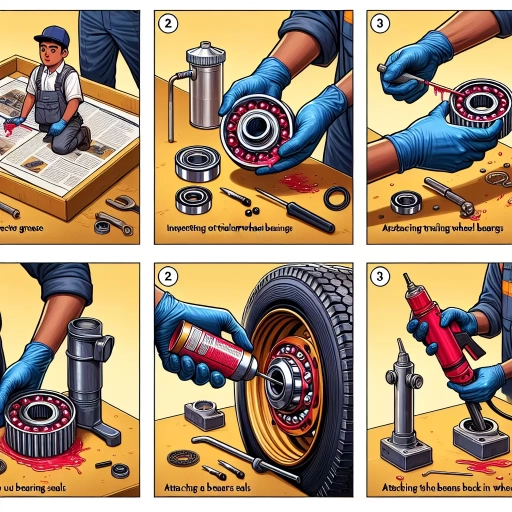

How To Grease Trailer Wheel Bearings

Here is the introduction paragraph: Properly greasing trailer wheel bearings is a crucial maintenance task that can help prevent costly repairs, ensure safety on the road, and prolong the lifespan of your trailer. However, many trailer owners are unsure about how to perform this task effectively. In this article, we will guide you through the process of greasing trailer wheel bearings, highlighting the importance of preparation, the step-by-step greasing process, and the final checks and maintenance required to keep your trailer running smoothly. To start, preparation is key to a successful greasing process, and in the next section, we will discuss the essential steps to take before you begin.

Preparation is Key

Preparation is key when it comes to maintaining your trailer's wheel bearings. A well-maintained wheel bearing can make all the difference in ensuring a smooth and safe towing experience. To achieve this, there are several steps you need to take. Firstly, you need to choose the right grease for your wheel bearings, as using the wrong type can lead to premature wear and tear. Once you have the right grease, you can then proceed to jack up the trailer and remove the wheels, giving you access to the wheel bearings. Finally, you will need to remove the hub cap and grease seal to inspect and repack the bearings. By following these steps, you can ensure that your trailer's wheel bearings are properly maintained, reducing the risk of breakdowns and accidents. With the right preparation, you can enjoy a hassle-free towing experience. So, let's start with the first step: choosing the right grease.

Choose the Right Grease

When it comes to choosing the right grease for your trailer wheel bearings, there are several factors to consider. The type of grease you choose will depend on the operating conditions of your trailer, including the temperature range, load, and speed. For most trailer applications, a high-quality, lithium-based grease is a good choice. This type of grease provides excellent lubrication and protection against corrosion and wear. However, if you plan to use your trailer in extreme temperatures, you may need to choose a grease that is specifically designed for high or low temperatures. Some greases are also designed for use in high-load or high-speed applications, so be sure to choose a grease that meets the demands of your trailer. Additionally, consider the compatibility of the grease with the materials used in your trailer's wheel bearings, such as steel or ceramic. By choosing the right grease for your trailer wheel bearings, you can help ensure smooth operation, reduce wear and tear, and extend the life of your bearings.

Jack Up the Trailer and Remove the Wheels

Jack up the trailer and remove the wheels. This is the first step in greasing trailer wheel bearings. Before you start, make sure the trailer is on a level surface and apply the parking brake. Next, position a jack under the trailer's axle and raise it until the wheel is off the ground. Remove the lug nuts and take off the wheel. Repeat this process for the other wheels. Once the wheels are removed, you'll have access to the wheel bearings. Make sure to set the wheels aside in a safe place where they won't get damaged or lost. It's also a good idea to take a picture of the wheel and hub assembly before you start, so you can refer to it later when you're reassembling everything.

Remove the Hub Cap and Grease Seal

Here is the paragraphy: Remove the hub cap and grease seal to access the bearings. The hub cap is usually held in place by a cotter pin or a screw. Remove the cotter pin or screw to release the hub cap. Once the hub cap is removed, you'll see the grease seal. Use a seal puller to remove the grease seal, taking care not to damage the seal or the hub. If the seal is stuck, you can use a little bit of penetrating oil to help loosen it. Once the seal is removed, you'll have access to the bearings and can begin the greasing process.

The Greasing Process

The greasing process is a crucial maintenance task that helps to extend the lifespan of bearings and other moving parts in machinery and vehicles. It involves the application of new grease to replace old, worn-out grease that has lost its lubricating properties. The process typically consists of three main steps: removing the old grease and debris, packing the new grease into the bearing, and reassembling the hub and applying a new grease seal. By following these steps, individuals can ensure that their machinery and vehicles continue to run smoothly and efficiently. In this article, we will delve into the details of each step, starting with the removal of old grease and debris, which is a critical first step in the greasing process.

Remove the Old Grease and Debris

The first step in the greasing process is to remove the old grease and debris from the wheel bearings. This is a crucial step as it ensures that the new grease can penetrate the bearings properly and do its job effectively. To remove the old grease, start by using a rag or paper towels to wipe away any excess grease from the outside of the bearings. Next, use a grease solvent or a degreaser to break down the old grease and debris. Apply the solvent to the bearings and let it sit for a few minutes to allow it to penetrate and loosen the old grease. Then, use a brush or a cloth to scrub away the old grease and debris from the bearings. Be sure to clean the bearings thoroughly, paying particular attention to the areas around the seals and the bearing caps. Once you have removed the old grease and debris, use a clean rag or paper towels to wipe away any remaining solvent or debris. This will ensure that the bearings are clean and free of any contaminants that could interfere with the new grease. By removing the old grease and debris, you are creating a clean slate for the new grease to adhere to, which will help to ensure that the bearings are properly lubricated and will run smoothly and quietly.

Pack the New Grease into the Bearing

When it comes to packing the new grease into the bearing, it's essential to do it correctly to ensure the longevity and smooth operation of your trailer's wheel bearings. To start, take a small amount of grease and place it in the palm of your hand. Then, use your thumb to work the grease into the bearing, making sure to fill all the spaces between the rollers and the bearing's inner and outer rings. Be careful not to overfill the bearing, as this can cause the grease to be pushed out during operation, leading to a mess and potentially damaging the surrounding components. Instead, aim to fill the bearing about 1/2 to 2/3 full, leaving enough space for the grease to expand when the bearing is in use. As you pack the grease, use a gentle pressing motion to ensure it's evenly distributed and not just sitting on the surface. You can also use a grease packer or a bearing packer tool to help get the grease into the tight spaces and ensure it's properly seated. Once you've packed the grease, use a clean rag to wipe away any excess that may have squeezed out during the process. By following these steps, you'll be able to properly pack the new grease into the bearing, providing your trailer's wheel bearings with the lubrication they need to run smoothly and efficiently.

Reassemble the Hub and Apply New Grease Seal

Here is the paragraphy: Reassembling the hub and applying a new grease seal is the final step in the greasing process. Once the new grease has been applied to the bearings, it's time to put everything back together. Start by sliding the hub back onto the spindle, making sure it's properly seated and aligned. Next, apply a thin layer of grease to the seal and slide it into place, ensuring it's securely seated in the hub. Tighten the castle nut in a star pattern to avoid damaging the bearings or the seal. Finally, tighten the cotter pin to secure the castle nut in place. It's essential to ensure the seal is properly seated and the castle nut is tightened correctly to prevent grease from leaking out and contaminants from entering the hub. A properly reassembled hub with a new grease seal will ensure the bearings continue to run smoothly and prolong the life of the trailer's wheel bearings.

Final Checks and Maintenance

Before towing a trailer, it's essential to perform final checks and maintenance to ensure a safe and successful trip. This includes lowering the trailer and tightening the lug nuts, checking the wheel bearings for proper function, and regularly inspecting and maintaining the wheel bearings. By doing so, you can prevent potential issues and ensure your trailer is in good working condition. In this article, we will discuss the importance of these final checks and maintenance tasks, starting with the crucial step of lowering the trailer and tightening the lug nuts.

Lower the Trailer and Tighten the Lug Nuts

Lower the trailer and tighten the lug nuts. Once the bearings are greased, it's time to lower the trailer to the ground and tighten the lug nuts in a star pattern. Make sure they are snug but do not overtighten, as this can damage the wheel bearings. Check the lug nuts again after driving for a few miles to ensure they are still tight. Additionally, it's a good idea to check the tire pressure and make any necessary adjustments. Proper tire pressure can help extend the life of the wheel bearings and improve the overall safety of the trailer.

Check the Wheel Bearings for Proper Function

Here is the paragraphy: Before hitting the road, it's essential to check the wheel bearings for proper function. This step is crucial to ensure your safety and the safety of others on the road. To check the wheel bearings, start by lifting the trailer wheel off the ground using a jack. Then, spin the wheel by hand to check for any unusual noises, such as grinding or screeching sounds. If you notice any unusual noises, it may indicate that the bearings are worn out or damaged. Next, check the wheel for any play or movement by grasping the wheel at the 12 o'clock and 6 o'clock positions and trying to rock it back and forth. If the wheel moves excessively, it may indicate that the bearings are loose or worn out. Finally, check the bearing temperature by touching the hub assembly. If it's excessively hot, it may indicate that the bearings are malfunctioning. By performing these checks, you can ensure that your trailer wheel bearings are functioning properly and reduce the risk of a breakdown or accident on the road.

Regularly Inspect and Maintain the Wheel Bearings

Regularly inspecting and maintaining the wheel bearings is crucial to ensure the longevity and safety of your trailer. Over time, the bearings can wear out, causing friction and heat buildup, which can lead to premature failure. To prevent this, it's essential to inspect the bearings every 3,000 to 5,000 miles or at least once a year. Start by jacking up the trailer and removing the wheel to access the bearings. Look for signs of wear, such as rust, corrosion, or scoring on the bearing surfaces. Check the bearing seals for any signs of damage or leakage. If you find any issues, replace the bearings immediately. Additionally, make sure to repack the bearings with new grease every 12,000 to 15,000 miles or as recommended by the manufacturer. This will help to keep the bearings lubricated and running smoothly. By regularly inspecting and maintaining the wheel bearings, you can prevent costly repairs, reduce the risk of accidents, and ensure a safe and enjoyable towing experience.