The bottling process typically involves filling glass bottles with the filtered brandy, capping them with a cork or screw cap, and labeling them with the brand name, age, and other relevant information. Some brandies may also undergo additional processing steps, such as the addition of a small amount of sugar or caramel to enhance the flavor and color. However, this is not a common practice and is generally discouraged by brandy producers who prioritize the natural flavor and character of the spirit. Overall, the filtration and bottling process is an important step in the brandy-making process, as it helps to ensure the quality and consistency of the final product.