How To Set Up Ratchet Straps

Whether you're securing cargo for transport or setting up outdoor equipment, ratchet straps can be your best ally. These simple yet tremendously useful tools are integral for anyone who values safety and stability. However, if mishandled, they can become a source of frustration. In this guide, we'll dispel the mystery behind these essential items. We will walk alongside you in an informative journey which will cover three significant chapters: 'Understanding the Basics of Ratchet Straps', a thorough 'Step-by-Step Guide to Set Up Ratchet Straps', and a vital segment on 'Troubleshooting Common Ratchet Strap Issues'. By the end of this article, you'll not only be familiar with every cog and click of a ratchet strap but will also be able to set up one with blindfolded confidence. Let's begin this voyage by first grasping the fundamentals, setting a firm foundation by 'Understanding the Basics of Ratchet Straps'.

Whether you're securing cargo for transport or setting up outdoor equipment, ratchet straps can be your best ally. These simple yet tremendously useful tools are integral for anyone who values safety and stability. However, if mishandled, they can become a source of frustration. In this guide, we'll dispel the mystery behind these essential items. We will walk alongside you in an informative journey which will cover three significant chapters: 'Understanding the Basics of Ratchet Straps', a thorough 'Step-by-Step Guide to Set Up Ratchet Straps', and a vital segment on 'Troubleshooting Common Ratchet Strap Issues'. By the end of this article, you'll not only be familiar with every cog and click of a ratchet strap but will also be able to set up one with blindfolded confidence. Let's begin this voyage by first grasping the fundamentals, setting a firm foundation by 'Understanding the Basics of Ratchet Straps'.1. Understanding the Basics of Ratchet Straps

Ratchet straps serve a critical function in cargo transportation - securing heavy goods and ensuring safety measures are adhered to. This article aims to equip you with a deep understanding of these crucial tools. We'll unfurl the complexities of ratchet straps, breaking down what they're made of, how they work, and the pivotal role they play in load securing and safety practices. The components of a ratchet strap constitute our first area of focus. This foundational knowledge becomes the driving force that propels you from a novice to an informed user, capable of selecting the right ratchet strap that meets your securing needs and safety requirements. Adjust your harness for this fascinating dive into the nuts and bolts of ratchet straps, as we address their key components in the following section.

1.1 The key Components of a Ratchet Strap

1.1 The Key Components of a Ratchet Strap

Understanding the fundamental elements of a ratchet strap is an integral piece of the larger picture of knowing how to efficiently and safely set them up. Each component plays a distinct role in attaining maximum durability, flexibility, and strength, not only securing cargo but also ensuring the safety of the user and those around. To start with, one of the prime components of a ratchet strap is the ratchet buckle itself. This is the mechanism that tightens the strap and holds it in place, providing the tension needed to secure items effectively. Designed with an ingenious mechanism, it utilizes a gear and a pawl system that allows the strap to move in one direction, preventing it from slackening or coming loose until the release lever is applied. Next is the strap, generally crafted from durable polyester webbing, known for its exceptional strength and resistance to abrasion and UV damage. This webbing strap is, in essence, the hand that grips and holds the cargo in place. Typically, it comes in various lengths and widths to accommodate various cargo sizes and weight capacities. Another key element is the end fittings or hooks that are often placed at the ends of the strap. These are generally J-hooks, S-hooks or flat hooks which are designed to latch onto an anchor point. Their function is pivotal, as they secure the ratchet strap to the vehicle or structure and provide an additional layer of safety. Last but not least are the tie-down anchors. These are the points where the ratchet strap attaches to the vehicle or trailer, providing an anchor point for the strap. These points must be strong enough to sustain the force exerted by the strapped down load. Understanding each of these components, their functionality, and how they work together creates a sturdy foundation for the successful operation of ratchet straps. By familiarizing yourself with these key pieces and their roles, you're setting the right tone for optimal setup efficiency, safe handling, and the securing of loads with utmost confidence. This comprehensive understanding is not just beneficial—it's crucial—to fully grasp the basics of ratchet straps and their setup process.1.2 The Functioning of a Ratchet Strap

1.2 The Functioning of a Ratchet Strap Understanding the intricacies of a ratchet strap's functioning is key to its proper usage. Essentially a ratchet strap is a robust tie-down device ideal for securing various types of cargo. This device opens up to its full length, allowing you to loop it around a secure item or structure, then uses the ratchet mechanism to tighten and provide a secure hold. The efficiency of a ratchet strap lies in the mechanism at its heart - the ratchet. A ratchet is primarily composed of a handle, a latch, and a gear. When you move the ratchet handle up and down, the gear rotates. There is a small pivoting lever known as the pawl. When the handle raises, the pawl gives way for the gear to shift, but when the handle lowers, the pawl locks into the gear's teeth, stopping it from moving backward. This restricts the strap's movement to only one direction – hence, providing secure tension. Each part plays a critical role in the system. For instance, the handle and ratchet buckle offer leverage when applying tension to the strap, whilst the latch functions as a lock to ensure the strap remains in place after tightening it. Ratchet straps come in various sizes and styles, with different load limits, to accommodate a wide array of applications - from securing furniture in a moving truck, keeping a kayak stable on a car roof to holding down heavy machinery in a cargo plane. Remember to always consider the weight and type of your cargo when choosing a ratchet strap since an inappropriate choice could lead to damage or even accidents. Mastering the inner workings of a ratchet strap is an important step towards using it efficiently and safely. Being more than a mere assemblage of parts, a ratchet strap cleverly utilizes the principles of physics to provide us a relatively hassle-free and safe means of securing our loads. Understanding its functioning not only provides insight into its ingenious design but also enables you to set it up correctly and ensure maximum safety and stability during transit.

1.3 The Role of Ratchet Straps in Load Securing and Safety Practices

In the realm of load securing and safety practices, the role of ratchet straps is indisputably crucial. Serving as a vital aid in safe transportation, ratchet straps have garnered deserved attention in their capacity to protect goods during shipping and handling effectively. Ratchet straps, also synonymous with tie-down straps or lashing straps, provide essential assistance in anchoring and securing cargo during transits, reducing potential incidents of mishandling or displacement. A ratchet strap operates by using a ratchet mechanism - an object allowing motion in one direction while preventing it in the opposite direction - to tighten and secure heavy loads. The tightly tethered strap ensures stability, mitigating the shifts and wobbles during the journey, shielding both the cargo and transportation vehicle from potential damages. Whether it's for business logistics or a simple household relocation, ratchet straps offer a tangible safeguarding solution, making them virtually ubiquitous in various transportation endeavors. Their role in safety practices runs deeper than surface understanding. Accidents and loss of goods during transport not only affect the profits but also bear broader implications for safety. An unsecured load can shift, causing an imbalance in the vehicle, which in worst-case scenarios can lead to accidents, endangering the lives of the people involved. During transport, the forces of acceleration, deceleration, and cornering act on the load. The ratchet straps counteract these forces, keeping the load in place and ensuring the vehicle's balance. The implementation of ratchet straps also adheres to stringent safety regulations and guidelines, reinforcing their pivotal function in load securing and safety practices. For instance, the Department of Transportation in many countries mandates the use of ratchet straps for load stability during transport, underlining their essential role in cargo management. The penalties for non-compliance can be severe, ranging from heavy fines to legal consequences. The quality of ratchet straps also carries a significant weight in safety practices. High-quality ratchet straps offer enhanced durability and strength, vital for securing heavy loads without any risk of breakage or slack. They perform under extreme conditions, providing a reliable bundling solution and reducing risk factors associated with the transport of heavy or fragile items. In conclusion, ratchet straps play an instrumental role in ensuring load safety and secure transportation. They not only serve as a crucial tool for effectively tethering cargo but also contribute significantly to meeting safety norms and regulations. As a testament to their utility, ratchet straps are widely employed across global shipping and logistics sectors, monumental in preventing the costly losses in goods, and more importantly, securing the safety of everyone involved in the process. Thus, understanding the functioning and proper utilization of ratchet straps becomes an inherent part of load securing and safety training.

2. Step-by-Step Guide to Set Up Ratchet Straps

Securely fastening your goods for transit, whether it be in a moving truck or a cargo ship, is crucial. "The Step-by-Step Guide to Set Up Ratchet Straps" serves as a comprehensive guide to ensure you're doing so effectively and appropriately. It informs readers on assembling the ratchet strap parts, threading the strap through the ratchet, and tightening and securing the ratchet strap, three critical processes that, if correctly done, prevent the loss or damage to goods. Setting up ratchet straps may seem daunting; however, by understanding the assembly of its parts, we could transform a seemingly complex process into an achievable task. That's why our first supporting paragraph, "Assembling the Ratchet Strap Parts", breaks down this process into manageable steps. Let's start our journey to ensure a safe and stress-free transit for your goods by first exploring the proper assembly of ratchet strap parts.

2.1 Assembling the Ratchet Strap Parts

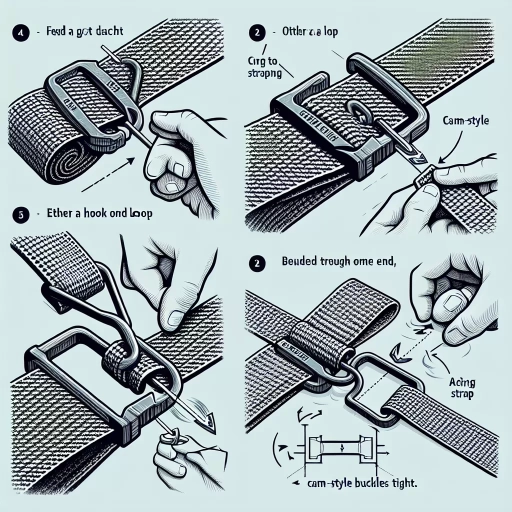

In the assembly process, the first step towards setting up ratchet straps involves getting familiarized with the ratchet strap components. As part of the 2.1 Assembling the Ratchet Strap Parts, it's imperative to understand the key parts that make up this invaluable tool. As such, the ratchet strap primarily includes a ratchet buckle and a strap with a hook at each end. This assembly process requires precision and attention to detail to ensure that the strap effectively secures the load. The ratchet buckle, metal in nature, forms the core of the strap mechanism. It has a handle that swings back and forth, and a small circular barrel where you thread the strap. You will find a release catch on the buckle, which facilitates the securing of the load as well as the eventual release. On the other hand, the strap is typically made of durable polyester webbing, designed to withstand high tension and stress. At one end of the strap, a hook is attached, used for securing the strap to the anchor point, while the other end is plain, intended for threading through the buckle. To assemble these parts, start by opening the ratchet handle to expose the circular barrel. Thread the plain end of the strap carefully through the slot in the center barrel of the closed ratchet, then out the other side. Ensure the strap isn't twisted. When done correctly, pulling the strap can cause the ratchet to rotate. The correct assembly of ratchet strap parts greatly contributes to the tool's performance and the overall safety and security of transported goods. By understanding these key points of the assembly process and applying them diligently, one can ensure the most effective and efficient use of ratchet straps, which in itself is an essential skill in cargo transportation and handling. With practice, the process of assembling the parts of a ratchet strap will become an effortless task, leading to peace of mind knowing your loads are safely secured.

2.2 Threading the Strap through the Ratchet

2.2 Threading the Strap through the Ratchet

In the quest to set up ratchet straps effectively, understanding the process of threading the strap through the ratchet is quintessential. This seemingly complex procedure can become second nature with a bit of patience and practice. If done correctly, it ensures that your items are securely fastened, thereby fostering safety and reliability during transportation or storage. To begin this step, hold the ratchet in an open position where the ratchet handle is pointing upwards and the hub slot is easily visible. Start threading by sliding the webbing of the strap into the slot in the center rotating spool of the ratchet. Push it through until it emerges from the bottom side, taking special care not to twist the strap in the process. Twisting can compromise the strap's strength and stability. Therefore, it is vital to keep it flat and properly oriented. Also, remember to leave some slack in the lead end of the strap. A slack of approximately 6 inches would do as it helps in achieving a tight grip once you start to ratchet. Once the strap is threaded, pull it through ensuring that it's tight and secure. One way to validate the correct threading is to pull on the strap and ensure it doesn't feed back into the ratchet. At this point, you have successfully threaded the strap through the ratchet. Moreover, this process is not only about achieving physical correctness but it is also about understanding the mechanics behind the strapping. Each component of the ratchet and strap plays a critical role in the tensioning system. Mastering this process can give you a level of assurance and confidence in the safety provided by ratchet straps. In conclusion, the art of threading the strap through the ratchet is a crucial step towards correctly setting up ratchet straps. Besides following the steps, being informative about what each step contributes to the larger purpose can help in refining your threading technique. Through a combination of careful execution and awareness, this process can be mastered with ease, ensuring the safety and security of your cargo.2.3 Tightening and Securing the Ratchet Strap

To adeptly tighten and secure a ratchet strap, one must first open the ratchet handle until it’s completely flat, creating a "T" shape. The axle (small, round cylinder), nestled in the ratchet crank handle’s assembly, becomes the pivotal point for this action. As a part of the 2.3 tightening and securing procedure, the ratchet strap should be threaded through the axle. The strap should make an exit underneath the ratchet. Once done, it becomes the pulling end; the loose end of the ratchet strap. At this stage, staying cautious is paramount, as improper threading can lead to slippage during the securing process. Once threaded properly, the most critical step begins, where the ratchet strap is subjected to tightening. As you begin this process, ensure the object (to be secured) is straight and unwavering. Applying tension will require a considerable effort, hence the hand tightening the strap should be firm and steady. Here, manipulate the ratchet handle and move it up and down, swiftly and steadily, to incrementally tighten the strap. In the midst of this, gauge the strength of your ratchet strap by applying an appropriate amount of tension. Over tightening can result in strap damage or failure, which ultimately leads to load displacement or damaging the object itself. Use your best judgment to decide when the strap becomes ‘tight enough’. Securing the ratchet strap is the final step. In this crucial phase, close the ratchet handle all the way down, so it’s snug against the base of the ratchet assembly. Your ratchet strap is now secured. Penned down in this comprehensive step-by-step guide, these tips and tricks aim to not only facilitate easier understanding, but also ensure the safety of your load during transit. Escalating one’s confidence, this meticulous guide on tightening and securing a ratchet strap eliminates the chaos and uncertainty that tends to surround ratchet straps. Empowering readers to secure their goods efficiently, this guide serves as a roadmap towards mastering the appears-to-be complicated task of setting up ratchet straps. Hence, tightening and securing a ratchet strap should not be seen as an arduous task; instead, by following these dedicated steps in our guide, one can ensure that their items would be secured with a steadfast and unyielding grip. Easy to follow and effective in its result, this guide serves as the perfect toolbox for anyone seeking to harness the full potential of their ratchet straps.

3. Troubleshooting Common Ratchet Strap Issues

The use of ratchet straps is ubiquitous in various industries for secure load-transportation purposes. However, dealing with common ratchet strap issues such as a stuck strap, strap slippage, and loosening problems can prove frustrating and impacting on the operations. This informative guide aims to discuss these troubleshooting issues, providing you with practical steps to resolve them effectively. Our thorough investigation will cover three significant areas. The first segment, 'Releasing a Stuck Ratchet Strap', provides insights on how best to unhook a stiff strap without inflicting damage on the material or yourself. The second segment will scrutinize 'Addressing Slippage and Loosening Problems', focusing on effective ways of ensuring that the strap remains firm and secure for optimal load transportation. The third segment is all about 'Preventive Care and Maintenance Practices', an essential routine to keeping your ratchet straps in the best form while extending their lifespan. So, how does one go about releasing a stuck ratchet strap? Let us delve into this intricate process in the sections that follow.

3.1 Releasing a Stuck Ratchet Strap

Sure, here's a 500-word paragraph on "3.1 Releasing a Stuck Ratchet Strap": It's a common issue that many users face: finding oneself with a jammed ratchet strap, where the mechanics have become stubbornly uncooperative. The frustration this can cause is understandable, especially when all you want to do is secure your valuable cargo. However, fear not — a stuck ratchet strap is not the end of world nor does it necessitate its disposal. In fact, understanding this prevalent issue and learning a few clever troubleshooting tricks can provide immense ease when dealing with this tool. So, how can you deal with such a predicament? First and foremost, it's crucial to maintain safety. Always ensure that the load is not excessively reliant on the ratchet strap before attempting to release it. A sudden release under high tension can lead not only to damage to the load, but can cause severe injury as well. To commence the process, it would help to apply a lubricant like WD-40 to the ratchet mechanism. Before doing so, wipe away any visible dirt or gunk using a cloth as it could be the culprit causing the jam. Spray the lubricant onto the ratcheting mechanism, ensuring you reach all its nooks and crannies. Let it soak in for a few minutes, this could help alleviate the issue. If the lubricant doesn't do the trick, it's time to employ some good old-fashioned brute force. But remember, do it with care. Try to keep the strap straight and aligned properly. Misalignment can often cause a strap to catch, preventing you from releasing the tension. Another common issue that confronts users is that the ratchet strap may not release because it's under excess tension. This often recurs when the ratchet strap is over-tightened. In order to solve this problem, you need to manually decrease the tension on the strap. You can do this by prying the teeth of the ratchet apart with a screwdriver. While pulling the ratchet handle, insert the screwdriver in between the teeth. The screwdriver acts as a lever, helping you to decrease the tension on the strap. In some scenarios, if the strap is still proving difficult to release, it could be due to a twist in the strap. Here, a careful inspection to locate the twist will help. Once located, feeding the strap back through the ratchet in the opposite direction can help unjam it. Finally, remember that while troubleshooting is effective, prevention is arguably more beneficial. Regular cleaning, proper handling, and storing of ratchet straps can prevent them from jamming. It's an aspect of maintenance that's essential but often overlooked. In conclusion, from applying a bit of lubricant to a dab of brute force, through to careful inspection, and proper storage, there's a multitude of ways to release a stuck ratchet strap. Troubleshooting doesn't have to be a daunting task — it just requires a bit of know-how and patience. So, the next time you're faced with a defiant ratchet strap, you will be equipped to handle the situation without panic or frustration. After all, understanding your tools is as important as any project they are used in.

3.2 Addressing Slippage and Loosening Problems

3.2 Addressing Slippage and Loosening Problems

As a pivotal part of the larger topic 'Troubleshooting Common Ratchet Strap Issues', addressing slippage and loosening problems plays a crucial role in maintaining the functionality of ratchet straps. It's a common issue owners face, yet one that can be mitigated with a proper understanding of the problem and effective solutions. Ratchet straps, like any other mechanical device, are subject to wear and tear which can lead to decreased efficiency and potential safety issues if not properly addressed. Notably among these issues are slippage and loosening problems, two common culprits that can be attributed to a variety of factors ranging from environmental conditions, improper handling, to the quality of materials used in the manufacture of the straps. Slippage in ratchet straps often indicates a lack of sufficient tension during the fastening process. This compromises the stability of the load being transported, making it prone to movement and potential damage. Similarly, loosening can occur over time due to gradual loss of friction, often as a result of repeated use or extended periods of heavy load bearing, meaning the strap loses its grip. However, these challenges can be tackled effectively. First, ensure you're using high-quality ratchet straps, made from durable materials that can withstand pressure and resist wear and tear. Regular inspection of the straps for signs of degradation is crucial. Look out for frayed edges, tears, or signs of rust on the metal parts. Further, when tightening the ratchet strap, apply adequate force to ensure a firm grip. Double-check the strap has been threaded properly through the ratchet mechanism. The strap should be flat and free of twists, which might reduce tension. If the straps continually loosen during use, considering using a 'locking' method such as the lock-off or back-off technique. In conclusion, addressing slippage and loosening problems in ratchet straps is a proactive measure that guarantees the longevity of the tool and the safety of the loads being handled. Hopefully, this information helps in improving the efficiency and durability of your ratchet straps, preventing future slippage and loosening issues effectively.3.3 Preventive Care and Maintenance Practices

Regular preventive care and maintenance practices can make all the difference when it comes to the longevity and reliability of ratchet straps. There are many proactive steps you can take to maintain the performance and extend the lifespan of these essential tools. Regular inspections are crucial to ensuring that your ratchet straps are in good working order. Look for signs of wear and tear, such as fraying, cracks, or rust. Any visible damage may weaken the strap and make it less effective at securing loads. If you spot these signs of wear, it's a clear indication that the strap needs to be replaced. Misusing the straps can also lead to complications. It's important to avoid pulling the strap at an angle as it can cause the ratchet to jam or the strap to snap. Keeping the ratchet straps clean is another preventive measure. Over time, dirt and grime can accumulate on the straps and in the ratchet mechanism, which can obstruct its function. Washing the straps with a mild detergent and drying them properly before storage can significantly increase their lifespan. Lastly, correct storage practices can drastically reduce the risk of ratchet strap issues. Always store your straps in a dry and cool place to avoid undue exposure to the weather elements, which can lead to material degradation. When properly looked after, your ratchet straps will not only last longer but also perform better. This not only helps you avoid the common ratchet strap issues but will also save you the cost and inconvenience of frequent replacements. Remember, effective preventive care and maintenance practices go a long way in guaranteeing the safety and efficiency of your operations with ratchet straps.