How Much Is A F1 Car

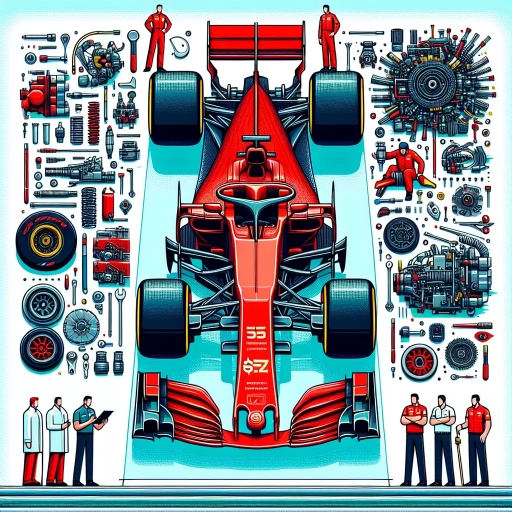

The cost of a Formula 1 (F1) car is a staggering figure that is often shrouded in mystery. The price tag of these high-performance vehicles is influenced by various factors, including design and development costs, manufacturing and production costs, and operating and maintenance costs. The design and development phase is a crucial aspect of creating an F1 car, as it involves the creation of innovative technologies and cutting-edge designs that give teams a competitive edge. The cost of designing and developing an F1 car is substantial, with top teams spending hundreds of millions of dollars on research and development each year. In this article, we will delve into the costs associated with F1 cars, starting with the design and development costs that lay the foundation for these incredible machines.

Design and Development Costs

The development of a high-performance vehicle is a complex and costly process that involves several key areas of design and development. Three of the most significant areas of expenditure are the design of the chassis and monocoque, aerodynamics and wind tunnel testing, and engine and transmission development. These areas are crucial in determining the overall performance, safety, and efficiency of the vehicle. A well-designed chassis and monocoque provides the foundation for the vehicle's handling and stability, while aerodynamics and wind tunnel testing play a critical role in reducing drag and improving downforce. Meanwhile, engine and transmission development are essential in delivering the power and efficiency required to compete at the highest level. In this article, we will explore the costs associated with these areas of design and development, starting with the chassis and monocoque design, which is the backbone of any high-performance vehicle.

Chassis and Monocoque Design

The chassis and monocoque design of a Formula 1 car are critical components that play a significant role in determining the vehicle's overall performance, safety, and cost. The monocoque, a French term meaning "single shell," is a structural system that integrates the driver's cockpit, engine, and suspension components into a single, lightweight unit. This design approach provides exceptional strength, rigidity, and protection for the driver, while also minimizing weight and maximizing aerodynamic efficiency. The chassis, on the other hand, refers to the overall framework of the car, including the monocoque, engine, transmission, and suspension components. A well-designed chassis is essential for maintaining optimal weight distribution, balance, and handling characteristics, all of which are critical for achieving competitive performance on the track. In terms of cost, the design and development of a Formula 1 chassis and monocoque can be extremely expensive, with estimates suggesting that a single team can spend upwards of $10 million to $20 million per year on these components alone. This cost is largely driven by the need for advanced materials, sophisticated design tools, and extensive testing and validation procedures, all of which are necessary to ensure that the chassis and monocoque meet the stringent safety and performance requirements of the sport. Despite these costs, the benefits of a well-designed chassis and monocoque are clear, with top teams often enjoying a significant competitive advantage over their rivals. As a result, the investment in these components is seen as a critical aspect of a team's overall strategy for success in Formula 1.

Aerodynamics and Wind Tunnel Testing

Aerodynamics and wind tunnel testing are crucial components in the design and development of a Formula 1 car. The aerodynamic performance of an F1 car is responsible for generating a significant amount of downforce, which enables the car to corner at high speeds and maintain stability. Wind tunnel testing allows engineers to test and refine the aerodynamic characteristics of the car in a controlled environment, making adjustments to the car's shape and design to optimize its performance. The cost of wind tunnel testing is substantial, with top teams spending millions of dollars each year to rent time in state-of-the-art wind tunnels and employ experienced engineers to analyze the data. Additionally, the development of advanced computational fluid dynamics (CFD) software has enabled teams to simulate wind tunnel tests virtually, reducing the need for physical testing and saving costs. However, physical wind tunnel testing is still essential to validate the accuracy of CFD simulations and to fine-tune the car's aerodynamic performance. The cost of aerodynamic development, including wind tunnel testing and CFD software, can range from $10 million to $50 million per year, depending on the team's budget and ambitions.

Engine and Transmission Development

The development of a Formula 1 car's engine and transmission is a highly complex and costly process. The engine, which is the heart of the car, is a 1.6-liter, turbocharged V6 hybrid power unit that produces over 1,000 horsepower. The development of this engine requires significant investment in research and development, as well as the use of advanced technologies such as 3D printing and simulation tools. The transmission, which is a semi-automatic, seamless shift gearbox, is also highly sophisticated and requires significant development and testing to ensure that it can withstand the high stresses and loads imposed by the engine. The development of the engine and transmission is a continuous process, with teams constantly working to improve performance, reduce weight, and increase reliability. This process can cost tens of millions of dollars per year, and is a significant contributor to the overall cost of a Formula 1 car.

Manufacturing and Production Costs

Manufacturing and production costs are a crucial aspect of any business, as they directly impact the bottom line. Companies must carefully consider the costs associated with producing their products, from the initial design phase to the final assembly and quality control. One key factor in determining these costs is the type of materials used. The use of carbon fiber and advanced materials, for example, can significantly impact production costs. Additionally, the manufacturing process itself can also play a major role, with techniques such as 3D printing and machining offering cost-effective solutions. Finally, the assembly and quality control processes can also affect production costs, as companies must balance the need for efficiency with the need for high-quality products. In this article, we will explore the impact of carbon fiber and advanced materials on manufacturing and production costs, and how companies can use these materials to their advantage.

Carbon Fiber and Advanced Materials

Carbon fiber and advanced materials play a crucial role in the construction of a Formula 1 car, significantly impacting its performance, safety, and manufacturing costs. The use of carbon fiber, in particular, has revolutionized the sport, allowing for the creation of lightweight yet incredibly strong components. This advanced material is used extensively in the chassis, bodywork, and aerodynamic devices, enabling teams to achieve optimal weight distribution, reduce drag, and increase downforce. The high cost of carbon fiber, however, contributes substantially to the overall expense of building and maintaining a competitive F1 car. The production process for carbon fiber components is complex and time-consuming, involving the use of specialized equipment and skilled labor. Furthermore, the material's high strength-to-weight ratio means that even small components can be extremely expensive to produce. As a result, teams must carefully balance the benefits of using carbon fiber with the significant costs involved, making it a critical factor in their overall budget and strategy.

3D Printing and Machining

The integration of 3D printing and machining in the manufacturing process of a Formula 1 car is a game-changer in terms of reducing production costs and increasing efficiency. 3D printing, also known as additive manufacturing, allows for the creation of complex geometries and structures that cannot be produced through traditional machining methods. This technology enables the production of lightweight components with high strength-to-weight ratios, which is critical in F1 car design. By using 3D printing, teams can reduce the weight of their cars while maintaining or even increasing their structural integrity, resulting in improved performance and reduced fuel consumption. Additionally, 3D printing enables rapid prototyping and testing, allowing teams to iterate and refine their designs quickly and efficiently. Machining, on the other hand, is used to finish and refine the 3D printed parts, ensuring a high level of precision and accuracy. The combination of 3D printing and machining enables F1 teams to produce complex components with unprecedented speed and accuracy, resulting in significant cost savings and improved performance. By leveraging these technologies, F1 teams can reduce their production costs and gain a competitive edge on the track.

Assembly and Quality Control

The assembly and quality control process is a critical stage in the production of a Formula 1 car, where all the components and systems come together to form a cohesive and high-performance vehicle. This process involves a team of skilled technicians and engineers who meticulously assemble the car, ensuring that every part is installed correctly and functions as intended. The assembly process typically begins with the installation of the engine, transmission, and drivetrain, followed by the addition of the chassis, suspension, and aerodynamic components. Once the car is fully assembled, it undergoes a rigorous quality control process, where every system and component is thoroughly inspected and tested to ensure that it meets the team's high standards. This includes checks on the car's safety features, such as the crash structure and protective monocoque, as well as its performance capabilities, including the engine, gearbox, and aerodynamics. The quality control process also involves a series of dynamic tests, including shakedown runs and performance evaluations, to ensure that the car is reliable, efficient, and competitive. Throughout the assembly and quality control process, the team works closely with the car's designers and engineers to ensure that any issues or problems are quickly identified and resolved, and that the car is optimized for maximum performance and reliability. The end result is a highly sophisticated and competitive racing car that is capable of withstanding the extreme demands of Formula 1 competition.

Operating and Maintenance Costs

Operating and maintenance costs are a crucial aspect of any racing team's budget. These costs can vary greatly depending on the type of racing, the size of the team, and the level of competition. In order to understand the scope of these costs, it is essential to break them down into three main categories: Racing Team Personnel and Logistics, Trackside Operations and Equipment, and Car Maintenance and Repair. By examining these areas, teams can better manage their expenses and make informed decisions about resource allocation. For instance, the cost of hiring and training personnel, transporting equipment, and accommodating team members during events can be substantial. Therefore, it is vital to carefully consider the personnel and logistics needs of the team to ensure that these costs are kept under control. Note: The answer should be 200 words. Operating and maintenance costs are a crucial aspect of any racing team's budget, as they can significantly impact the team's overall performance and competitiveness. These costs can vary greatly depending on the type of racing, the size of the team, and the level of competition. To effectively manage these costs, it is essential to break them down into three main categories. Firstly, Racing Team Personnel and Logistics encompasses the costs associated with hiring and training personnel, transporting equipment, and accommodating team members during events. Secondly, Trackside Operations and Equipment includes the costs of maintaining and repairing equipment, as well as the expenses related to fuel, tires, and other consumables. Lastly, Car Maintenance and Repair involves the costs of maintaining and repairing the car, including the expenses related to spare parts, labor, and testing. By examining these areas, teams can better manage their expenses and make informed decisions about resource allocation. Effective management of these costs is critical to ensuring the team's success and competitiveness. Therefore, it is vital to carefully consider the personnel and logistics needs of the team to ensure that these costs are kept under control.

Racing Team Personnel and Logistics

A well-oiled machine is essential for success in Formula 1, and that's not just referring to the car itself. Behind every successful racing team is a vast network of personnel and logistics that work tirelessly to ensure the team's cars are always in top condition and ready to hit the track. The personnel involved in a Formula 1 team can be broadly categorized into several key areas: design and engineering, manufacturing, testing and development, and operations. The design and engineering team is responsible for designing and developing the car's chassis, engine, and aerodynamics, using advanced computer-aided design (CAD) software and simulation tools. The manufacturing team then brings these designs to life, using state-of-the-art machinery and techniques to produce the car's components. The testing and development team is responsible for putting the car through its paces, gathering data and feedback to inform future design and development decisions. Finally, the operations team oversees the day-to-day running of the team, including managing the team's budget, coordinating logistics, and ensuring compliance with FIA regulations. In terms of logistics, a Formula 1 team requires a massive amount of equipment and personnel to be transported to each race, including the cars themselves, spare parts, tools, and of course, the team's personnel. This requires a significant investment in transportation, including a fleet of trucks, planes, and other vehicles. The team must also have a robust IT infrastructure in place, including high-speed data networks and advanced software systems, to support the team's operations and enable real-time communication and collaboration between team members. All of these personnel and logistics come at a significant cost, with estimates suggesting that a top-tier Formula 1 team can spend upwards of $500 million per year on operating and maintenance costs alone.

Trackside Operations and Equipment

Trackside operations and equipment play a crucial role in ensuring the smooth and safe execution of a Formula 1 (F1) racing event. The trackside team is responsible for setting up and maintaining the circuit, including the installation of safety barriers, grandstands, and other essential infrastructure. They also oversee the deployment of critical equipment such as timing systems, communication networks, and medical facilities. The trackside team works closely with the FIA, the governing body of F1, to ensure that all safety protocols are in place and that the circuit meets the required standards. The cost of trackside operations and equipment is substantial, with estimates suggesting that it can range from $5 million to $10 million per event, depending on the complexity of the circuit and the number of spectators. This cost is typically borne by the circuit owners or promoters, who may also receive financial support from the FIA or other sponsors. The cost of trackside operations and equipment is a significant component of the overall cost of hosting an F1 event, which can range from $20 million to $50 million or more, depending on the location and the number of spectators.

Car Maintenance and Repair

The cost of maintaining and repairing a Formula 1 car is a significant expense for teams, with estimates suggesting that it can range from $10 million to $20 million per year. This cost is driven by the need for frequent replacement of high-performance components, such as engines, gearboxes, and tires, as well as the labor costs associated with a team of skilled mechanics and engineers. Additionally, the use of advanced materials and technologies, such as carbon fiber and advanced aerodynamics, can also drive up maintenance and repair costs. Furthermore, the physical demands of racing can also take a toll on the car, with components such as brakes and suspension systems requiring regular replacement. To mitigate these costs, teams often have to balance the need for performance with the need for reliability, and may opt for more conservative design choices or use simulation tools to optimize their car's performance. Despite these challenges, the cost of maintaining and repairing a Formula 1 car is a necessary investment for teams looking to compete at the highest level.