How To Make A Pipe

Here is the introduction paragraph: Making a pipe can be a fun and rewarding DIY project, allowing you to create a unique and personalized smoking experience. To get started, it's essential to understand the basics of pipe making, including the different types of materials and tools required. Once you have a solid foundation, you can begin designing and planning your pipe, taking into account factors such as shape, size, and functionality. Finally, with a clear plan in place, you can start assembling and finishing your pipe, adding the final touches to create a beautiful and functional piece. In this article, we'll take a closer look at the process of making a pipe, starting with the fundamentals. Understanding the Basics of Pipe Making is the first step in creating a high-quality pipe, and it's where we'll begin our journey.

Understanding the Basics of Pipe Making

Pipe making is a complex process that requires a deep understanding of various factors, including the materials used, the type of pipe being made, and the tools required for the job. To create a high-quality pipe, it's essential to start with the basics and work your way up. This article will delve into the fundamentals of pipe making, covering the essential aspects that every pipe maker should know. We'll explore the importance of choosing the right materials for your pipe, understanding the different types of pipes, and familiarizing yourself with the necessary tools. By the end of this article, you'll have a solid foundation in pipe making and be well on your way to creating your own high-quality pipes. So, let's start with the first crucial step: choosing the right materials for your pipe.

Choosing the Right Materials for Your Pipe

When it comes to choosing the right materials for your pipe, there are several factors to consider. The type of material you choose will affect the durability, functionality, and overall aesthetic of your pipe. Here are some common materials used for pipe making, each with their own unique characteristics. Briar wood is a popular choice for pipe making due to its durability and resistance to heat. It is also a natural, sustainable material that can be sourced from various parts of the world. However, briar wood can be expensive and may require additional processing to achieve the desired shape and texture. Corncob pipes, on the other hand, are a more affordable option and are often used for casual, everyday smoking. They are lightweight, easy to clean, and can be made from a variety of materials, including wood, plastic, and metal. Metal pipes, such as those made from aluminum or stainless steel, are durable and resistant to corrosion. They are also easy to clean and can be made in a variety of shapes and sizes. However, metal pipes can be prone to overheating and may not provide the same level of flavor and aroma as other materials. Meerschaum pipes are made from a type of white mineral that is prized for its ability to absorb moisture and odors. They are often used for smoking tobacco and are known for their cool, dry smoke. However, meerschaum pipes can be fragile and may require special care to maintain their shape and texture. Ultimately, the right material for your pipe will depend on your personal preferences, smoking habits, and budget. By considering the unique characteristics of each material, you can choose a pipe that meets your needs and provides a enjoyable smoking experience.

Understanding the Different Types of Pipes

When it comes to pipe making, understanding the different types of pipes is crucial. There are several types of pipes, each with its own unique characteristics, advantages, and disadvantages. The most common types of pipes include metal pipes, PVC pipes, copper pipes, and glass pipes. Metal pipes are durable and can withstand high water pressure, but they can be prone to corrosion and are often noisy. PVC pipes, on the other hand, are resistant to corrosion and are quieter than metal pipes, but they can be prone to cracking and are not suitable for high-temperature applications. Copper pipes are a popular choice for plumbing due to their durability and resistance to corrosion, but they can be expensive and require soldering. Glass pipes, also known as borosilicate pipes, are non-toxic and resistant to corrosion, but they can be fragile and require careful handling. Additionally, there are also other types of pipes such as clay pipes, concrete pipes, and fiberglass pipes, each with their own unique characteristics and uses. Understanding the different types of pipes and their properties is essential for pipe makers to choose the right material for their project and ensure a safe and functional pipe.

Familiarizing Yourself with Pipe Making Tools

Familiarizing yourself with pipe making tools is a crucial step in the pipe making process. To start, you'll need a few essential tools, including a pipe cutter, a drill press, a sanding drum, and a metal file. A pipe cutter is used to cut the pipe to the desired length, while a drill press is used to create holes for the stem and mouthpiece. A sanding drum is used to smooth out the pipe's surface, and a metal file is used to shape and refine the pipe's edges. Additionally, you may also need a pipe reamer, a pipe scraper, and a pipe buffing wheel to further refine and polish the pipe. It's also important to note that the quality of your tools can greatly impact the quality of your finished pipe, so it's worth investing in high-quality tools. By familiarizing yourself with these tools and practicing their use, you'll be well on your way to creating a high-quality, functional pipe.

Designing and Planning Your Pipe

Designing and planning your pipe is a crucial step in ensuring a functional and efficient plumbing system. When it comes to creating a well-designed pipe, there are several key factors to consider. First, it's essential to sketch out your pipe design, taking into account the layout of your space and the specific needs of your plumbing system. This will help you visualize the flow of water and identify any potential issues. Additionally, considering the functionality of your pipe is vital, as it will impact the overall performance of your plumbing system. This includes thinking about the type of pipe material to use, the size and shape of the pipe, and the location of fittings and valves. Finally, measuring and calculating pipe dimensions is critical to ensure a proper fit and prevent leaks. By taking the time to carefully plan and design your pipe, you can avoid costly mistakes and ensure a reliable plumbing system. To get started, let's begin by sketching out your pipe design.

Sketching Out Your Pipe Design

When sketching out your pipe design, it's essential to consider the functionality and aesthetics of the final product. Start by brainstorming the type of pipe you want to create, such as a simple hand pipe or a more complex water pipe. Think about the materials you'll use, such as glass, metal, or wood, and how they'll impact the overall design. Consider the size and shape of the pipe, as well as any features you want to include, like a carb hole or a built-in screen. Make a rough sketch of your design, using simple shapes and lines to get a sense of the overall layout. Don't worry too much about proportions or details at this stage – just focus on getting your ideas down on paper. As you refine your design, think about the flow of smoke and how the user will interact with the pipe. Consider the ergonomics of the design, making sure it's comfortable to hold and use. You may also want to research existing pipe designs for inspiration and to get a sense of what works well and what doesn't. Once you have a solid design concept, you can start thinking about the technical aspects of bringing your pipe to life, such as the materials and tools you'll need, and the steps involved in the construction process. By taking the time to carefully sketch out your pipe design, you'll be able to create a functional and visually appealing pipe that meets your needs and exceeds your expectations.

Considering the Functionality of Your Pipe

When designing and planning your pipe, it's essential to consider its functionality. Think about how you intend to use your pipe and what features are necessary to enhance your smoking experience. For instance, if you plan to use your pipe for dry herbs, you may want to include a built-in grinder or a storage compartment for your herbs. On the other hand, if you prefer to smoke concentrates, you may want to incorporate a dab rig or a reclaim catcher. Additionally, consider the size and portability of your pipe, as well as the material it's made of. If you plan to take your pipe on-the-go, you may want to opt for a smaller, more durable design. You should also think about the airflow and filtration system, as a well-designed pipe can provide a smoother, more enjoyable hit. By considering the functionality of your pipe, you can create a customized smoking experience that meets your specific needs and preferences.

Measuring and Calculating Pipe Dimensions

When it comes to designing and planning your pipe, measuring and calculating pipe dimensions is a crucial step. To ensure a proper fit and function, you need to accurately measure the length, diameter, and wall thickness of your pipe. Start by measuring the length of your pipe using a ruler or tape measure, taking into account any bends or curves. Next, measure the diameter of your pipe using a caliper or micrometer, making sure to record the measurement in inches or millimeters. It's also essential to measure the wall thickness of your pipe, which can be done using a caliper or by consulting the manufacturer's specifications. Once you have these measurements, you can use them to calculate the volume and flow rate of your pipe. For example, you can use the formula V = πr^2h to calculate the volume of a cylindrical pipe, where V is the volume, π is a constant, r is the radius, and h is the height. Similarly, you can use the formula Q = A \* v to calculate the flow rate, where Q is the flow rate, A is the cross-sectional area, and v is the velocity. By accurately measuring and calculating your pipe dimensions, you can ensure a safe and efficient pipe system that meets your specific needs.

Assembling and Finishing Your Pipe

Assembling and finishing your pipe is a crucial step in ensuring its durability and functionality. To achieve a high-quality pipe, it's essential to follow a series of steps that involve cutting and shaping pipe components, assembling the pipe using adhesives and fasteners, and applying finishing touches. By mastering these techniques, you can create a pipe that meets your specific needs and requirements. In this article, we will delve into the world of pipe assembly and finishing, providing you with the knowledge and skills necessary to create a top-notch pipe. First, we will explore the process of cutting and shaping pipe components, which is a critical step in preparing your pipe for assembly. (Note: The supporting paragraph should be 200 words and the last sentence should be a transition to the first supporting paragraph)

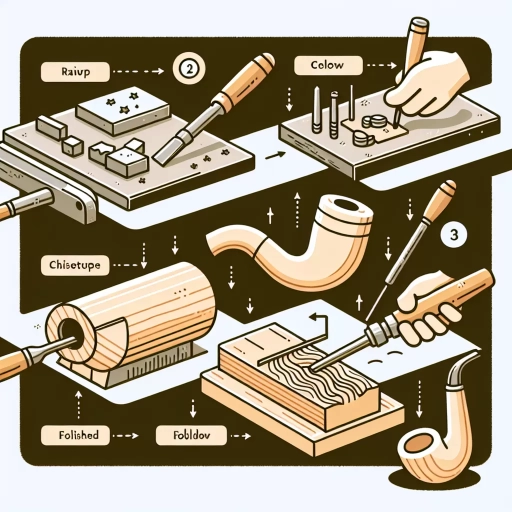

Cutting and Shaping Pipe Components

Cutting and shaping pipe components is a crucial step in the pipe-making process. To achieve a precise cut, use a pipe cutter or a hacksaw, depending on the type of pipe material. For metal pipes, a pipe cutter is ideal, while a hacksaw is better suited for plastic or PVC pipes. When using a pipe cutter, ensure the pipe is securely held in place and the cutter is adjusted to the correct size. For a hacksaw, use a miter box or a guide to maintain a straight cut. To shape the pipe, use a pipe bender or a heat gun, depending on the desired shape and material. A pipe bender is perfect for creating smooth, curved bends, while a heat gun is ideal for shaping metal pipes into complex forms. Always follow safety guidelines when working with power tools and heat sources. Additionally, use a deburring tool to remove any sharp edges or burrs from the cut pipe, ensuring a smooth finish and safe handling. By carefully cutting and shaping your pipe components, you'll be able to create a functional and visually appealing pipe that meets your needs.

Assembling the Pipe Using Adhesives and Fasteners

Assembling the pipe using adhesives and fasteners is a crucial step in creating a functional and durable pipe. To begin, apply a small amount of adhesive, such as epoxy or pipe cement, to the ends of the pipe sections and fittings. Make sure to follow the manufacturer's instructions for the recommended amount and application method. Next, carefully align the pipe sections and fittings, ensuring they are properly seated and aligned. Use a clamp or other holding device to secure the pieces in place while the adhesive sets. For added strength and security, use fasteners such as pipe clips, straps, or bands to reinforce the connections. These fasteners can be tightened to provide additional support and prevent leaks. It's essential to tighten the fasteners in a star pattern to avoid applying uneven pressure, which can cause damage to the pipe or fittings. Once the adhesive has fully set and the fasteners are securely in place, inspect the pipe for any signs of leaks or damage. If necessary, apply additional adhesive or tighten the fasteners to ensure a secure and watertight connection. By following these steps and using the right adhesives and fasteners, you can create a strong and reliable pipe that will withstand the test of time.

Applying Finishing Touches to Your Pipe

Applying the finishing touches to your pipe is the final step in bringing your project to life. This stage involves adding the last details that will enhance the appearance and functionality of your pipe. Start by sanding the entire pipe to smooth out any rough edges or burrs, ensuring a comfortable grip and even surface. Next, apply a finish, such as a wood sealant or wax, to protect the material and bring out the natural colors and textures. If desired, add decorative elements like metal bands, engravings, or carvings to give your pipe a personalized touch. Finally, inspect your pipe for any imperfections and make any necessary adjustments before declaring it complete. With these finishing touches, your pipe is now ready for use, and with proper care, it will provide you with years of enjoyment.