How To Measure Resistance

Measuring resistance is a fundamental concept in electronics and electrical engineering, and it's essential to understand the basics of resistance measurement to work with circuits and devices effectively. Resistance is a measure of the opposition to the flow of electric current, and it's a critical parameter in designing and troubleshooting electrical systems. To measure resistance accurately, you need to understand the underlying principles, choose the right methods, and follow best practices to ensure safety and reliability. In this article, we'll delve into the world of resistance measurement, starting with the basics of resistance and how it's defined. We'll explore the different methods for measuring resistance, including the use of multimeters and other specialized tools. Finally, we'll discuss the best practices and safety precautions to keep in mind when working with electrical systems. By understanding the basics of resistance measurement, you'll be well-equipped to tackle a wide range of electrical projects and applications. Understanding the Basics of Resistance Measurement is the first step in this journey, and it's where we'll begin.

Understanding the Basics of Resistance Measurement

Resistance measurement is a fundamental concept in electrical engineering, crucial for understanding the behavior of electrical circuits. It is essential to grasp the basics of resistance measurement to design, analyze, and troubleshoot electrical systems efficiently. In this article, we will delve into the world of resistance measurement, exploring its importance, types, and key concepts. We will start by defining resistance and its significance in electrical circuits, followed by an examination of the different types of resistance, including ohmic and non-ohmic. Additionally, we will discuss the key concepts of voltage, current, and power, which are intricately linked to resistance measurement. By understanding these fundamental principles, engineers and technicians can ensure the safe and efficient operation of electrical systems. Let's begin by defining resistance and its importance in electrical circuits.

Defining Resistance and Its Importance in Electrical Circuits

Resistance is a fundamental concept in electrical circuits, referring to the opposition to the flow of electric current. It is measured in ohms (Ω) and is a critical parameter in determining the behavior of electrical circuits. In essence, resistance is a measure of how much a material or component resists the flow of electric current. The higher the resistance, the lower the current that flows through it, and vice versa. Understanding resistance is crucial in designing and analyzing electrical circuits, as it directly affects the voltage, current, and power dissipation in a circuit. Resistance is also a key factor in determining the efficiency and safety of electrical systems, as excessive resistance can lead to overheating, energy loss, and even electrical fires. In contrast, too little resistance can result in excessive current flow, causing damage to components and posing a risk to users. Therefore, accurately measuring resistance is essential in ensuring the proper functioning and safety of electrical circuits, making it a vital aspect of electrical engineering and electronics.

Types of Resistance: Ohmic and Non-Ohmic

Resistance is a fundamental property of materials that opposes the flow of electric current. There are two primary types of resistance: ohmic and non-ohmic. Ohmic resistance, also known as linear resistance, is a type of resistance that remains constant regardless of the voltage applied across it. This type of resistance is typically found in materials such as copper, aluminum, and other metals. Ohmic resistance is characterized by a linear relationship between voltage and current, meaning that as the voltage increases, the current also increases proportionally. This relationship is described by Ohm's Law, which states that current (I) is equal to voltage (V) divided by resistance (R): I = V/R. Ohmic resistance is commonly found in devices such as resistors, which are designed to provide a specific amount of resistance in a circuit. On the other hand, non-ohmic resistance, also known as nonlinear resistance, is a type of resistance that changes depending on the voltage applied across it. This type of resistance is typically found in materials such as semiconductors, thermistors, and varistors. Non-ohmic resistance is characterized by a nonlinear relationship between voltage and current, meaning that as the voltage increases, the current does not increase proportionally. This type of resistance is often used in devices such as diodes, transistors, and other semiconductor devices, which are designed to control the flow of current in a circuit. Understanding the difference between ohmic and non-ohmic resistance is crucial in designing and analyzing electronic circuits, as it can significantly impact the performance and behavior of the circuit.

Key Concepts: Voltage, Current, and Power

Voltage, current, and power are fundamental concepts in understanding the basics of resistance measurement. Voltage, measured in volts (V), is the potential difference between two points in a circuit, driving electric current from one point to another. Current, measured in amperes (A), is the flow of electric charge, typically carried by electrons, through a conductor. Power, measured in watts (W), is the rate at which electrical energy is transferred by an electric circuit. The relationship between these three concepts is governed by Ohm's Law, which states that voltage (V) is equal to current (I) multiplied by resistance (R). Understanding these concepts is crucial in measuring resistance, as it allows for the calculation of resistance using the measured voltage and current. For instance, if the voltage and current are known, the resistance can be calculated using the formula R = V/I. Conversely, if the resistance and voltage are known, the current can be calculated using the formula I = V/R. This interplay between voltage, current, and power is essential in understanding the behavior of electric circuits and accurately measuring resistance.

Methods for Measuring Resistance

Measuring resistance is a crucial aspect of electrical engineering and electronics. It is essential to determine the resistance of a component or circuit to ensure it functions correctly and efficiently. There are several methods for measuring resistance, each with its own advantages and limitations. In this article, we will explore three primary methods for measuring resistance: using a multimeter, bridge circuits, and alternative methods such as ohmmeters and resistance meters. We will begin by discussing the step-by-step process of using a multimeter, a widely used and versatile tool for measuring resistance. By following this guide, you will be able to accurately measure resistance and troubleshoot electrical circuits with confidence. Using a multimeter is a fundamental skill for any electrical engineer or electronics enthusiast, and it is an essential tool for measuring resistance in a variety of applications. Let's start with the basics of using a multimeter to measure resistance.

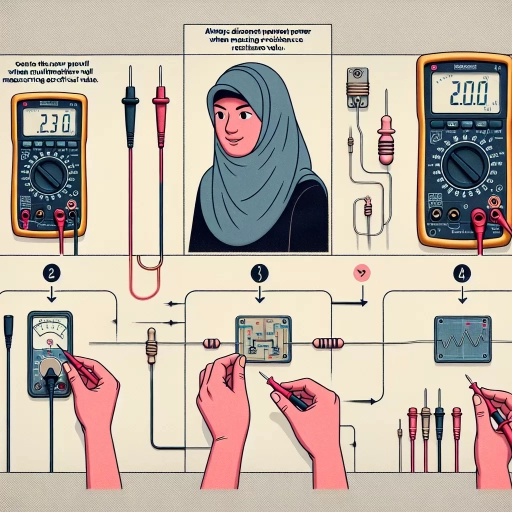

Using a Multimeter: A Step-by-Step Guide

Using a multimeter is a straightforward process that requires attention to detail and a basic understanding of electrical measurements. To start, ensure the multimeter is set to the correct function, in this case, the ohms (Ω) or resistance setting. Next, choose the appropriate range for the expected resistance value, taking into account the type of component or circuit being measured. For example, if measuring the resistance of a small resistor, a lower range such as 200Ω or 2kΩ may be suitable, while a higher range like 20kΩ or 200kΩ may be needed for larger resistors or circuits with higher resistance values. Once the range is selected, touch the multimeter's probes to the component or circuit, ensuring good contact and avoiding any short circuits. Take note of the displayed reading, which may be in ohms (Ω), kilohms (kΩ), or megohms (MΩ), and record the value for future reference. It's also essential to consider the multimeter's accuracy and any potential sources of error, such as lead resistance or parasitic capacitance, which can affect the measurement. By following these steps and taking the necessary precautions, you can obtain accurate and reliable resistance measurements using a multimeter.

Bridge Circuits: Wheatstone and Kelvin Bridges

Bridge circuits are a type of electrical circuit used to measure resistance, and they are commonly employed in various applications, including laboratory settings and industrial environments. Two of the most widely used bridge circuits are the Wheatstone bridge and the Kelvin bridge. The Wheatstone bridge is a simple and versatile circuit that consists of four resistors arranged in a diamond configuration, with a voltage source connected across two opposite corners and a null detector connected across the other two corners. By adjusting the value of one of the resistors, the voltage across the null detector can be made to zero, indicating that the ratio of the resistances in the two arms of the bridge is equal to the ratio of the resistances in the other two arms. This allows for the measurement of an unknown resistance by comparing it to a known resistance. The Kelvin bridge, on the other hand, is a more complex circuit that is used to measure very low resistances, typically in the range of milliohms or microohms. It consists of a four-terminal resistor and a voltage source, and it uses a technique called "four-terminal sensing" to eliminate the effects of lead resistance and other errors. The Kelvin bridge is commonly used in applications such as measuring the resistance of electrical contacts, switches, and connectors. Both the Wheatstone and Kelvin bridges are widely used in various industries, including aerospace, automotive, and medical devices, due to their high accuracy and reliability.

Alternative Methods: Ohmmeters and Resistance Meters

When it comes to measuring resistance, there are alternative methods that can be employed, particularly in situations where a multimeter is not available or practical. Ohmmeters and resistance meters are specialized instruments designed specifically for measuring resistance, offering a more straightforward and often more accurate approach. An ohmmeter is a device that measures electrical resistance by applying a known voltage to the circuit and measuring the resulting current. The resistance is then calculated using Ohm's law, which states that resistance equals voltage divided by current. Ohmmeters are commonly used for measuring resistance in low-voltage applications, such as in electronics and automotive systems. On the other hand, a resistance meter is a more advanced device that uses a variety of techniques, including bridge circuits and pulse-width modulation, to measure resistance. Resistance meters are often used in high-precision applications, such as in laboratory settings and industrial process control. Both ohmmeters and resistance meters offer a range of benefits, including high accuracy, fast measurement times, and the ability to measure resistance in a variety of units, including ohms, kilohms, and megohms. Additionally, many modern ohmmeters and resistance meters are digital, providing a clear and easy-to-read display of the measured resistance value. Overall, ohmmeters and resistance meters are valuable tools for anyone who needs to measure resistance, offering a reliable and efficient way to obtain accurate results.

Best Practices and Safety Precautions

When it comes to best practices and safety precautions in various industries, it is essential to prioritize accuracy, safety, and efficiency. To achieve these goals, it is crucial to follow established guidelines and protocols. In this article, we will discuss three critical aspects of best practices and safety precautions: ensuring accuracy through calibration and error reduction, handling electrical components and equipment safely, and troubleshooting common issues and errors. By understanding and implementing these best practices, individuals can minimize risks, prevent accidents, and optimize their work processes. Ensuring accuracy is a fundamental aspect of many industries, and calibration plays a critical role in achieving this goal. By calibrating equipment and instruments regularly, individuals can reduce errors and ensure that their work is accurate and reliable. In the next section, we will delve into the importance of calibration and error reduction, exploring the best practices and techniques for ensuring accuracy in various industries.

Ensuring Accuracy: Calibration and Error Reduction

Ensuring accuracy in resistance measurement is crucial to obtain reliable results. Calibration and error reduction are essential steps to guarantee the precision of the measurements. Calibration involves adjusting the multimeter to match the known resistance of a standard resistor, ensuring that the device is functioning correctly. This process helps to eliminate any systematic errors that may arise from the instrument itself. Error reduction, on the other hand, involves minimizing the impact of external factors that can affect the measurement, such as temperature fluctuations, electromagnetic interference, and lead resistance. To reduce errors, it is recommended to use high-quality test leads, keep the measurement area clean and dry, and avoid touching the test leads or the device being measured. Additionally, using a multimeter with a high degree of accuracy and a low input impedance can also help to minimize errors. By following these best practices, users can ensure that their resistance measurements are accurate and reliable, which is critical in a wide range of applications, from electronics design and manufacturing to quality control and troubleshooting.

Safety First: Handling Electrical Components and Equipment

When handling electrical components and equipment, safety should always be the top priority. Electrical shock, electrocution, and even death can occur if proper precautions are not taken. To ensure a safe working environment, it is essential to follow best practices and safety precautions when handling electrical components and equipment. First and foremost, always turn off the power supply to the circuit or device before starting work. Verify that the power is off using a multimeter or other testing device to ensure there is no voltage present. Next, wear personal protective equipment (PPE) such as insulated gloves, safety glasses, and a face mask to prevent electrical shock and injury from flying debris. Additionally, use insulated tools and equipment to prevent electrical shock and ensure a safe working environment. It is also crucial to follow proper lockout/tagout procedures to prevent accidental start-up of equipment. Furthermore, ensure that all electrical components and equipment are properly grounded and bonded to prevent electrical shock and ensure a safe working environment. Finally, always follow the manufacturer's instructions and guidelines for handling and testing electrical components and equipment, and never attempt to repair or modify electrical equipment without proper training and authorization. By following these best practices and safety precautions, individuals can minimize the risk of electrical shock and ensure a safe working environment when handling electrical components and equipment.

Troubleshooting Common Issues and Errors

When troubleshooting common issues and errors in resistance measurement, it's essential to follow a systematic approach to identify and resolve the problem efficiently. First, ensure that the multimeter is set to the correct function and range for the measurement. Check the leads and connections for any signs of damage, wear, or corrosion, and replace them if necessary. Verify that the test leads are properly connected to the circuit or component being measured, and that the multimeter is not in contact with any other conductive surfaces. If the measurement is inconsistent or inaccurate, try reversing the test leads to rule out any polarity issues. Additionally, check for any loose connections or solder joints, and ensure that the circuit is powered off before taking measurements. If the issue persists, consult the multimeter's user manual or contact the manufacturer's technical support for further assistance. By following these steps, you can quickly identify and resolve common issues and errors, ensuring accurate and reliable resistance measurements.